Reactor cavity water injection cooling system with combination of active and passive power

A technology for reactor cavity water injection and cooling system, which is applied in cooling devices, reactors, nuclear power generation, etc., can solve the problems of low cooling rate of molten material and long solidification time of molten material, and achieve short solidification time, small space occupation and long-term circulation cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

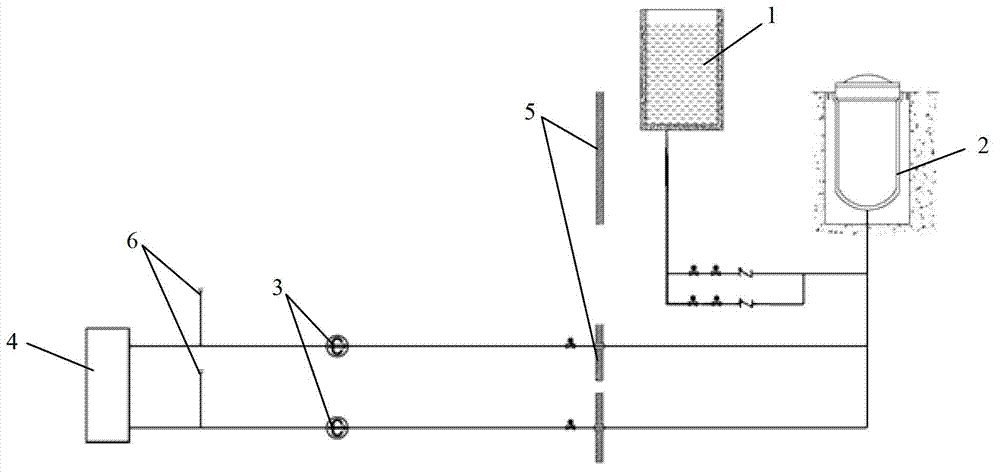

[0024] like figure 1 As shown, the combined active and passive reactor cavity water injection cooling system (CIS) includes a passive reactor cavity water injection tank 1 and two reactor cavity water injection cooling pumps 3, and the passive reactor cavity water injection tank 1 passes through The passive injection pipeline is connected to the reactor cavity 2, the reactor cavity water injection cooling pump 3 is arranged outside the containment 5, the inlet pipe of the reactor cavity water injection cooling pump 3 is connected to the refueling water tank 4, and the outlet of the reactor cavity water injection cooling pump 3 The pipeline runs through the containment vessel 5 and connects with the reactor cavity 2 . The refueling water tank 4 can be installed outside the containment or inside the containment. The preferred solution is to install the refueling water tank in the pit below the core, and the refueling water tank is located at the lowest point, so as to facilitate...

Embodiment 2

[0033] The present invention also provides another active and passive combined reactor cavity water injection cooling system (CIS) structure, the main difference from Embodiment 1 is that the passive reactor cavity water injection tank is arranged outside the containment, which is different from the passive The passive injection pipeline connected to the reactor cavity water injection tank is respectively connected to the outlet pipelines of two reactor cavity water injection cooling pumps. The refueling water tank as the cooling water source may also be placed outside the containment.

[0034] The operation mode and working process of the CIS system in Embodiment 2 are similar to those of the CIS system in Embodiment 1. However, since the passive reactor cavity water injection tank is placed outside the containment, it is no longer possible to supplement the passive reactor cavity water injection tank with steam condensate from the PCS system. Therefore, an external water sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com