A high-efficiency self-adjusting shock absorber

A self-adjusting, shock absorber technology, applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problems of reduced service life, poor shock absorber comfort, shock absorber spring damage, etc., to achieve improved Comfort, improve ride comfort, and prevent rebound effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

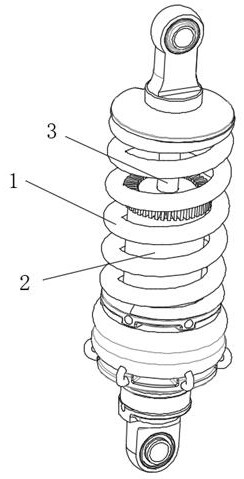

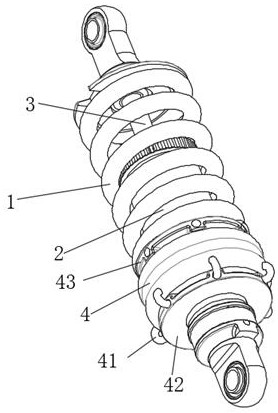

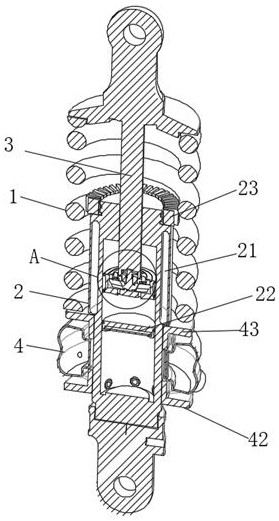

[0042] see Figure 1-10 , a high-efficiency self-adjusting shock absorber, including a cylinder 2, a tie rod 3 and a shock absorber spring 1, the tie rod 3 is slidably inserted into the cylinder 2, the shock absorber spring 1 is sleeved on the outer wall of the cylinder 2, and the end of the tie rod 3 Piston 5 is fixed on the upper part, and sealing ring 52 is fixed on the circumferential side of piston 5. A cavity is arranged inside piston 5, and an acceleration vane 51 is arranged in the cavity. The structure is rotatably connected in the cavity. The end of the tie rod 3 is provided with a deceleration chamber 31. One end of the rotating shaft 511 extends into the deceleration chamber 31 and is fixed with a brake disc 512. The deceleration chamber 31 is filled with magnetorheological fluid. The piston 5 The bottom of the piston 5 is provided with a number of oil holes 53 communicating with the cavity, the top of the piston 5 is provided with a number of first one-way holes 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com