A copper-gas media Damascus structure and its making method

A technology of gas medium and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of low manufacturing cost, and achieve the effects of being beneficial to heat conduction, structural stability, and reducing interconnection delay.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The specific embodiments of the present invention will now be described in further detail with reference to the accompanying drawings:

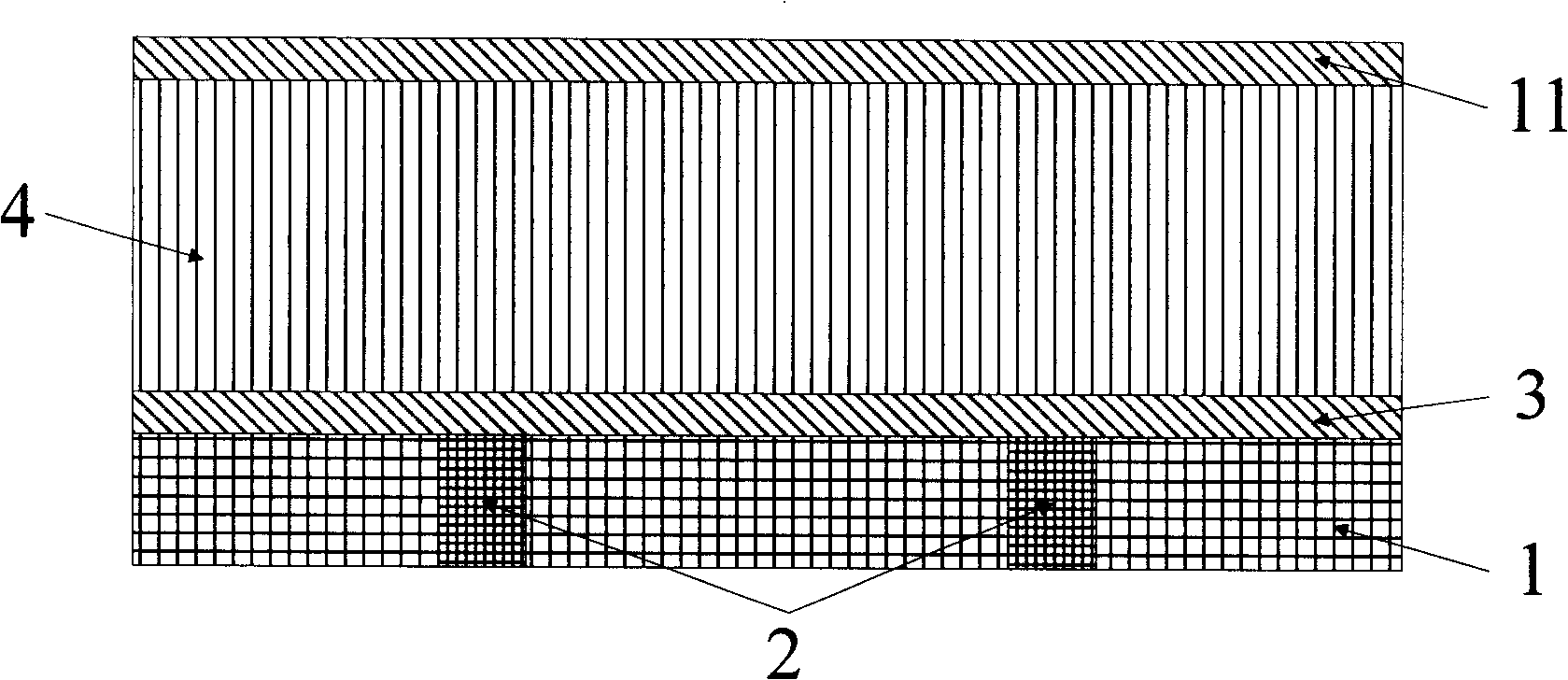

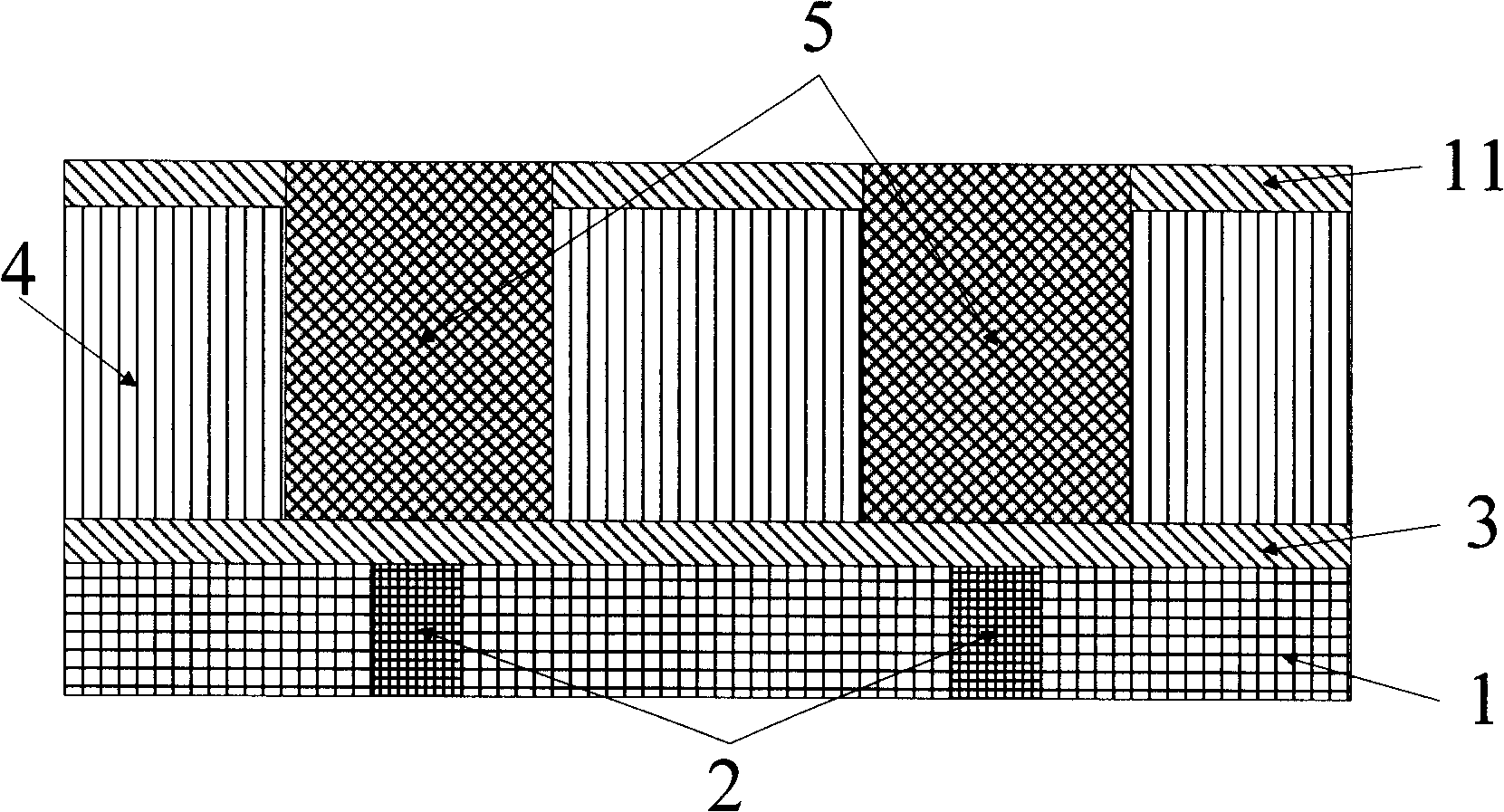

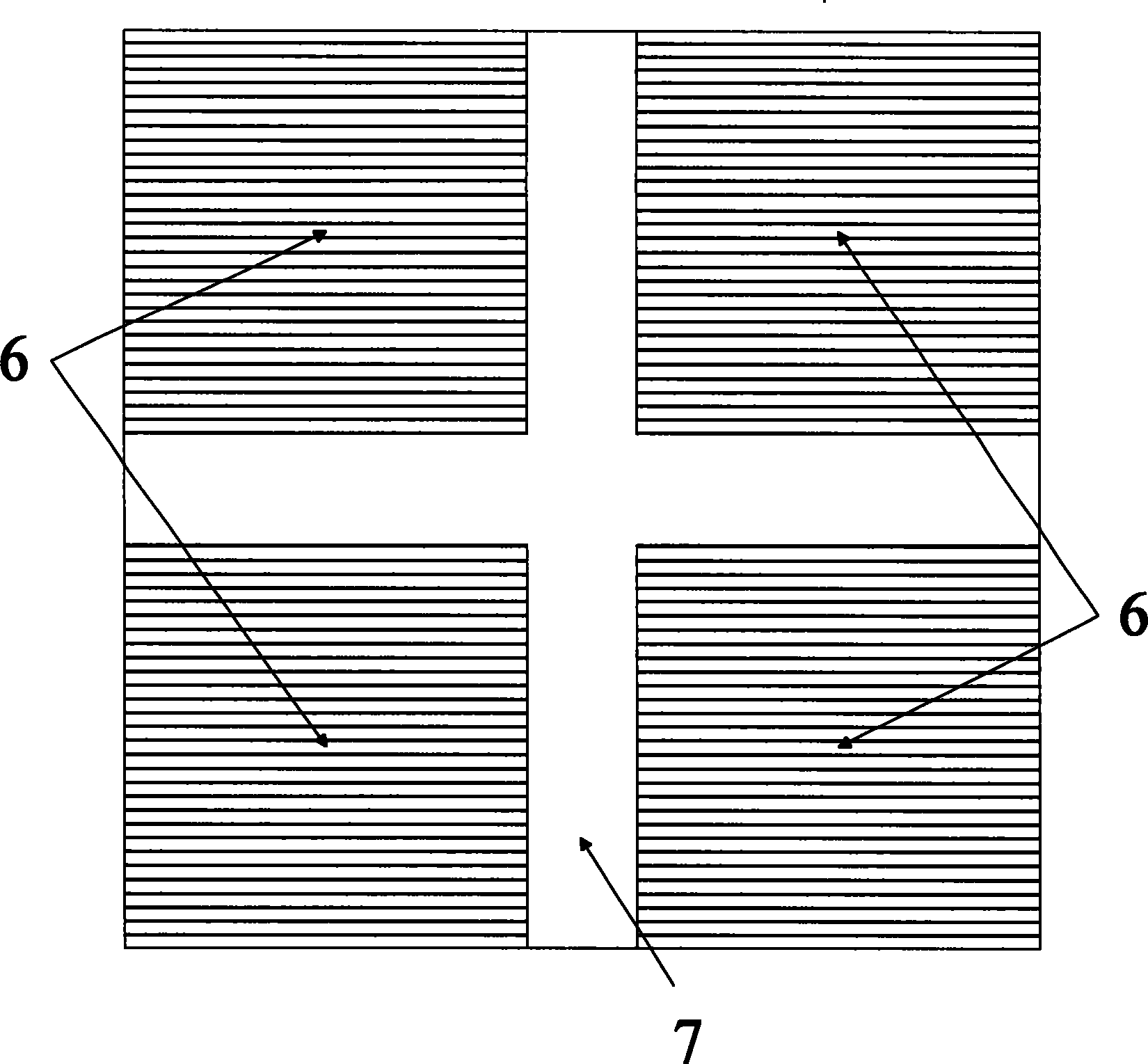

[0058] The copper-gas medium multilayer Damascus structure of the present invention is as Picture 9 Shown ( Picture 9 It is a schematic diagram of the copper-gas medium Damascus structure of the present invention), and there is a dielectric layer 1 at the bottom of the entire structure. In each layer of the multi-layer Damascus structure of the Damascus structure, the diffusion barrier layer and the copper seed layer 8 are lined at the bottom and around the copper wiring 2, and the copper seed layer between the diffusion barrier layer and the copper seed layer 8 The liner is at the bottom and around the copper wiring 2, the diffusion barrier layer is lined at the bottom and around the copper seed layer; the oxide film 5 is wrapped around the diffusion barrier layer, and the silicon carbide etching barrier layer 11 covers the package T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com