Heating module and system for dye sublimation

A dye sublimation and heating module technology, applied in the field of dye sublimation printing heating modules and systems, can solve problems such as deterioration of printing quality, deformation of transfer sheets, damage to fragile objects, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

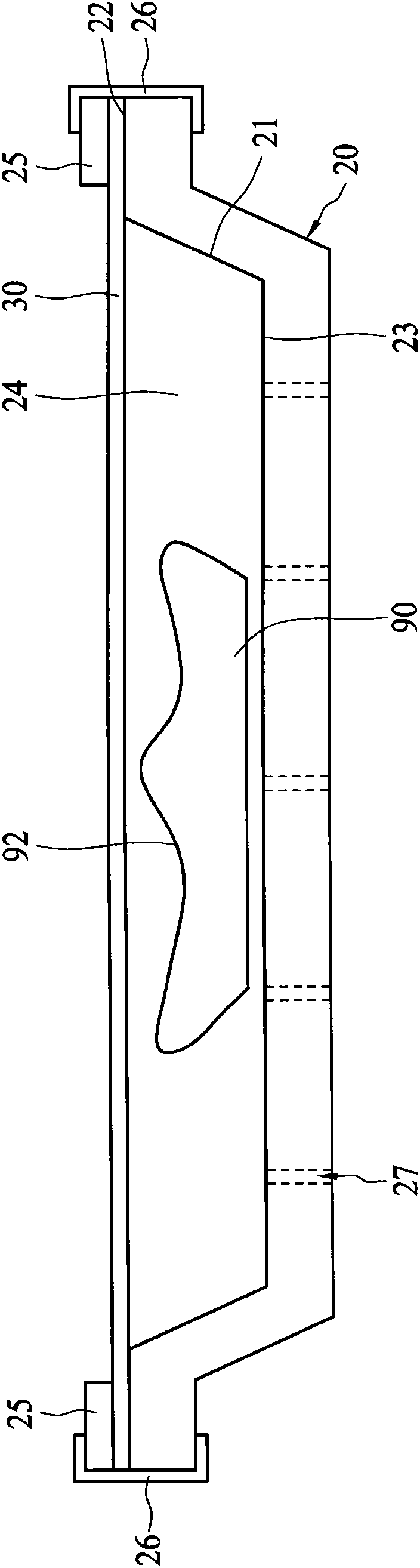

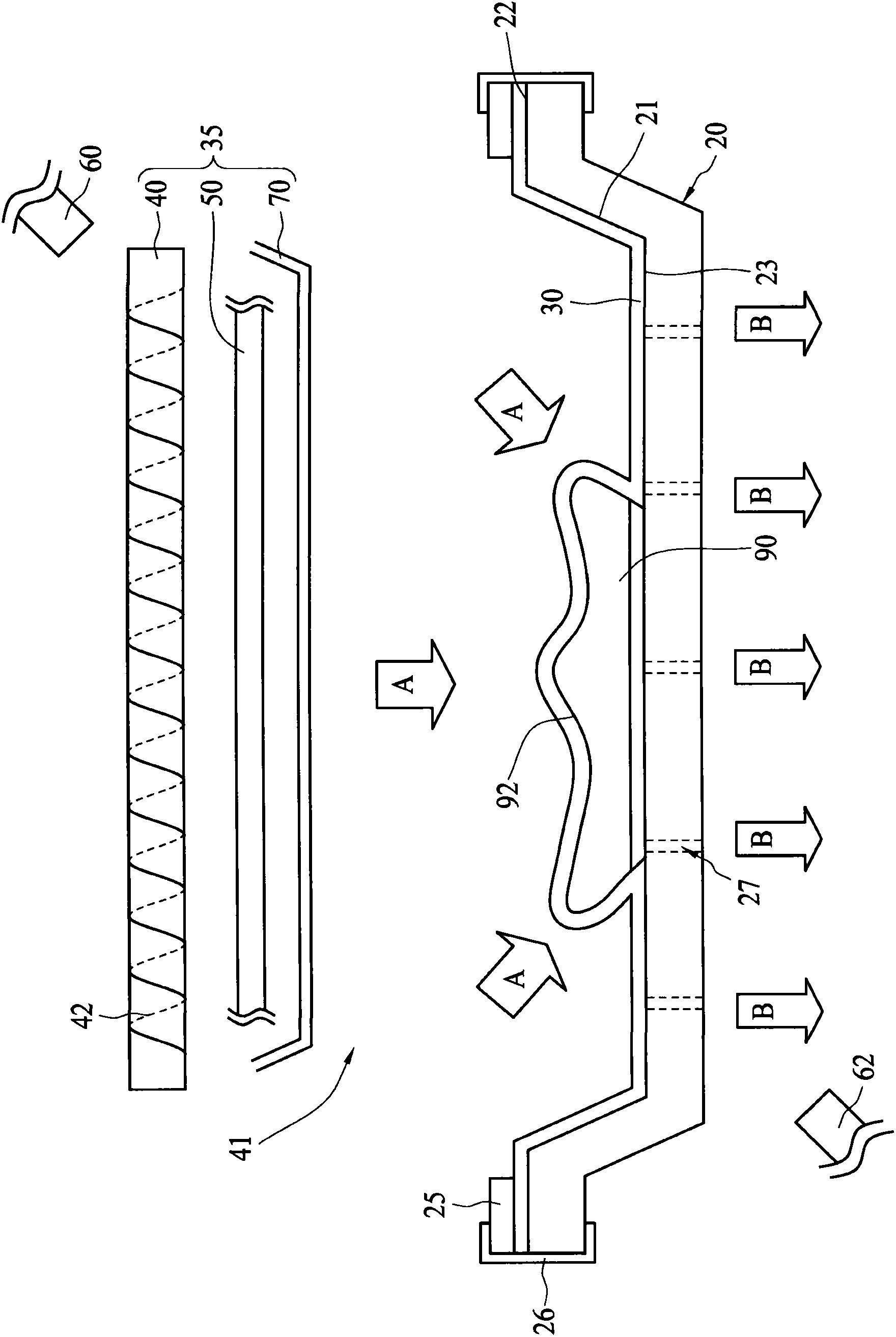

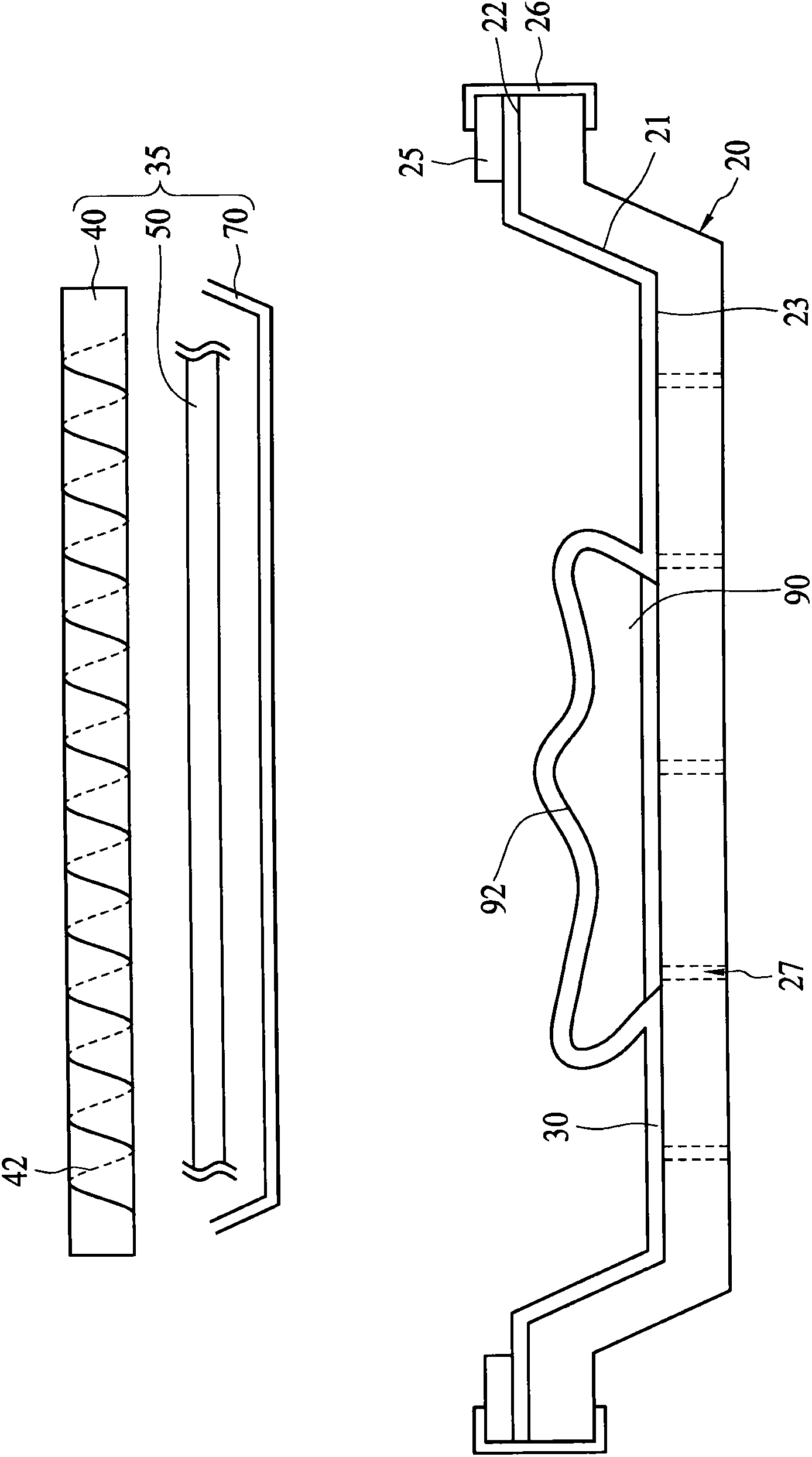

Image

Examples

Embodiment 1

[0068]

[0069]

[0070] According to the offset errors measured by the above tests, it is obvious that the analog heating process, the pre-heating process, the coil cycle and the gradual vacuum process all significantly affect the value of the offset error (the smaller the offset error, the better).

[0071]The invention can avoid radiation from being directly projected on the object, can heat the object uniformly, can reduce the time of the dye transfer printing process, and improve the transfer printing efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com