Shutter driving device for camera module

A driving device and camera module technology, applied in shutter, camera, optics and other directions, can solve the problems of increasing the driving force of the solenoid valve, increasing the power, limiting the camera module, etc., to achieve the effect of shortening the stroke, reducing power consumption, and reducing the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

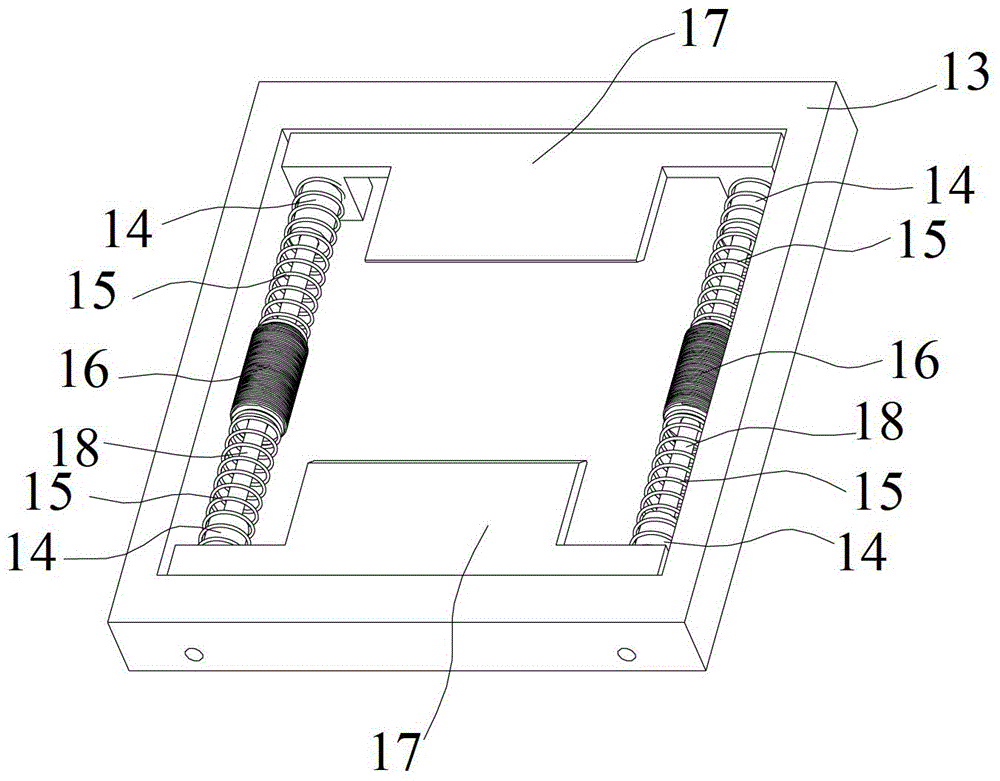

[0029] Such as image 3 , Figure 4 As shown, a shutter driving device for a camera module according to the present invention includes a frame 13, two "T" shutter blades 17, four permanent magnets 14, four springs 15, two guide rods 18, two An electromagnet 16, a light-passing area 19, the frame 13 is a rectangular frame structure, and two fixing holes are respectively arranged on its two opposite faces, and the "T" type shutter blade 17 is composed of a transverse "T" cap And the "T" structure of the longitudinal "T" body, the two "T" shutter blades 17 are symmetrically distributed in the frame 13, and the horizontal "T" cap of each "T" shutter blade 17 There is a through hole at each of the two ends, the through hole is aligned with the fixing hole on the frame 13, and a hollow cylindrical permanent magnet 14 is respectively fixed along the longitudinal "T" body direction at each through hole. A spring 15 is fixed on each permanent magnet, and a hollow cylindrical electrom...

Embodiment 2

[0034] Figure 7As shown, the shutter driving device for the camera module described in the second embodiment includes a frame 13, two horizontal "middle" shutter blades 17, two permanent magnets 14, two springs 15, two guide rods 18, An electromagnet 16, a light-passing area 19, the frame 13 is a rectangular frame-like structure, and two fixing holes are respectively arranged on its two opposite faces, and the described horizontal "middle" word shutter blade 17 includes the blade body and its two The two cantilevers at the end, the two horizontal "middle" shutter blades 17 are symmetrically distributed in the frame 13, and there is a through hole on the cantilever of each horizontal "middle" shutter blade 17, the through hole The hole is aligned with the fixing hole on the frame 13, and one guide rod is fixed in the fixing hole of the frame 13 after directly passing through the through hole of the horizontal "middle" shutter blade, and a hollow cylindrical shape is fixed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com