Installation structure for capacitor

A technology for mounting structures and capacitors, applied in capacitors, electrical components, etc., can solve problems such as unfavorable capacitor heat dissipation, capacitor shaking, capacitor explosion, etc., and achieve the effects of promoting use, ensuring stability, and protecting capacitors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

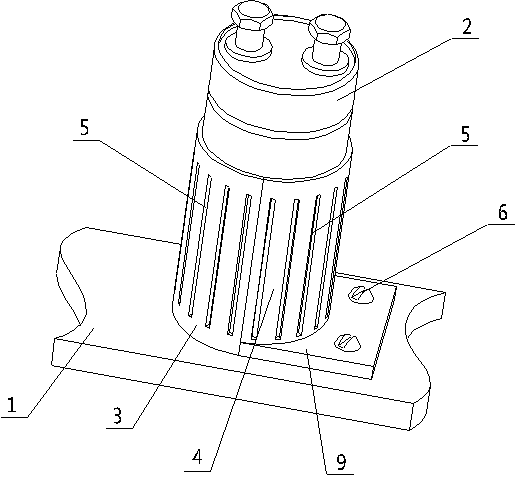

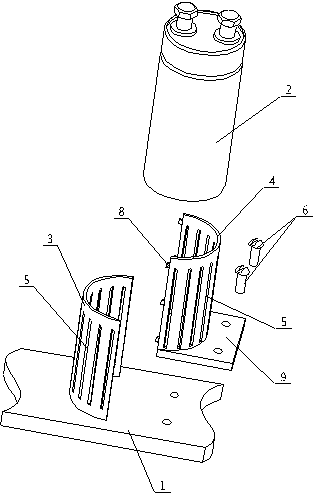

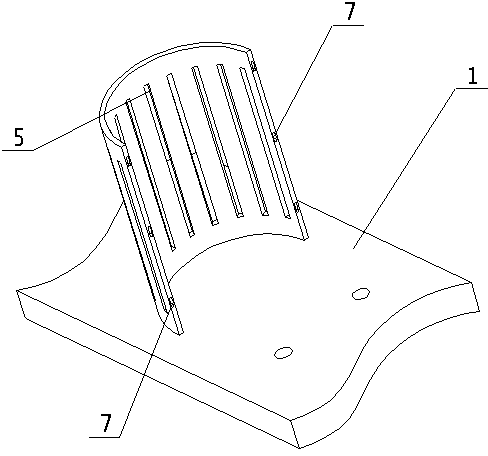

[0015] The present invention is described below in conjunction with accompanying drawing.

[0016] attached Figure 1-4 It is a capacitor mounting structure according to the present invention, comprising a mounting base plate 1, a capacitor 2, a left fixed plate 3, a right fixed plate 4 and a movable plate 9; the left fixed plate 3 is welded on the mounting base plate 1, and its cross section is Semi-circular, and its inner diameter is the same as the outer diameter of the capacitor 2; the shape of the right fixed plate 4 is consistent with that of the left fixed plate 3, and its openings face each other and cooperate with each other; the height of the left fixed plate 3 and the right fixed plate 4 Both are 3 / 4 times of the height of the capacitor 2; the opening end of the left fixing plate 3 is provided with a fixing groove 7; the opening end of the right fixing plate 4 is provided with a protrusion 8 matched with the fixing groove 7; Movable plate 9 is welded on the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com