Secondary optical lens with adjustable beam angle

A technology of secondary optical lens and beam angle, applied in the optical field, can solve the problem of uniform light spot of multi-chip LED.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The content of the invention of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

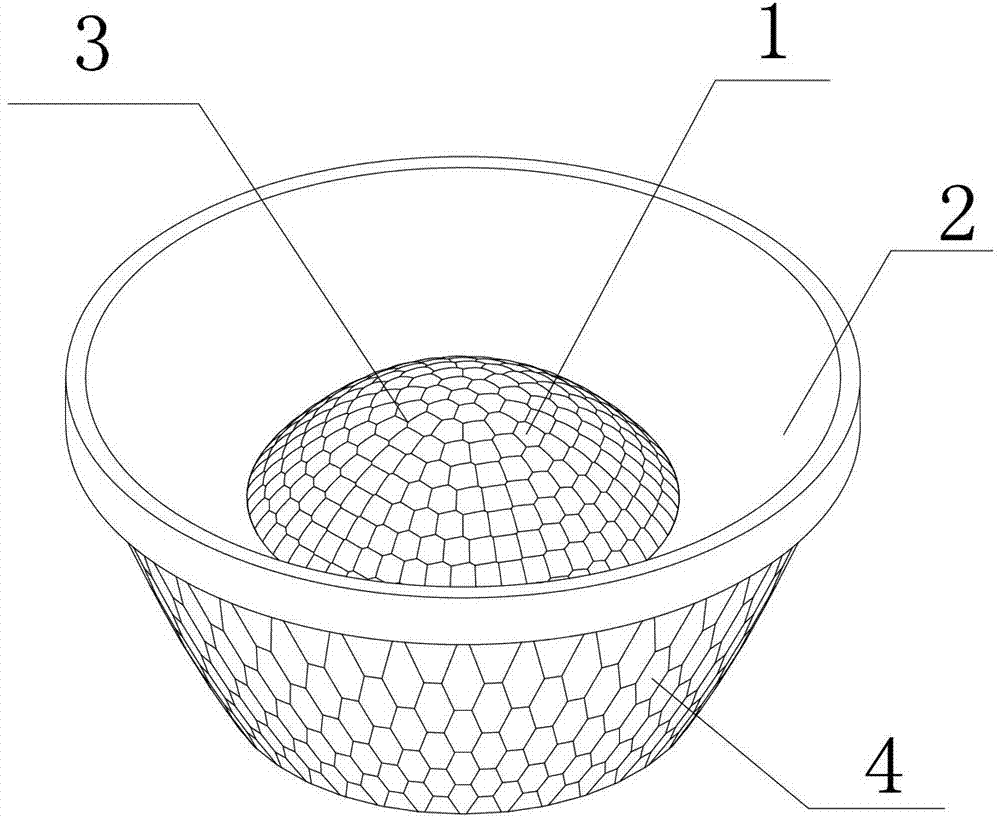

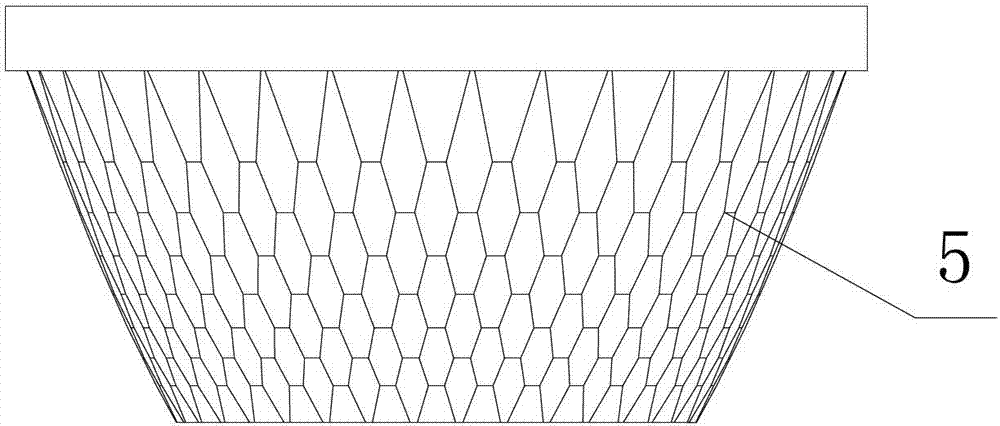

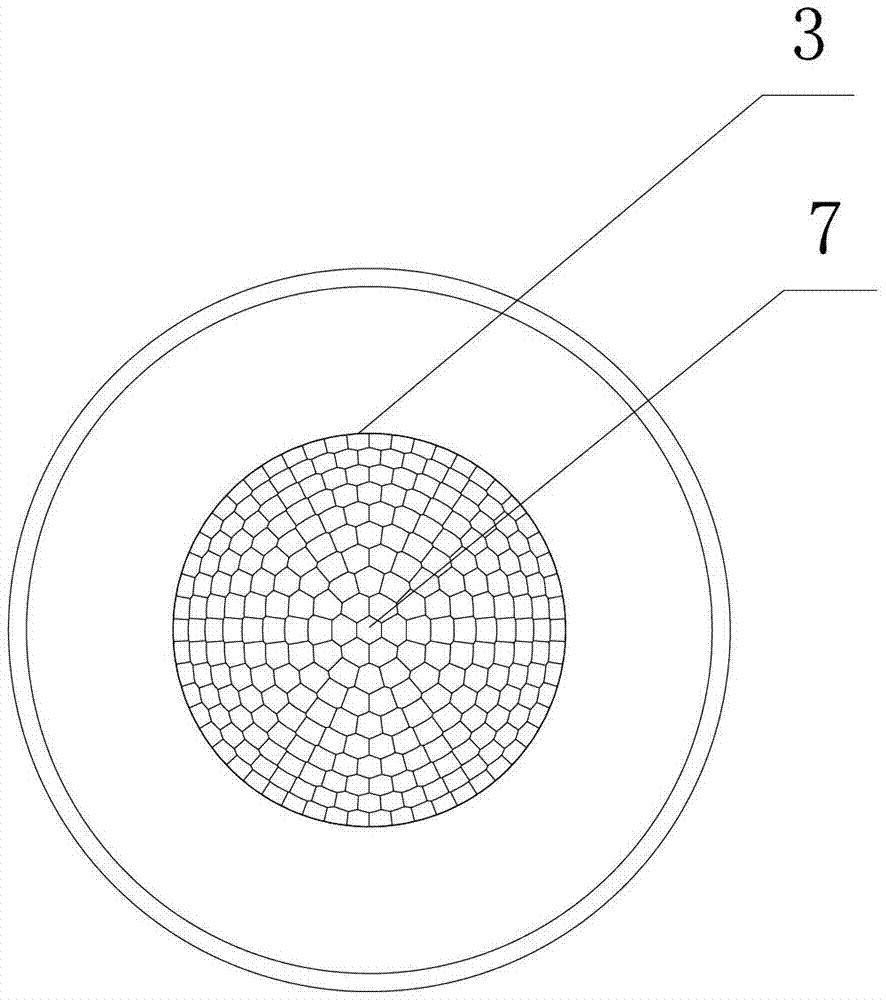

[0025] Such as figure 1 As shown, a secondary optical lens with adjustable beam angle includes a light-gathering part 1 located in the central area of the lens and a total reflection part 2 surrounding the outer edge of the light-gathering part 1 . Among them, when the center point O of the light-emitting surface of the multi-chip LED is located at the focus position of the secondary optical lens, the light emitted from the center O point of the light-emitting surface of the multi-chip LED has a smaller angle with the optical axis OZ. The central light-gathering part 1 collects, converges and mixes light within the range of the divergence angle ±Δθ; the light with a larger angle with the optical axis OZ is collected by the total reflection part 2 on the outer edge, and is also processed Convergence and light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com