An integrated chassis filter board structure

A filter board and integrated technology, applied in the field of filters, can solve the problems of wires occupying the internal space of customer equipment, less available space for equipment, inconvenient update and disassembly, etc., to avoid electromagnetic interference and physical damage, save space, and be less prone to errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions in the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

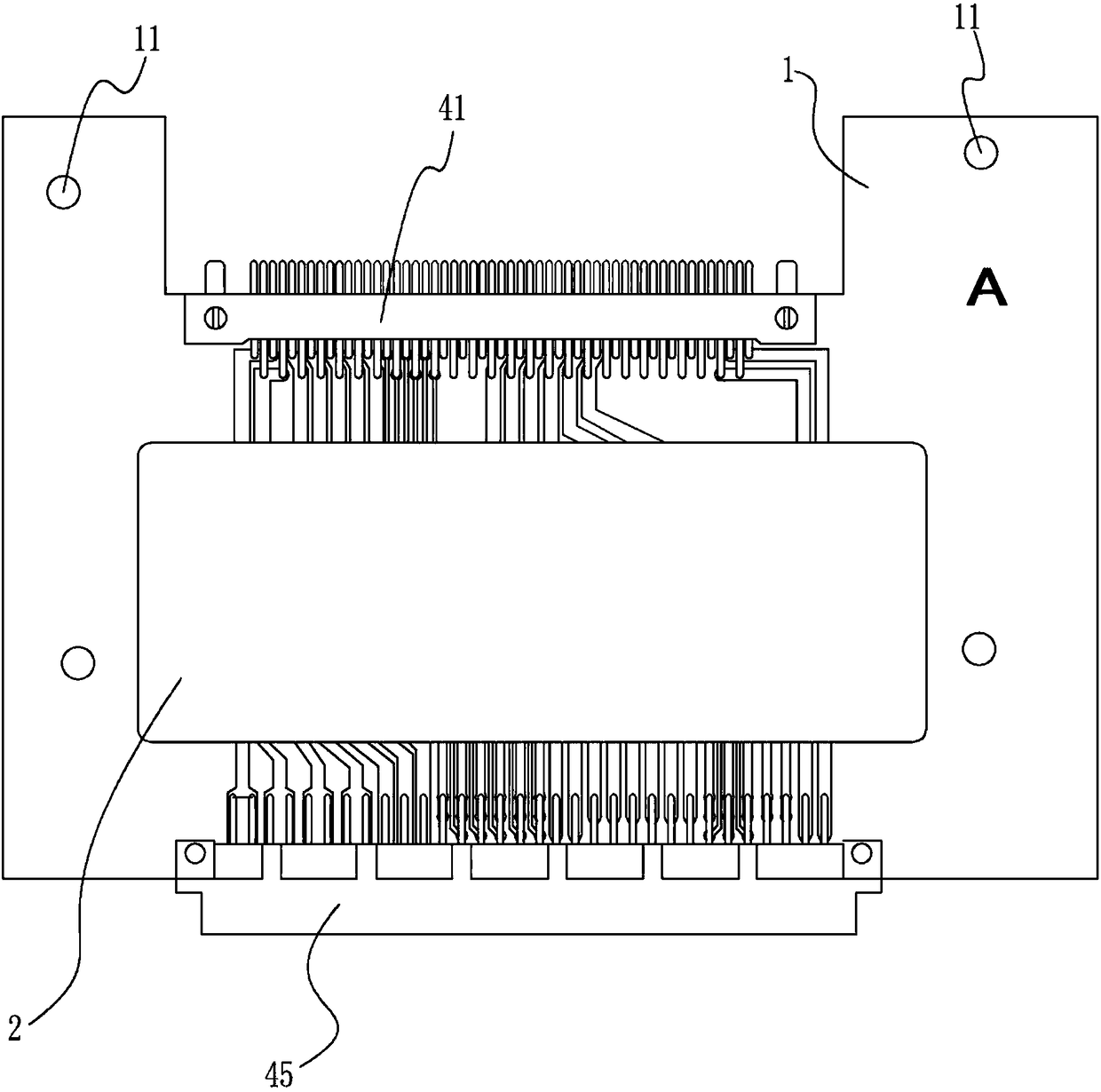

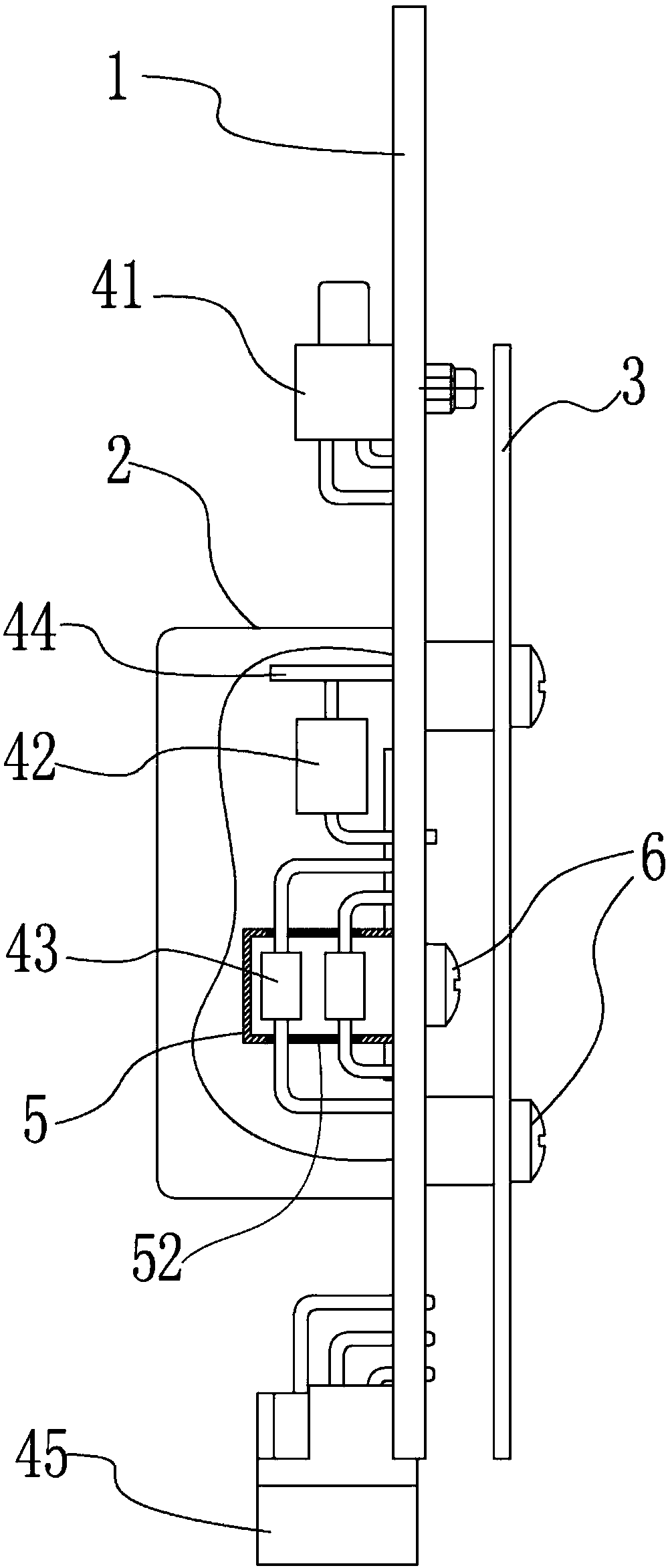

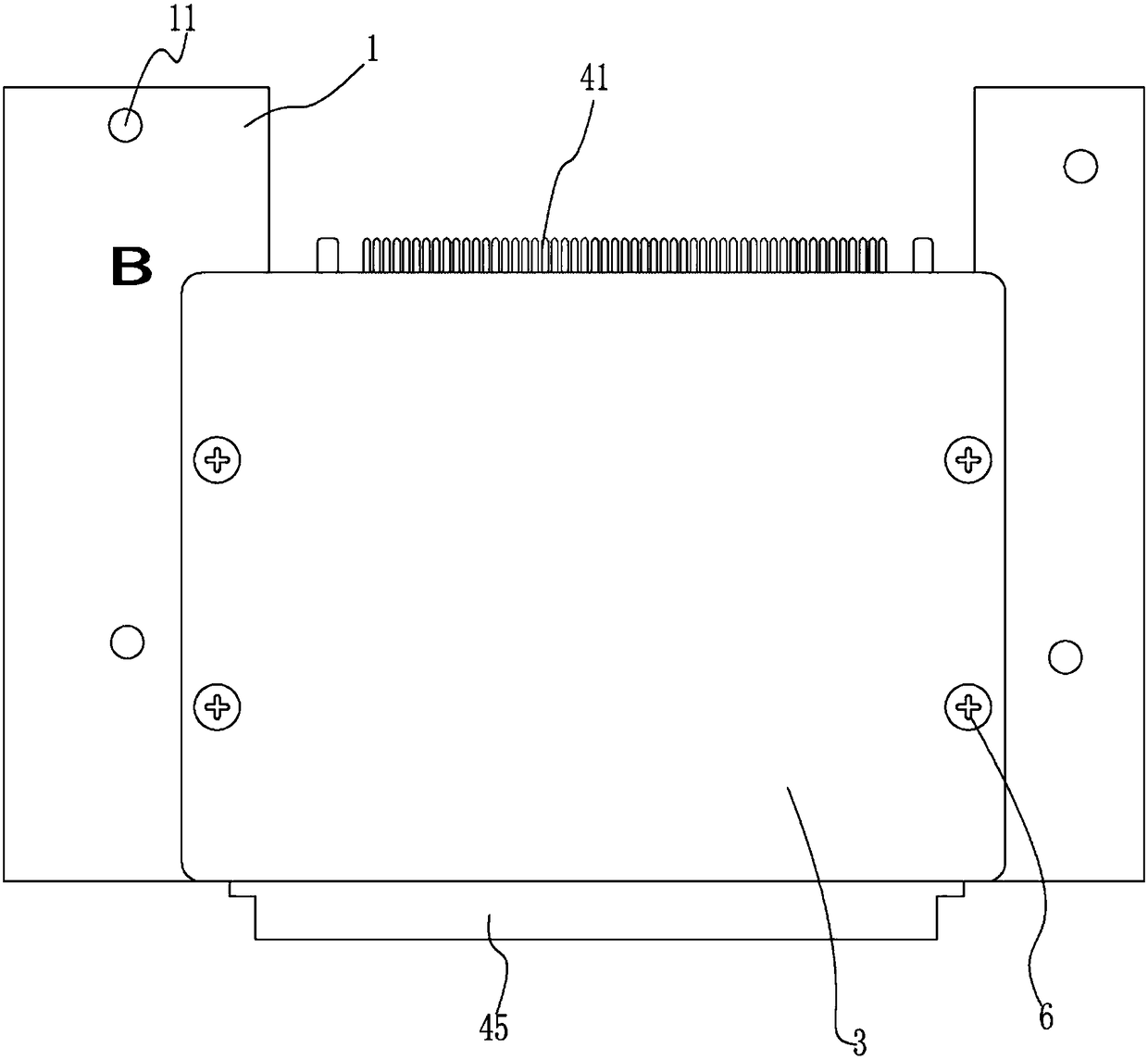

[0019] As shown in the figure, the present invention proposes an integrated chassis filter board structure, including a PCB substrate 1, a shield cover 2, a protective plate 3, a filter, and an installation box 5, wherein the PCB substrate 1 is provided with several installation screws. A hole 11 and a fixing column 12, the fixing column 12 is provided with a fixing screw hole, and the fixing screw hole communicates with two opposite sides of the PCB substrate 1;

[0020] The shielding cover 2 and the protective plate 3 are all fixed on the PCB substrate 1 by screws 6 and fixing screw holes, and the shielding cover 2 and the protective plate 3 are respectively located on two opposite sides of the PCB substrate 1, so that the PCB substrate 1 Electromagnetic protection and physical protection are carried out on the electronic co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com