Fastening type high-power LED light source module and special fastening tool thereof

An LED light source, high-power technology, applied in the field of snap-on high-power LED light source modules and their special snap-on fixtures, can solve problems such as difficulty in disassembly, easy rusting of bolts, affecting product appearance, etc., to save maintenance costs, The effect of quick disassembly and quick and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

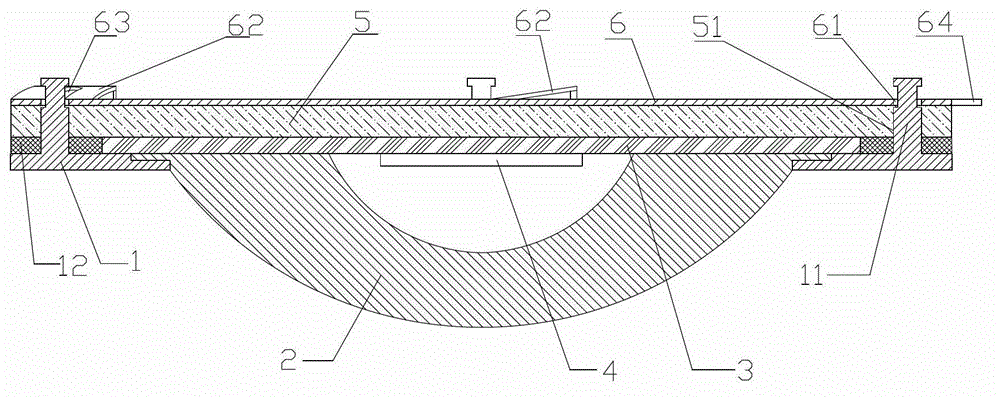

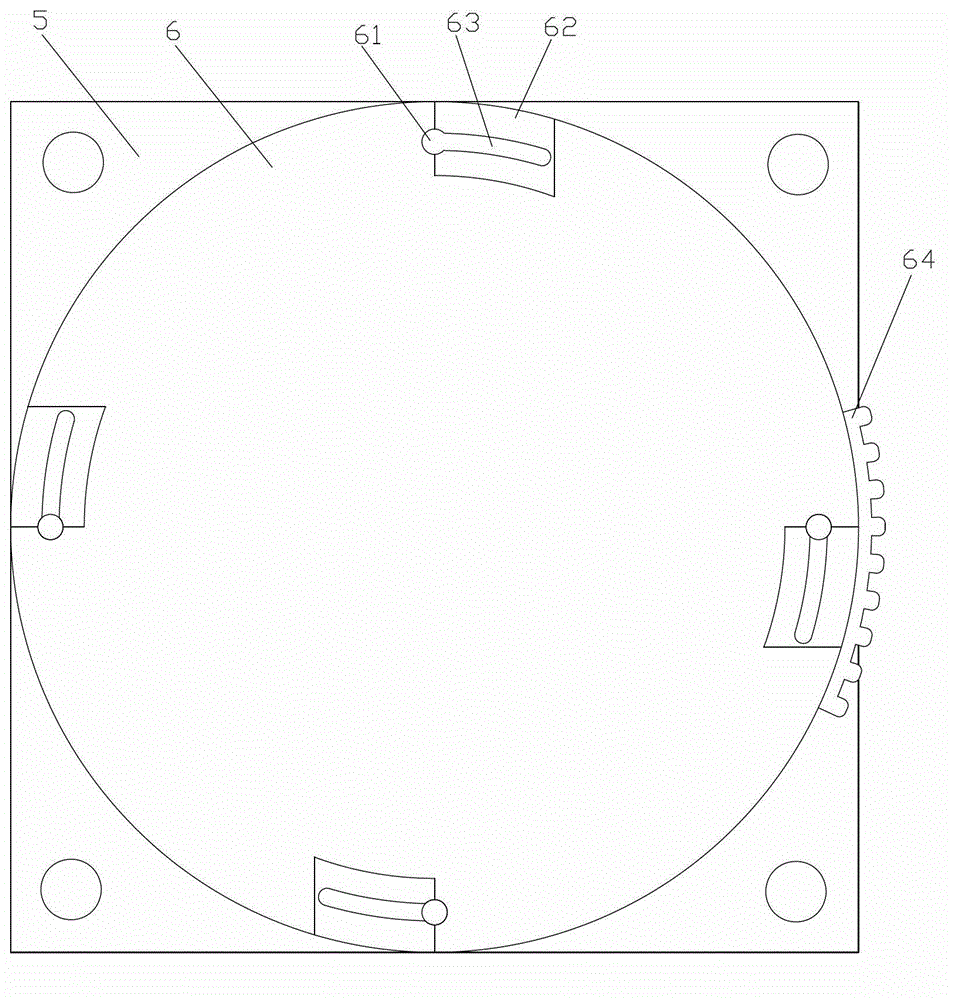

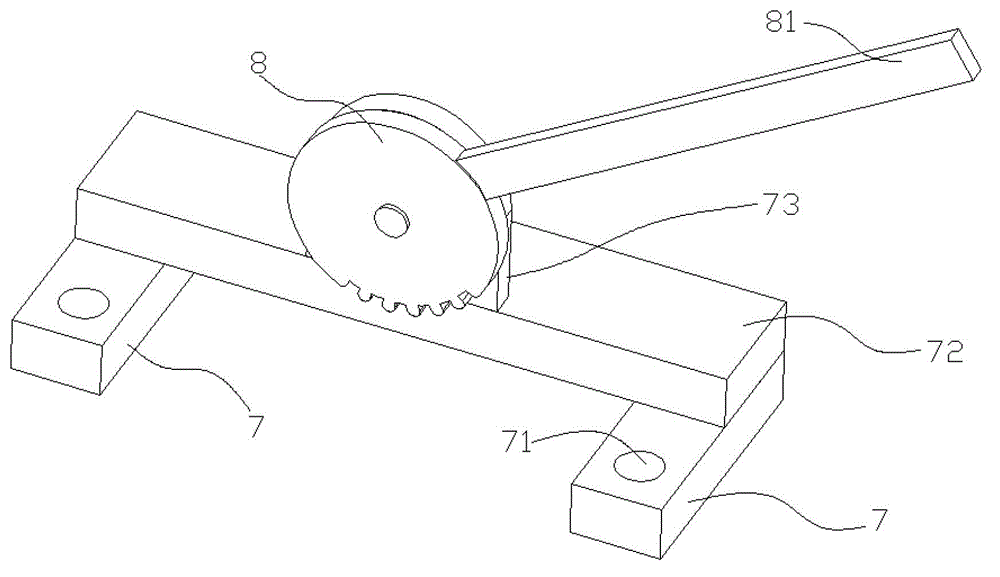

[0013] Such as figure 1 As shown, the fastening type high-power LED light source module described in the present invention sequentially includes a light source mask 1, a lens 2 limited on the light source mask 1, a temperature chamber 3 and an LED light source 4 attached to the temperature chamber 3 , and the heat conduction substrate 5 located on the other side of the temperature chamber 3, several riveting columns 11 are evenly distributed on the back of the light source mask 1, and the riveting columns 11 for the light source mask 1 are arranged on the heat conduction substrate 5 The first through hole 51 passing through; a pinch plate 6 is also provided on the outside of the heat conduction substrate 5, and the pinch plate 6 is provided with a second through hole 61 for the riveting column 11 of the light source mask 1 to pass through, and An ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com