Light-emitting diode (LED) drive power supply device

A technology of LED driving and power supply device, applied in electric light source, lighting device, electric lamp circuit layout and other directions, can solve the problems of large output low frequency ripple, slow voltage drop at the output end of LED driving power supply, affecting the working efficiency of LED driving power supply, etc. , to achieve the effect of improving work efficiency, reducing voltage drop time, and reducing afterglow phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

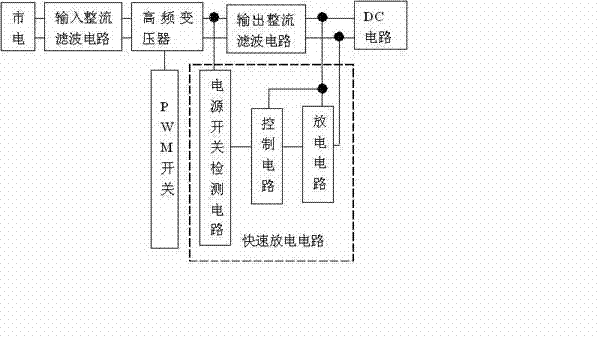

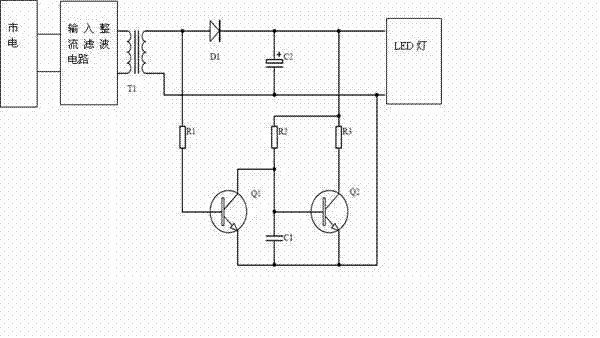

[0021] Refer to attached figure 1 And attached figure 2 As shown, the present invention provides a LED drive power supply device, which is used to quickly discharge the large capacitor at the output end of the LED drive power supply; the device mainly includes an input rectification filter circuit, a high frequency transformer, a PWM switch, an output rectification filter circuit and a DC circuit; It also includes a fast discharge circuit, which includes a power switch detection circuit, a control circuit and a discharge circuit; one end of the power switch detection circuit is connected between the high-frequency transformer and the output rectifying and filtering circuit, and the other end is connected to The control circuit collects and provides switch signals; the control circuit performs logic control according to the switch signals provided by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com