Differential pressure controller for liquid level detection and measuring method

A differential pressure controller and liquid level detection technology, which is applied in the direction of liquid level indicators for physical variable measurement, can solve the problems of sensor safety hazards and other problems, and achieve the goal of eliminating safety hazards, improving accuracy and safety, and improving detection speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

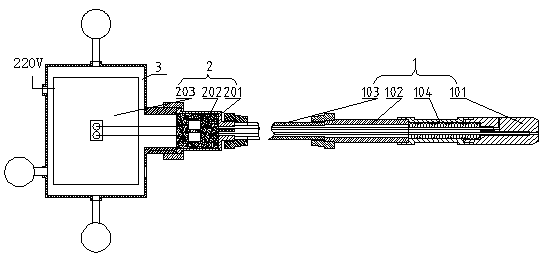

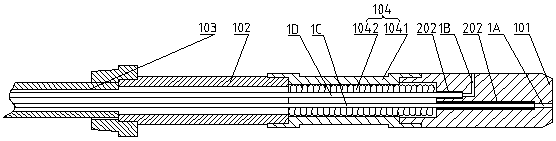

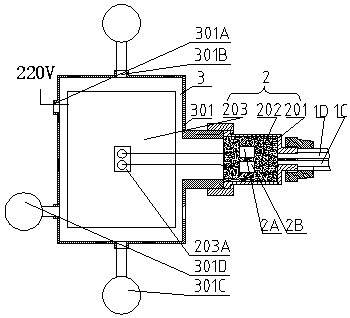

[0035] like Figure 1~3 As shown, the described differential pressure controller for liquid level detection includes a passive detection head 1 for detecting the liquid level height, and a gas-electric converter 2 for receiving the output signal of the passive detection head 1; It is characterized in that: the passive detection head 1 includes two liquid inlets separated from each other, one high and one low from the liquid surface; among them, the two liquid inlets, one high and one low, are respectively connected with two air pressure sensors for detecting The change data of the air pressure of two liquid inlets, one high and one low; the gas-electric converter 2 includes two air pressure sensors and a control unit for receiving the difference between the two air pressure se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com