Self-encapsulating passive wireless pressure sensor based on flexible substrate

A pressure sensor, passive wireless technology, applied in the field of sensors, can solve the problems of limiting the overall characteristics of the device, difficult to obtain the quality factor, increasing the size of the device, etc., to achieve the effect of simple structure, low packaging cost, and protection of the internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

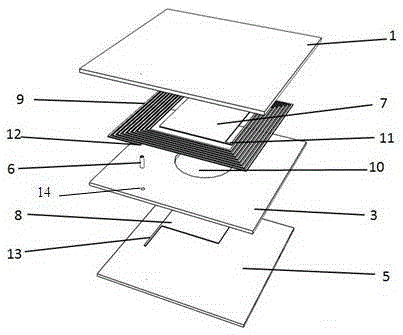

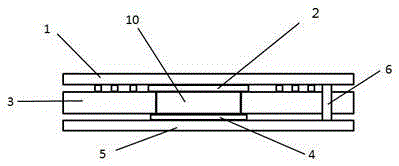

[0019] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0020] like figure 1 and figure 2 As shown, a passive wireless pressure sensor with self-packaging function based on a flexible substrate of the present invention includes an upper flexible substrate 1, an upper metal layer 2, a middle flexible substrate 3, a lower Metal layer 4 and lower flexible substrate 5 . The upper flexible substrate 1, the middle flexible substrate 3 and the lower flexible substrate 5 are all made of flexible materials, such as polyimide (PI), liquid crystal polymer (LCP), or polyethylene terephthalate. Alcohol esters (PET). Electrical vias 14 and cavities 10 are provided on the middle flexible substrate 3 . Preferably, the cavity 10 is located in the middle of the middle flexible substrate 3 . The cavity 10 is located in the middle of the middle flexible substrate 3, which can reduce th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com