Gear shifting mechanism of power head with adjustable multi-level rotational speed

A technology of shifting mechanism and power head, which is used in rotary drilling rigs, rotary drilling, controlled components, etc., can solve the problem of small adjustment range, small drilling parameter range, inability to meet the diversity and large range of rotational speed and torque. range conversion and other issues, to achieve the effect of wide application range, stable transmission and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

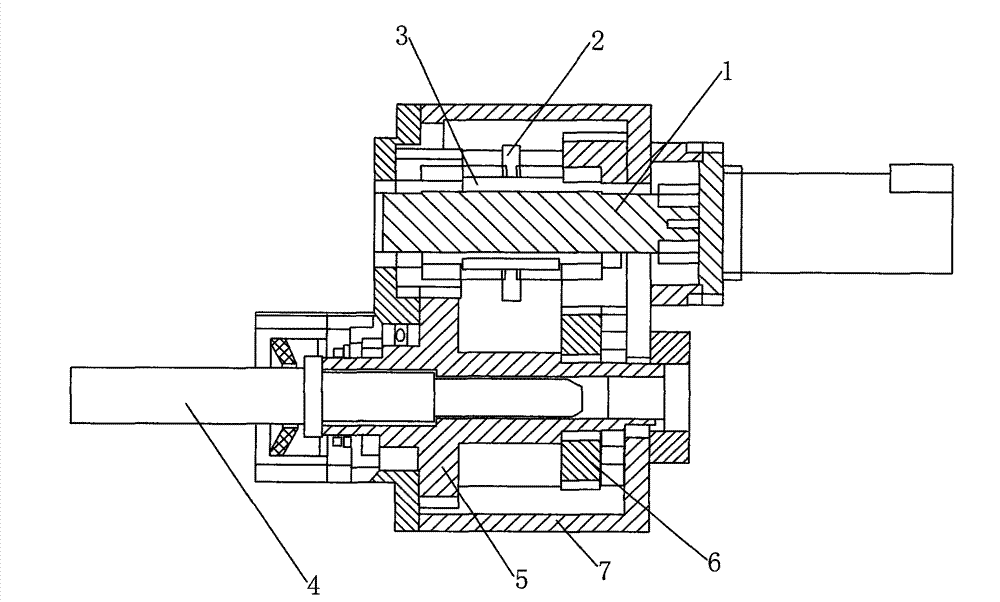

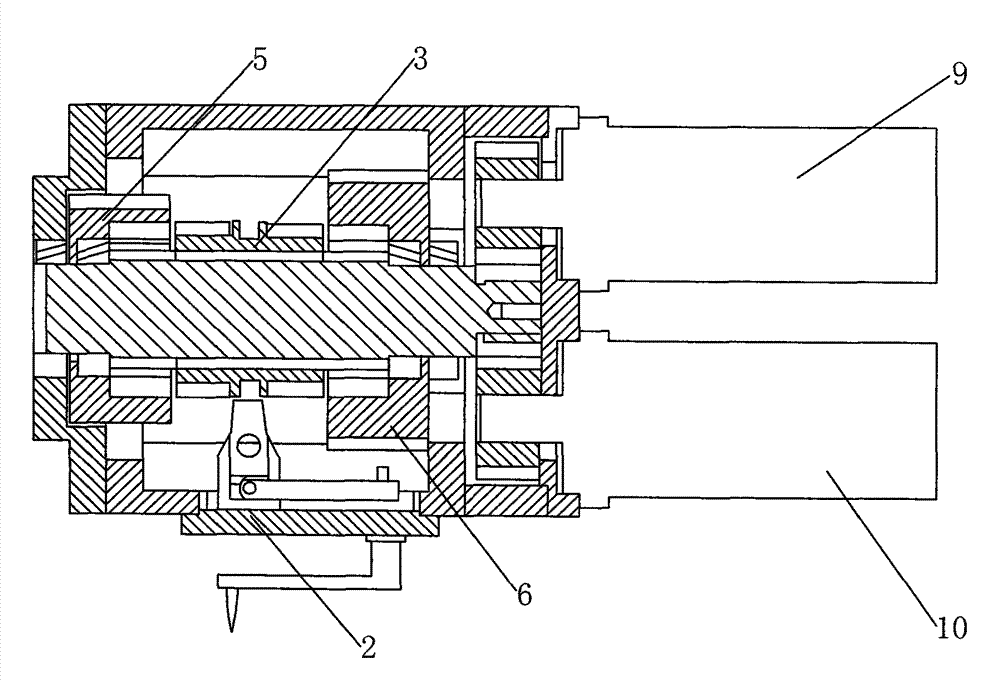

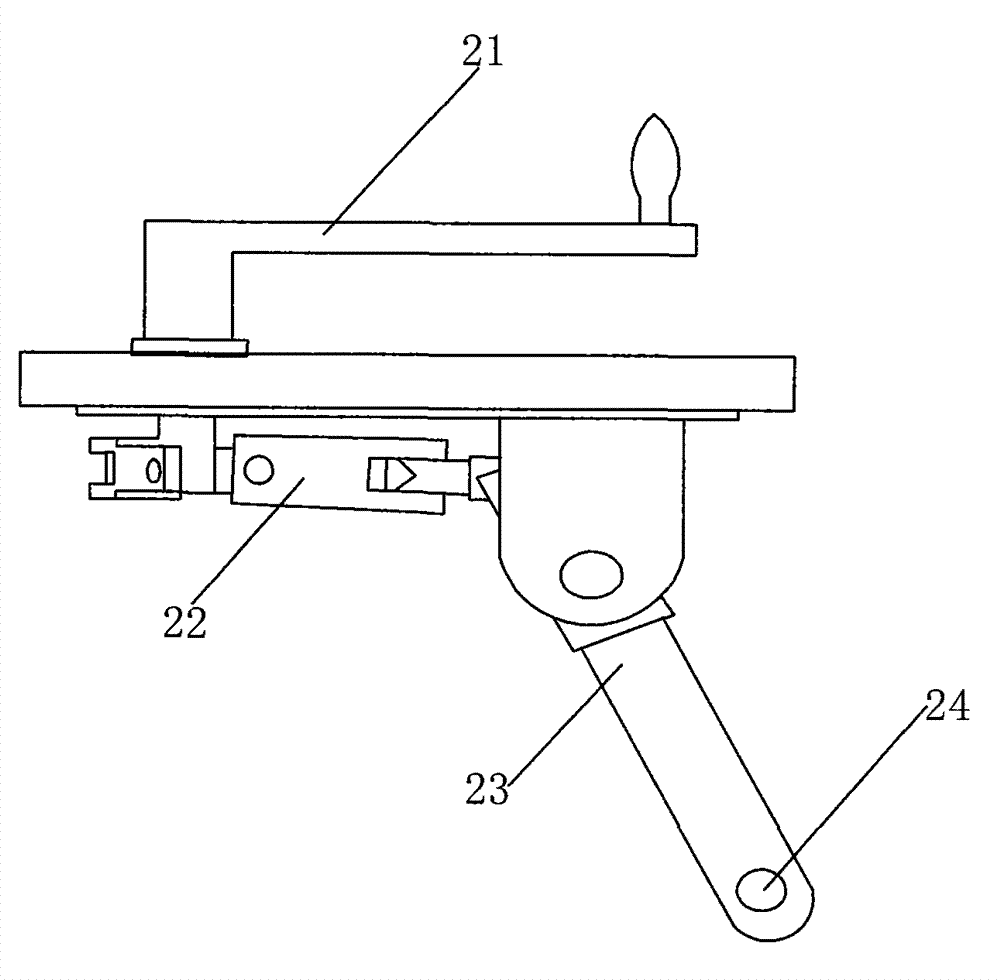

[0017] like figure 1 and figure 2 As shown, the multi-stage rotating speed adjustable power head shifting mechanism is mainly composed of a drill rod and a drill rod drive mechanism, and the drill rod drive mechanism includes two groups of motors 9 and 10 arranged side by side, such as figure 2 Two sets of motors 9 and 10 are shown in , and three or more sets of motors can be used in specific applications, which can be combined and assembled according to the torque range required by the project. The two sets of motors 9 and 10 jointly drive a gear shaft 1 . The corresponding motors on the gear shaft 1 are provided with multiple gears. The gear shaft is provided with a sliding gear 3 and a shifting fork mechanism 2 , the sliding gear 3 is driven and arranged on the gear shaft, and the sliding gear 3 is slidably arranged on the gear shaft 1 under the action of the shifting fork mechanism 2 .

[0018] The drill rod is arranged in a housing 7, and one side of the housing is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com