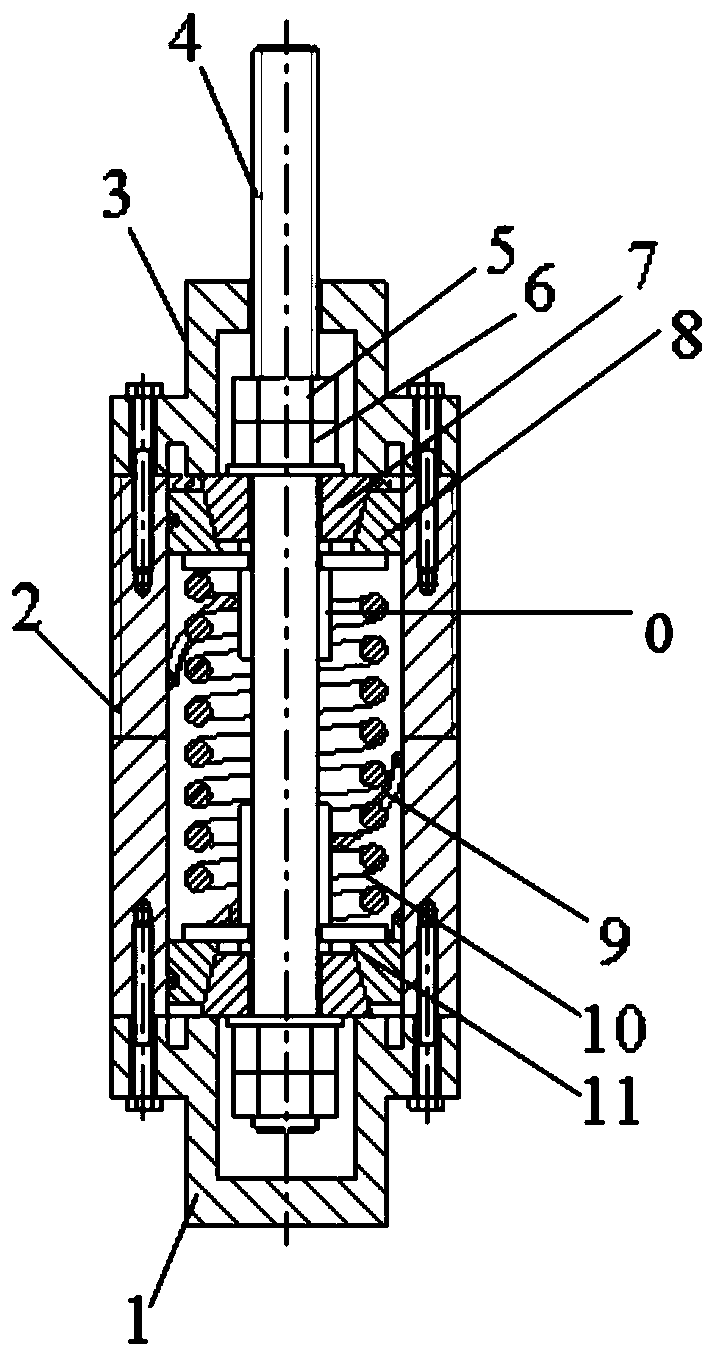

Spiral friction damping device for electrical equipment

A technology for electrical equipment and shock absorbing devices, applied in the direction of friction shock absorbers, shock absorbers, mechanical equipment, etc., can solve the problems of low frictional energy consumption, residual deformation, frequent replacement, etc., and achieve a clear shock absorbing mechanism and improved Friction performance, the effect of ensuring safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

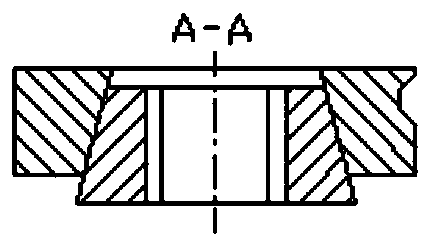

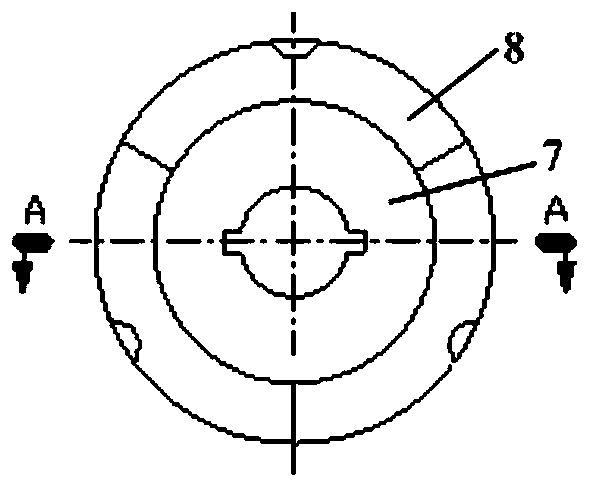

[0046] like figure 2 As shown, the inner ring 7 of the friction assembly is a single-taper ring, and the outer ring 8 is a single-taper ring composed of three segmented rings of the same size. The tapered surfaces of the inner ring 7 and the outer ring 8 fit together, There is a guide groove on the outer side of the outer ring 8, and a corresponding spiral guide ridge 9 is provided on the inner wall of the cylinder body 2. The two form a spiral motion pair. When the transmission shaft 4 moves up and down, the outer ring 8 is driven to move up and down, and the outer ring 8 is rotated at the same time. .

[0047] The friction components include the following components by mass percentage: C0.4%, Al 1.2%, Si 0.45%, Mo1.5%, V 0.15%, Ti 0.05%, B 0.005%, Re 0.2%, Mg 0.5%, The balance is Fe and impurities; the barrel includes the following components by mass percentage: C0.3%, Si 0.8%, W 0.9%, Cr3.9%, Ti1.2%, Mn4%, Mo0.9%, S0.04%, the balance is iron and impurities; the guide rid...

Embodiment 2

[0049] like image 3 As shown, the friction assembly is composed of two single-tapered inner rings 7 and a double-tapered outer ring 8. The outer ring 8 is a single-tapered ring composed of three segmented rings of the same size. The tapered surfaces of the ring 7 and the outer ring 8 fit together, the outer ring 8 is provided with a guide groove, and the inner wall of the cylinder 2 is provided with a corresponding spiral guide ridge 9, the two form a spiral motion pair, and when the transmission shaft 4 moves up and down, it drives The outer ring 8 moves up and down, and the outer ring 8 is rotated at the same time.

[0050] The friction components include the following components by mass percentage: C0.48%, Al 1.0%, Si 0.80%, Mo1.2%, V 0.15%, Ti 0.05%, B 0.005%, Re 0.22%, Mg 0.3%, The balance is Fe and impurities; the barrel includes the following components by mass percentage: C0.5%, Si 0.6%, W 1.2%, Cr2.9%, Ti1.8%, Mn2%, Mo1.2%, S0.02%, the balance is iron and impuritie...

Embodiment 3

[0052] like Figure 4 As shown, guide ridges are provided on the outside of the outer ring 8, and guide grooves are provided on the inside of the corresponding cylinder 2, and the two form a helical motion pair.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com