Preparation method of dielectric substrate

A technology for dielectric substrates and substrates, which can be applied to devices, printed circuits, coatings, etc. that apply liquid to the surface, and can solve problems such as unsatisfactory physical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

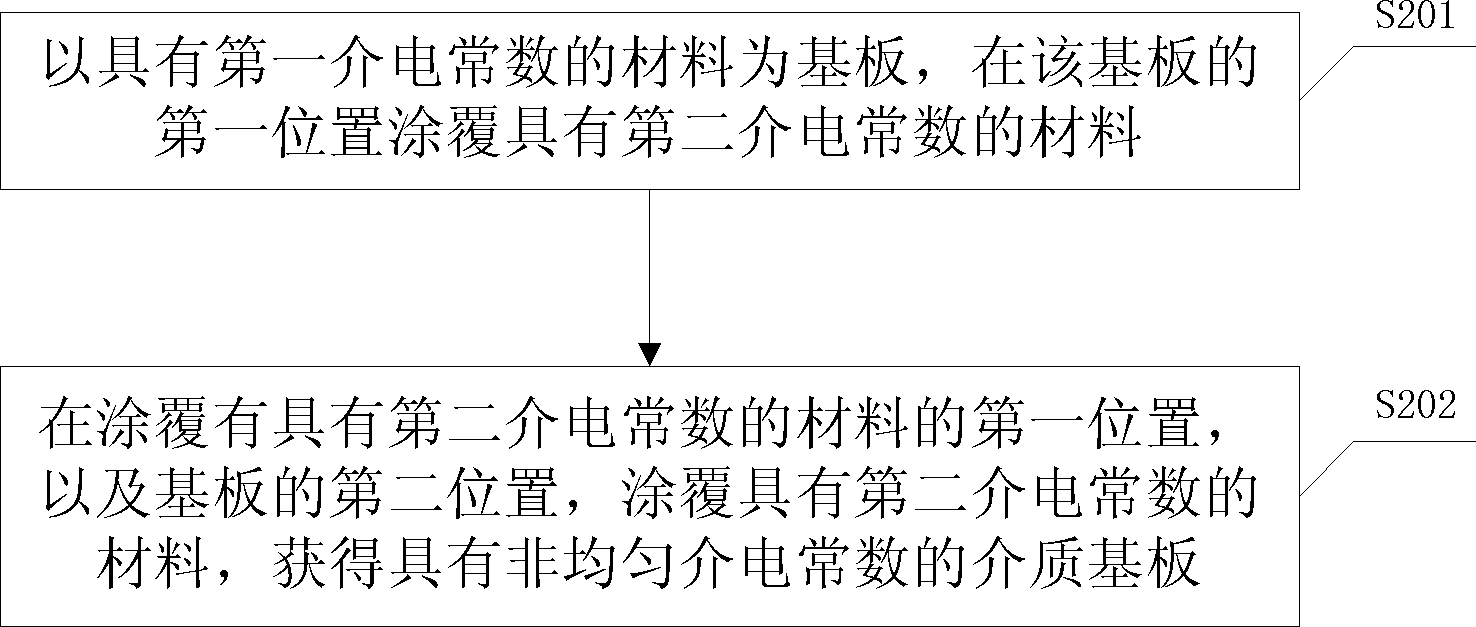

[0021] see figure 2 , which is a flowchart of a method for preparing a dielectric substrate provided in Embodiment 1 of the present invention, the method includes the following steps:

[0022] S201: Using a material with a first dielectric constant as a substrate, coating a material with a second dielectric constant on a first position of the substrate.

[0023] For example, a polymer material with a first dielectric constant is used as a substrate, and a material with a dielectric constant greater than the first dielectric constant is coated on the substrate. The material with a dielectric constant greater than the first dielectric constant may be ceramics, mica, glass, plastic, or metal oxide.

[0024] S202: On the first position coated with the material with the second dielectric constant and the second position of the substrate, coat the material with the second dielectric constant to obtain a dielectric substrate with a non-uniform dielectric constant.

[0025] For exa...

Embodiment 2

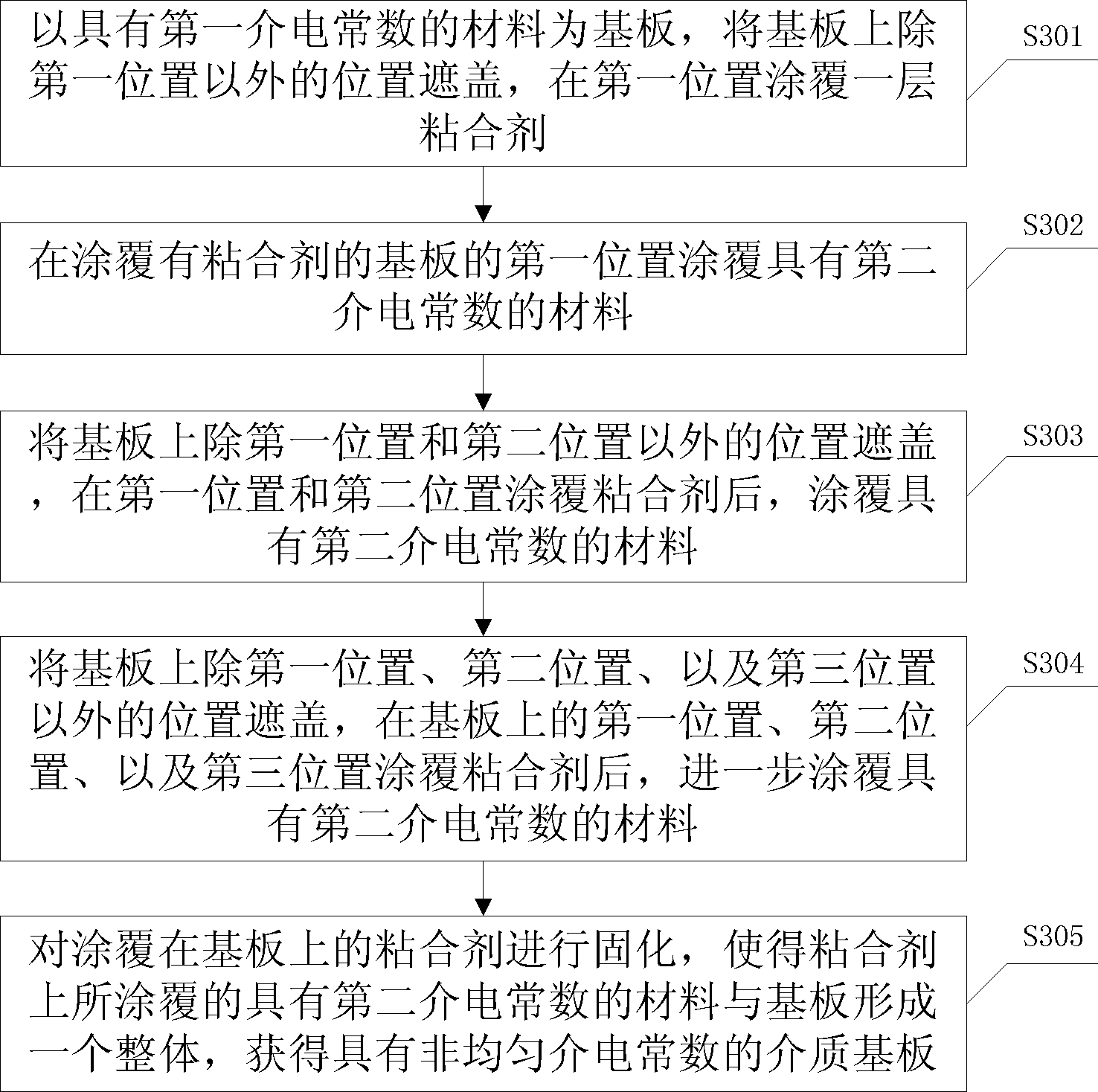

[0028] see image 3 , which is a flowchart of a method for preparing a dielectric substrate provided in Embodiment 2 of the present invention, the method includes the following steps:

[0029] S301: Using a material with a first dielectric constant as a substrate, covering positions on the substrate except the first position, and coating a layer of adhesive on the first position.

[0030] For example, a polymer material with a first dielectric constant is used as a substrate, and a layer of epoxy resin glue is coated on the substrate. In a specific implementation process, the adhesive is not limited to epoxy resin glue, and can be replaced by other adhesives having the same function as epoxy resin glue, such as vinyl ester resin.

[0031] S302: Coating a material with a second dielectric constant on a first position of the substrate coated with the adhesive.

[0032] For example, the ceramic powder is coated on the first position where the epoxy glue is coated on the substra...

Embodiment 3

[0042] see Figure 4 , which is a flowchart of a method for preparing a dielectric substrate provided in Embodiment 3 of the present invention, the method includes the following steps:

[0043] S401: Using a material with a first dielectric constant as a substrate, uniformly mix a material with a second dielectric constant and a binder in a preset ratio to obtain a mixed material.

[0044] For example, the ceramic material with the second dielectric constant is mixed with the epoxy resin glue in a preset ratio, and the preset ratio is set so as not to affect the adhesiveness of the epoxy resin glue and is actually required.

[0045] In a specific implementation process, ceramics can be replaced by mica, glass, plastic, or metal oxides.

[0046] S402: Covering positions on the substrate other than the first position, and coating the mixed material obtained in step S401 on the first position of the substrate.

[0047] Wherein, the first dielectric constant is smaller than the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com