Explosion-proof detection control method for combustible liquid level

An explosion-proof detection and control method technology, applied in the direction of liquid level control, non-electric variable control, control/regulation system, etc., can solve problems such as threatening the safe production of petrochemical enterprises, cable damage, poor sealing, etc., to eliminate potential safety hazards, The effect of improving strength and ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

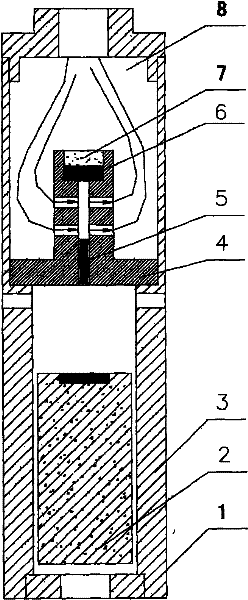

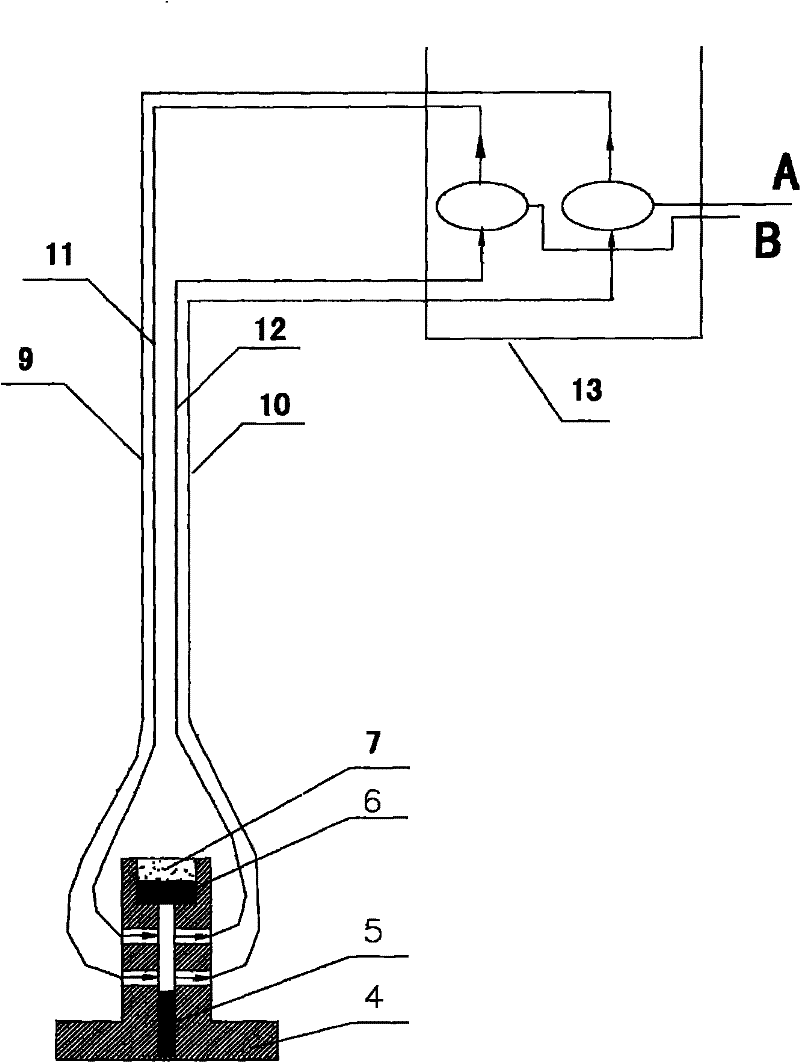

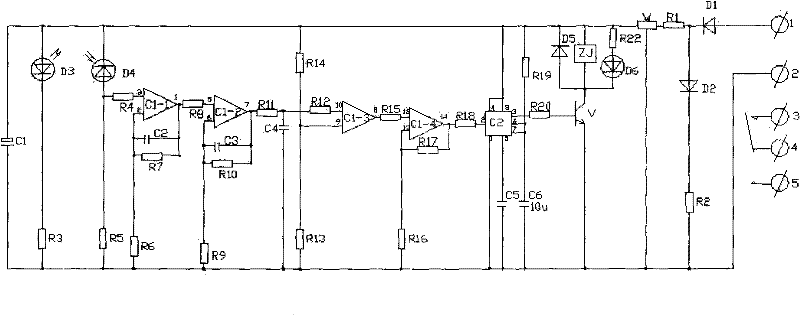

[0025] like figure 1 , 2 , 3 shows: an explosion-proof detection and control method for flammable liquid level, which converts the change of flammable liquid level into an optical signal through an optical fiber detection probe, and the optical signal passes through an optical fiber transmission system to a place far away from the oil and gas dense area to be detected The photoelectric conversion system detects and controls the flammable and explosive liquid level in a timely manner; and sends out two electrical signals to the external actuator through the photoelectric conversion system. The external actuator can be directly connected to the valve for control, or connected to the computer to realize positioning filling , each time the oil level is detected, the system will send out a voice alarm prompt.

[0026] The optical fiber detection probe has two detection points, and is lowered into the oil tank with the oil crane pipe for:

[0027] 1. When the liquid level starts t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com