Transformer clamp and mounting method

A technology of transformer clamping and installation methods, which is applied in the direction of inductance/transformer/magnet manufacturing, transformer/inductor coil/winding/connection, electrical components, etc., which can solve the problem of uneven force, high installation labor intensity, and affecting transformer performance and other issues to achieve the effect of improving installation efficiency, reducing installation labor intensity and realizing mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

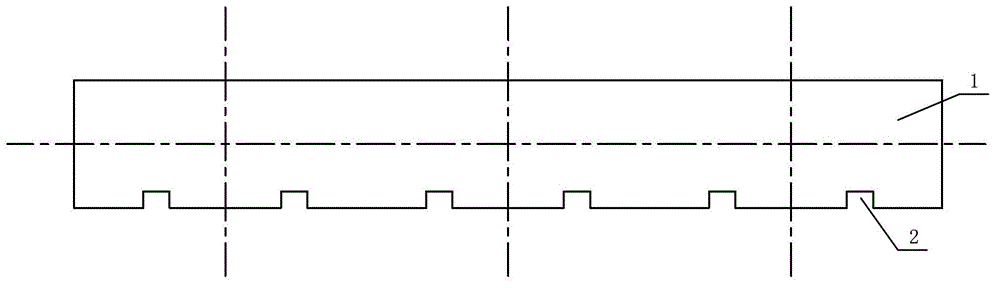

[0014] Such as figure 1 As shown, the present invention includes a transformer body 4 and a clamp body 1, and slots 2 are slotted on the lower side of the clamp body 1 near the coil. There are six slots on the clip body.

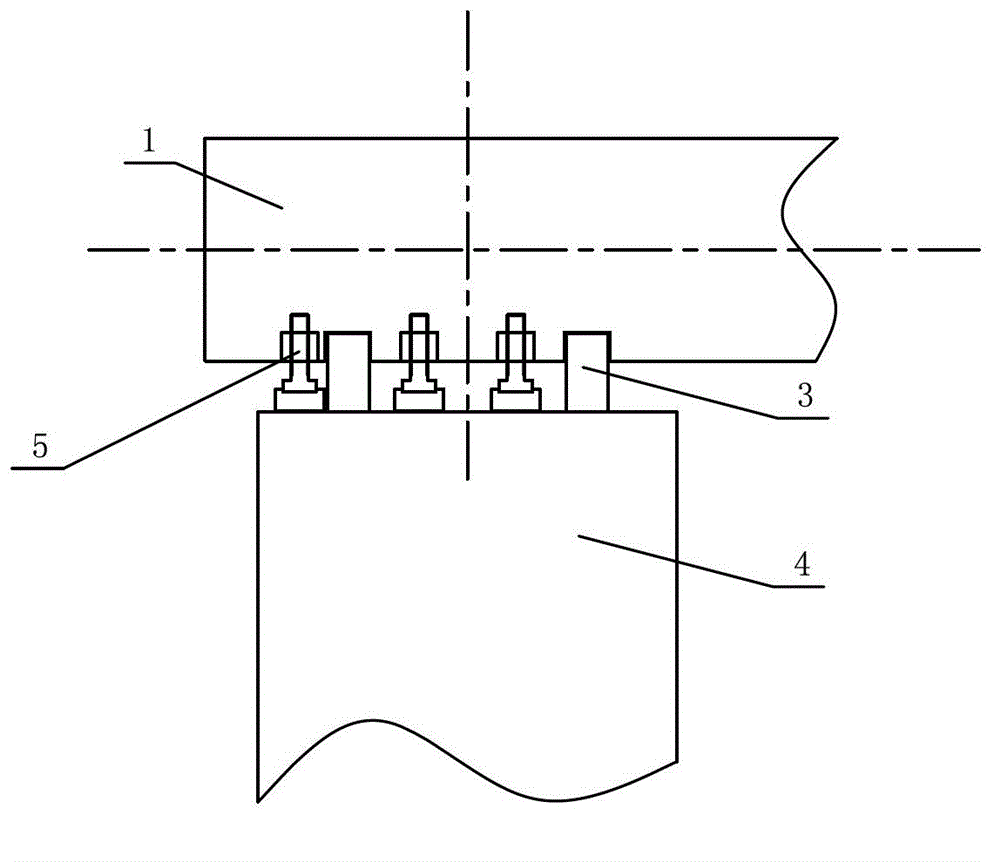

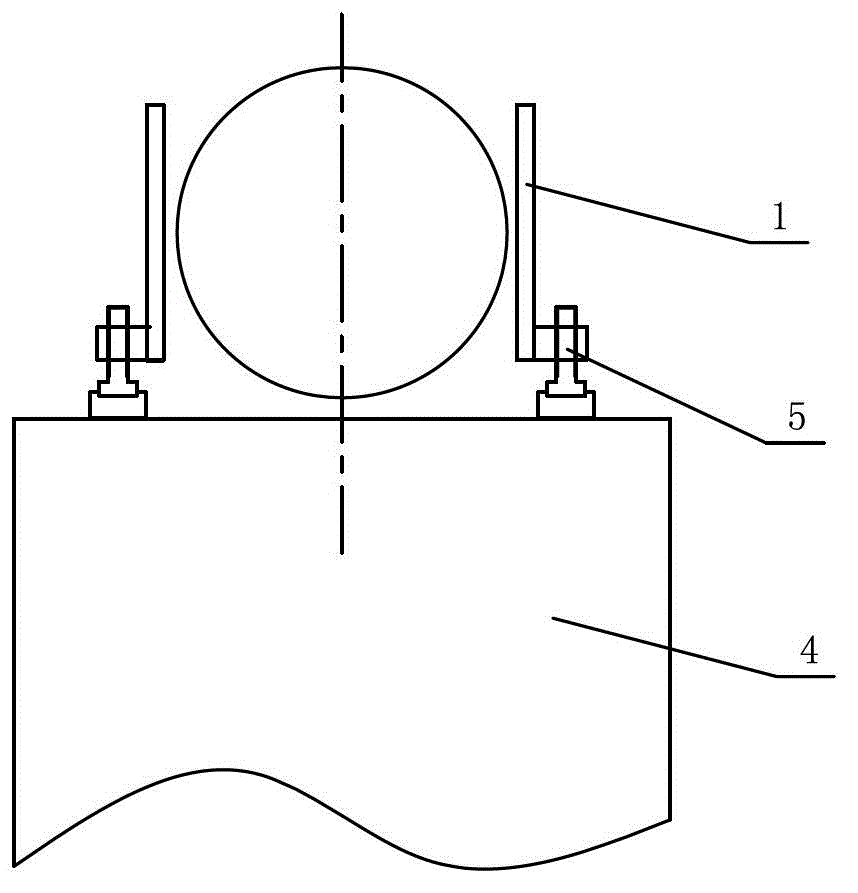

[0015] Such as figure 2 , image 3 As shown, when in use, a transformer installation method, first install the transformer body 4, then install the clamp body 1, fix the transformer clamp body 1 on the upper and lower parts of the transformer body, and tighten it with a tensioning device Fasten, then put the hydraulic device 3 (which can be a part of the oil cylinder or jack) into the space between the clamp body 1 and the coil, and the upper end of the hydraulic device 3 leans against the slot of the clamp body, The other end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com