Optic fiber level switch

A liquid level switch and optical fiber technology, which is applied in the field of optical fiber liquid level switches, can solve the problems of decreased accuracy and stability, the surface cannot be kept clean, and the working stability is decreased. Simple and fast effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

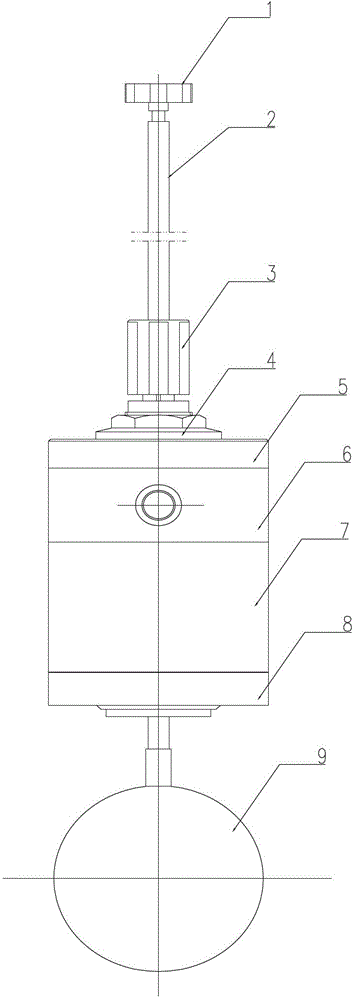

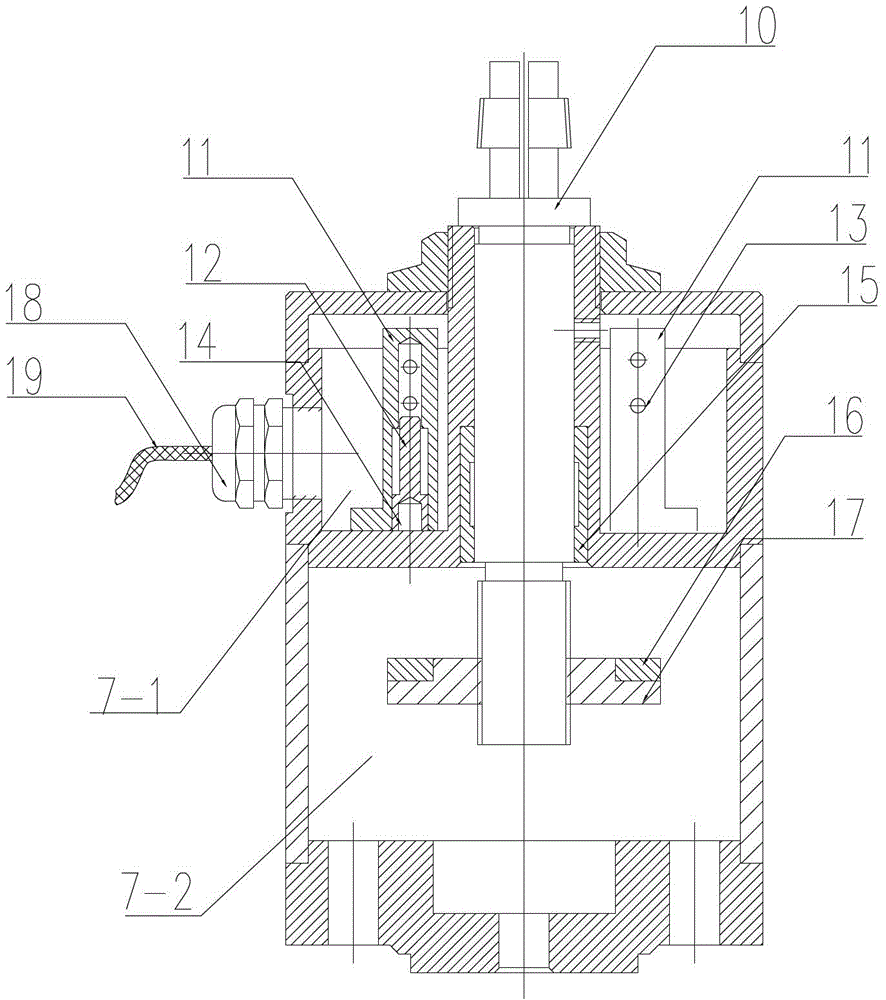

[0032] Example 1: See figure 1 , figure 2 , Figure 5 , Figure 7 As shown, an optical fiber type liquid level switch includes an isolation box 7, a floating ball 9, and a floating ball connecting rod 2. An optical cable clamping joint 18 is provided on the side wall of the isolation box 7, and the floating ball connecting rod 2 The guide post 10 passes through the isolation box 7 and is arranged in a sliding fit with the isolation box 7 and fixed with the guide post 10. A guide sleeve 15 is provided between the contact surface of the guide post and the isolation box, and the float 9 is set in the isolation box. The end of the floating ball connecting rod 2 below 7; the isolation box 7 is divided into an upper cavity 7-1 and a lower cavity 7-2 by a partition; a collimator bracket is provided in the upper cavity 7-1 11. The collimator bracket 11 is provided with a collimator 13 and a light blocking axis 12 for blocking the output of the collimator parallel light, the collimator ...

Embodiment 2

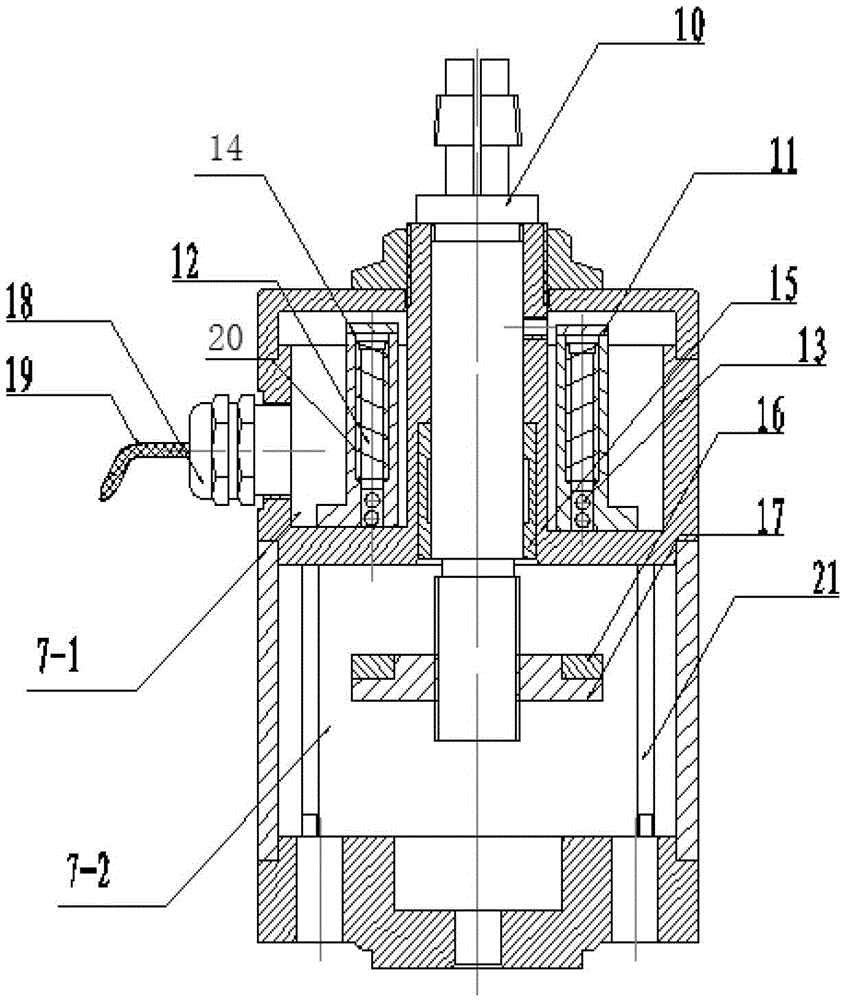

[0035] Example 2: See figure 1 , image 3 , Image 6 , Figure 8 As shown, an optical fiber type liquid level switch includes an isolation box 7, a floating ball 9, and a floating ball connecting rod 2. An optical cable clamping joint 18 is provided on the side wall of the isolation box 7, and the floating ball connecting rod 2 The guide post 10 passes through the isolation box 7 and is arranged in a sliding fit with the isolation box 7 and fixed with the guide post 10. A guide sleeve 15 is provided between the contact surface of the guide post and the isolation box, and the float 9 is set in the isolation box. 7 the end of the floating ball connecting rod 2 below; the isolation box 7 is divided into an upper cavity and a lower cavity by a partition; a collimator bracket 11 is provided in the upper cavity, and the collimator bracket 11 is provided with The collimator 13 and the light-blocking axis 12 for blocking the collimator output parallel light, the light-blocking axis 12 i...

Embodiment 3

[0037] Example 3: Same as Example 2, except that Figure 4 As shown, an optical fiber type liquid level switch includes an isolation box 7, a floating ball 9, and a floating ball connecting rod 2. An optical cable clamping joint 18 is provided on the side wall of the isolation box 7, and the floating ball connecting rod 2 The guide post 10 passes through the isolation box 7 and is arranged in a sliding fit with the isolation box 7 and fixed with the guide post 10. A guide sleeve 15 is provided between the contact surface of the guide post and the isolation box, and the float 9 is set in the isolation box. 7 the end of the floating ball connecting rod 2 below; the isolation box 7 is divided into an upper cavity and a lower cavity by a partition; a collimator bracket 11 is provided in the upper cavity, and the collimator bracket 11 is provided with The collimator 13 and the light blocking axis 12 for blocking the collimator output parallel light, the collimator 13 is arranged belo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com