Communication optical cable sheath pipe

A technology for optical fiber cables and sheathing tubes, which can be used in electrical components and other directions to solve problems such as poor mechanical properties, poor flame retardancy, and easy deformation at high temperatures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A communication optical fiber cable sheath tube, which includes a four-layer structure from the inside to the outside, which are respectively a water-blocking layer, a heat-insulating layer, a shielding layer, and a protective layer; the water-blocking layer is extruded with a heat-insulating layer, so The shielding layer is extruded outside the heat insulation layer, and the protective layer is extruded outside the shielding layer; the thickness of the water blocking belt layer is 0.3-0.5mm, the thickness of the heat insulation layer is 0.2-0.3mm, and the thickness of the shielding layer is 0.05 mm. -0.1mm, the thickness of the protective layer is 2mm;

[0017] The heat insulation layer is a double-layer synthetic mica tape; the shielding layer is aluminum foil; the protective layer is a modified polyethylene composite material layer, which is prepared from the following raw materials in parts by weight:

[0018] 100 parts of high-density polyethylene, 50 parts of low-...

Embodiment 2

[0022] A communication optical fiber cable sheath tube, which includes a four-layer structure from the inside to the outside, which are respectively a water-blocking layer, a heat-insulating layer, a shielding layer, and a protective layer; the water-blocking layer is extruded with a heat-insulating layer, so The shielding layer is extruded outside the heat insulation layer, and the protective layer is extruded outside the shielding layer; the thickness of the water blocking belt layer is 0.3-0.5mm, the thickness of the heat insulation layer is 0.2-0.3mm, and the thickness of the shielding layer is 0.05 mm. -0.1mm, the thickness of the protective layer is 2mm;

[0023] The heat insulation layer is a double-layer synthetic mica tape; the shielding layer is aluminum foil; the protective layer is a modified polyethylene composite material layer, which is prepared from the following raw materials in parts by weight:

[0024] 150 parts of high-density polyethylene, 90 parts of low-...

Embodiment 3

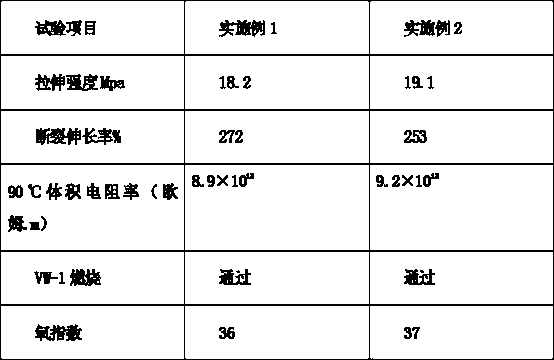

[0028] Carry out performance detection test to the sheath pipe protective layer of embodiment 1-2, each performance numerical value is as table 1:

[0029] Table 1

[0030]

[0031] Salt resistance test: soak the test material in Example 1 in 10% sodium chloride solution for 30 days, the tensile strength decreased by 0.7%, the elongation at break decreased by 0.3%, and other properties and characterizations had no obvious changes.

[0032] Alkali resistance test: the test material of Example 1 was soaked in 10% sodium hydroxide solution for 30 days, the tensile strength decreased by 0.8%, the elongation at break decreased by 0.2%, and other properties and characterizations had no obvious changes.

[0033] Heat resistance performance: when the test material of Example 1 was placed in steam at 160°C for 48 hours, the tensile strength decreased by 2.3%, the elongation at break decreased by 1.9%, and the resistivity decreased by 3.7%. There was no significant change in other pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com