Nanoscale dynamic separation-type grinder

A separate, nano-scale technology, applied in the field of grinding machines, can solve the problems of materials and grinding media blocking the separator, reducing grinding efficiency, disassembling the separator, and inconvenient cleaning, etc., to achieve nano-scale grinding, improve grinding efficiency, and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, the present invention is described in further detail:

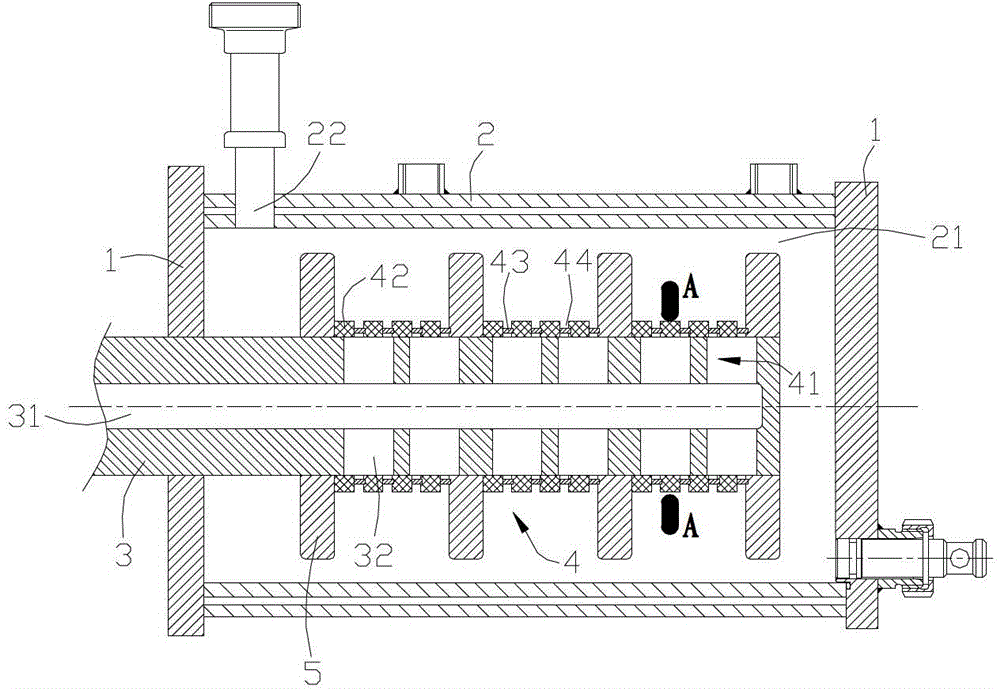

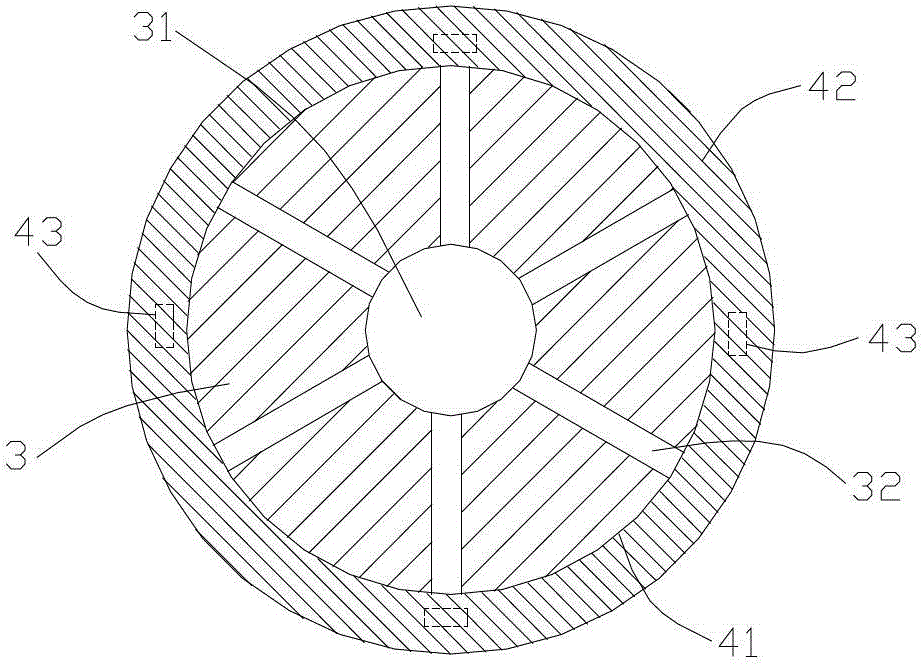

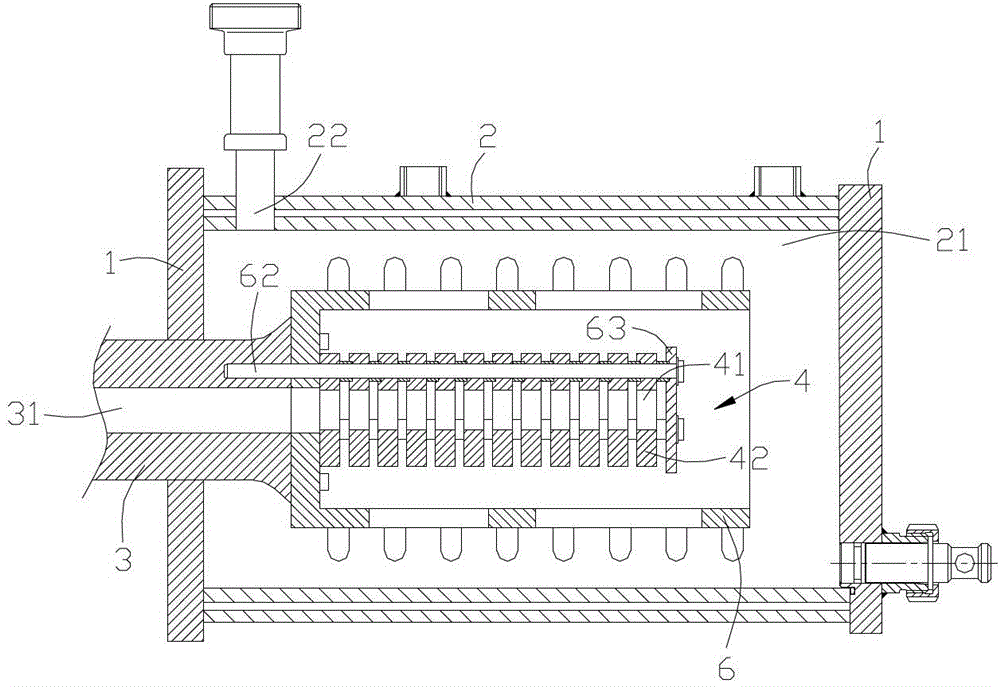

[0023] Take the PHN SuperMaxZeta Nanomill grinding machine as an example below. This grinding machine includes a grinding cylinder 2 formed with a grinding chamber 21 inside and a feeding chamber 22 connected to the grinding chamber. The two ends of the grinding chamber are respectively sealed by end caps 1; The above-mentioned feed chamber can be set on the grinding cylinder or on the end cover; at the same time, the interlayer and the inlet and outlet of the cooling water can also be set on the grinding cylinder, and the way of low inlet and high outlet is adopted to make the grinding cylinder obtain Better Cooling An ideal cooling design would better allow grinding of temperature sensitive products. A main shaft 3 extends into the grinding chamber through the end cover, and the grinding chamber is provided with a grinding rotor driven by the main shaft to rotate. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com