Cross axle processing clamp

A cross shaft and fixture technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of difficult control of cross shaft rough turning processing quality, and achieve the effect of ensuring verticality, accuracy and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

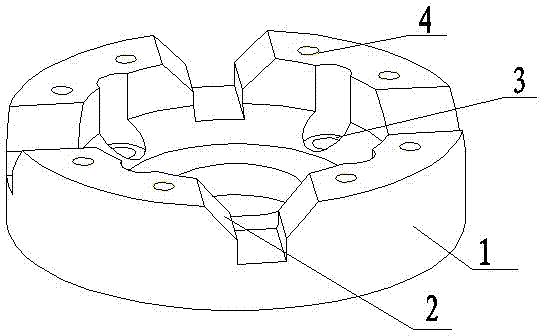

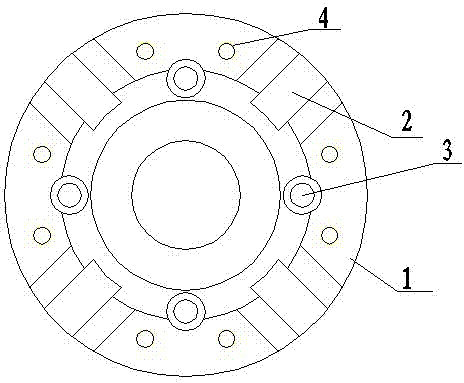

[0010] Such as figure 1 and figure 2 As shown, the present invention provides a kind of cross shaft machining fixture, and it comprises clamp body 1, and the manufacturing material of clamp body 1 is Crl2 steel, and clamp body 1 is cylindrical, is evenly provided with eight screw on the upper surface of clamp body 1. The hole 4 is symmetrically provided with four V-shaped grooves 2 along the cross-shaped direction on the clamp body 1, and four notches 3 are evenly provided on the inner side of the clamp body 1, and each two adjacent V-shaped grooves 2 are provided with There is a counterbore3.

[0011] When the present invention is used, the chuck on the main shaft of the ordinary lathe is removed first, and then the fixture is installed, and the fixture is installed on the main shaft L of the ordinary lathe through hole positioning and connecting bolts, and then the four axes of the cross shaft are respectively placed in a V shape. In slot 2, press firmly. Then the cross ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com