Reversing device for electronic components

A technology of electronic components and reversing devices, which is applied in the direction of conveyor objects, transportation and packaging, etc., to achieve the effect of cost saving and motor protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

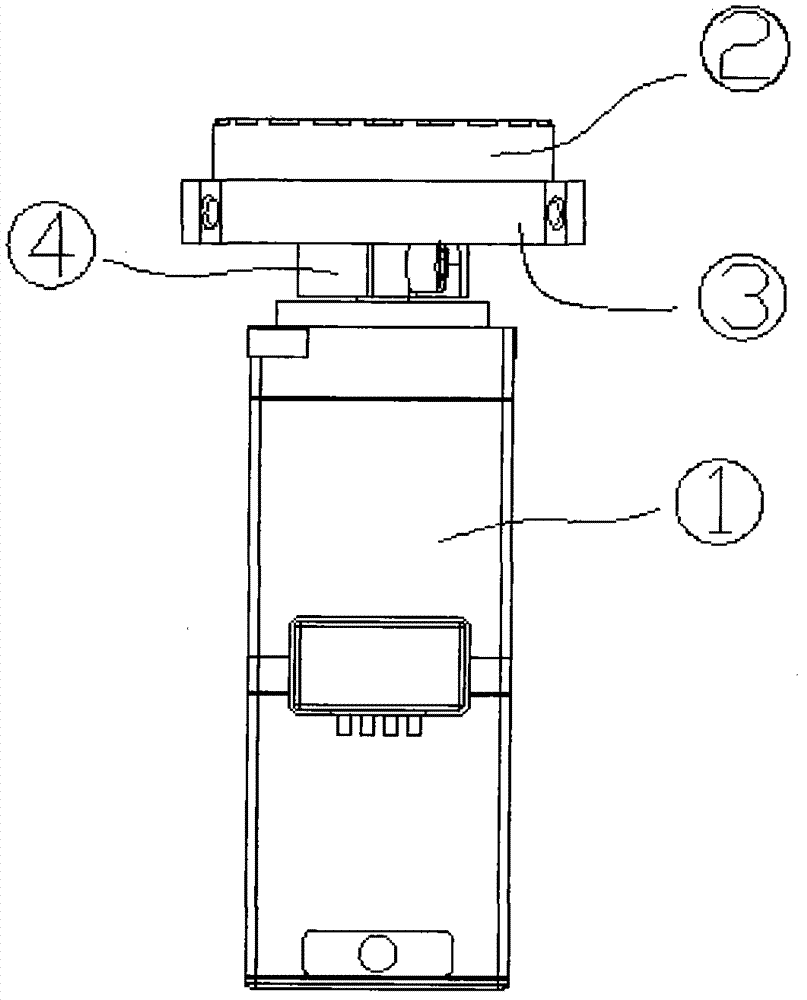

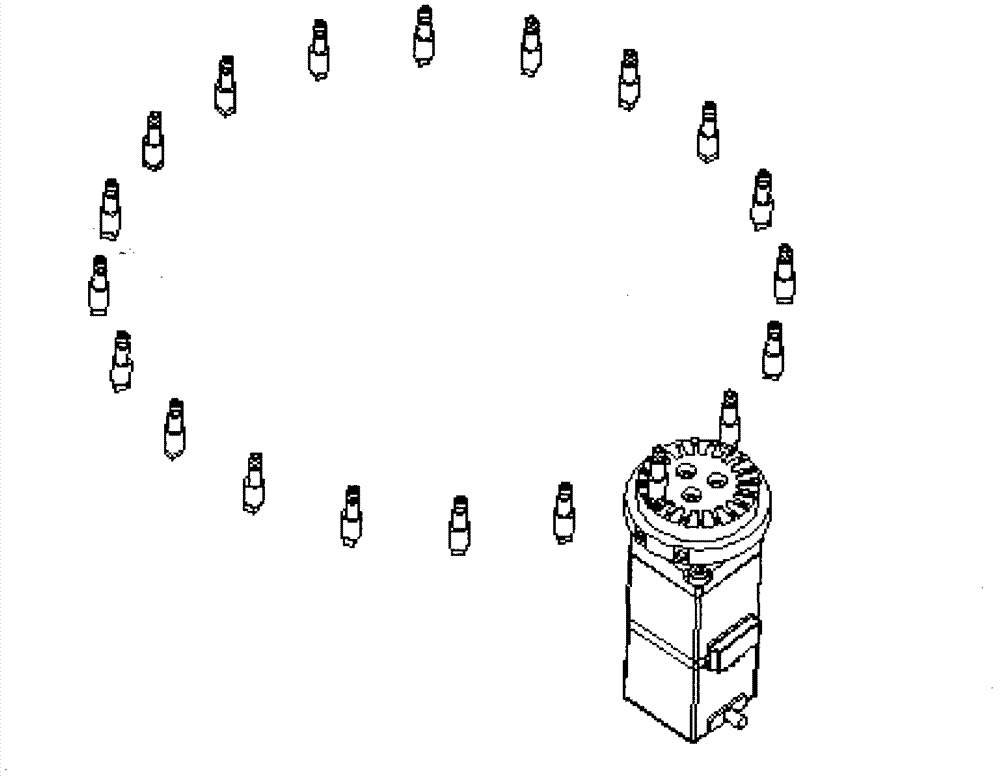

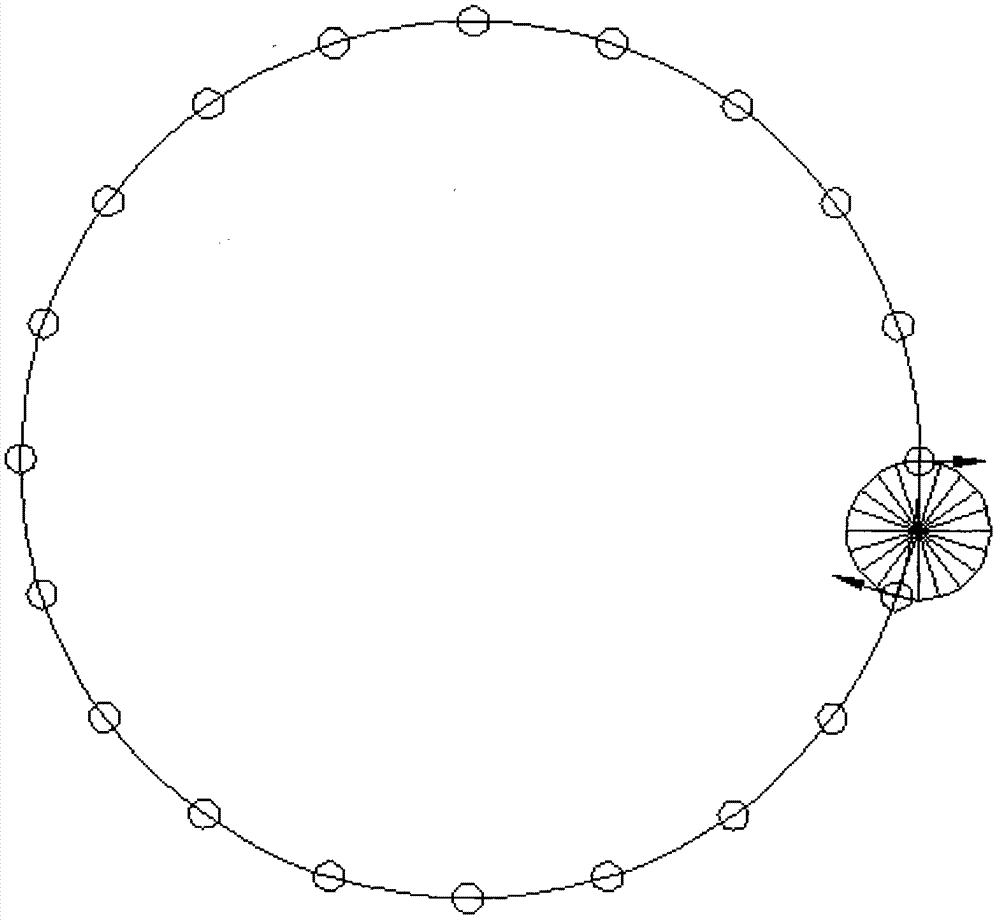

[0028] Such as figure 1 and figure 2 As shown, the electronic component reversing device described according to the present invention includes: a servo motor ①, a small turntable ②, a vacuum plate ③, and a connecting block ④, wherein the servo motor is connected to the small turntable through a connecting block, and can be dragged Turn the small turntable. image 3 As shown, there are several suction nozzles distributed on the large turntable above, the relative positions of the two turntables, and the arrows indicate the direction of the electronic components. Figure 4 As shown, when the electronic components adsorbed on the suction nozzle of the large turntable need to change direction, the suction nozzle releases the electronic components and is taken over by the small turntable below with vacuum. Figure 5 and 6 As shown, after the electronic components are handed over, the small turntable starts to rotate, and the large turntable also starts to rotate after a certai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com