Method for judging water demand of cementing material

A gelling material and water demand technology, applied in the direction of analyzing materials, measuring devices, flow characteristics, etc., can solve the problems of large water demand and inability to intuitively express the water demand of blended materials, and achieve a practical and intuitive detection method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with specific examples.

[0040] A method for judging the water demand of a gelling material of the present invention comprises the following steps:

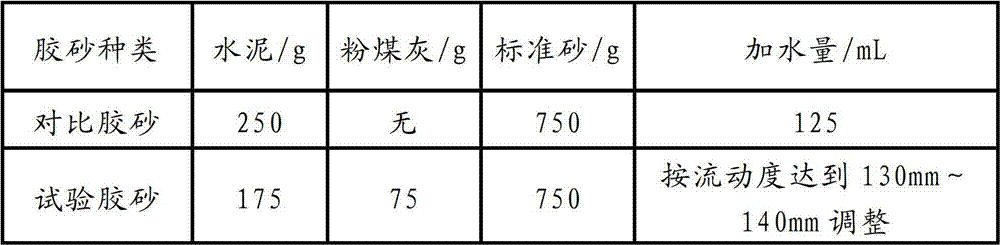

[0041] First, mix fixed quality cement and standard sand to form contrast mortar, and add water until the contrast mortar reaches the specified fluidity, and the specified fluidity range is 130mm to 140mm;

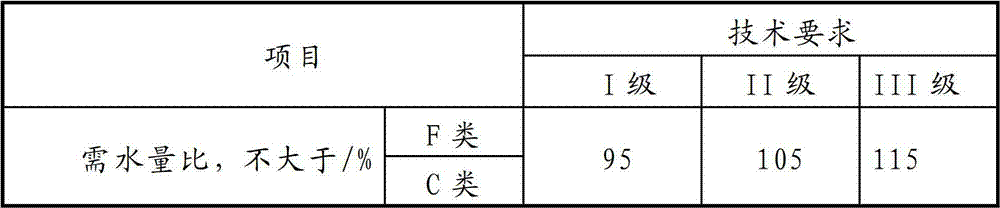

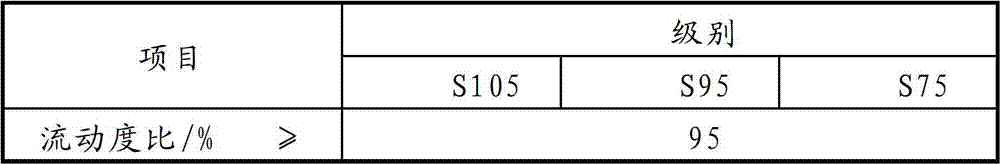

[0042] Then, a certain amount of cement is replaced by admixture materials, and cement, admixture materials and standard sand are mixed to form experimental mortar, and water is added until the comparison mortar reaches the specified fluidity; the admixture materials are fly ash, slag powder or A mix of both.

[0043] The substitution of admixtures relative to cement is determined by the following steps:

[0044] Weigh the same amount of cement and admixture, add water with the same water-cement ratio respectively, and after manual mixing, compare ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com