Waste plastic film decolouring regeneration method and system

A technology of plastic film and regeneration system, applied in the direction of plastic recycling, recycling technology, etc., can solve the problems of unfeasible industrialization and high processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

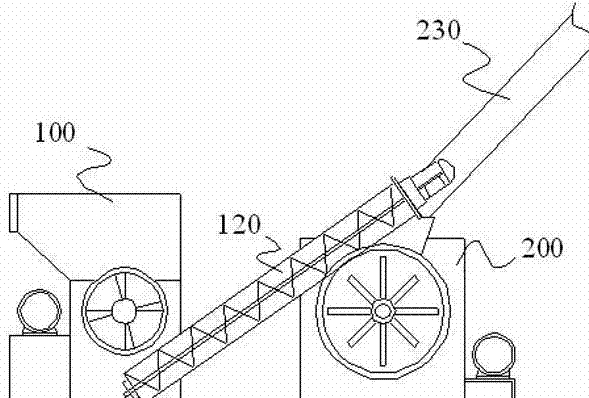

[0058] The present invention will be further described in detail below in conjunction with the accompanying drawings. The emphasis of the accompanying drawings is to show the structure of the entire system in a schematic manner and explain the working principle. In the drawings, some common components are omitted, such as the power equipment and transmission equipment of each equipment, and some structures that can be explained by text, such as spray humidification, spray cleaning and waste water recovery, etc. are omitted.

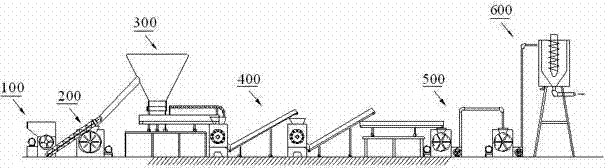

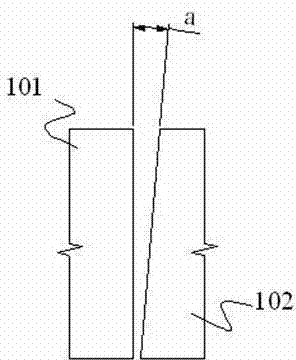

[0059] Such as figure 1 A waste plastic film decolorization regeneration system shown includes: a crusher 100 for crushing the film into a specific size; a high-speed centrifugal beating separator 200 for centrifugally beating and decolorizing the crushed film at high speed; connected to the high-speed centrifugal beating separator The collection and spraying system 300 between 200 and the residual impurity separation system 400; the residual impurity sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com