Warp knitting machine

A warp knitting machine and frame technology, applied in the field of warp knitting machines, can solve problems such as increasing the energy consumption of warp knitting machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

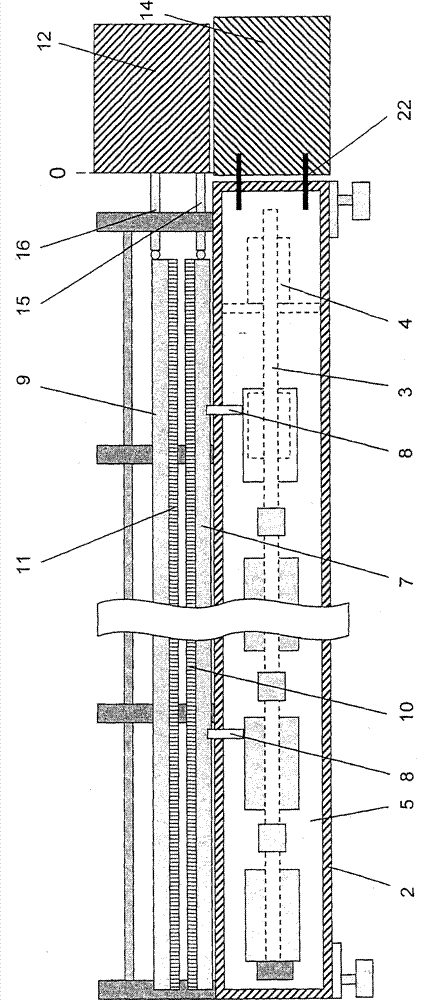

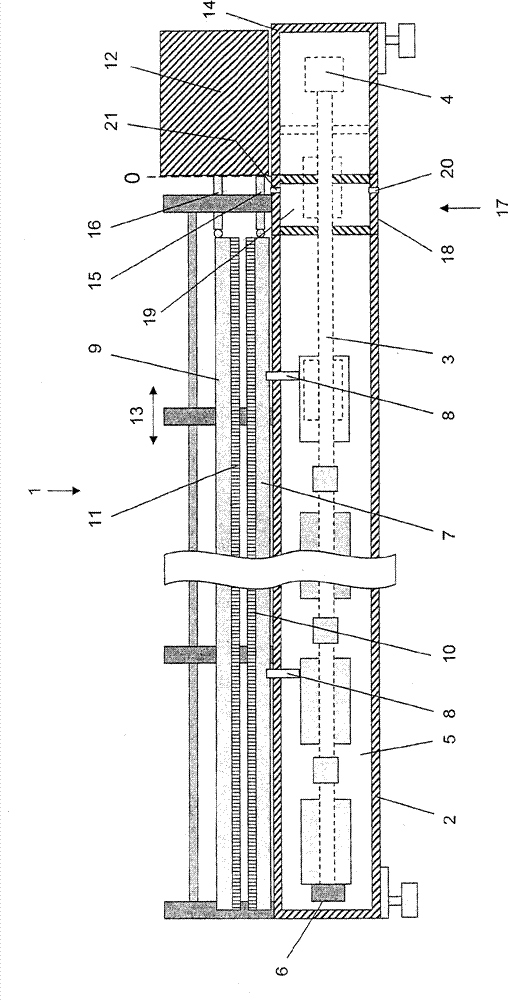

[0021] figure 1 Only briefly and very simplified is shown a warp knitting machine 1 which has a frame 2 in which a spindle 3 is arranged rotatably. The spindle 3 is driven by a drive motor 4 . An oil sump 5 is arranged in the frame 2, from which an oil pump 6 arranged on the main shaft 3 sucks oil in order to lubricate the bearing positions of the main shaft 3 and other moving parts.

[0022] The warp knitting machine 1 has at least two knitting tool holders, namely a needle holder 7 , which is driven by the spindle 3 via a push rod 8 , and a guide needle holder 9 . The knitting needle stand 7 is equipped with many knitting needles 10 side by side. Guide pin holder 9 is equipped with many guide pins 11 side by side. In a manner not shown in detail but known per se, the guide needle holder 9 is likewise driven via the spindle 3 , and the guide needles 11 can vibrate through the interspaces between the knitting needles 10 . In addition, the needle carriage is also driven par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com