Magnetic frame

A technology of magnetic frame and plate body, applied in the field of magnetic frame, can solve problems such as large noise, large vibration of hard disk, inconvenient assembly, etc., and achieve the effect of strengthening the structure and reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

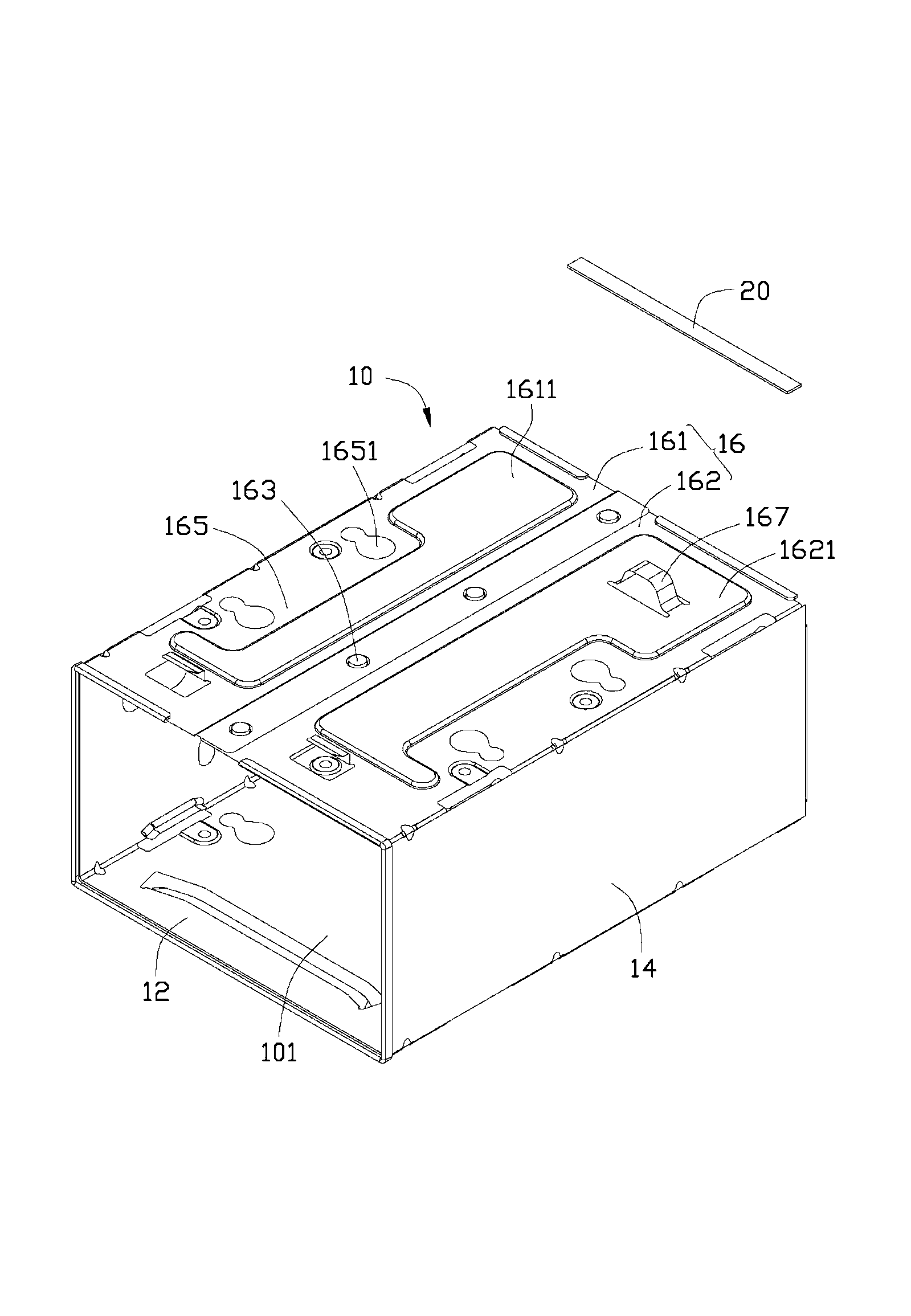

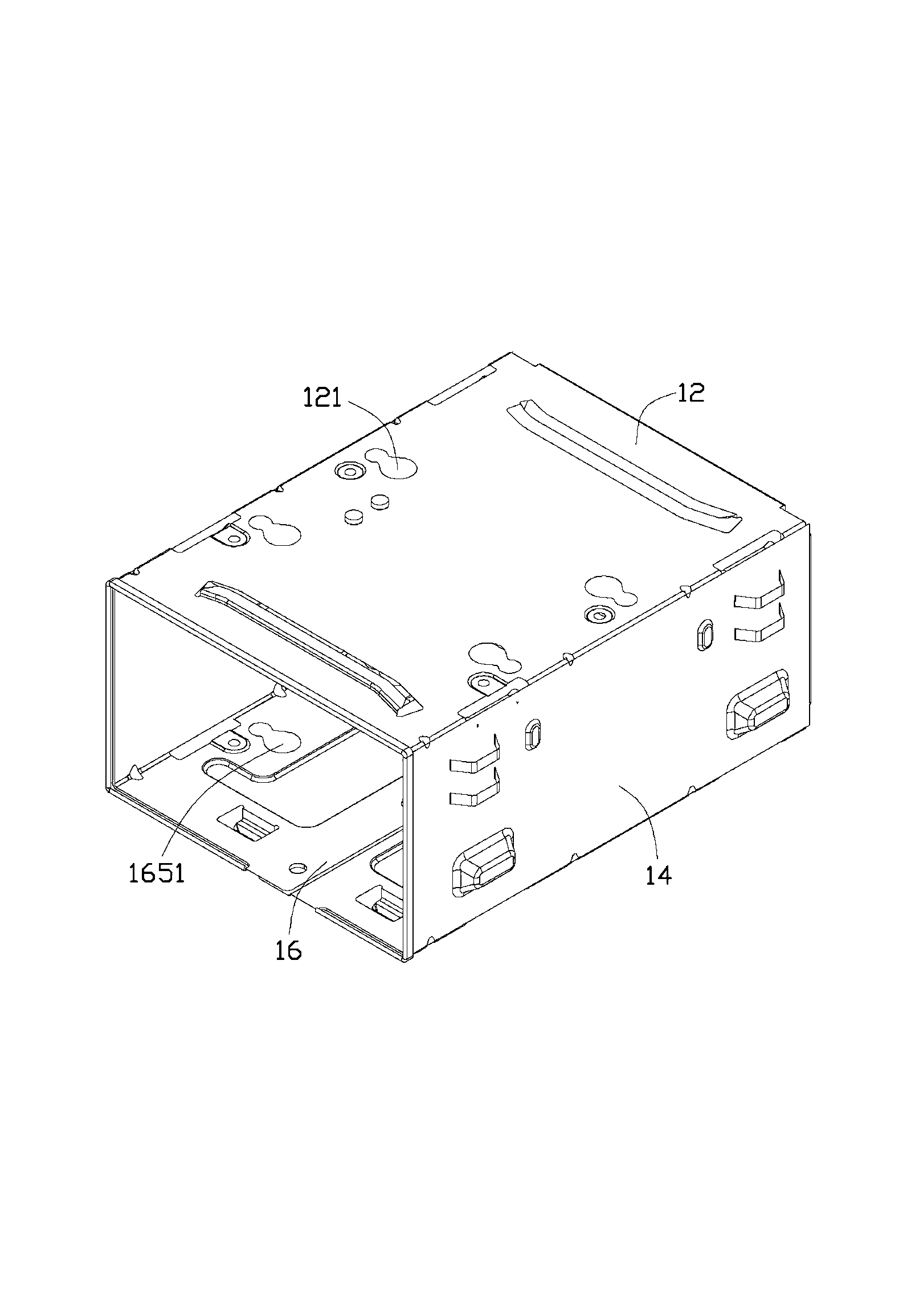

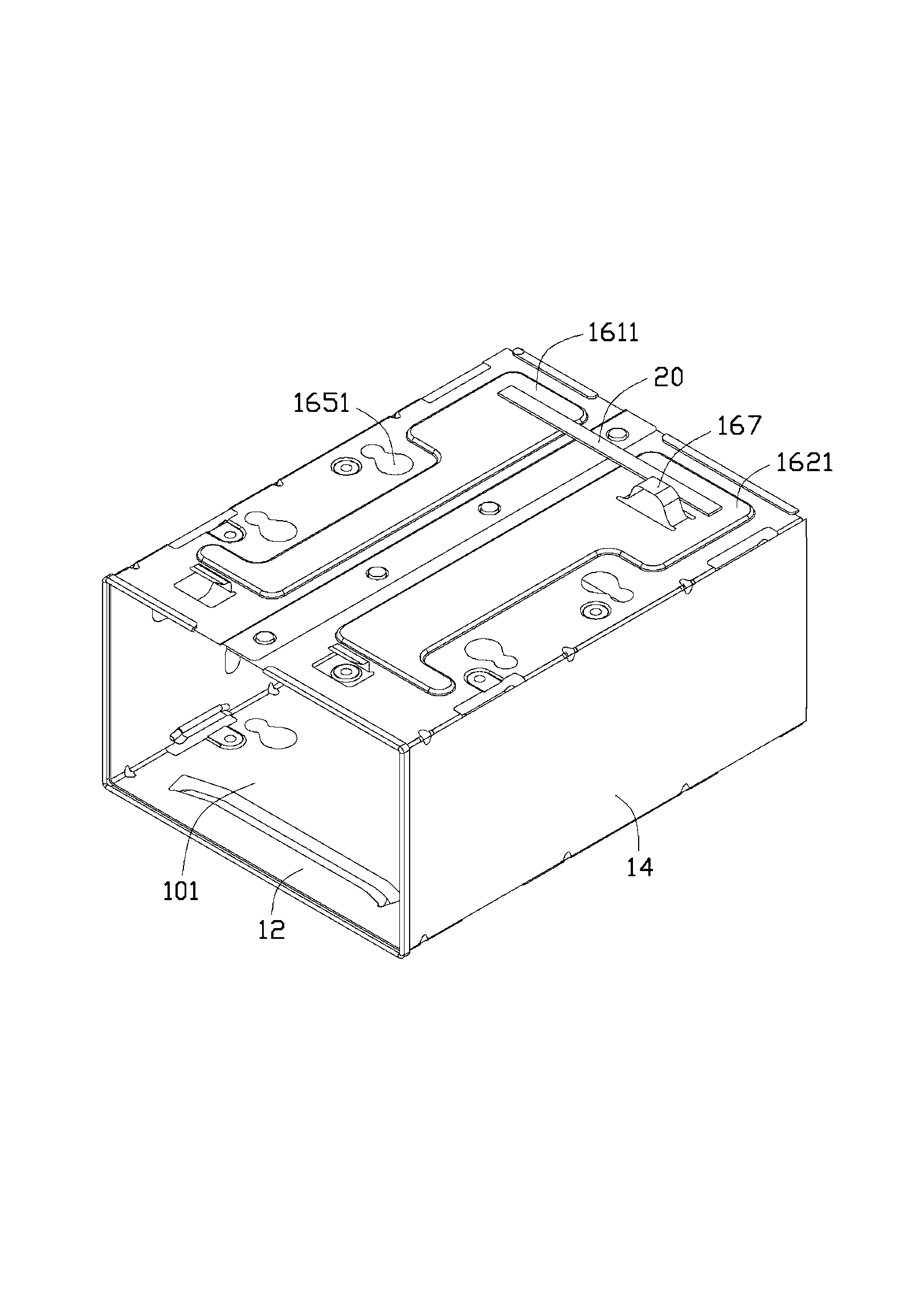

[0012] see figure 1 and figure 2 , The preferred embodiment of the magnetic frame of the present invention includes a magnetic frame main body 10 and a shock absorbing sheet 20 . The shock-absorbing sheet 20 is a long and narrow rectangular steel sheet with strong hardness.

[0013] The magnetic frame main body 10 includes a bottom plate 12 , a pair of side plates 14 vertically extending upward from left and right side edges of the bottom plate 12 , and a top plate 16 . The top plate 16 includes a first plate body 161 extending vertically inward from the top edge of the left side plate 14 and a second plate body 162 extending vertically inward from the top edge of the right side plate 14. The oppositely extending ends of the first board 161 and the second board 162 are partially overlapped, so as to be conveniently fixed together. The overlapping ends of the first plate 161 and the second plate 162 are provided with fixed holes 163 aligned up and down, and the first plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com