Gallium nitride based light emitting diode with current expanding structure

A technology of light-emitting diodes and current expansion, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of high voltage of LED chips, achieve the effects of not being easy to tilt and warping, reducing electrode shading, and retaining the effect of current expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

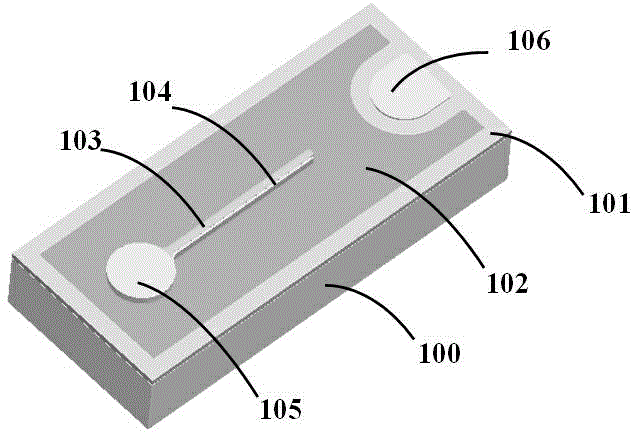

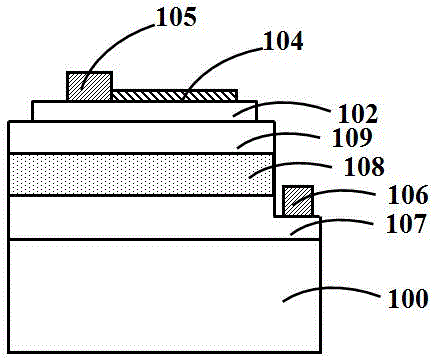

[0029] Such as figure 1 and 2 As shown, the GaN-based light-emitting diode with a current spreading structure includes a sapphire substrate 100 as the bottom layer; a light-emitting epitaxial layer 101 located on the substrate 100, and the light-emitting epitaxial layer consists of N-GaN layer 107, The light emitting layer 108 and the P-GaN layer 109 are composed; the ITO transparent conductive layer 102 located on the light emitting epitaxial layer 101; the current spreading structure located on the transparent conductive layer 102, and the current spreading structure includes the ITO transparent electrode extension bar 103 and the Au metal electrode extension bar 104 whose side wall is close to the side wall of the transparent electrode extension bar 103 ; the P electrode 105 on the ITO transparent conductive layer 102 and the N electrode 106 on the N-GaN layer 107 .

[0030] The ITO transparent electrode extension strip 103 can be made by reactive magnetron sputtering and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com