Patents

Literature

52results about How to "Less prone to mechanical failure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

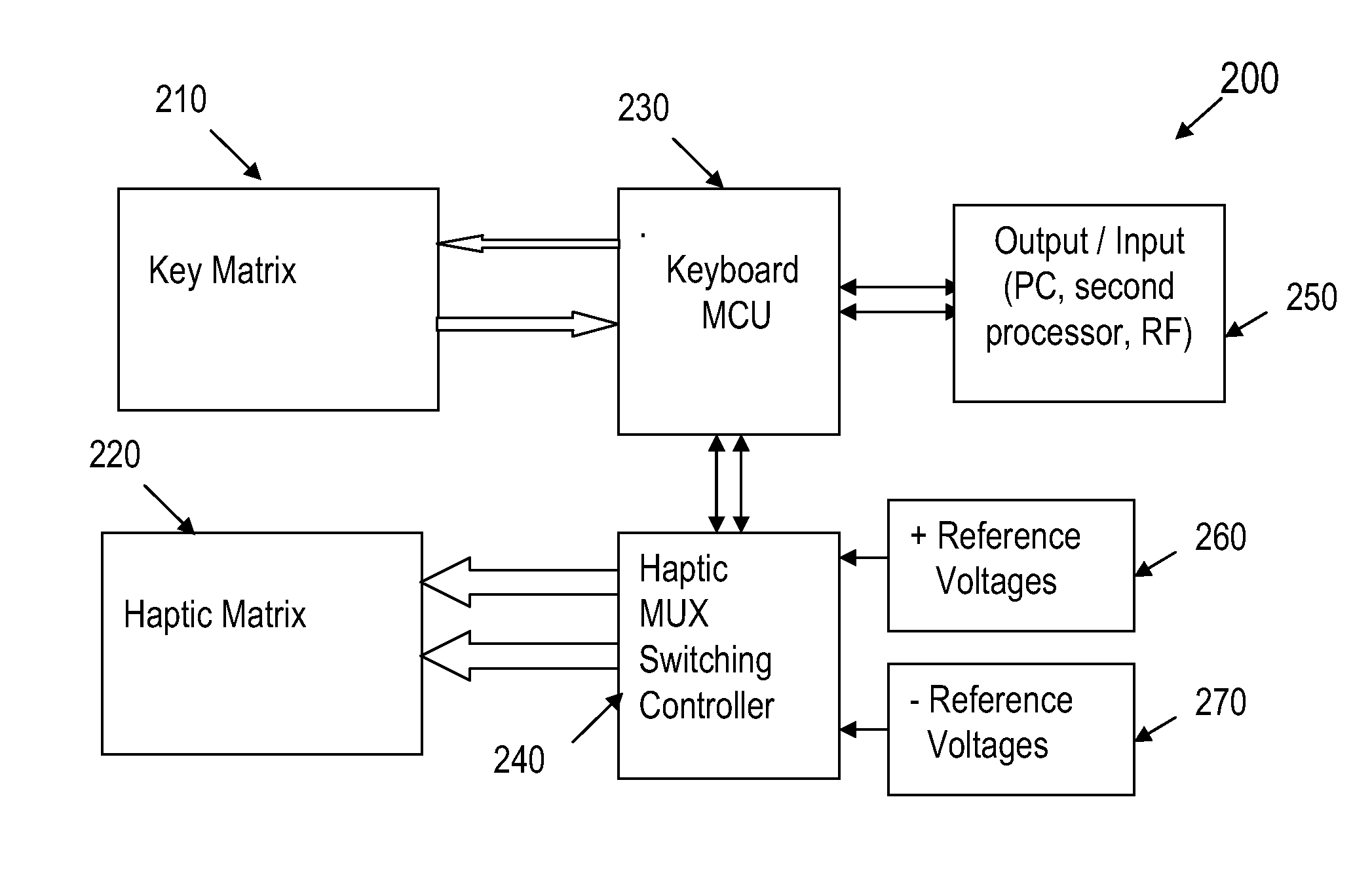

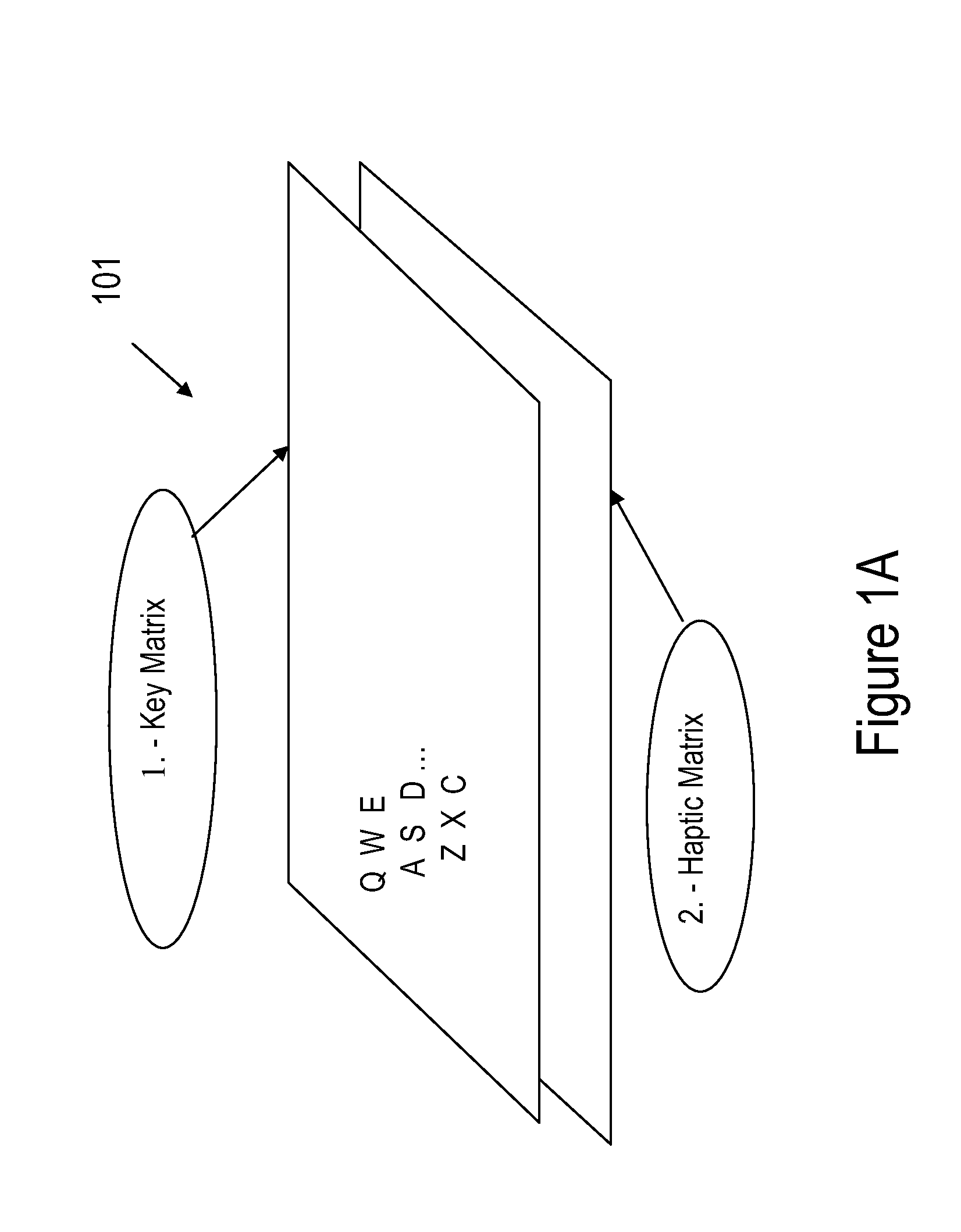

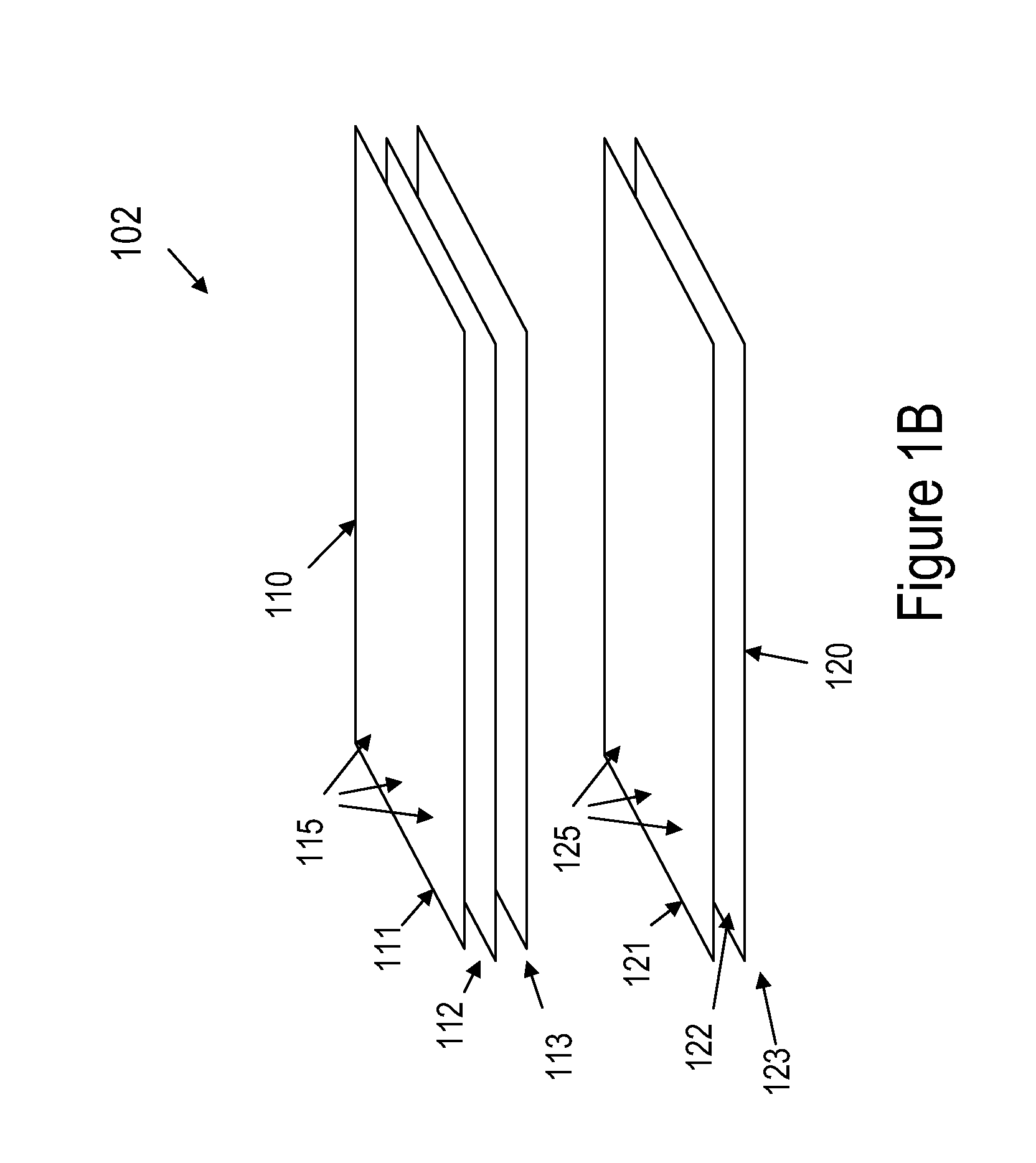

Haptic keyboard apparatus and method

InactiveUS20100089735A1Less-prone to mechanical failureQuick feedbackElectric switchesTactile feedbackControl signalTactile device

A haptic keyboard apparatus includes a membrane resistor keyboard device and a haptic device. The membrane resistor keyboard device includes a plurality of key switches, each of the key switches being responsive to touch by a user. The haptic device is coupled to the membrane resistor keyboard device. The haptic device includes a plurality of haptic cells, each of which is disposed under a corresponding key switch. Each of the haptic cells is configured to provide haptic feedback in response to the touch by the user. In a specific embodiment, the haptic keyboard apparatus also includes a processor and a haptic controller that provide control signals to the haptic device. In an embodiment, the control signals include programmable voltages and frequencies, causing the haptic cells to effect vibrational patterns in response to the control signals and provide haptic feedback to the user.

Owner:MINEBEA CO LTD

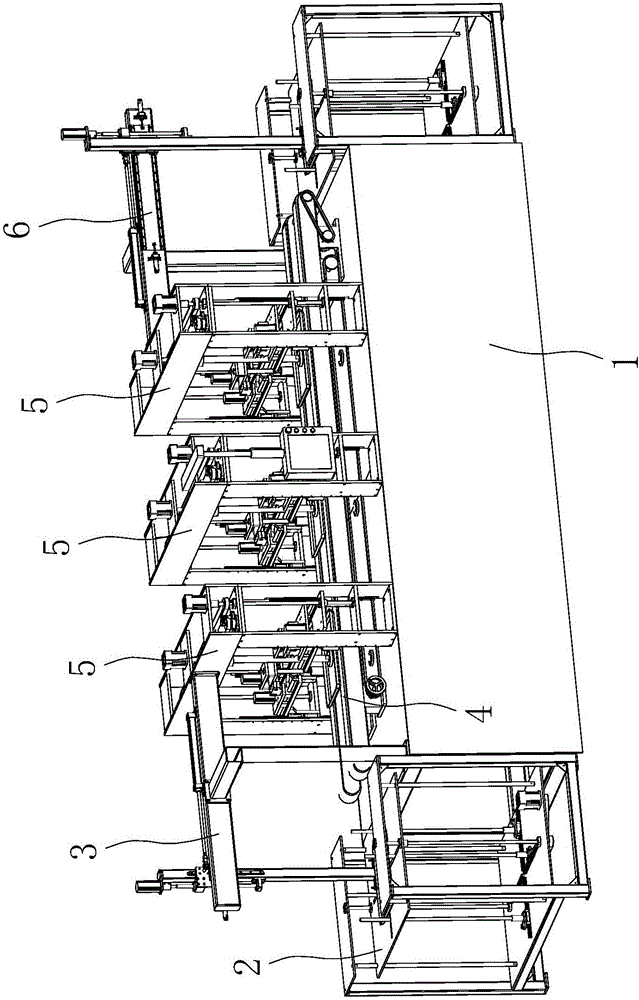

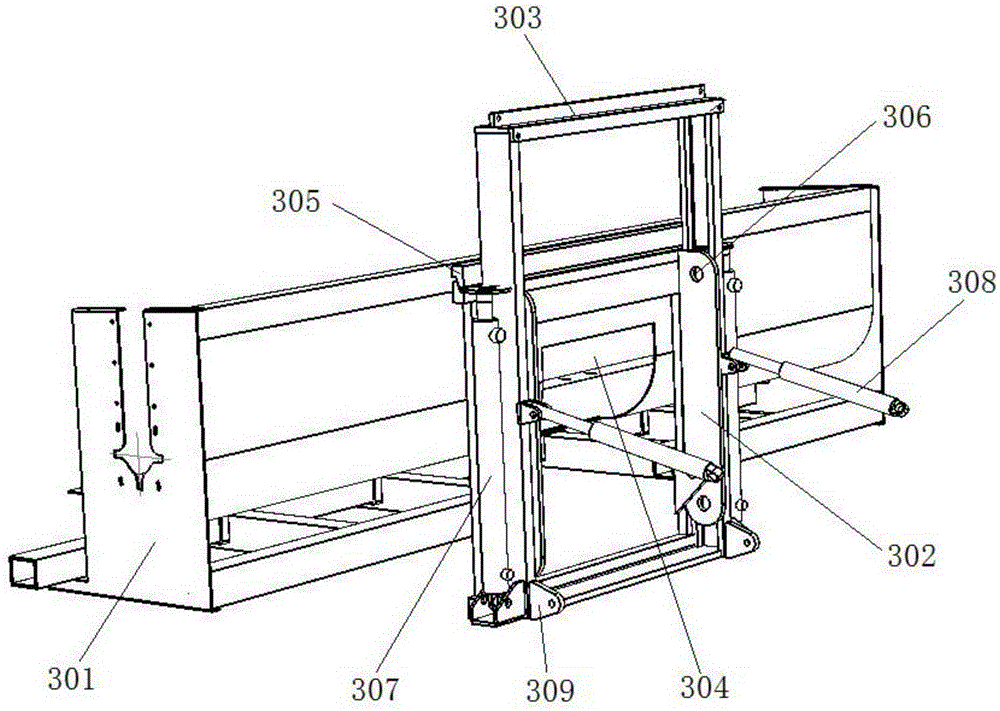

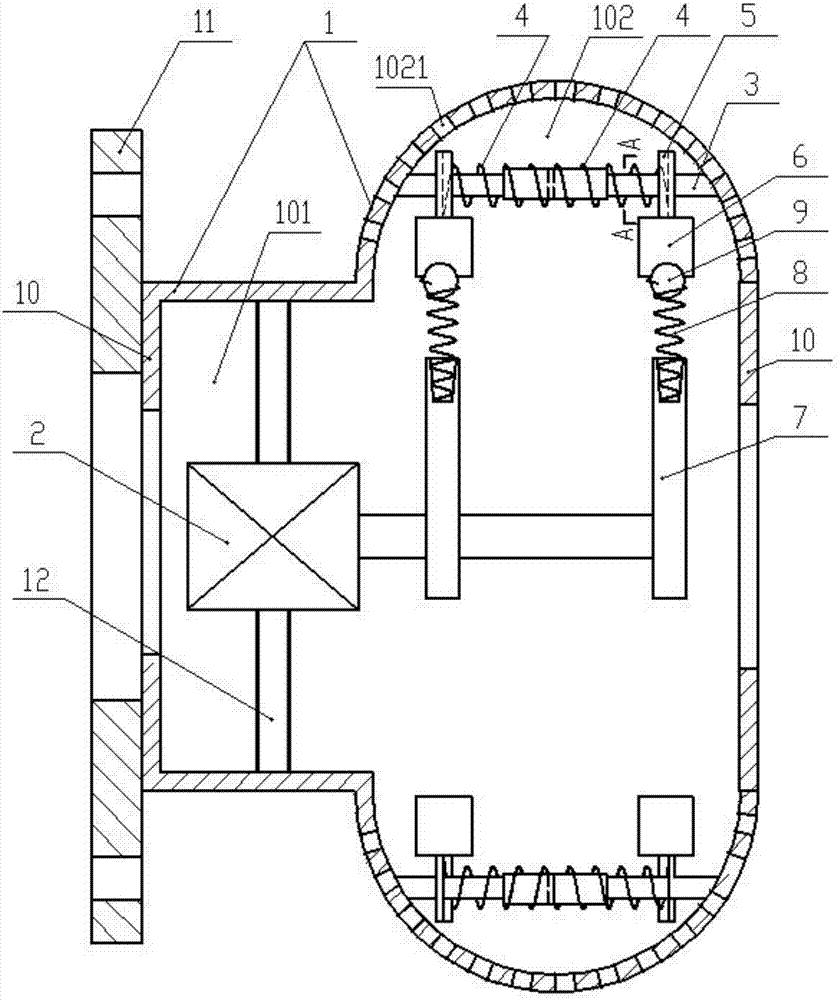

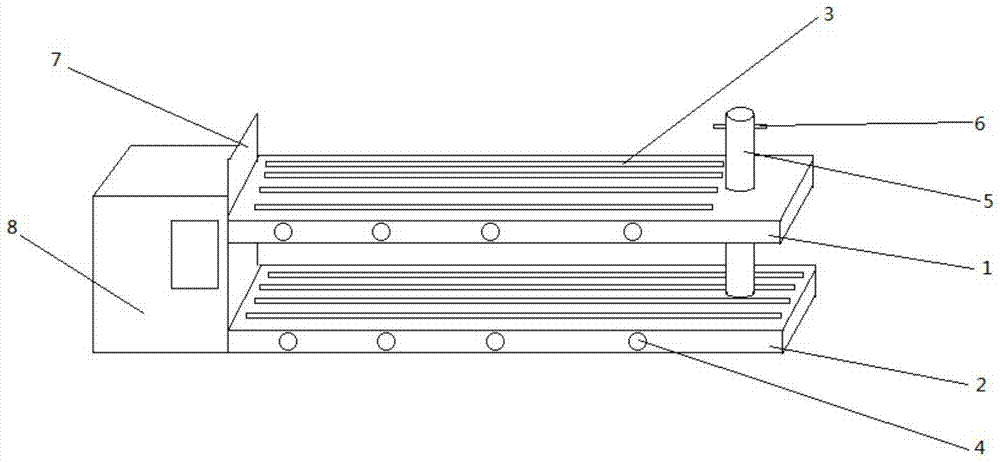

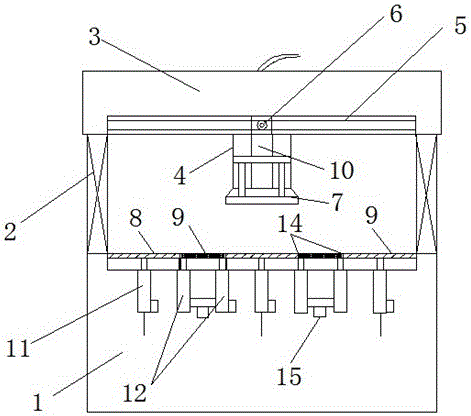

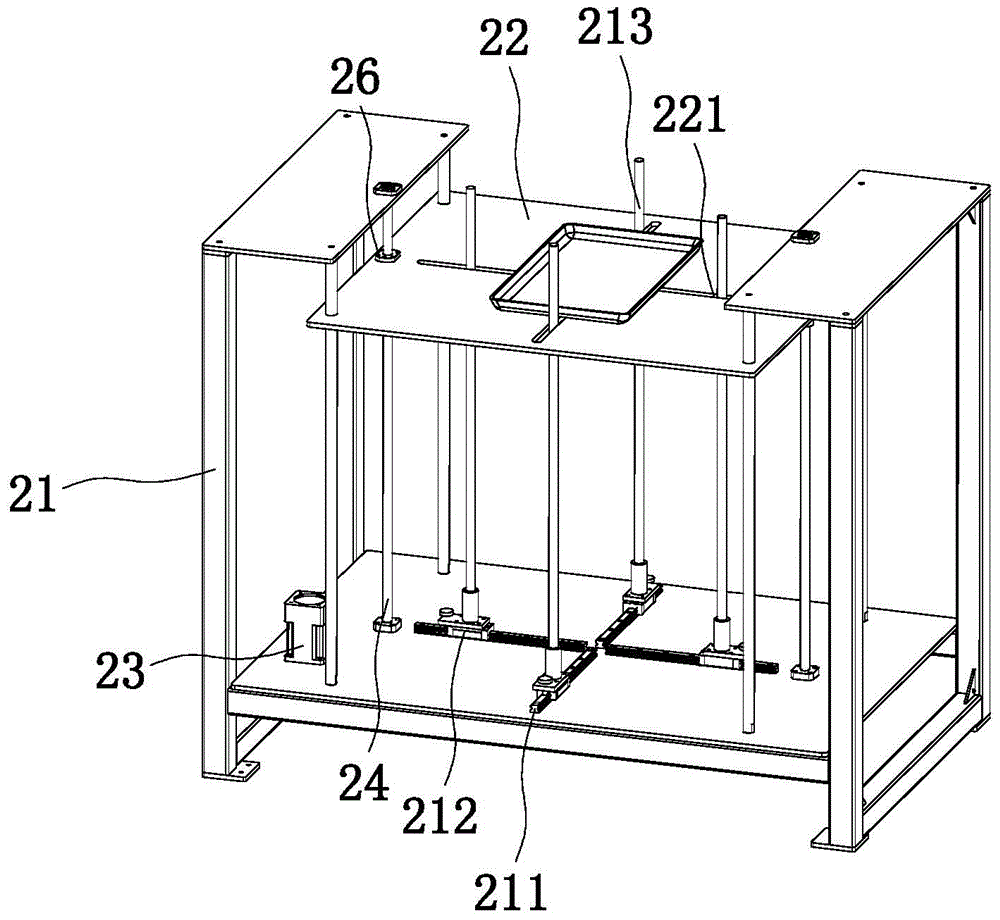

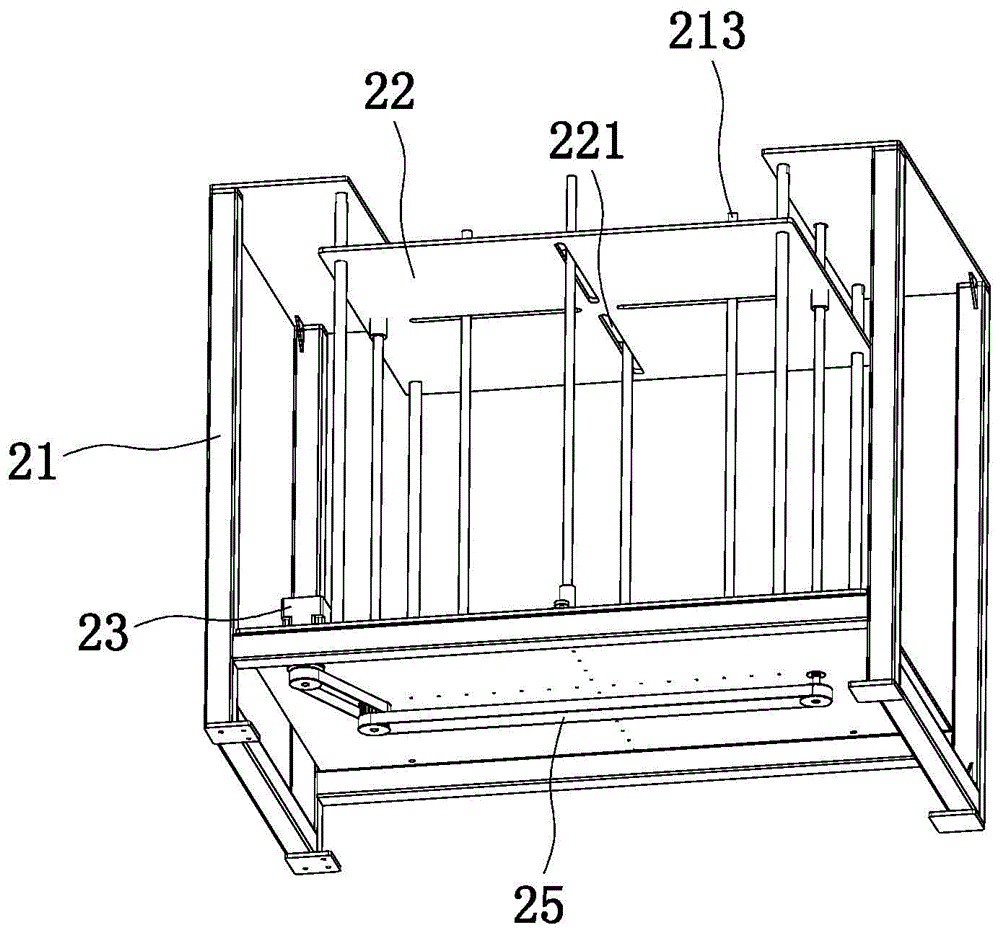

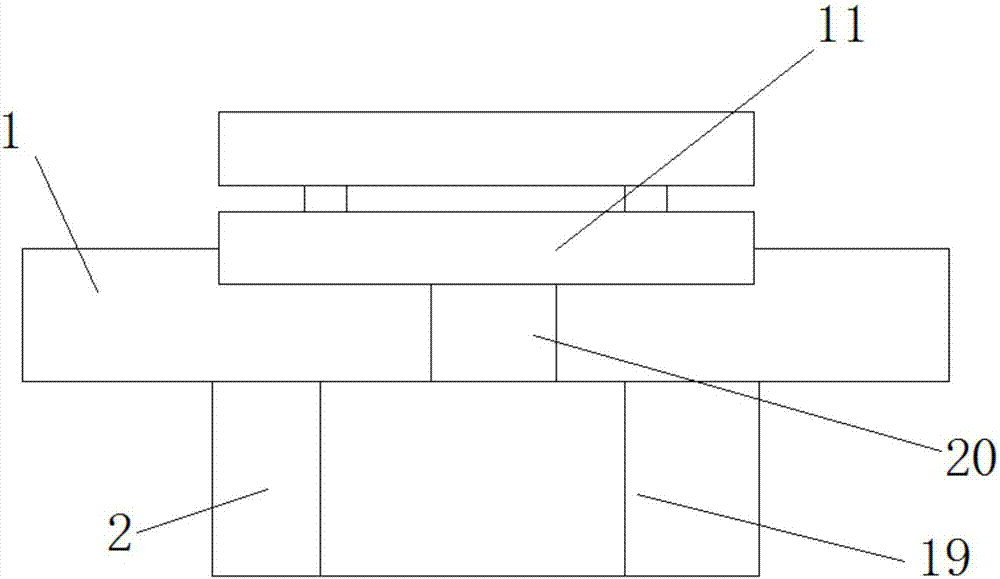

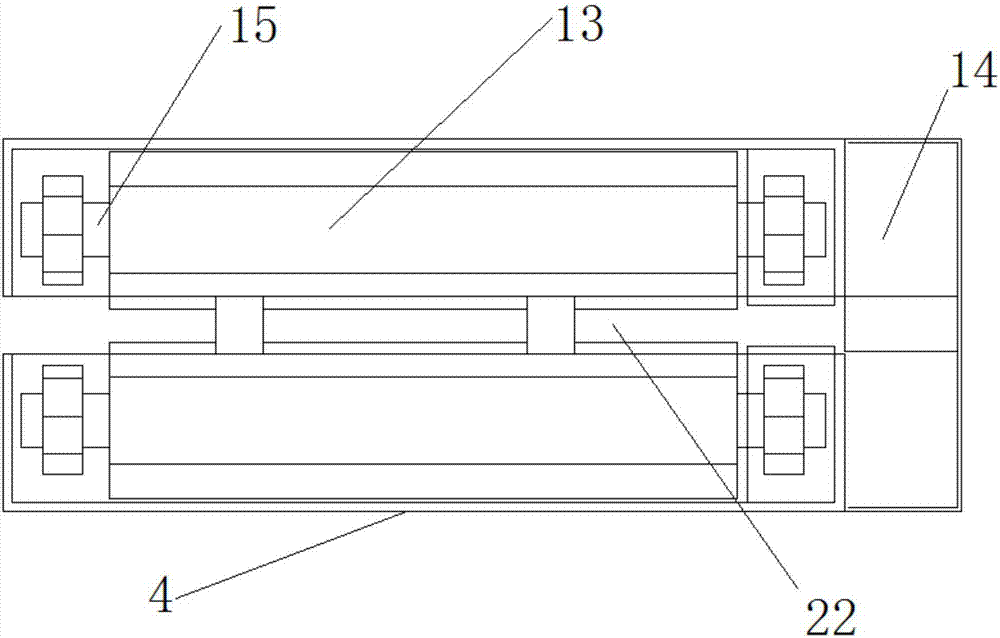

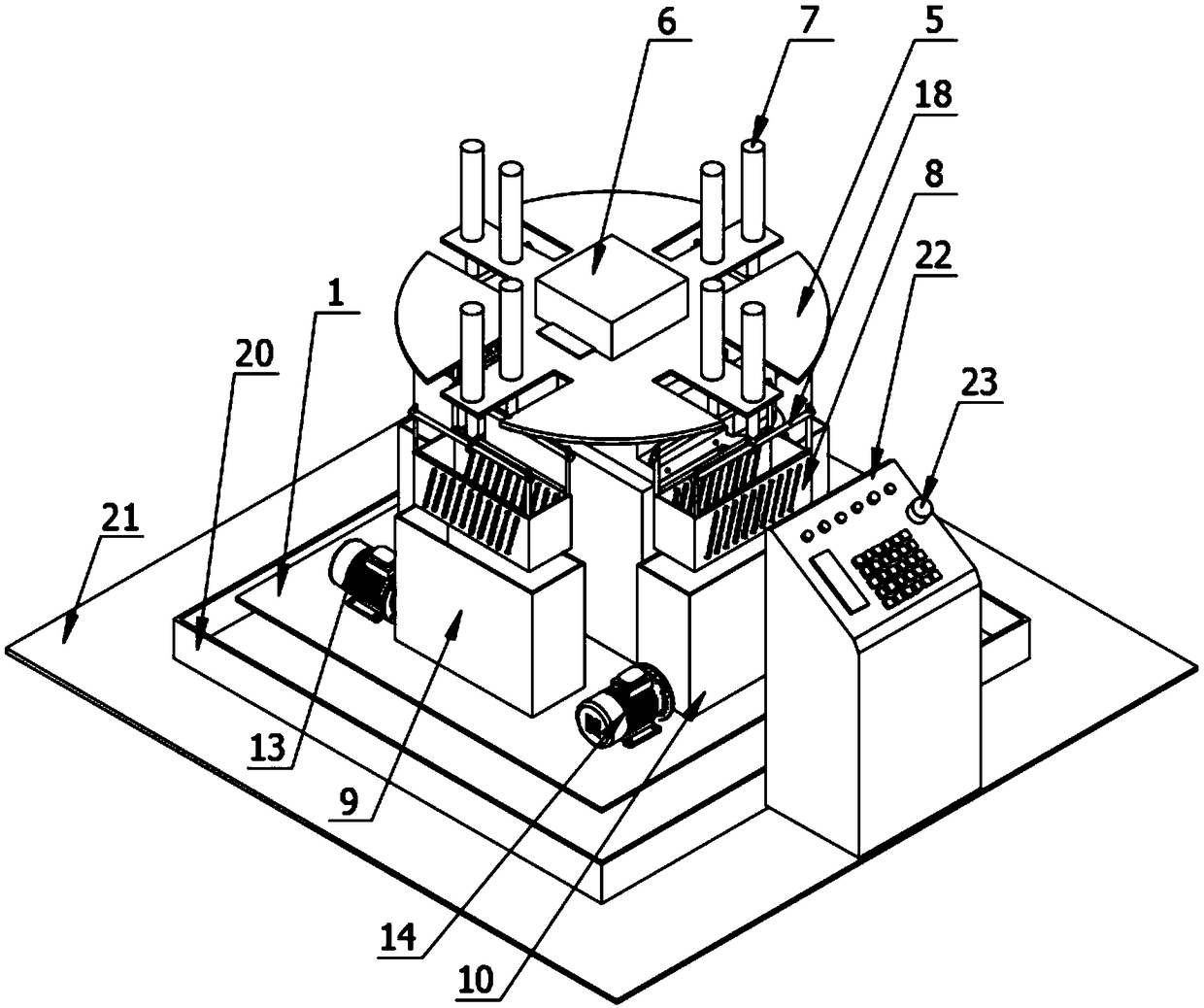

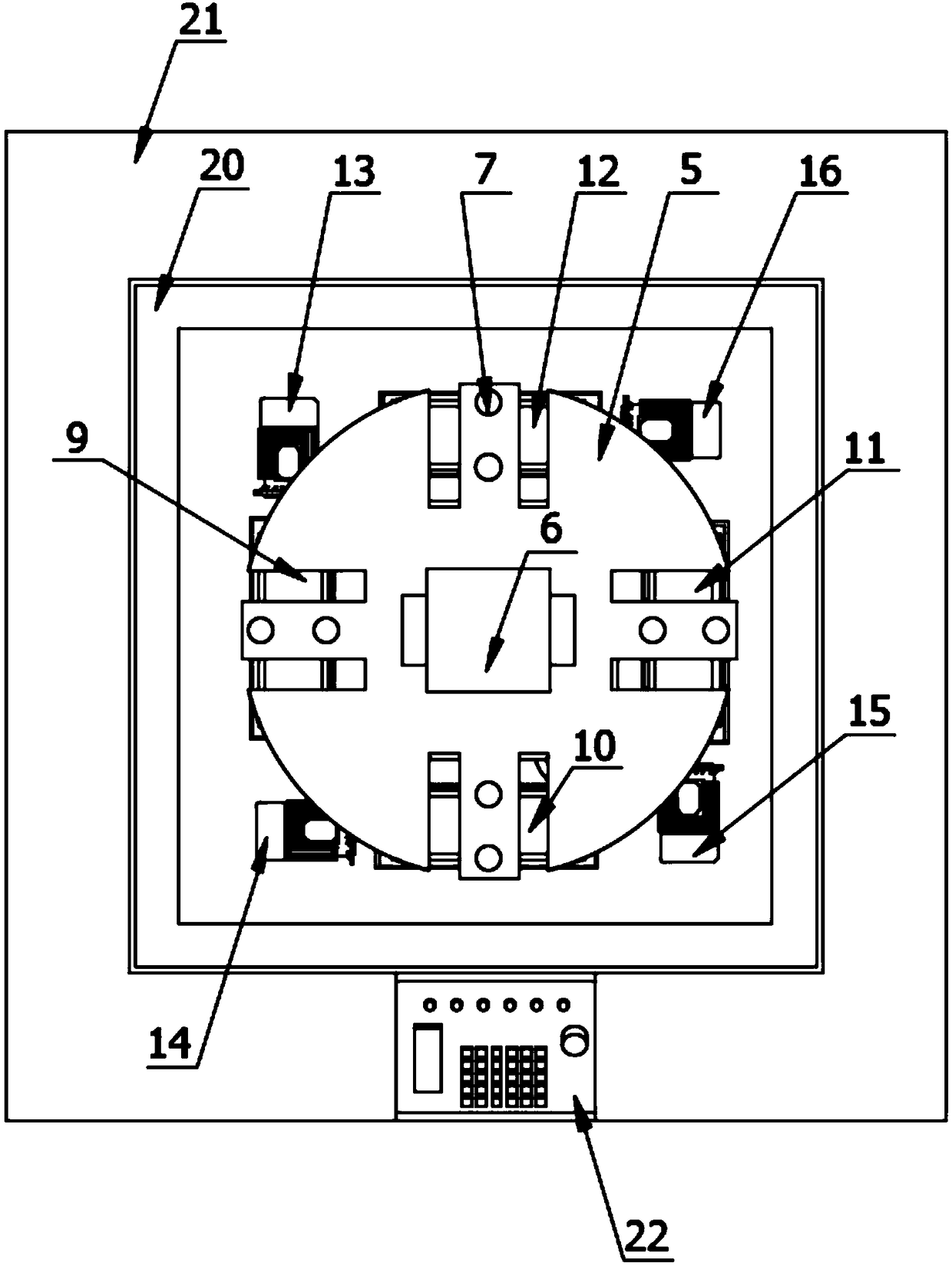

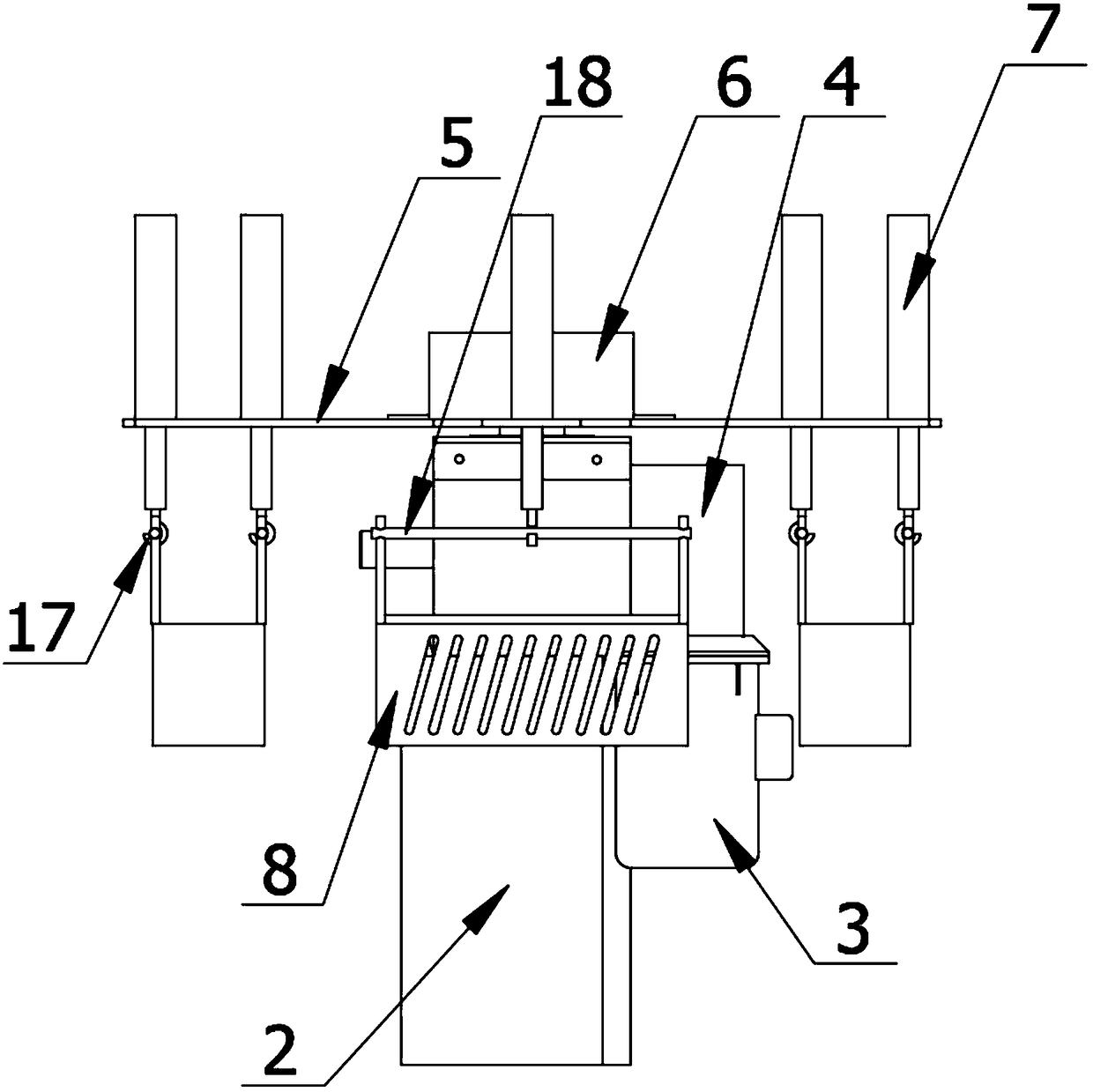

Edge grinding machine for special-shaped articles

ActiveCN105058210AImprove stabilityAccurate displacementEdge grinding machinesGrinding drivesProduction lineEngineering

The invention relates to an edge grinding machine for special-shaped articles. The edge grinding machine for the special-shaped articles comprises a machine frame, a feeding device, a taking device, two conveyor belts and one or more edge grinding devices, wherein the feeding device, the taking device, the conveyor belts and the edge grinding devices are arranged on the machine frame according to a production line. The articles are transferred between the feeding device and the conveyor belts through the taking device. The two conveyor belts are arranged on the front and rear sides of the machine frame respectively. A lifting air cylinder is arranged at the position, between the two conveyor belts, of the machine frame. An ejector rod is arranged on a piston rod of the lifting air cylinder in a rotating mode. A lower rotating disc supporting and holding the articles is arranged at the upper end of the ejector rod. Each edge grinding device comprises a support arranged on the machine frame, a rotating motor arranged on the support and located above the lower rotating disc and a grinding base arranged on the support in a vertically-sliding mode. A rotating shaft of each rotating motor is fixedly connected with an upper rotating disc which is used in cooperation with the lower rotating disc for clamping the articles. Each grinding base is provided with a sliding base in a horizontally-sliding mode. Each sliding base is provided with a grinding motor. Each grinding motor is in transmission connection with a grinding roller.

Owner:JINJIANG LIDA MACHINERY

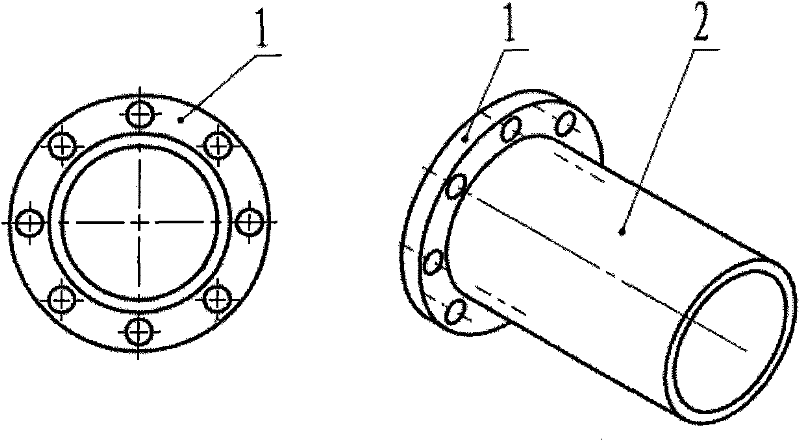

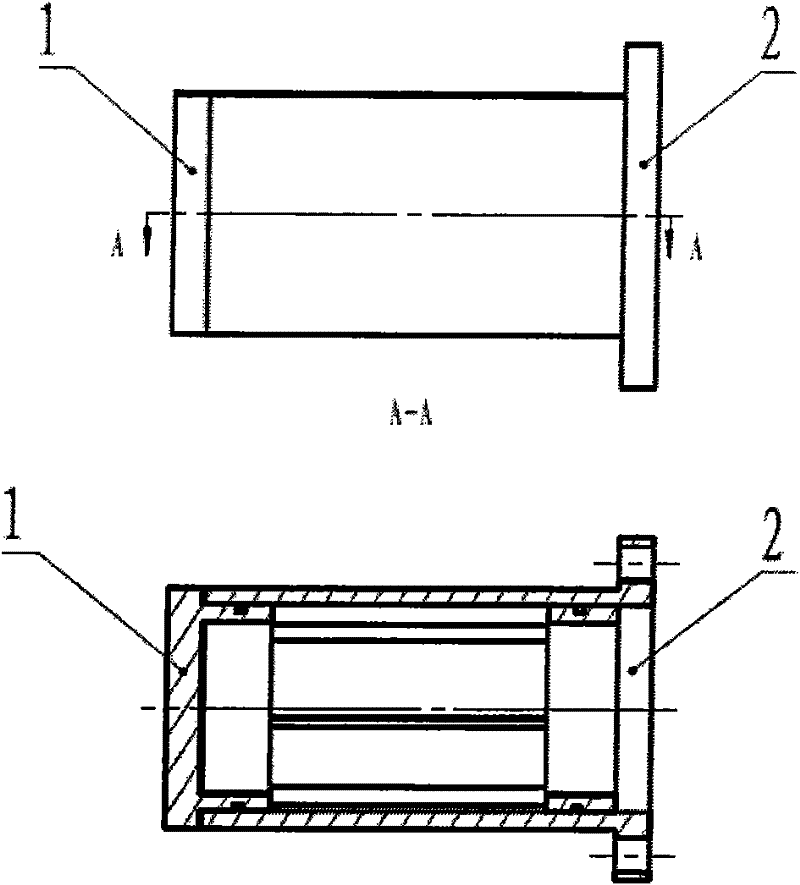

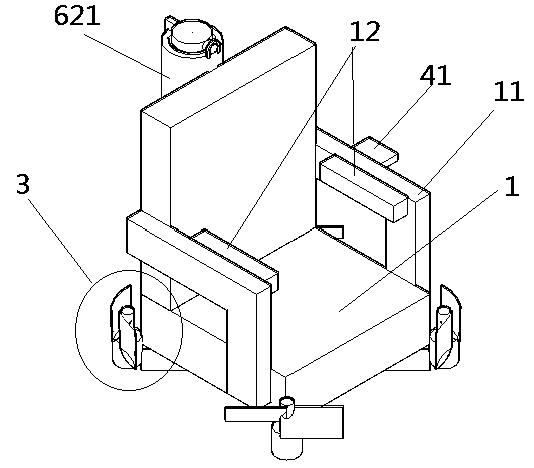

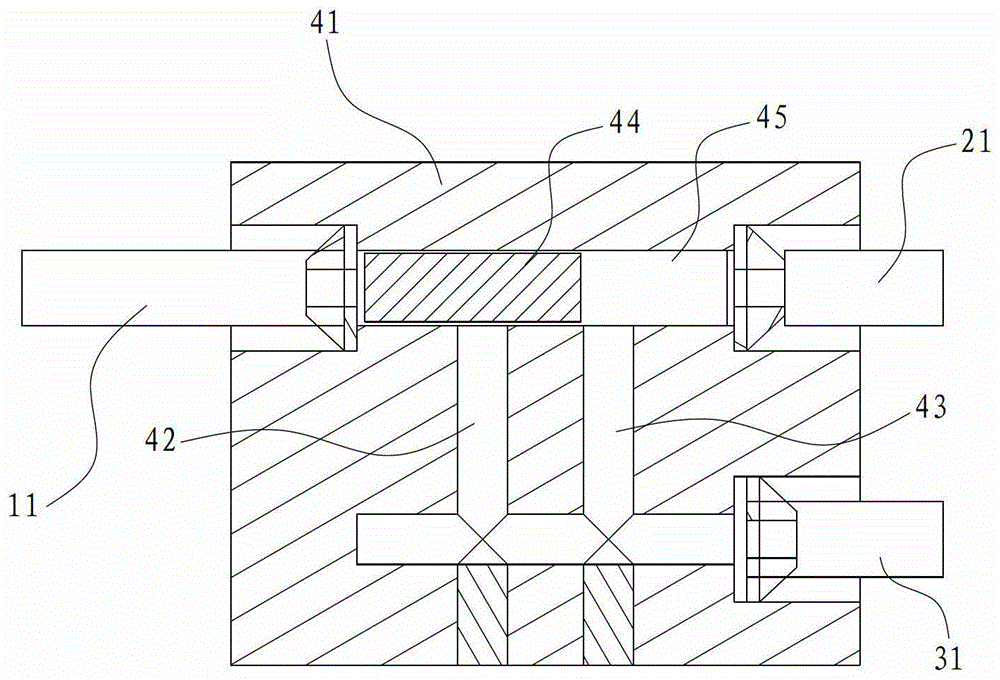

Method and device for rapid entry and exit of solid materials in high-pressure containers

InactiveCN102297262AFast in and outImprove efficiencyPressurized chemical processOperating means/releasing devices for valvesSpecial designHigh pressure

The invention discloses a method and a device for quickly entering and exiting solid materials in a high-pressure container. Through the specially designed box-type, inverted V-type feed valve and lantern-type, r-type discharge valve, the high-pressure container is especially suitable for the rapid entry and exit of solid materials, thus avoiding the fragility and frequent replacement of the valve caused by the use of conventional liquid valves. At the same time, it reduces the time required for solid materials to enter and exit the container, improves the processing speed, and increases the benefits. The invention can typically be used in intermittent steam explosion tanks, solid material steaming tanks, solid material sterilizing tanks, etc., and provides suitable equipment selection for the increasing high-temperature and high-pressure treatment of solid materials.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

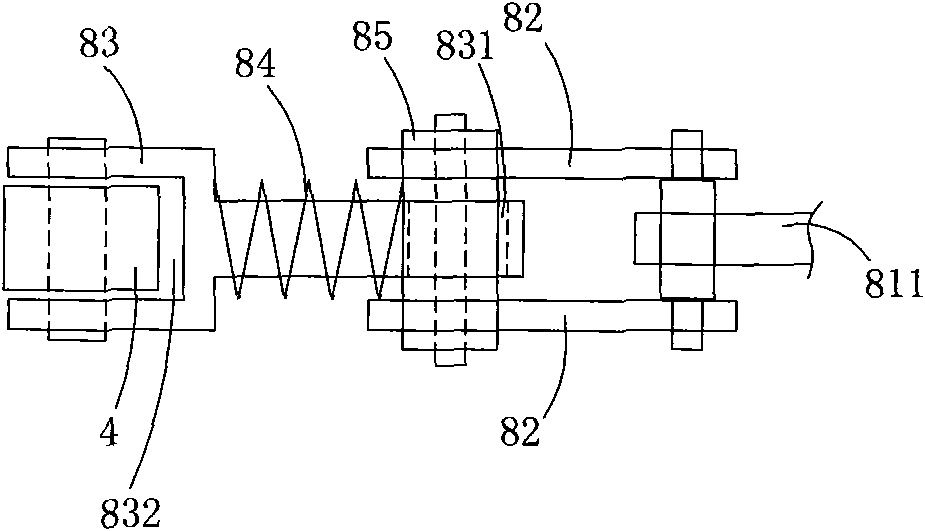

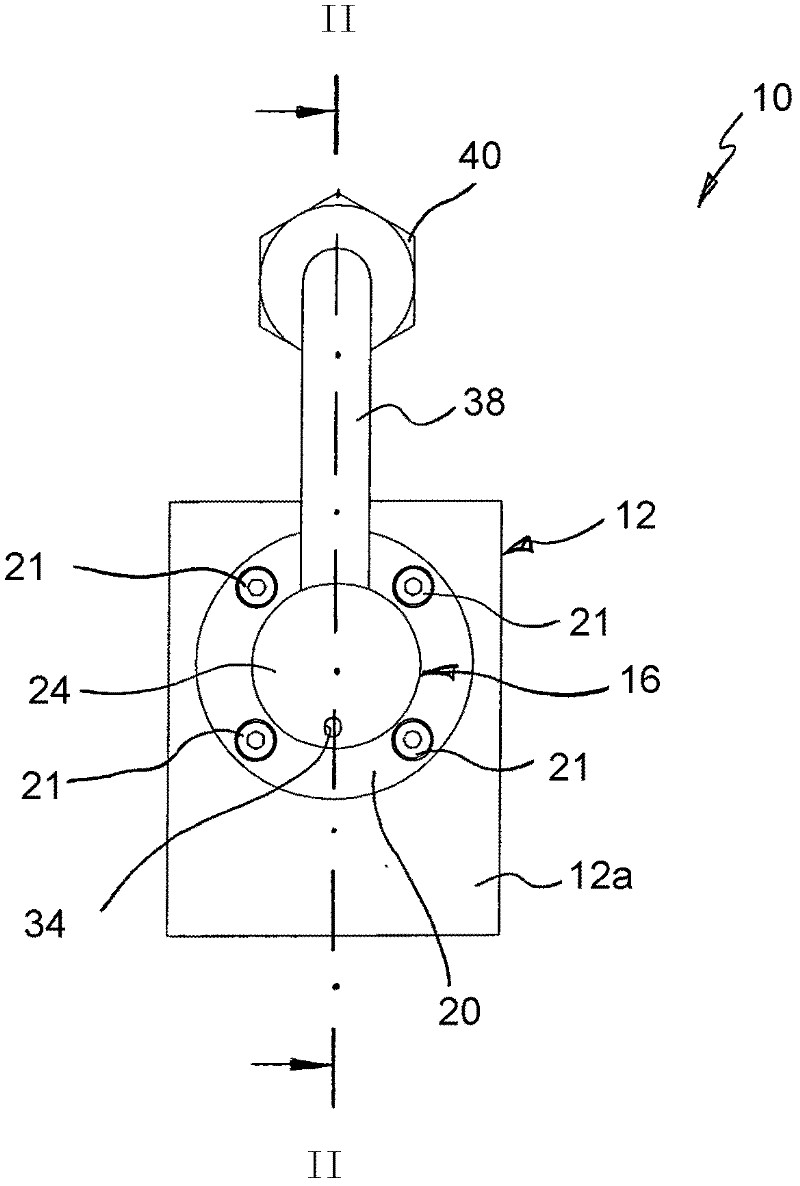

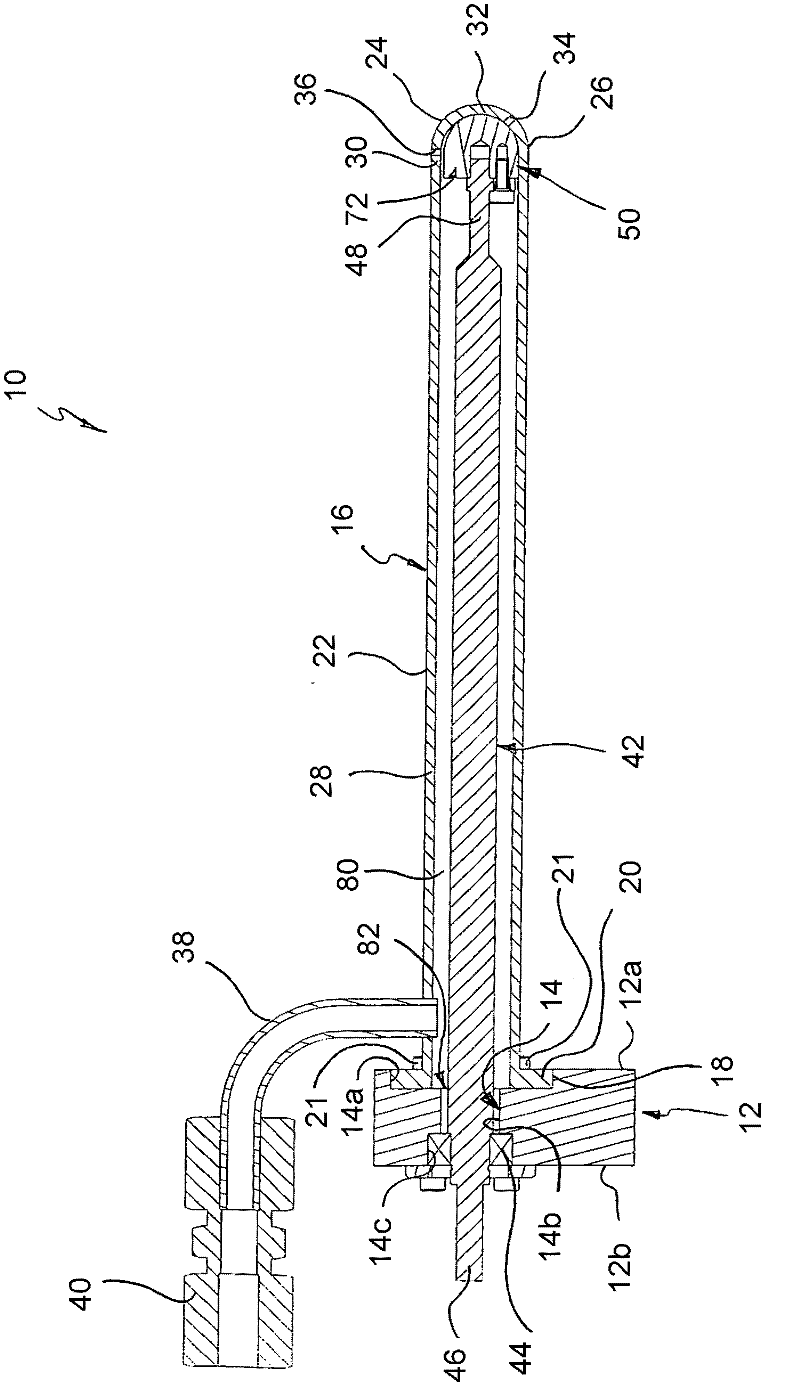

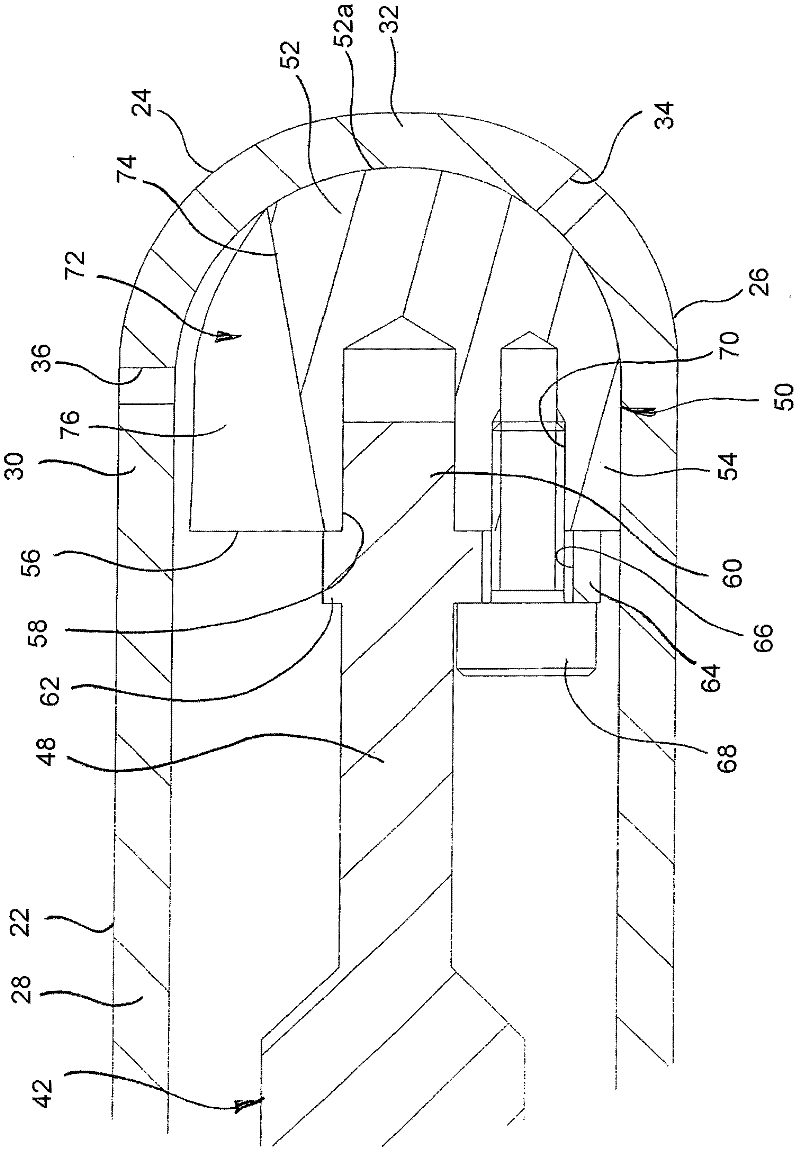

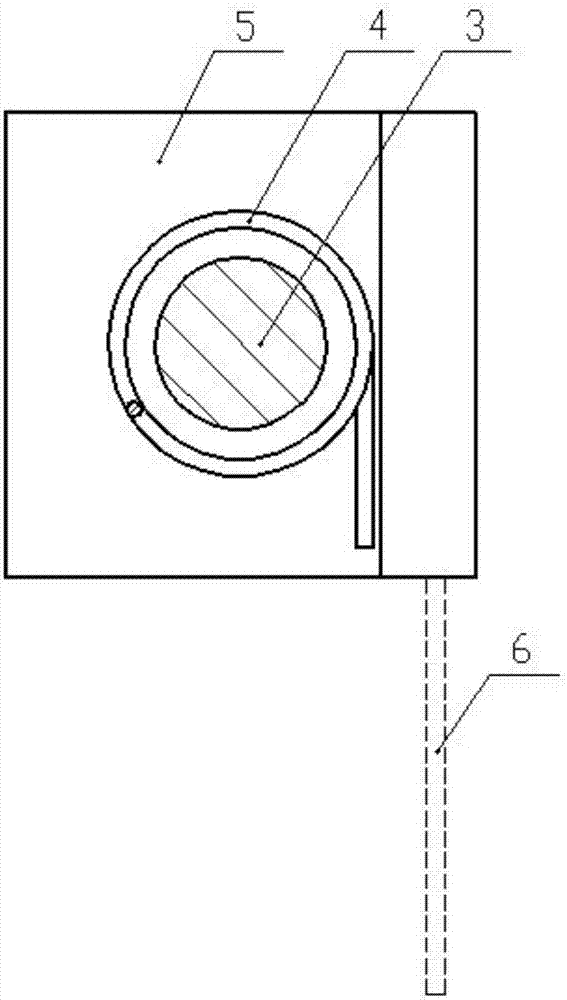

Permanent magnet opening and closing type DC intelligent circuit breaker

InactiveCN101615535AFew partsLess prone to mechanical failureEmergency protective circuit arrangementsCircuit-breaking switch detailsBusbarQuenching

The invention discloses a permanent magnet opening and closing type DC intelligent circuit breaker, comprising a base, an incoming busbar, a dynamic contact electrically connected with the incoming busbar, a dynamic contact supporting part, a static contact, an outgoing busbar electrically connected with the static contact, a static contact supporting part, an operating mechanism used for drivingthe dynamic contact to open and close and an arc quenching mechanism used for quenching arc; wherein, the arc quenching mechanism comprises an arcing shield and an arcing ring; the operating mechanism comprises a permanent magnet type electromagnetic actuating mechanism, an insulating driving rod and a clamping rod; the permanent magnet type electromagnetic actuating mechanism is provided with a telescopic actuating rod and a solenoid coil; one end of the clamping rod is connected with the middle of the dynamic contact supporting part in a rotary manner by a rotating shaft; the other end of the clamping rod is provided with a waist hole and is connected with one end of the insulating driving rod by a rotating shaft which passes through the waist hole; the other end of the insulating driving rod is fixedly connected with the actuating rod. The circuit breaker has simplified structure, fast breaking speed and few mechanical failure sources and can stably and reliably run for a long time.

Owner:乐清市牵引机电厂

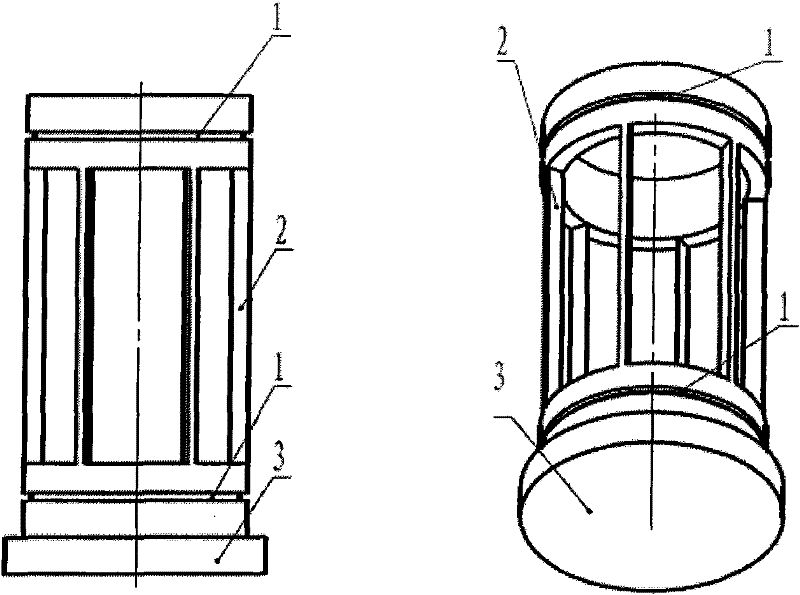

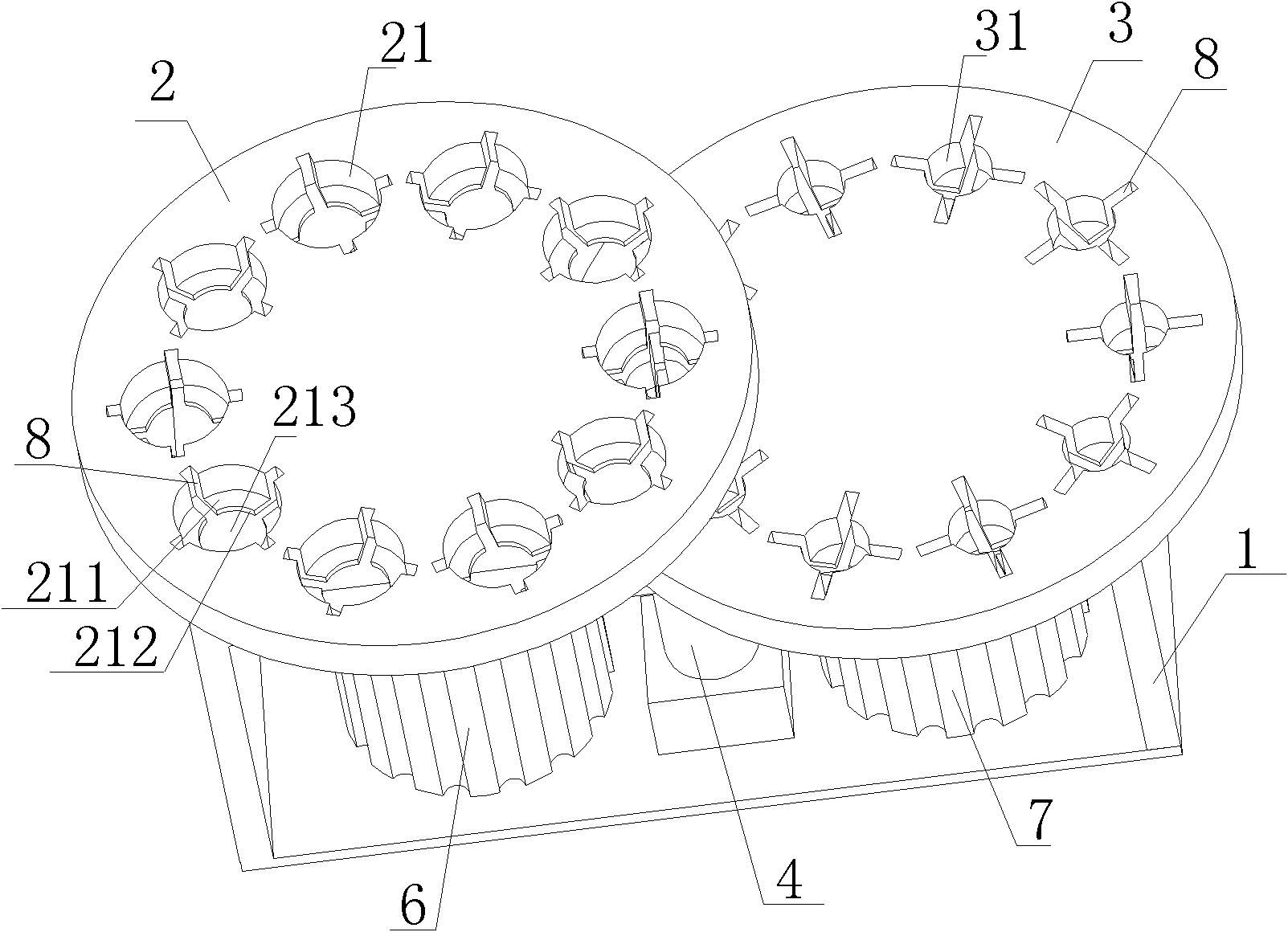

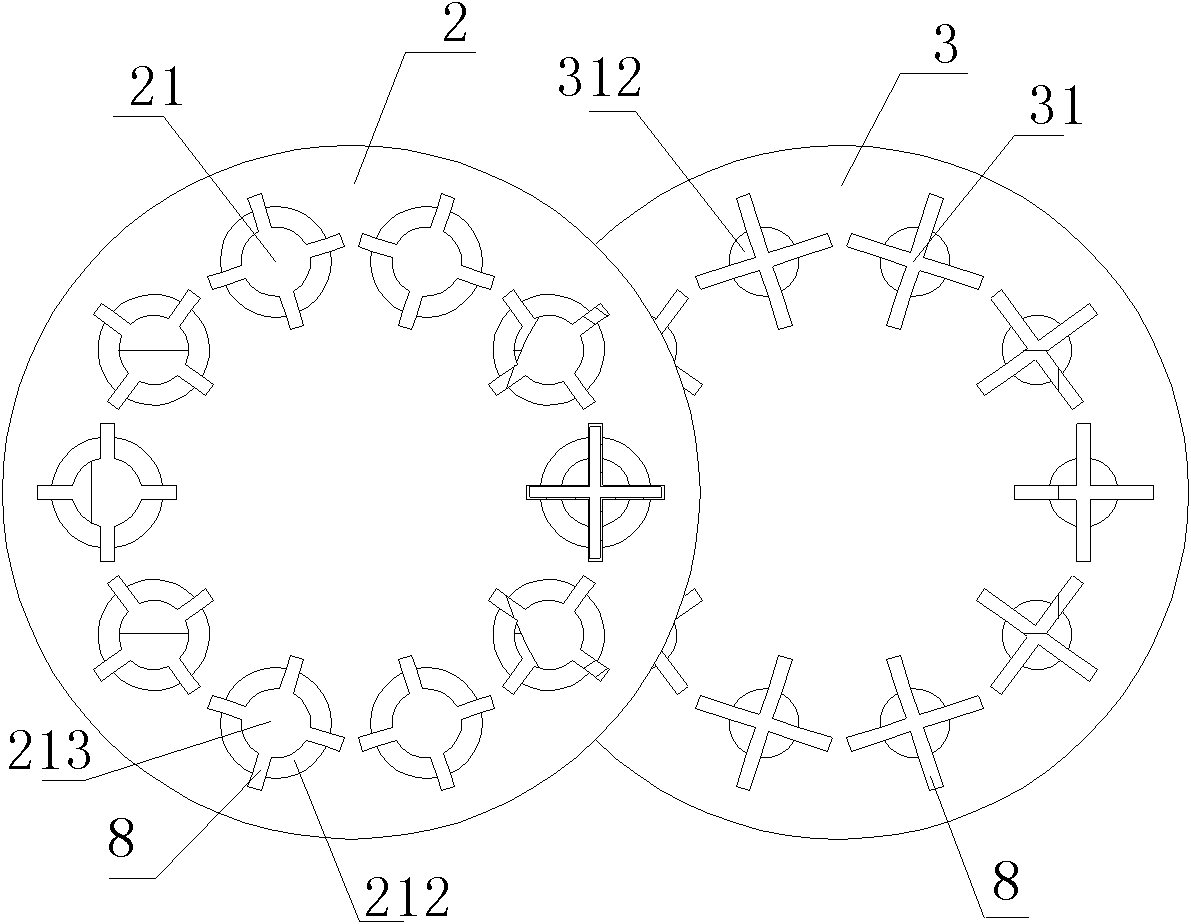

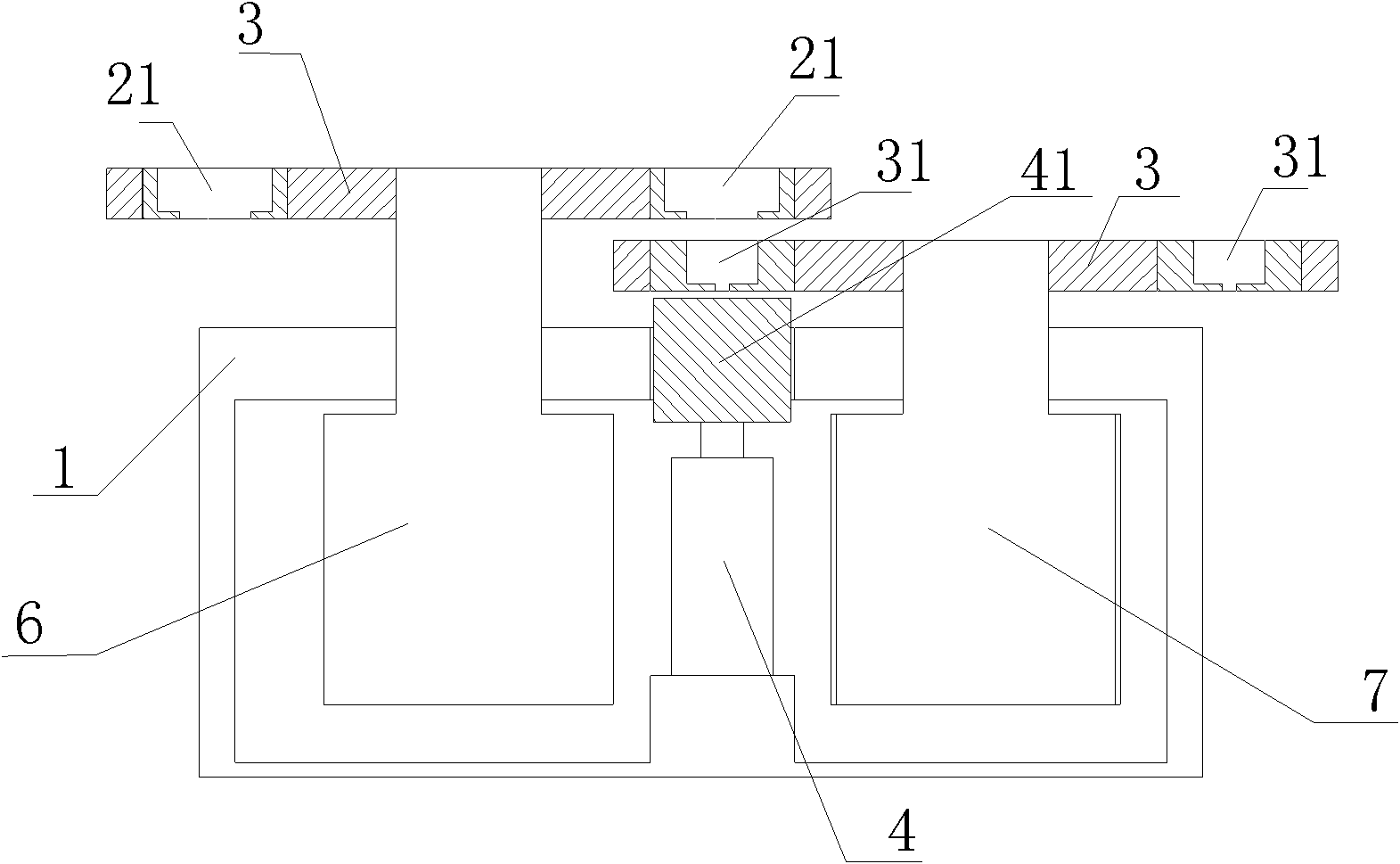

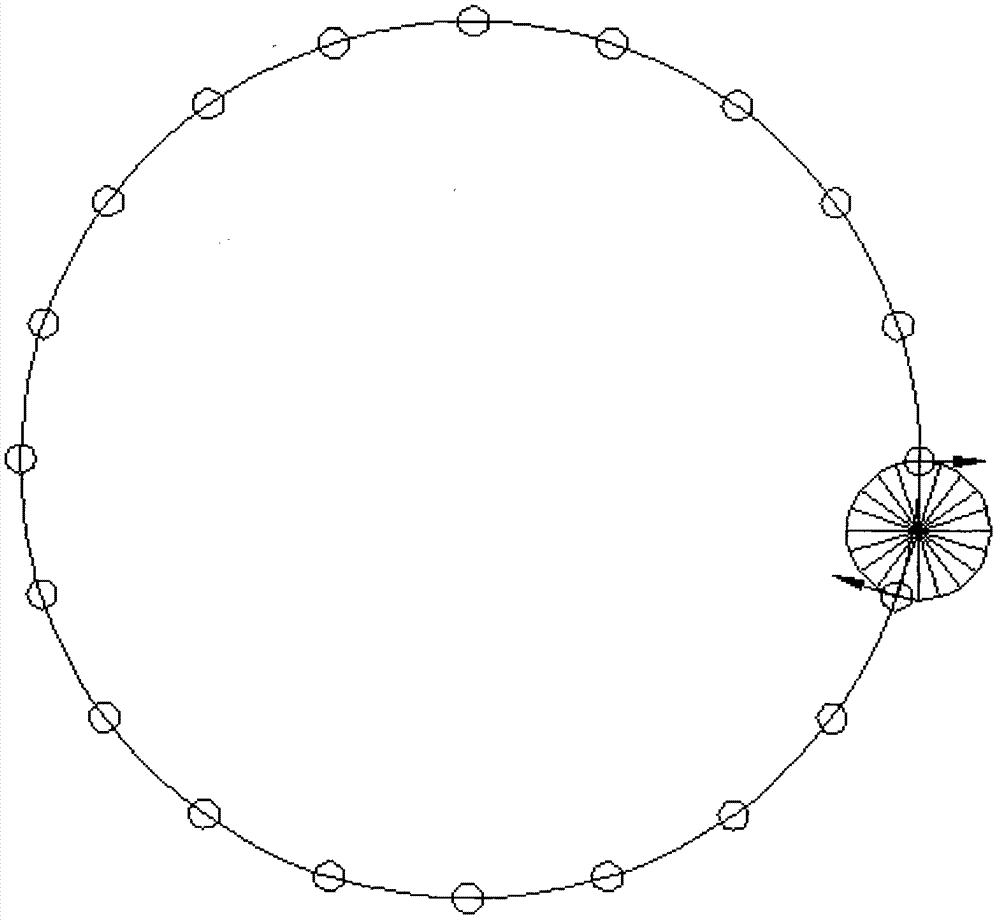

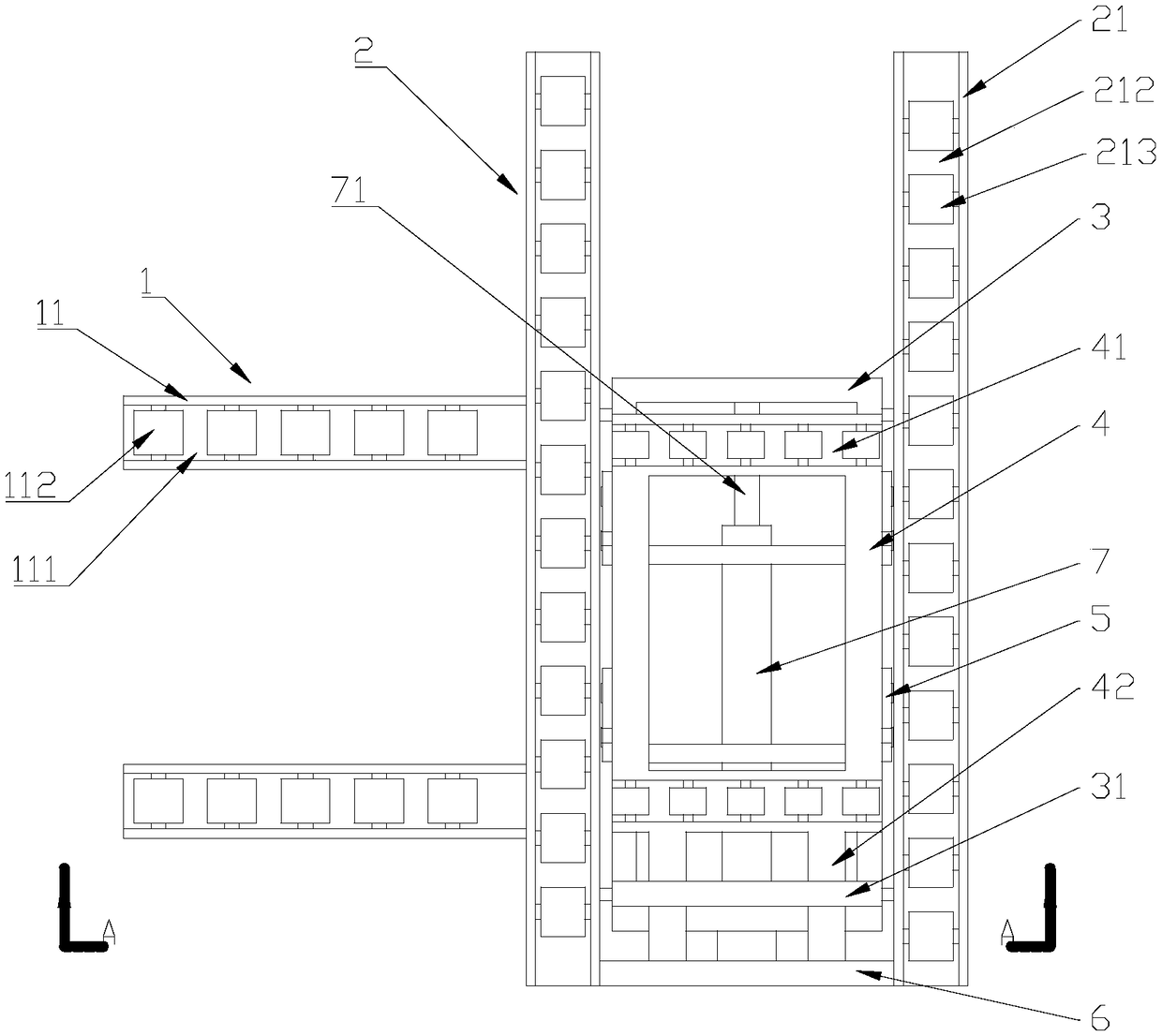

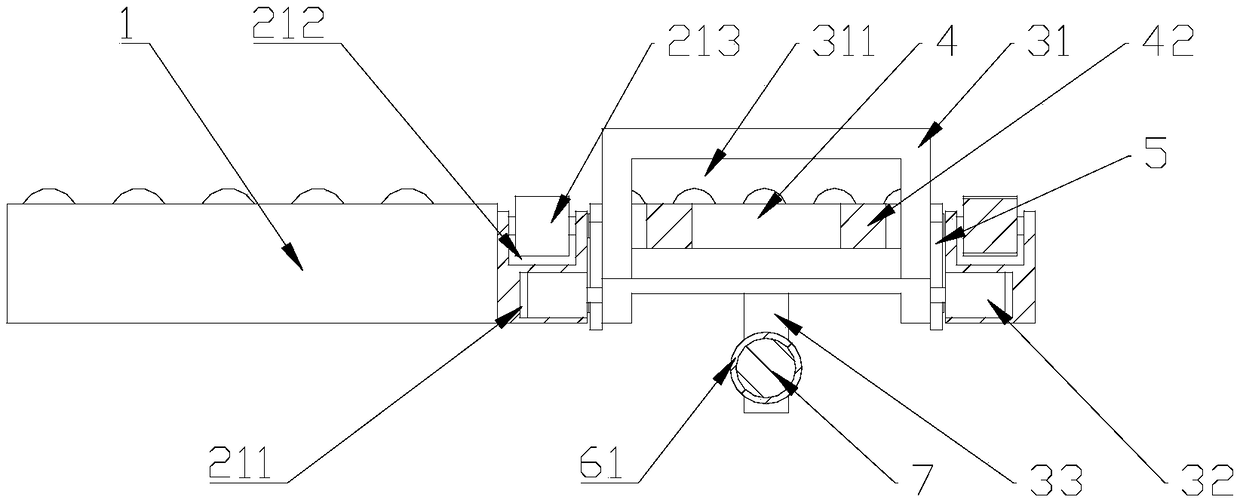

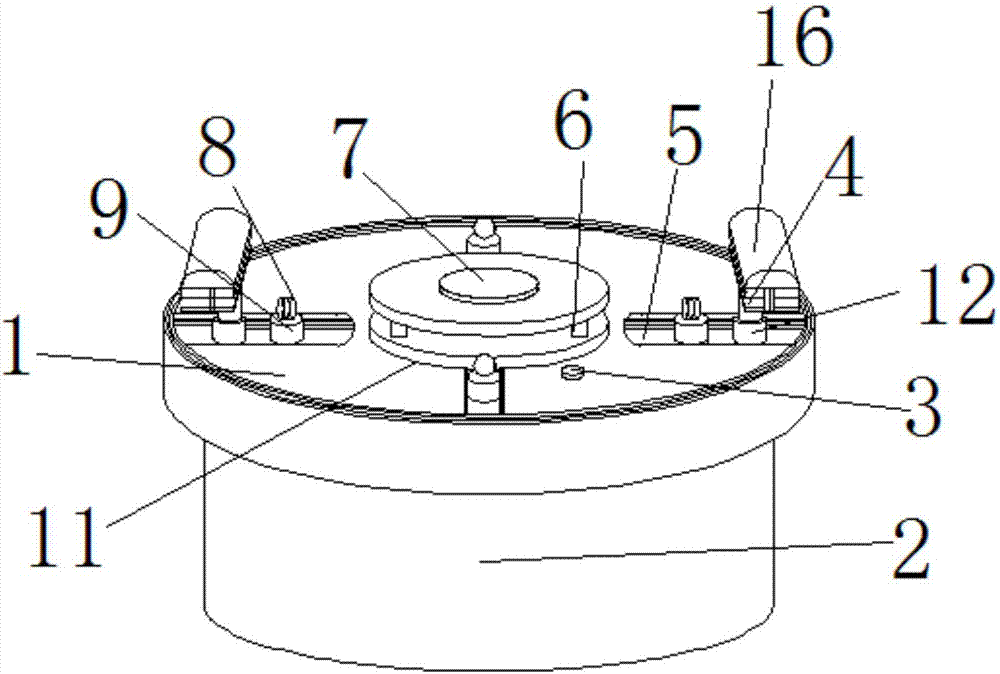

Device for sleeving bearing ring

InactiveCN101818763AThere is no stuck problemNo need to debugBearing componentsEngineeringMachine failure

The invention provides a device for sleeving a bearing ring. The device comprises a frame, a feeding mechanism, a ring sleeving mechanism and a discharging mechanism, wherein an outer ring storage plate and an inner ring storage plate are arranged on the frame; the outer ring storage plate and the inner ring storage plate are connected with each controllable motor respectively; the outer ring storage plate and the inner ring storage plate are horizontally arranged; the inner ring storage plate is arranged under the outer ring storage plate; storage holes are formed on the outer ring storage plate and the inner ring storage plate, are uniformly distributed along peripheries, and comprise accommodation chambers and brackets; an outer ring storage hole is necessarily formed on the outer ring storage plate and is overlapped with an inner ring storage hole which is formed on the inner ring storage plate up and down to form a ring sleeving channel; a through hole which allows an inner ring to pass through is formed on the bottom of the outer ring storage hole; a ring sleeving cylinder is positioned under the ring sleeving channel; a push rod of the ring sleeving cylinder is fixedly connected with a push block which can push a ring in the ring sleeving channel upwards till the ring leaves the outer ring storage plate, wherein the length of the push block is greater than the diameter of the storage holes; and a through groove which can allows the push block to pass through is formed on a side wall of the storage holes. The device for sleeving the bearing rings has the advantages of simple structure, quick model replacement, wide application range, rare occurrence of machine fault, and low cost.

Owner:NINGBO HUILIAN AUTOMATIC EQUIP +3

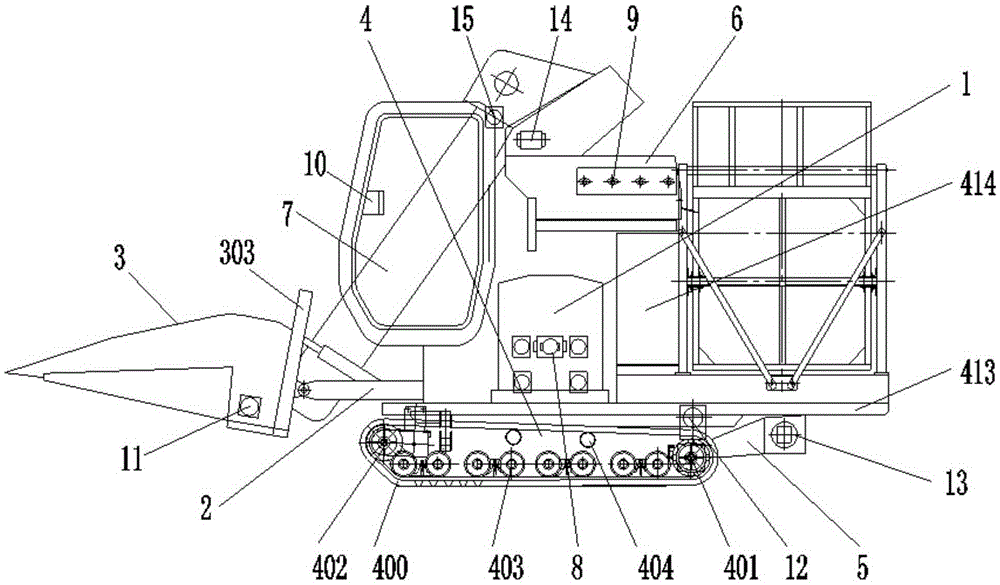

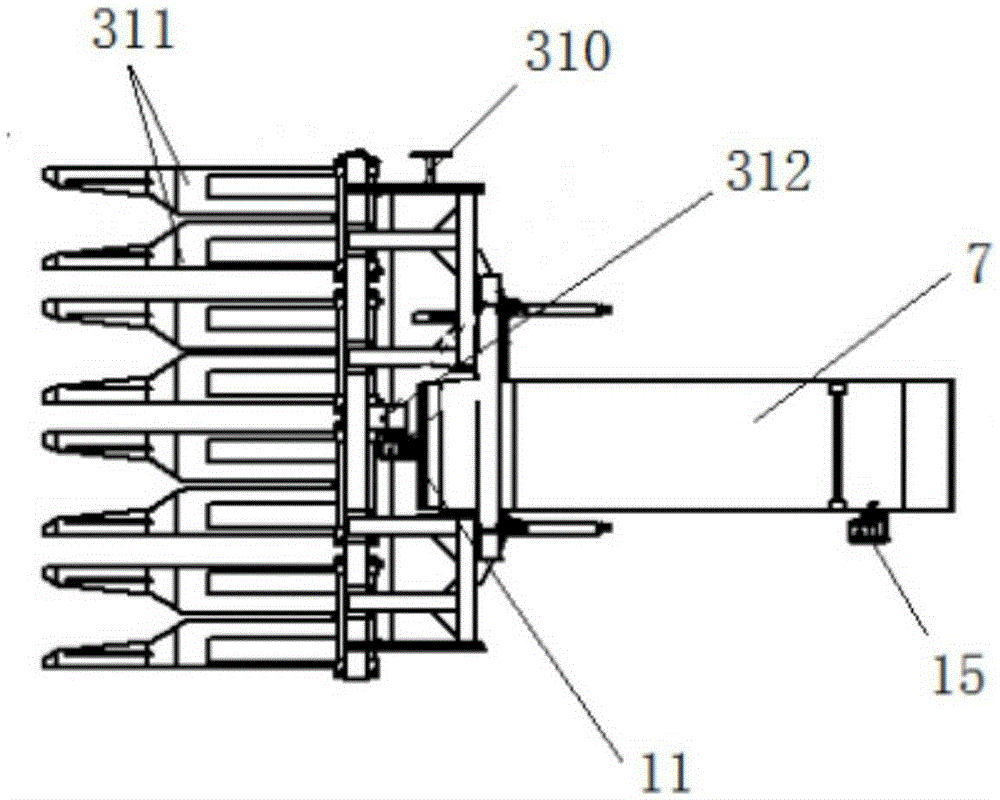

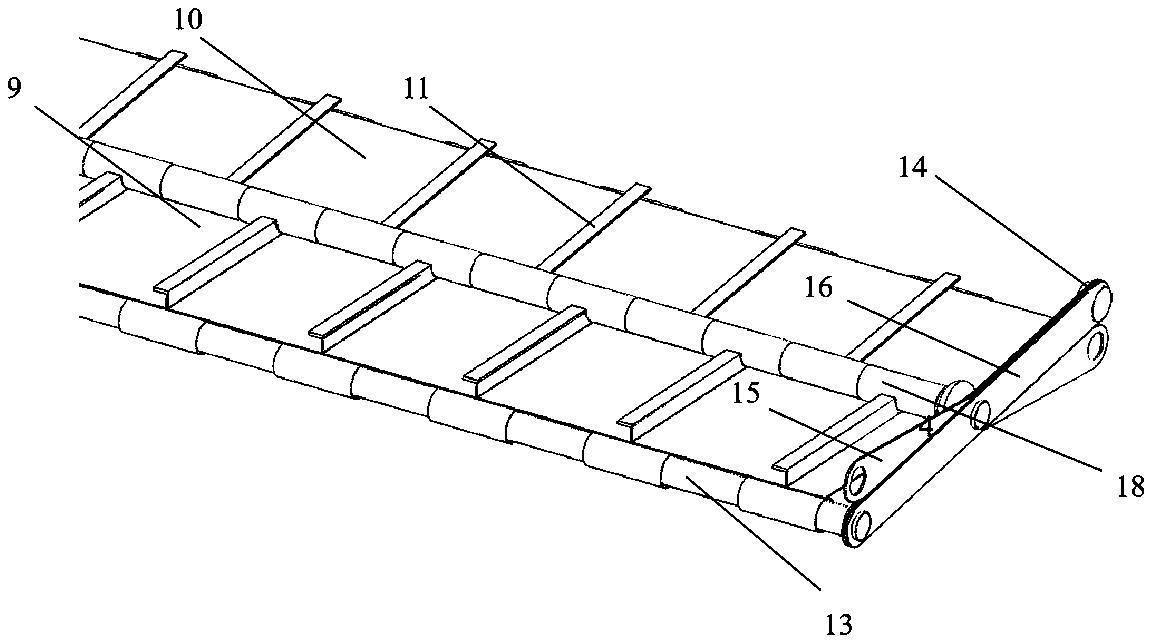

Crawler-type intelligent drive corn harvester

ActiveCN105165245AReduce connection complexityReasonable layoutMowersHydraulic motorAutomatic control

The invention provides a crawler-type intelligent drive corn harvester. The crawler-type intelligent drive corn harvester comprises a walking device, a header, a lift conveyer, a peeling device, a smashing device, a power assembly and a control system. The power assembly comprises an engine, a hydraulic pump, electro-hydraulic control valves and hydraulic motors, the control system comprises a programmable logic controller, an operating handle and a touch screen, and the programmable logic controller controls the electro-hydraulic control valves corresponding to all harvesting functional components to control the hydraulic motors corresponding to the functional components to operate, so that all the harvesting functional components operate individually, and the purposes of reasonably arranging, reducing the overall size and facilitating automatic control are achieved. In addition, as the header, the lift conveyor, the walking device and a safety auxiliary system are improved, the crawler-type intelligent drive corn harvester has the advantages of being reasonable and compact in layout, high in automation degree and passage capacity, large in load capacity, high in reliability, wide in operation range, small in harvest loss ratio, high in safety performance and long in service life.

Owner:天津萨克赛斯机械技术开发有限公司

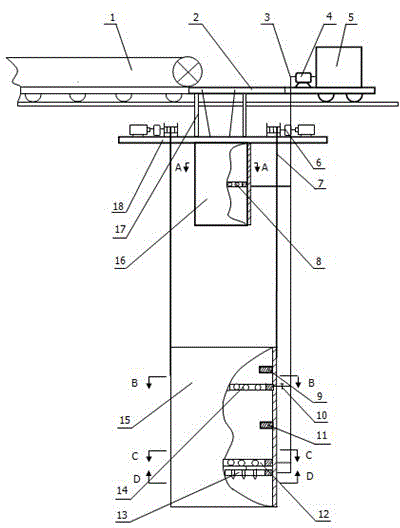

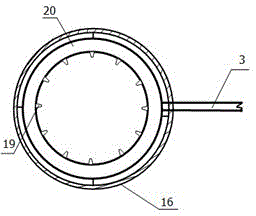

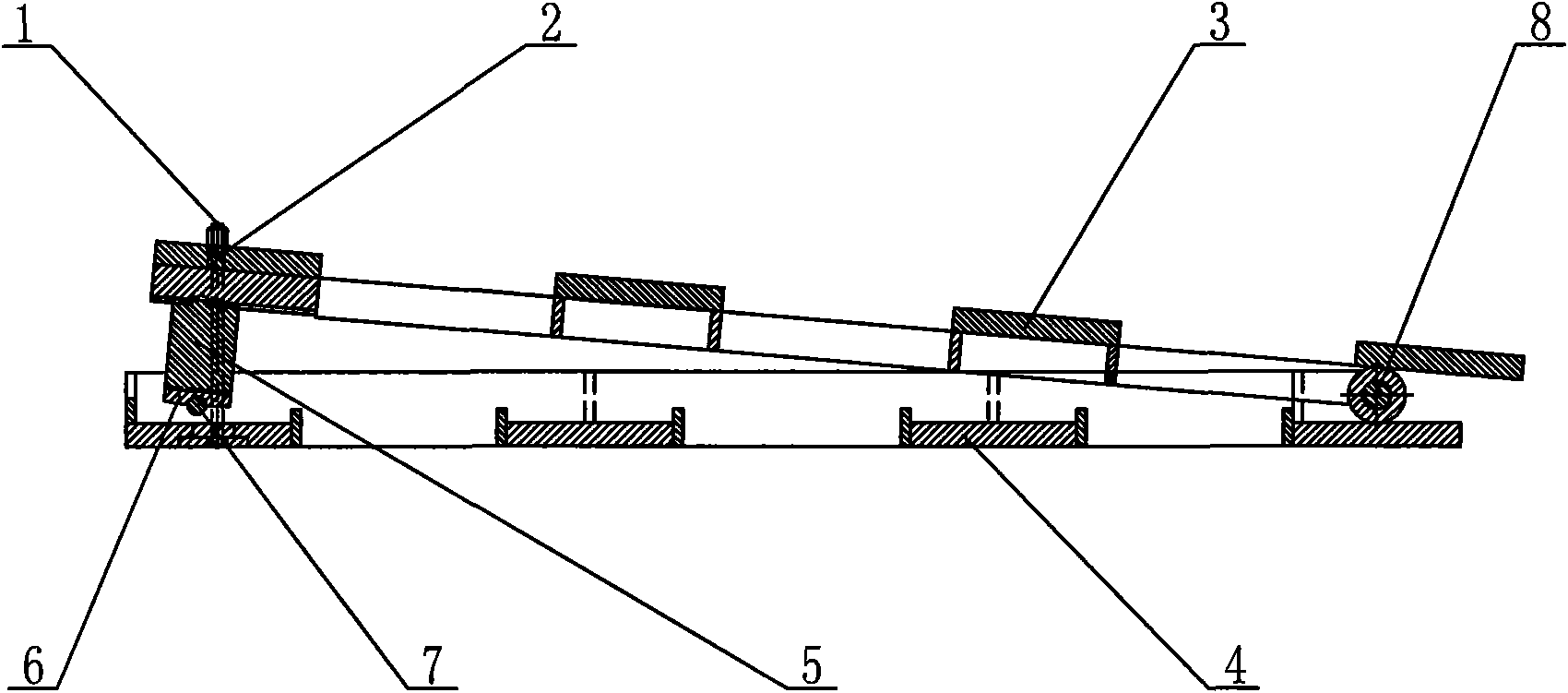

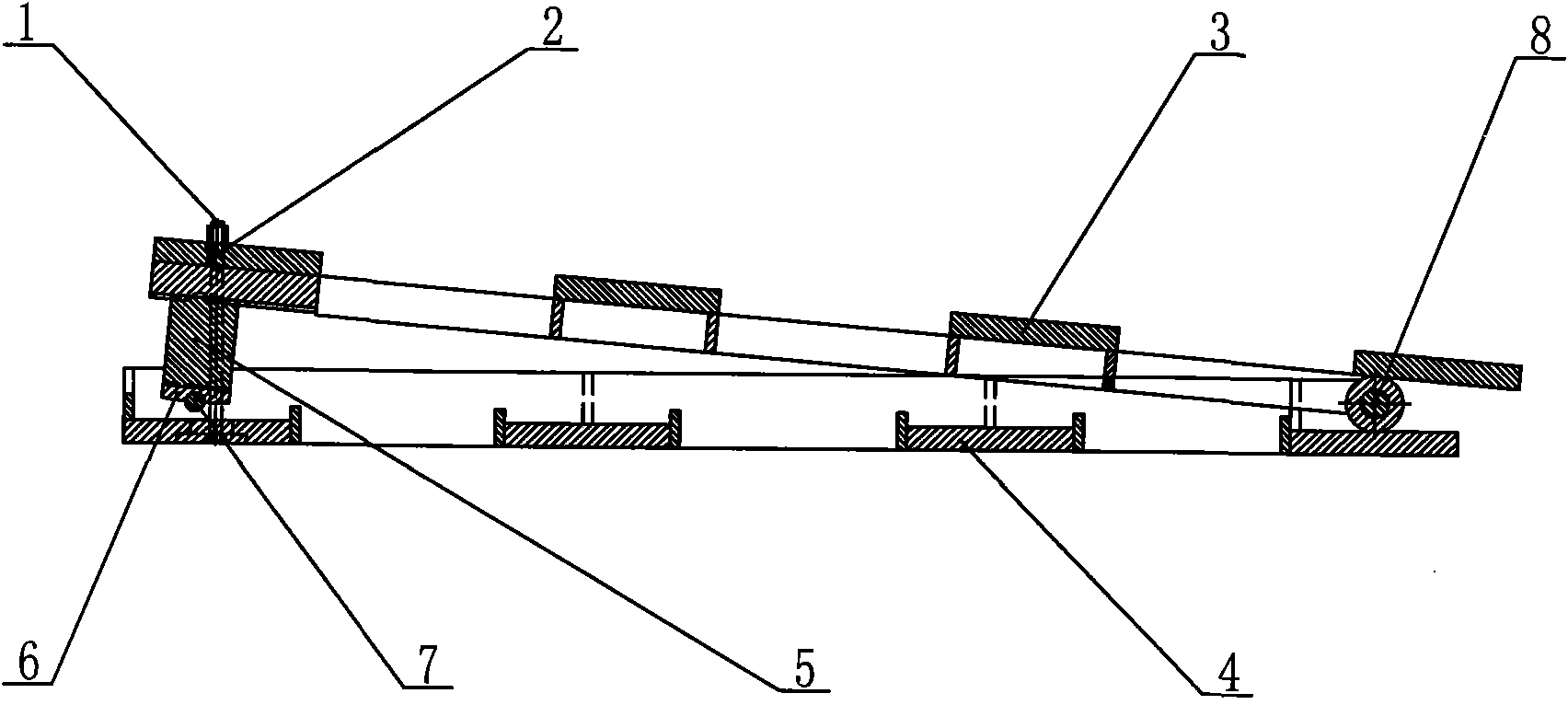

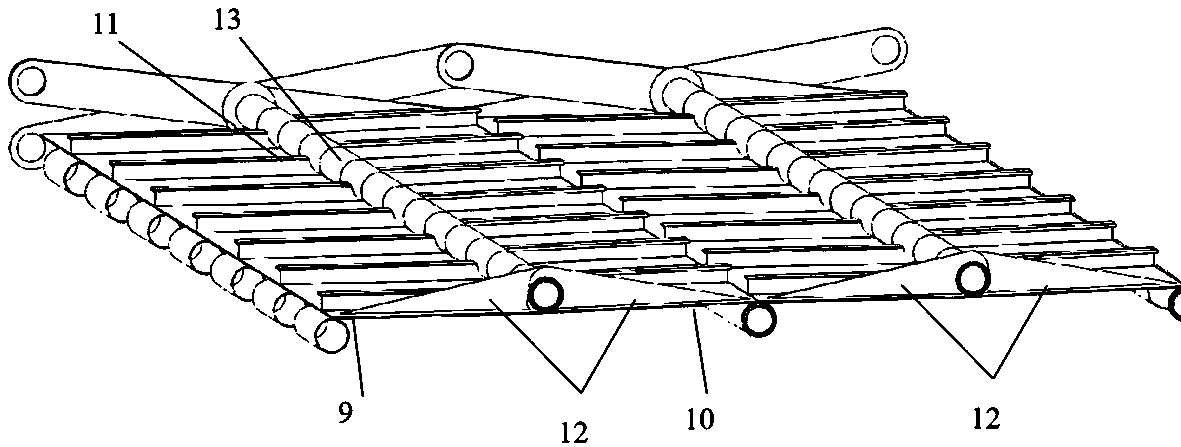

Dust falling system for trestle type coal unloading

ActiveCN104960944AReduce dust rangeReduce governance costsLoading/unloadingWater pipeEnvironmental geology

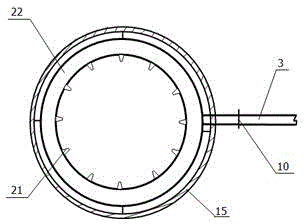

The invention relates to a dust falling system for trestle type coal unloading. According to the technical scheme, a movable water tank (5) is fixedly connected with a movable belt conveyor (1), the upper end of an upper moving cover (16) is fixed to a feeding port of a system platform (18), a lower moving cover (15) is located below the upper moving cover (16), and a synchronous lifting device (6) is connected with the lower moving cover (15) through a steel wire rope (7). An upper annular spraying device (8) is mounted on the inner wall of the upper moving cover (16). A dust sensor (9), a first layer lower annular spraying device (14), a radar level meter (11), a second layer lower annular spraying device (12) and a third layer lower annular spraying device (13) are sequentially mounted on the inner wall of the lower moving cover (15) from top to bottom. A high pressure water pump (4) is connected with the upper annular spraying device (8), the first layer lower annular spraying device (14), the second layer lower annular spraying device (12) and the third layer lower annular spraying device (13) respectively through high pressure water pipes (3). The dust falling system for trestle type coal unloading has the advantages of being small in water consumption, low in operation cost, good in dust removal effect and easy to maintain.

Owner:山东昌达自动化技术有限公司

The LED double-color-temperature automobile headlamp

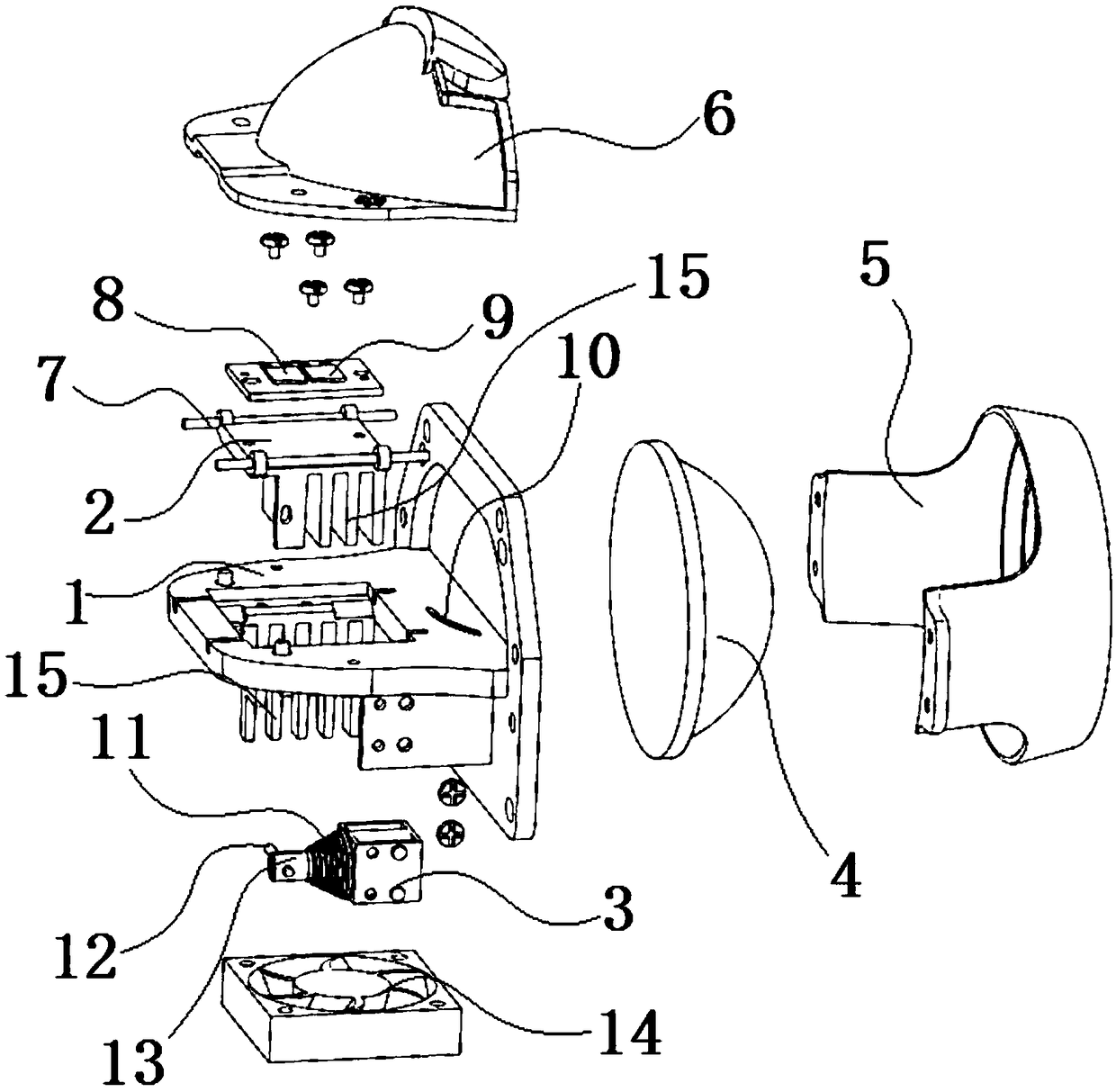

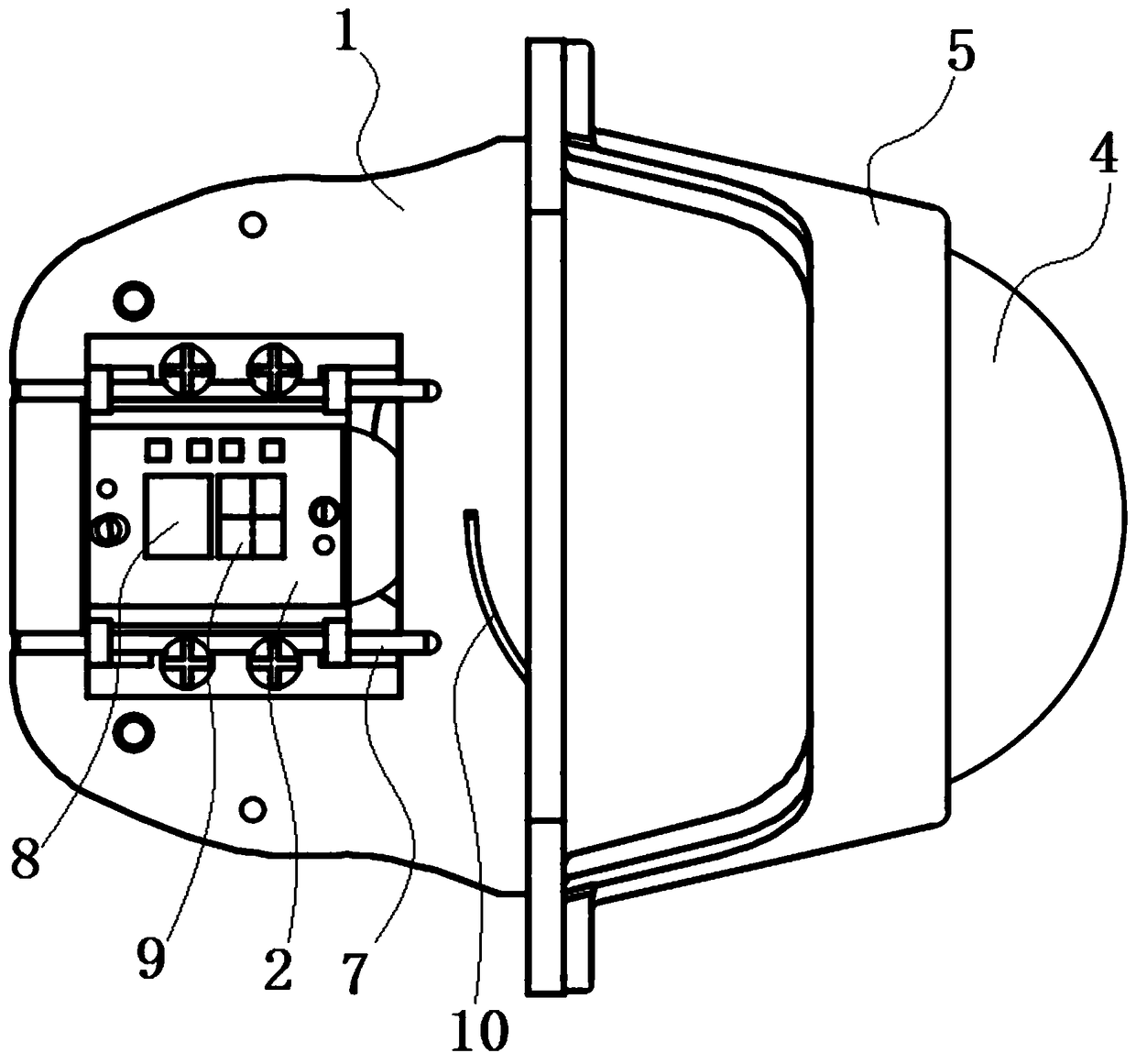

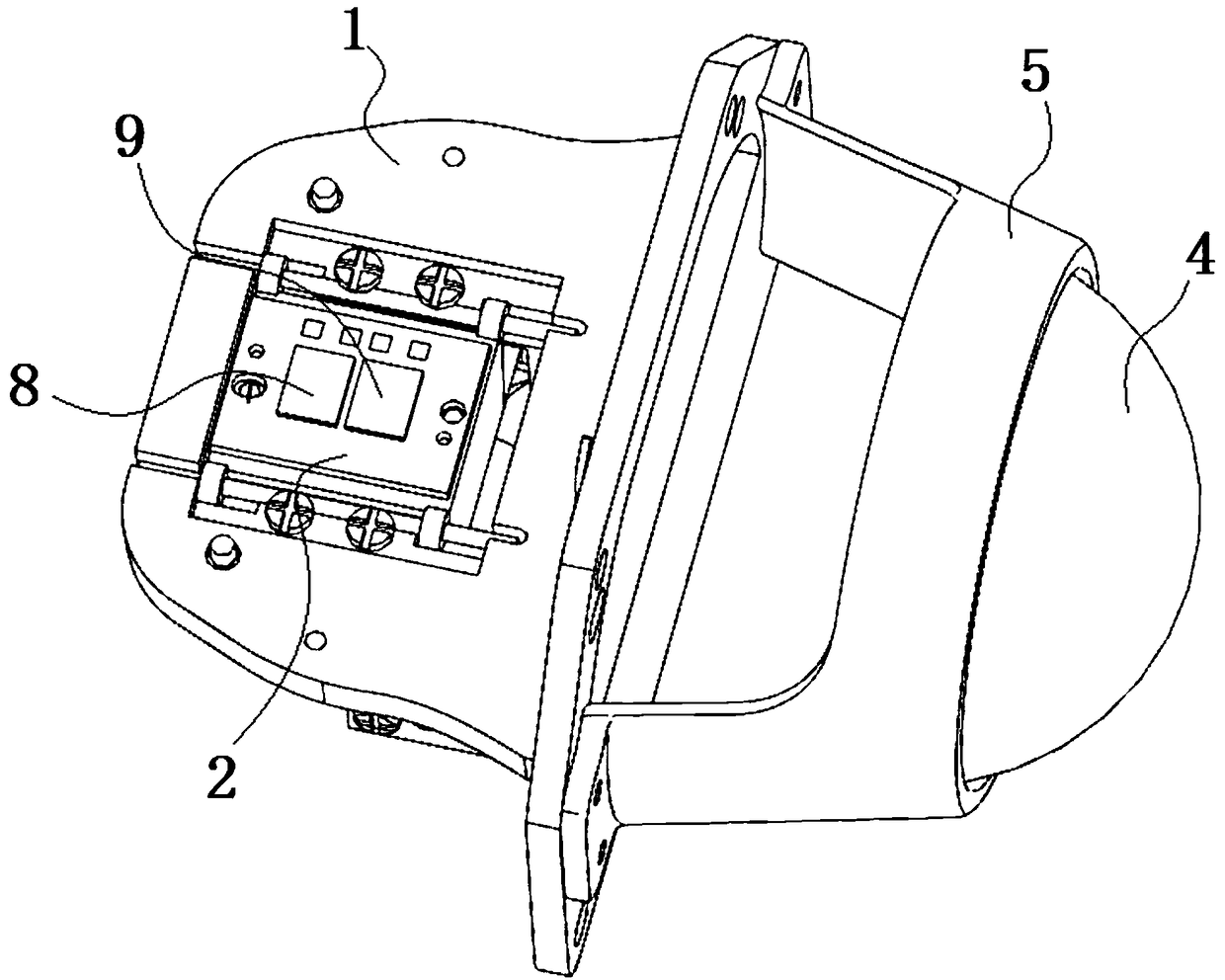

PendingCN109404856ASuit one's needsMeet the needs of safety and comfortVehicle headlampsLighting heating/cooling arrangementsHeadlampHeat spreader

The invention belongs to the technical field of automobile lamps, and provides an LED double-color-temperature automobile headlamp. The LED double-color-temperature automobile headlamp comprises a radiator, a light-emitting origin, light sources, a reflecting bowl and a lens, wherein the light sources comprise a first light source and a second light source with different color temperatures, the radiator is provided with a switching part where the first light source and the second light source are arranged, and the first light source and the second light source are changed according to states of the switching part. The first light source and the second light source are alternately located at the light-emitting origin, and light with different color temperatures can be provided in a headlamp, so that a user can have a more diversified and safe light using effect.

Owner:重庆舜辉庆驰光电科技有限公司

Nozzle arrangement

InactiveCN102548664AImprove work rateImprove efficiencySpray nozzlesLiquid spraying apparatusEngineeringDirect device

Owner:EISENMANN CORP

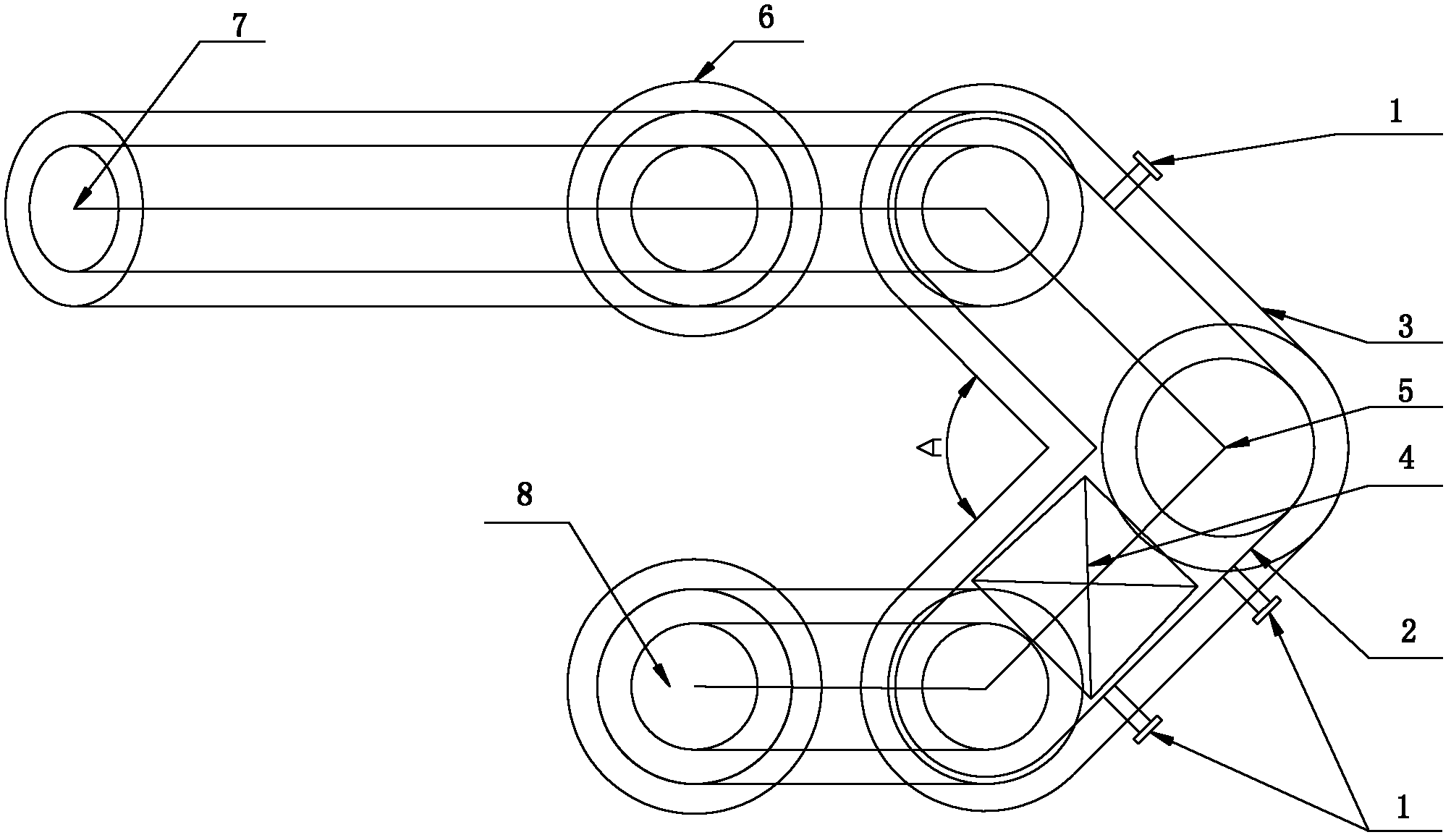

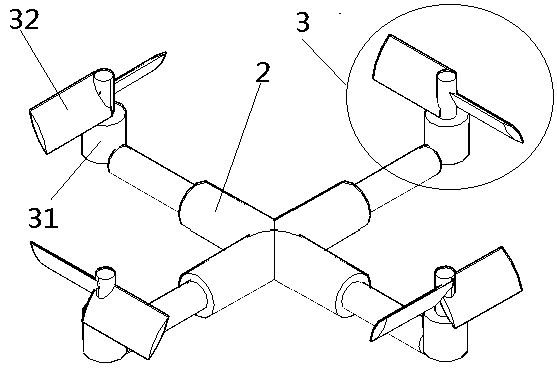

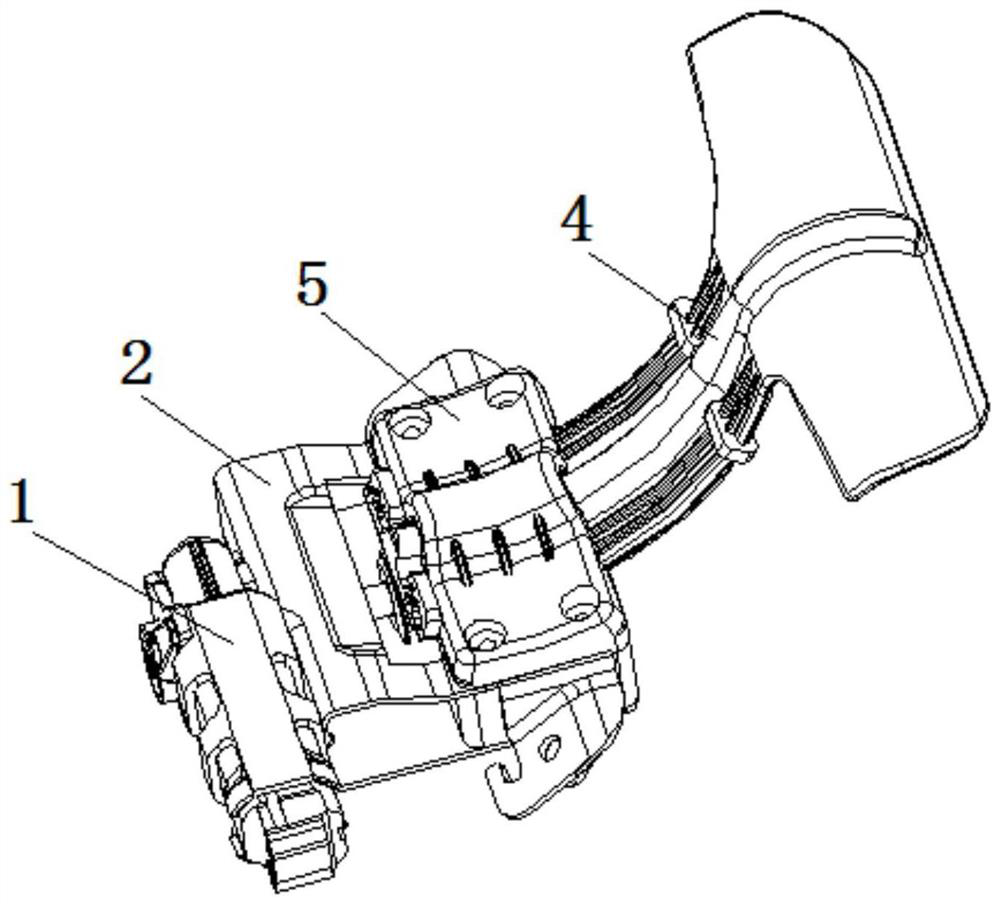

Air-sweeping type windscreen wiper

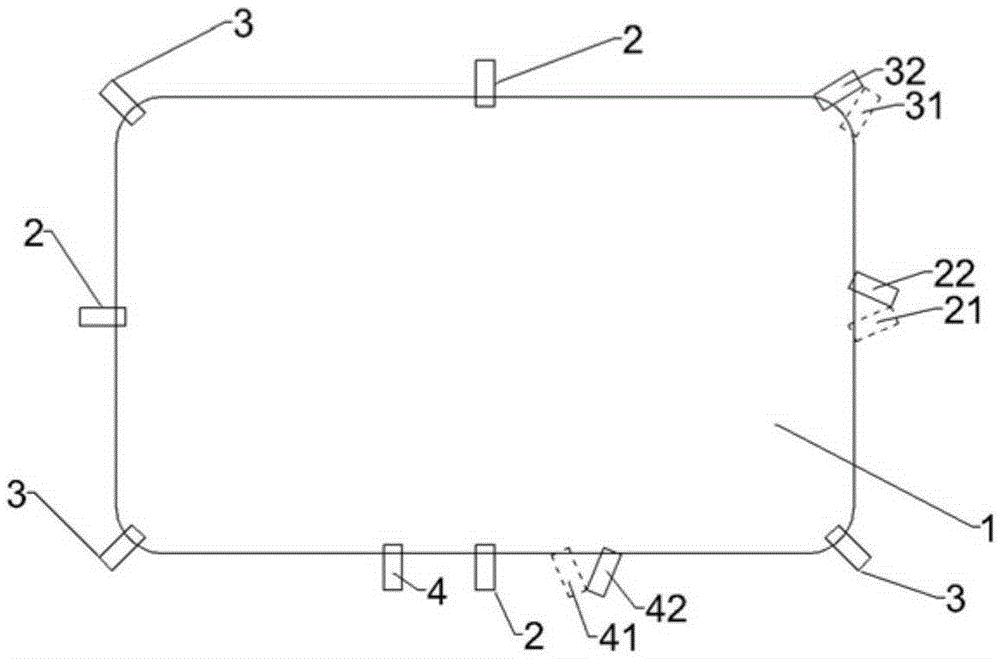

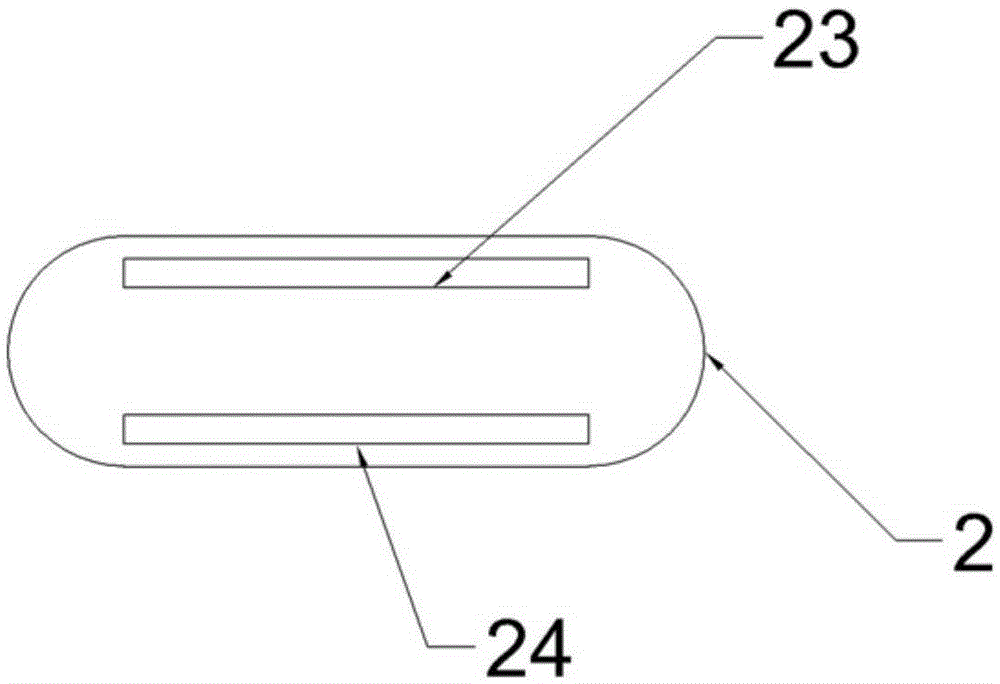

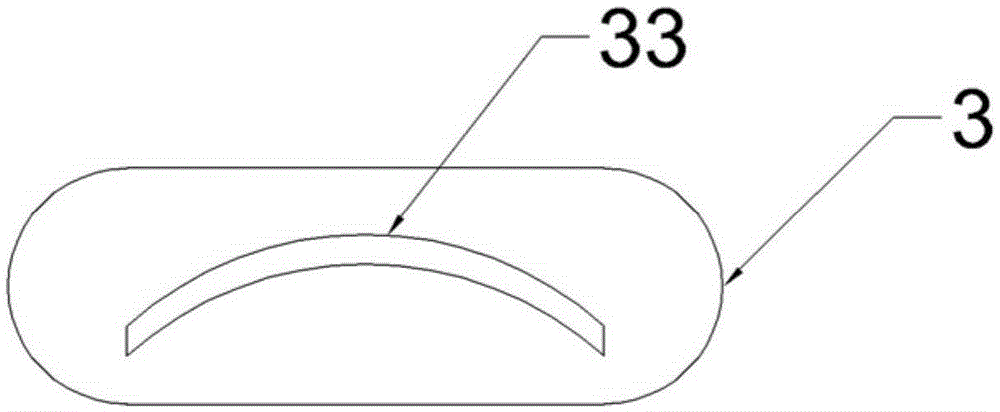

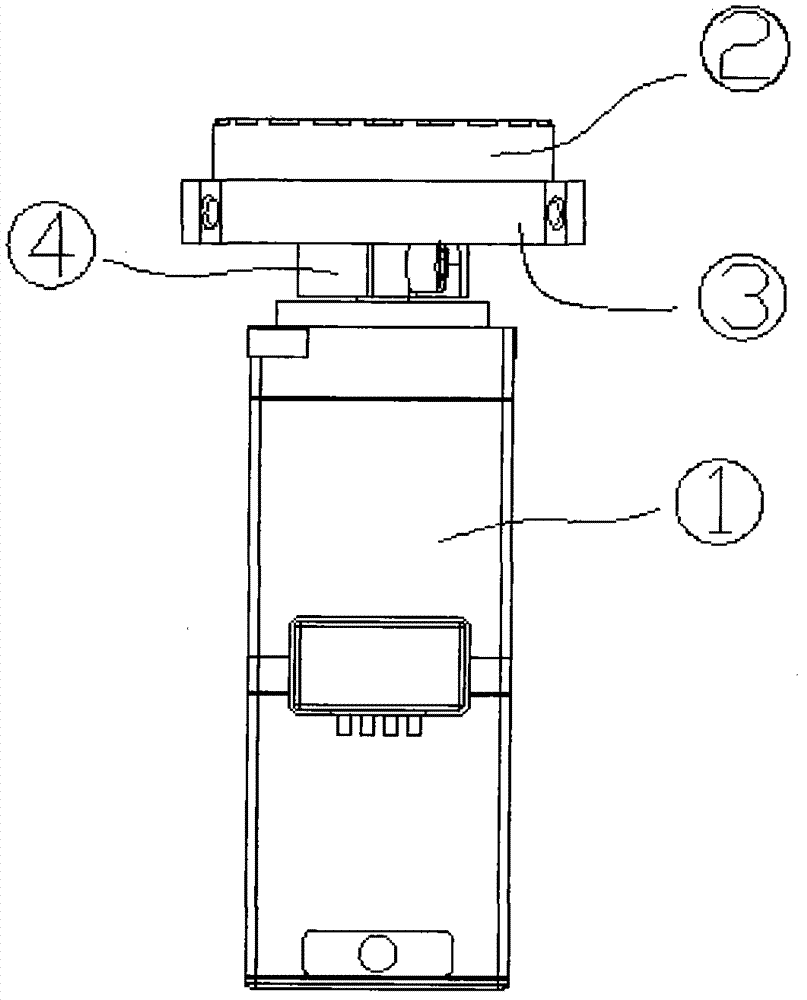

ActiveCN105196977ADoes not affect line of sightLess prone to mechanical failureVehicle cleaningWindshieldWindscreen wiper

The invention discloses an air-sweeping type windscreen wiper. The air-sweeping type windscreen wiper comprises a plurality of first nozzles and a plurality of second nozzles, wherein each first nozzle is arranged on the edge of a windshield in a rotary mode, and a rotary shaft of each first nozzle is perpendicular to the plane where the windshield is located; a thin-slot-shaped first air jet hole and a thin-slot-shaped second air jet hole are formed in the air jet end of each first nozzle in parallel, and the air jet directions of the first air jet holes and the second air jet holes are both parallel to the windshield; each second nozzle is arranged on the edge of the windshield in a rotary mode, and a rotary shaft of each second nozzle is perpendicular to the plane where the windshield is located; a third air jet hole is formed in the air jet end of each second nozzle, the section of each third air jet hole is arched, and a 30-degree angle is formed between the air jet direction of each third air jet hole and the windshield. The air-sweeping type windscreen wiper is intangible, mechanical faults do not occur easily, scraping of the windshield is avoided, and the sight of a driver can not be affected.

Owner:GUANGXI CHENYU BUILDING MATERIAL SCI & TECH

Reversing device for electronic components

The invention provides a high-speed reversing device for electronic components. The reversing device consists of a servo motor, a small turntable, a vacuum plate and a connecting block, wherein the servo motor which controls the small turntable to rotate is connected with the small turntable through the connecting block. By adopting the reversing device, downlink of upper electronic components is not required, and only a proper gap is required to be reserved so that the electronic components can be taken over by the small turntable. Therefore, the cost is saved. Moreover, the reversing device lowers the requirement on reversing time and is favorable to protect a motor.

Owner:FOSHAN BLUE ROCKET ELECTRONICS

Door bell

InactiveCN107507374AReliable structureNot prone to mechanical failureMechanical audible signallingFault rateMiddle segment

The invention discloses a doorbell, which comprises a shell with perforations on the surface, a motor compartment and a ringing compartment inside the shell, a motor is fixedly installed in the motor compartment, and a mandrel parallel to the main shaft of the motor is arranged in the ringing compartment. The two ends of the mandrel are respectively fixed on the two opposite side walls of the ring chamber. The middle of the mandrel is large and the two ends are small. Two torsion springs arranged symmetrically on the mandrel are sleeved on the mandrel, and half of the torsion spring is fixedly grounded It is tightly sleeved on the larger shaft section in the middle of the mandrel, and the other half is not fixedly connected with the smaller shaft section of the mandrel, and the end of the half torsion spring is fixedly connected with the rotating plate rotatably sleeved on the mandrel. The side of the plate facing the motor shaft is connected with a vibrating reed; a pair of connecting rods perpendicular to the main shaft are fixed on the shaft, a spring is installed at the end of the connecting rod, and a steel ball is fixed at the end of the spring away from the connecting rod. When the motor rotates , the steel ball can touch the vibrating reed. The doorbell has reliable structure, low failure rate, and can effectively avoid excessively long reverberation.

Owner:重庆亚唐科技有限公司

Electromagnetic reverse heat sealing machine

The invention discloses an electromagnetic reverse heat sealing machine. The electromagnetic reverse heat sealing machine comprises an upper heat pressing plate, a lower heat pressing plate, a slide support column, a limiting rod, electromagnets, heating rods, a slide rail plate and a phase reverse transformer; the lower heat pressing plate is fixed at the lower end of the slide rail plate; the upper heat pressing plate is mounted in a slide rail of the slide rail plate, is opposite and parallel to the lower heat pressing plate, and can move up and down in the slide rail plate; the electromagnets are mounted in the upper heat pressing plate and the lower heat pressing plate; the heating rods are mounted on opposite surfaces of the upper heat pressing plate and the lower heat pressing plate; the slide rail plate is connected with the phase reverse transformer; one end of the slide support column is fixed to the lower heat pressing plate and penetrates through the upper heat pressing plate; and the limiting rod is mounted at the other end of the slide support column. The electromagnetic reverse heat sealing machine has the beneficial effects of simple structure and stable work; and because of electromagnetic drive, mechanical faults are not easy to generate, and the noise is low.

Owner:天津骏睿科技有限公司

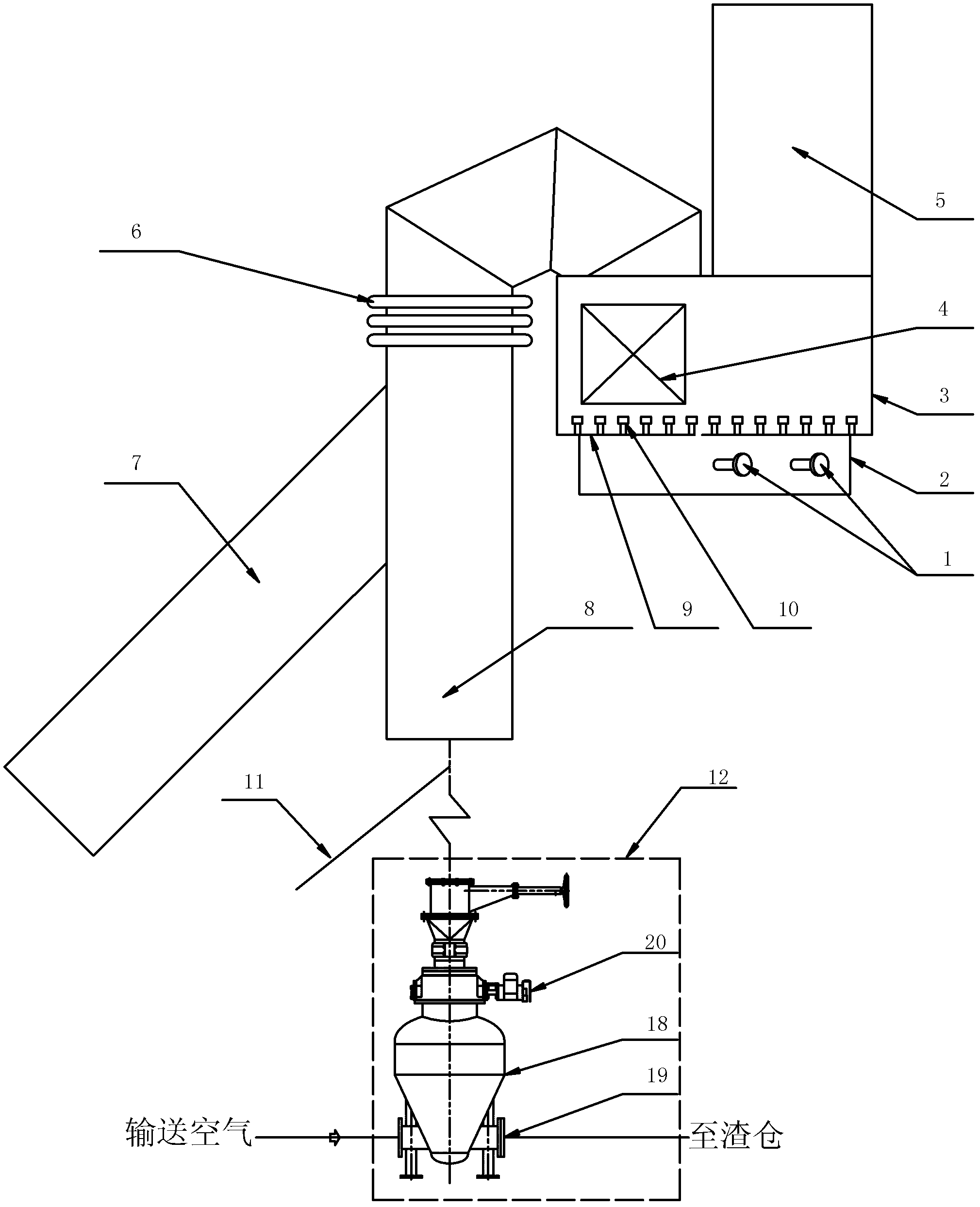

Recyclable ash flexible adjustment proportion discharging controller for recycling fluidized bed boiler

InactiveCN102620289ACompact structureFlexible adjustment of the ratio of return amount/ash discharge amountFluidized bed combustionApparatus for fluidised bed combustionFluidized bedStreamflow

The invention discloses a recyclable ash flexible adjustment proportion discharging controller for a recycling fluidized bed boiler. The recyclable ash flexible adjustment proportion discharging controller comprises an air chamber with a fluidized air port, wherein the air chamber is communicated with an discharging controller box; the top end of the discharging controller box is communicated with a recycling ash vertical pipe, a material-returning inclined pipe and a low-temperature ash discharging pipe; the pipe mouth of the recycling ash vertical pipe is arranged between the pipe mouth of the material-returning inclined pipe and the pipe mouth of the low-temperature ash discharging pipe; the discharging controller box is internally provided with a heat exchanging surface; and the heat exchanging surface is arranged in the region between the pipe mouth of the low-temperature ash discharging pipe and the pipe mouth of the recycling ash vertical pipe. According to the recyclable ash flexible adjustment proportion discharging controller disclosed by the invention, a proper recycling ash amount can be kept in the operation process of the recycling fluidized bed boiler, and remote operations can be implemented; and the recyclable ash flexible adjustment proportion discharging controller has the advantages of compact structure, small abrasion of heating surface pipe bundles, flexibility for ash flow adjustment, low ash discharging temperature, strong safety, freeness from mechanical rotary parts of a whole controller, low instrument cost, low operation cost and low maintenance cost.

Owner:HUANENG CLEAN ENERGY RES INST

Flexible portal blanking machine

InactiveCN106239602AApplicable cutting needsImprove stabilityMetal working apparatusPressesBraced frameEngineering

The invention discloses a flexible portal blanking machine which comprises a rack base, supporting frameworks, a position adjustment bracket, a blanking die head and a material feeding mechanism, wherein the position adjustment bracket is fixedly mounted above the rack base through the two supporting frameworks; a transverse sliding rail is arranged at the bottom of the position adjustment bracket; the blanking die head is movably mounted on the transverse sliding rail through a transmission roller at the top; a horizontal supporting platform is arranged at the top of the rack base, and is formed by combining a plurality of transverse platforms and adjustable platforms; the adjustable platforms are mounted between the transverse platforms; a single hydraulic mandril is arranged at the bottom of each transverse platform; and two hydraulic mandrils are arranged at the bottom of each adjustable platform. By the improvement on a fixed flat plate of the rack base on the conventional portal blanking machine, the flexible portal blanking machine can meet the cutting requirement of different types of materials or dies, is wider in practical scope and high in stability, and is not easy to subject to mechanical failures.

Owner:YANCHENG XIONGYING PRECISION MACHINERY

Landing chair controllable in direction

InactiveCN109592046AReduce areaReduce the influence of wind directionAircraft ejection meansParachutesMultiple pointSupply energy

The invention relates to a landing chair controllable in direction and relates to the field of aviation safety. The landing chair comprises an ejection chair, telescopic shafts, electric lift devices,a controller, a battery and an umbrella throwing device. The umbrella throwing device comprises a detection device, an ejection device and a parachute. The four telescopic shafts are symmetrically arranged below the ejection chair in the same height. The electric lift device is arranged at the tail end of each telescopic shaft. The controller is arranged inside the ejection chair, and the electric lift devices and the telescopic shafts are both electrically connected with the controller. The battery is arranged inside the ejection chair and supplies energy for the controller, the electric lift devices and the telescopic shafts. The detection device is arranged on the ejection chair and is connected with the controller. The ejection device comprises an ejection cylinder, a locking piece and an elastic piece, wherein the locking piece is arranged at the upper end of the ejection cylinder, and the elastic piece is arranged in the ejection cylinder. The parachute is arranged between the elastic piece and the locking piece, and the parachute is connected with the ejection chair at multiple points through a plurality of ropes. The landing chair can reduce the influence of the wind direction, and a pilot can manually control the landing chair to rapidly land on the designated ground after an air accident occurs.

Owner:FOSHAN SHENFENG AVIATION SCI & TECH

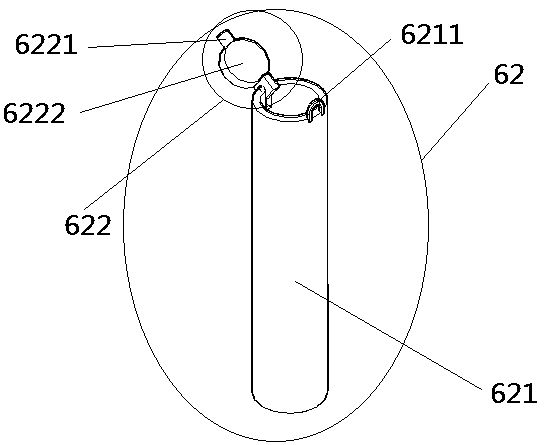

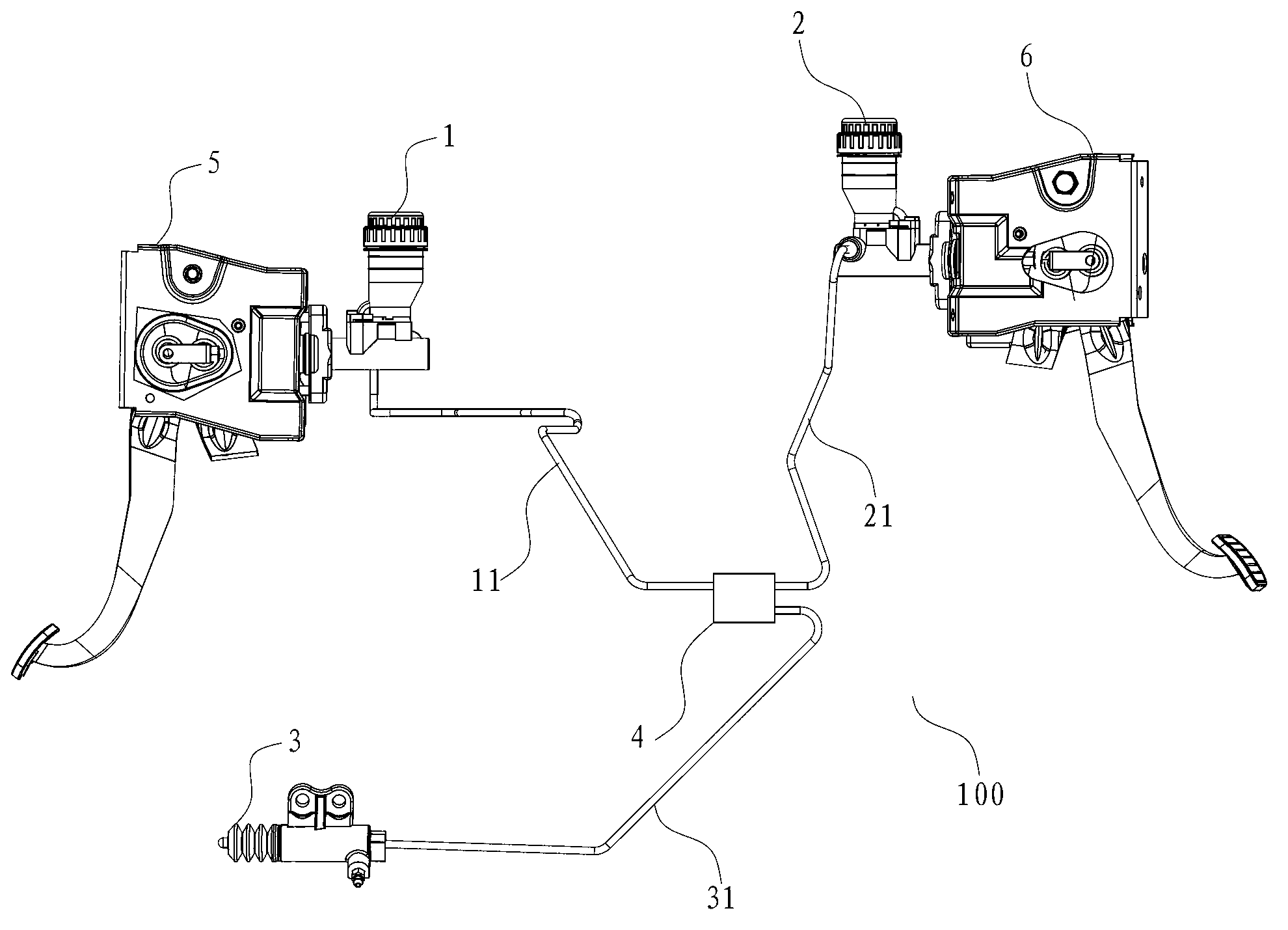

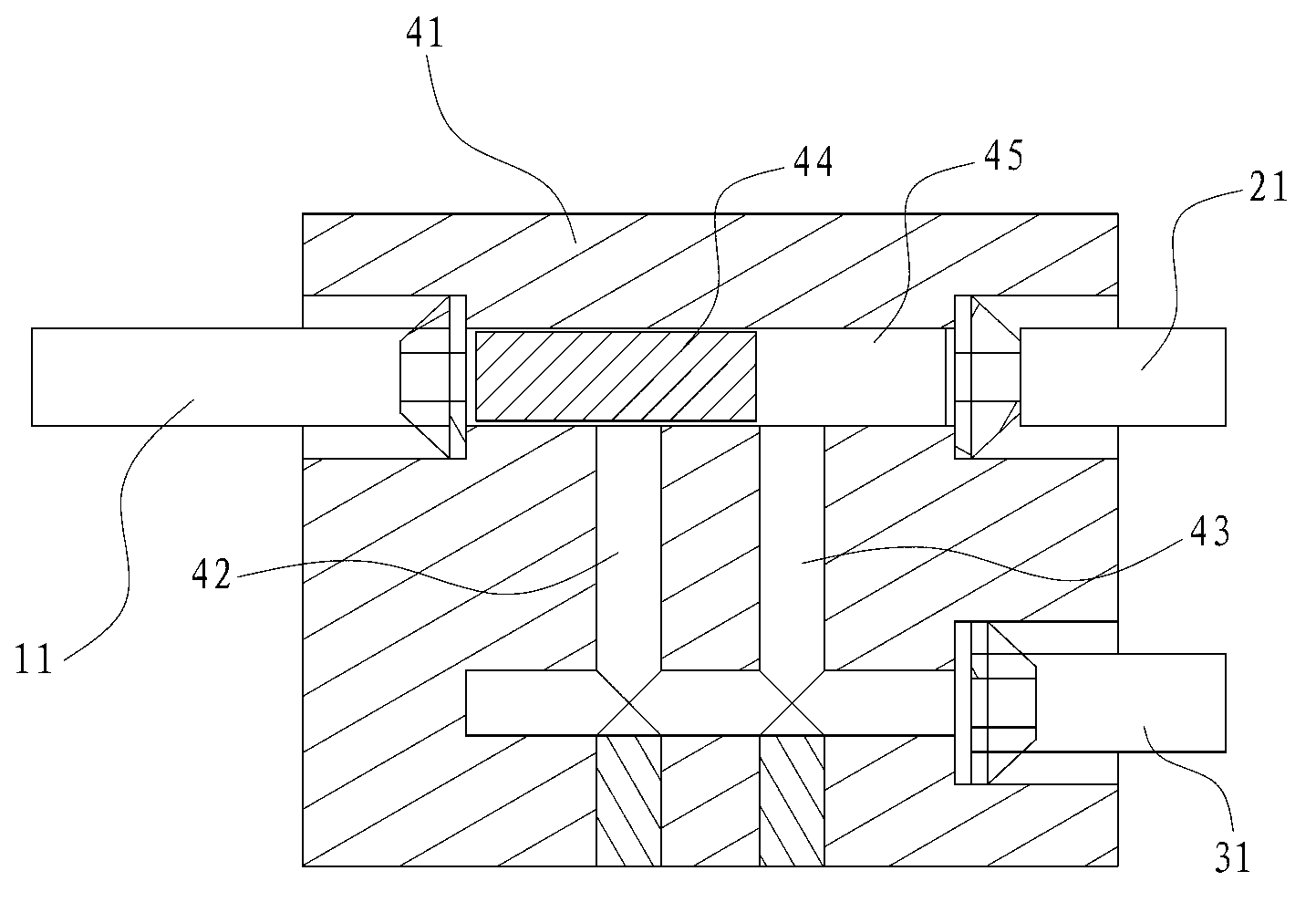

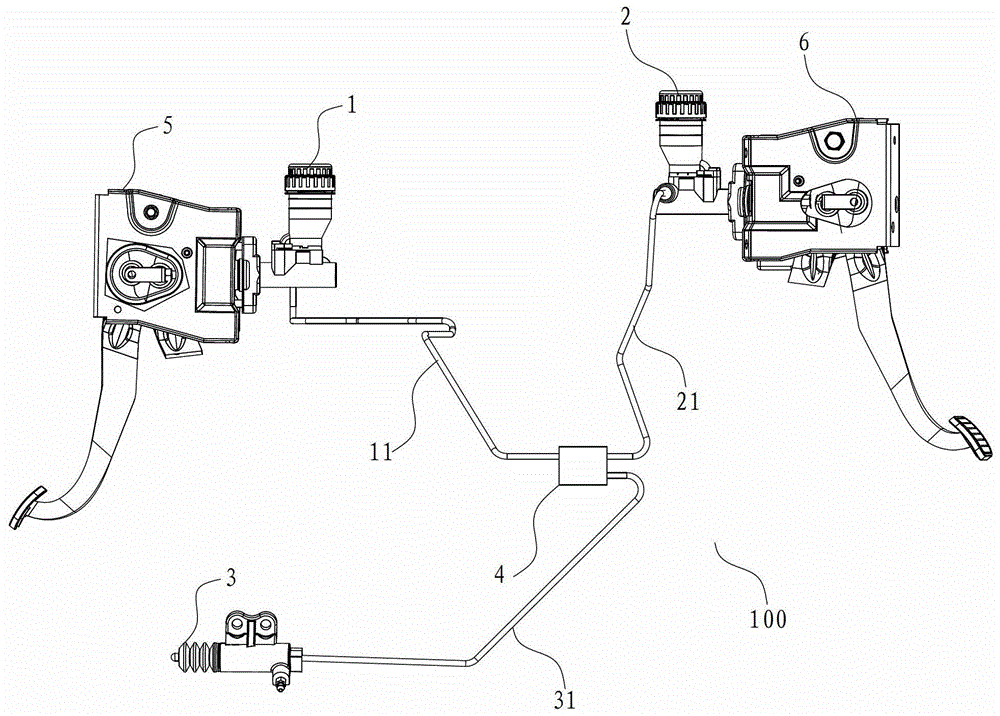

Clutch system used for automobile and automobile with same

The invention discloses a clutch system used for an automobile and an automobile with the same. The clutch system comprises a main clutch device, an auxiliary clutch device, a clutch slave cylinder and a hydraulic control device. The main clutch device comprises a main clutch master cylinder. The auxiliary clutch device comprises an auxiliary clutch master cylinder. The hydraulic device is respectively connected with the main clutch device, the auxiliary clutch device and the clutch slave cylinder. The hydraulic control device is constructed to selectively communicate the main clutch master cylinder and the clutch slave cylinder or communicate the auxiliary clutch master cylinder and the clutch slave cylinder. The clutch system used for the automobile can achieve the effect that the main clutch device and the auxiliary clutch device can control the same clutch slave cylinder, so that a main driver and an auxiliary driver can control a clutch respectively, and the problem that the system is damaged when a traditional main clutch device and a traditional auxiliary clutch device work simultaneously is solved. In addition, the clutch system is simple in structure and low in cost.

Owner:GREAT WALL MOTOR CO LTD

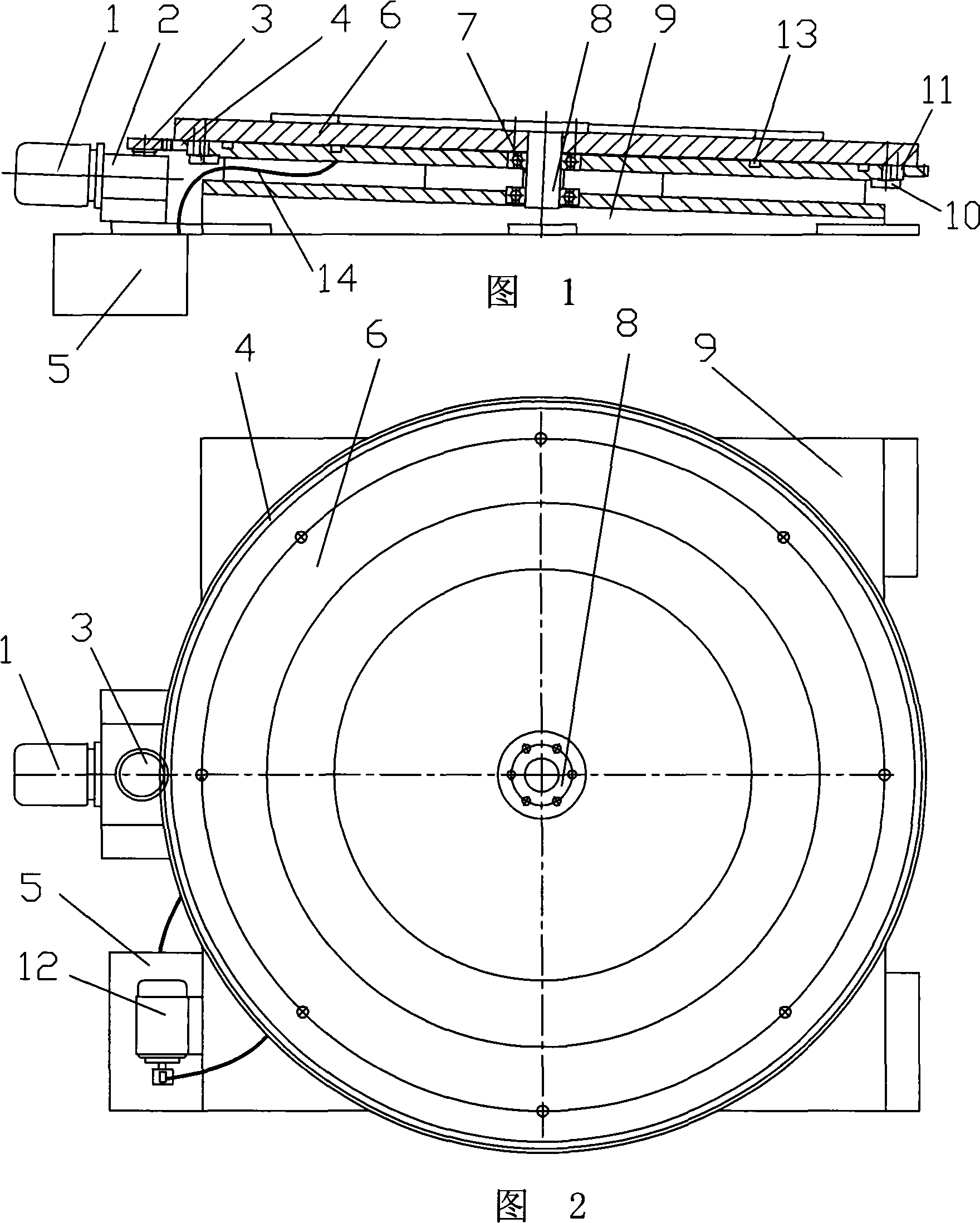

Angle rotary table for mechanical processing

InactiveCN101530970AHigh precisionShort adjustment timePositioning apparatusMetal-working holdersGear wheelEngineering

The invention relates to a novel angle rotary table for mechanical processing, in particular to a component which is suitable for processing, has an angle and needs to rotate for 360 degrees, and belongs to the technical field of mechanical structures. According to the technical proposal, the upside of a seat cushion is provided with an upper deck panel; the angle rotary table is characterized in that the center of the seat cushion is provided with a rotary positioning shaft by using a bearing, and the upper end of the rotary positioning shaft is fixedly connected with the upper deck panel; the seat cushion and the upper deck panel are mutually parallel and obliquely arranged; the edge of the upper deck panel is provided with a gearwheel which is meshed with a pinion positioned at an output end of a decelerator; and the upper surface of the seat cushion is provided with a groove for storing lubricating oil. The angle rotary table has the characteristics of high precision, convenient mounting and clamping, simple and high-speed adjustment, and the like.

Owner:WUXI QIAOLIAN WIND POWER TECH

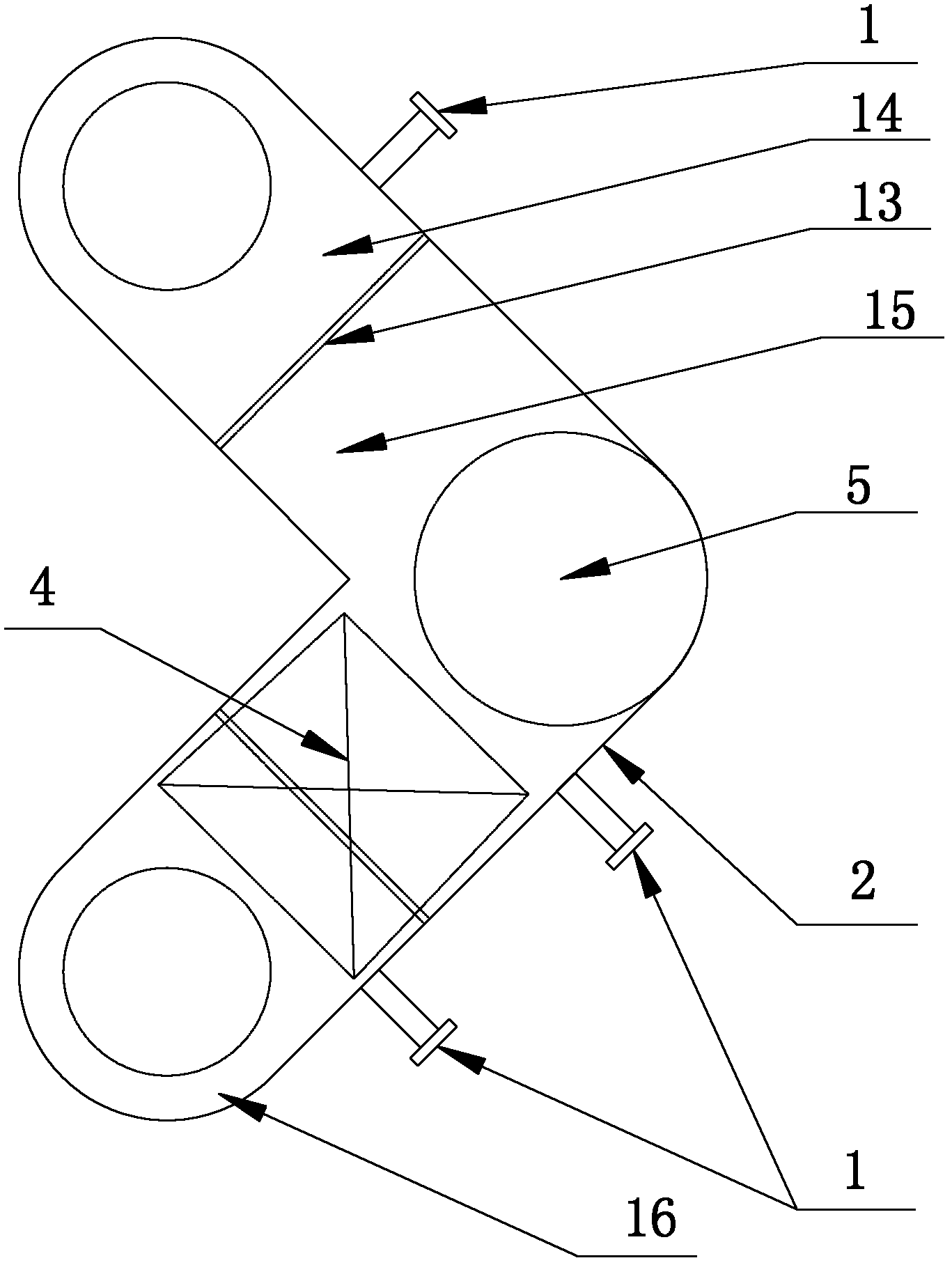

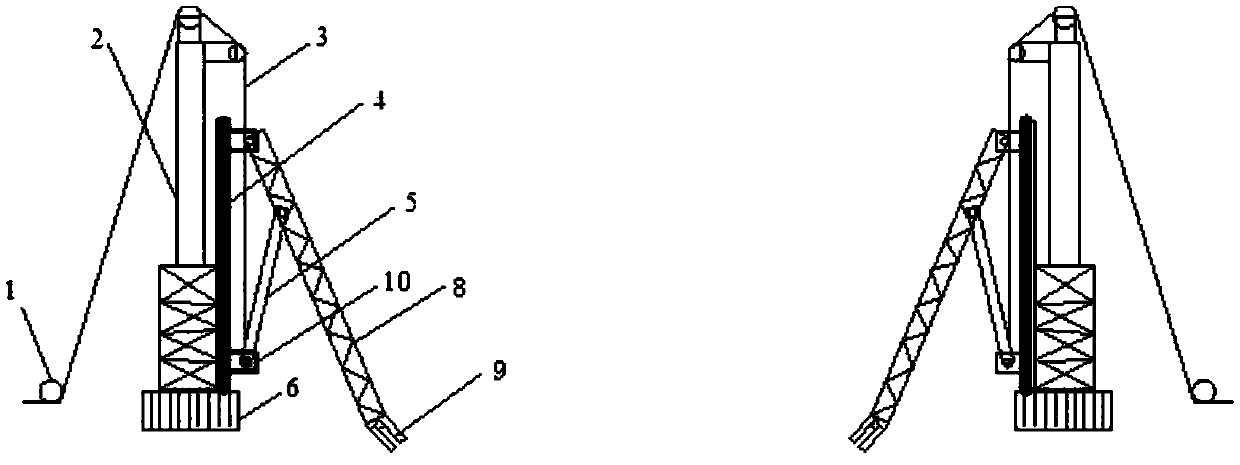

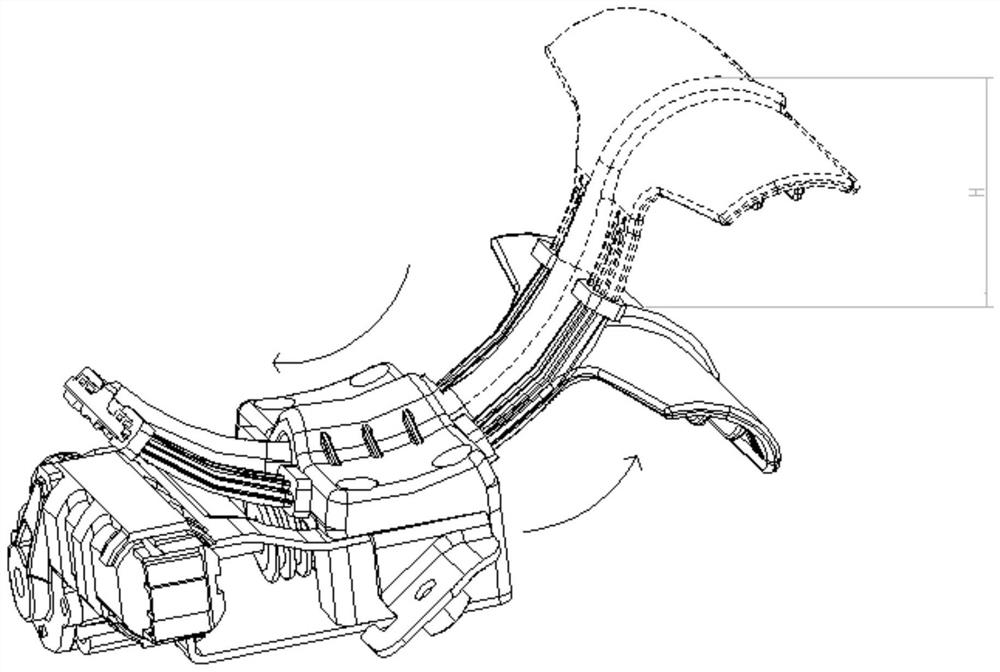

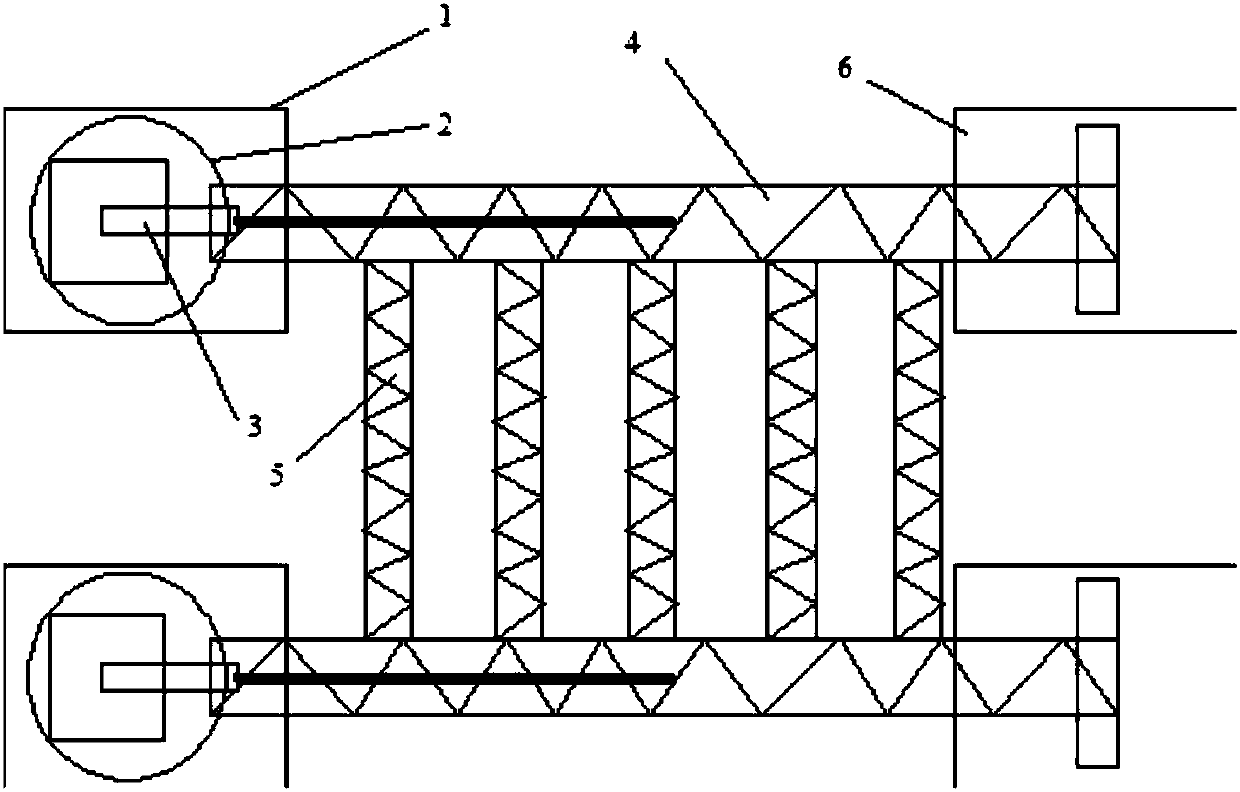

Folding rotary crossing over frame

ActiveCN110311324ASimple structureLess prone to mechanical failureApparatus for overhead lines/cablesEngineeringActuator

The invention discloses a folding rotary crossing over frame, which comprises a supporting mechanism, and a lifting mechanism and an actuator vertically disposed on the supporting mechanism, wherein the lifting mechanism comprises a lifting platform disposed on the supporting mechanism, a sliding rail fixed on the lifting platform in a vertical direction and upper and lower sliders arranged at oneside of the sliding rail; the lower slider is controlled by a steering pulley arranged at the other side of the supporting mechanism through a power rope; and the actuator comprises a folding arm connected with the upper slider, a folding strut connected with the lower slider, multiple network closing holding bars fixed in rail clamping grooves above the folding arm and a connecting pin shaft arranged at the other side of the folding arm. The structure is simple, and the engineering cost is reduced; the construction is convenient; the network closing speed is quick, a network closing assemblyfunction can be easily realized through a rotating mechanism, and an unsmooth docking situation does not happen easily.

Owner:CHINA ELECTRIC POWER RES INST +3

Angle tooling device with adjustable angle

InactiveCN101898310ACompact structureNot prone to mechanical failurePositioning apparatusMetal-working holdersEngineeringMachine tool

The invention relates to an angle tooling device with adjustable angle, which comprises a base, and is characterized in that one end of the base is pivoted with an adjusting seat, and the other end thereof is pivoted with an equal-height pad supporting seat which is provided with an equal-height pad that is fixedly connected with the adjusting seat; one end of the base is pivoted with the adjusting seat by a locating pins shaft, and the other end thereof is pivoted with the equal-height pad supporting seat by a supporting seat pin shaft; and the equal-height pad is fixedly connected with the adjusting seat by a bolt and a gasket. Compared with the prior art, The invention has the advantages that 1, the device has compact structure and does not easily cause mechanical failure; 2, a whole tooling is not needed to be replaced when different products are replaced, and the equal-height pads representing different angles are only needed to be changed, so that the time for replacing the tooling is shortened by 2 / 3; 3, the adjustment is rapid and can be accurately preformed without a professional machine tool operator, and the adjustment time is reduced by 1 / 2 compared with the original tooling; and 4, the cost is saved, and the maintenance is easy.

Owner:WUXI QIAOLIAN WIND POWER TECH

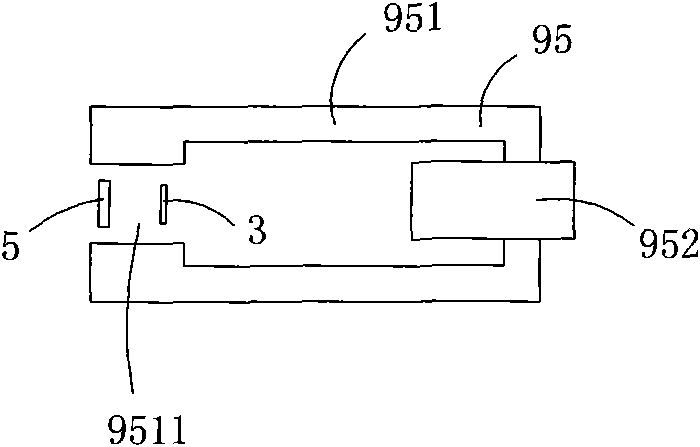

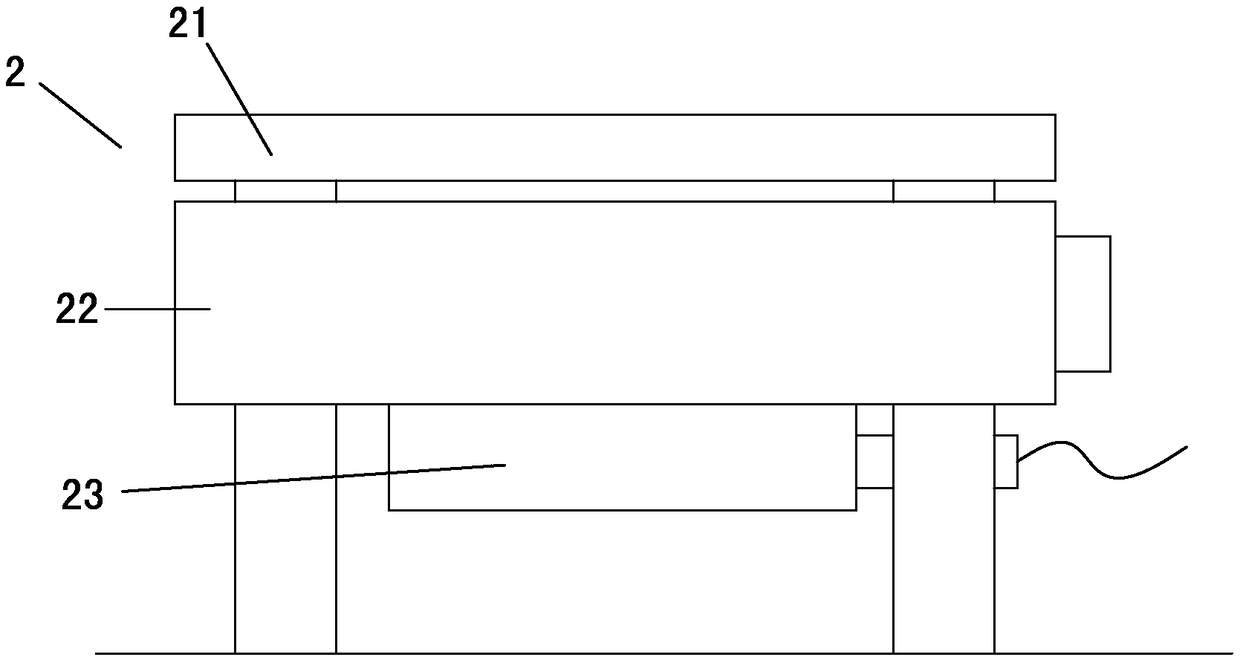

Full-automatic cutting edging machine for clothing trademarks

ActiveCN108755079AImplement sequential operationsAchieving the effect of the purposeFilament handlingSevering textilesTrademarkControl system

The invention discloses a full-automatic cutting edging machine for clothing trademarks. The machine comprises a machine base, a roll conveying device, a cutting device, a press conveying device, an edging device and a control system. The roll conveying device, the cutting device, the press conveying device, the edging device and the control system are arranged on the machine base, the roll conveying device is used for conveying rolled clothing trademark bands to the cutting device, and the cutting device is used for cutting the clothing trademark bands into segments; the press conveying device is used for conveying the clothing trademarks which are cut into segments to the edging device for press folding and formation of end edges and outputting the formed clothing trademarks; the controlsystem is used for controlling working operation of the whole machine. According to the full-automatic cutting edging machine, work of a series of steps such as roll conveying, cutting, edging can befully automatically and mechanically conducted, traditional manual operation is replaced, the working efficiency can be greatly improved, and convenience is provided for sewing.

Owner:SHISHI XINGGANG PLASTIC PACKAGING

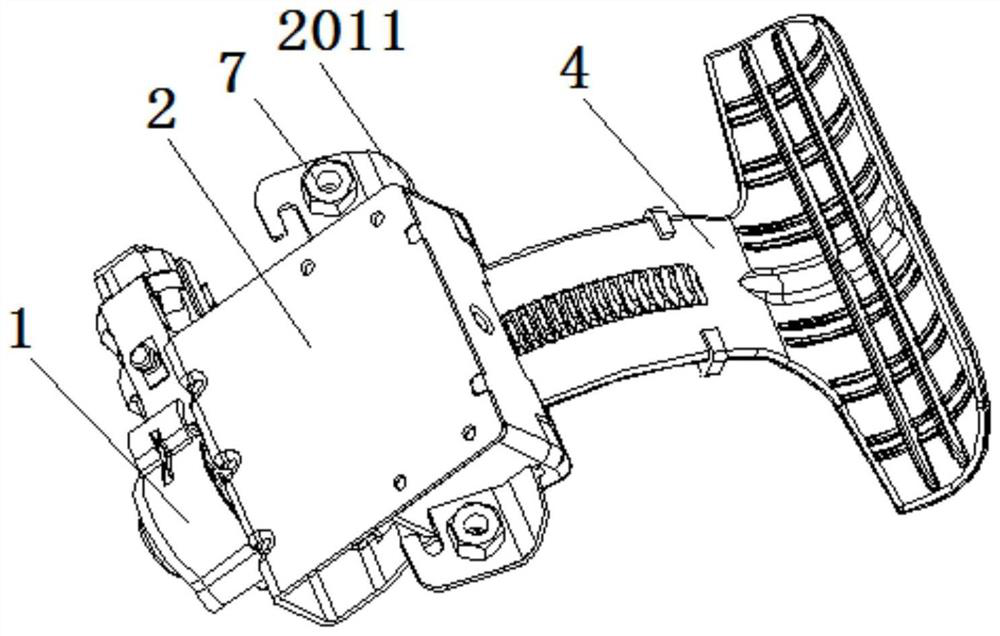

Adjustable mechanical side wing structure

An adjustable mechanical side wing structure comprises a driver, a worm mounting frame, a worm, a side wing supporting plate and a guide sliding way, wherein the driver is arranged on the outer side of the worm mounting rack, and a power output shaft of the driver is mounted on the worm mounting rack in a penetrating manner; the worm is arranged in the worm mounting frame and assembled on the power output shaft; the side wing supporting plate comprises a stroke adjusting part and a side wing supporting part arranged at the end of the stroke adjusting part, the stroke adjusting part is of an arc-shaped structure, teeth meshed with the worm are machined at the bottom of the stroke adjusting part, a sliding rail matched with the guide sliding way is machined on the stroke adjusting part, and teeth at the bottom of the stroke adjusting part of the side wing supporting plate are meshed with the worm after the side wing supporting plate is mounted on the worm mounting frame; and the guide slide way is arranged on the stroke adjusting part of the side wing supporting plate and is fixedly connected with the worm mounting frame. The side wing structure is small in occupied space, high in strength, simple in structure, convenient to install, few in manufacturing process, low in cost and large enough in stroke.

Owner:NEW DEV CHANGCHUN AUTO CONTROL SYST CO LTD

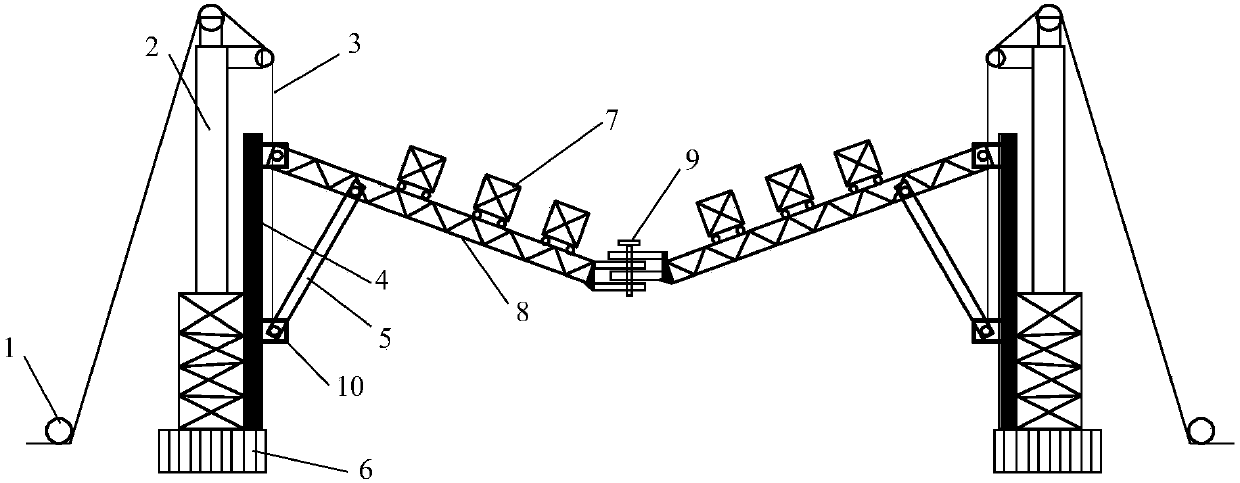

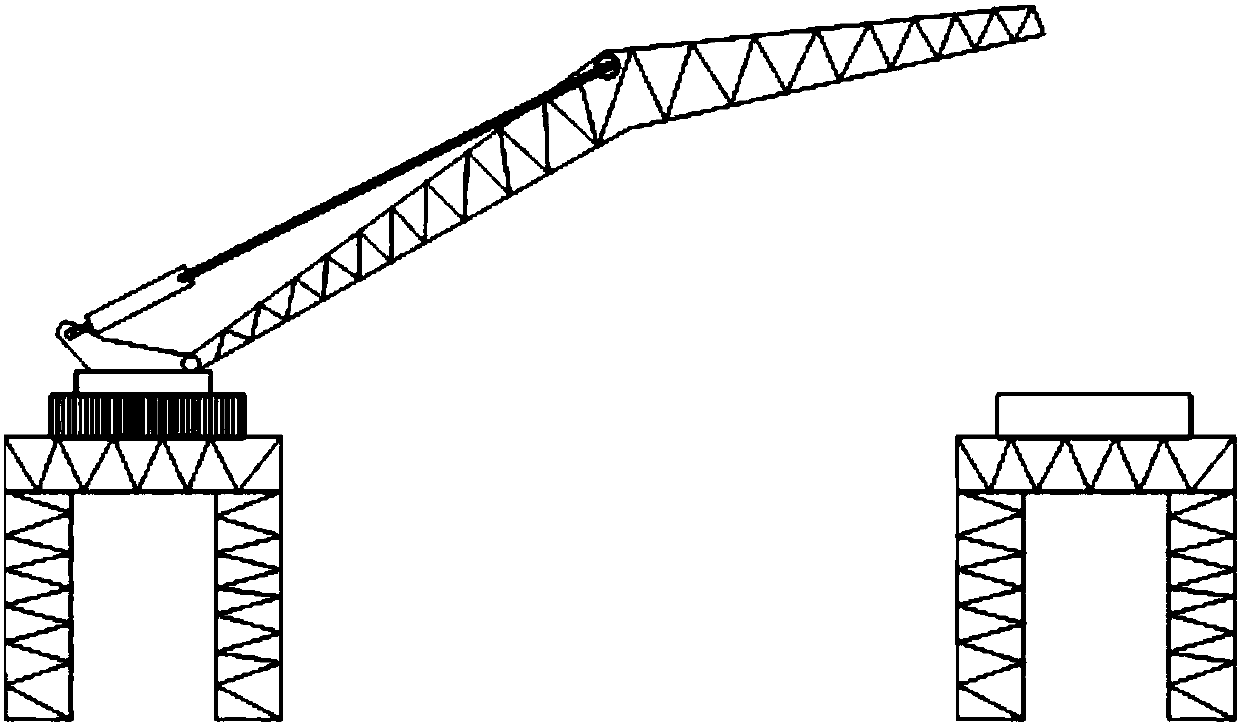

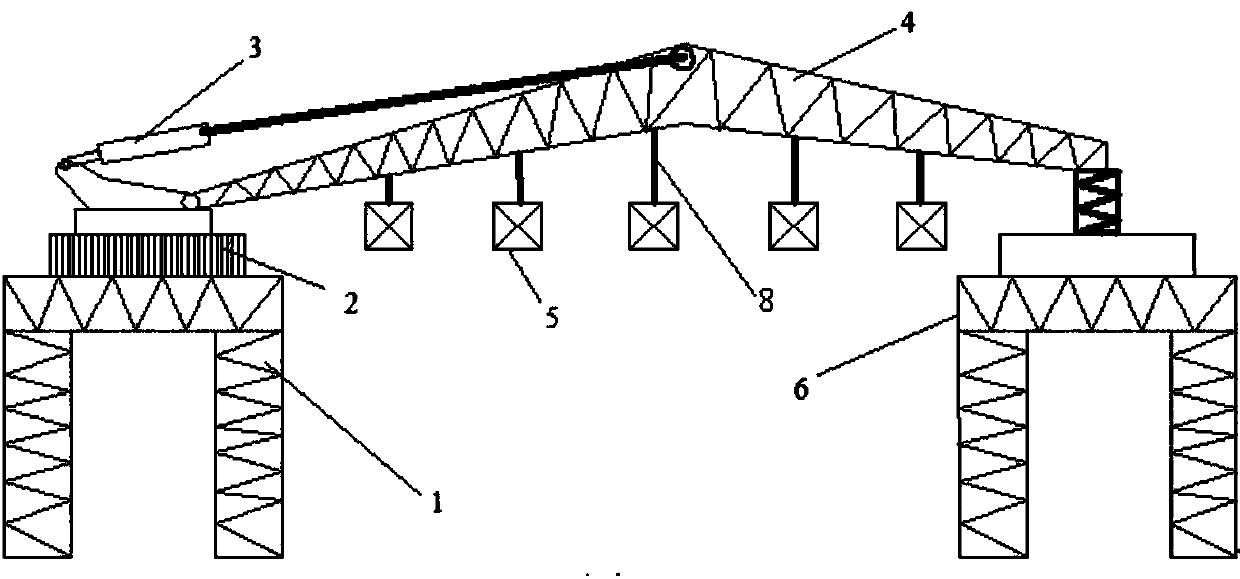

Rear pull rotary crossing-over frame

ActiveCN110311325AStable structureEasy to controlApparatus for overhead lines/cablesHydraulic cylinderAgricultural engineering

The invention discloses a rear pull rotary crossing-over frame, which comprises a worktable, a rotating mechanism disposed on the worktable, a rear pull hydraulic mechanism disposed on the rotating mechanism and a support table, wherein the rotating mechanism comprises a rotating platform; the rear pull hydraulic mechanism comprises a rear pull hydraulic cylinder disposed on the rotating platformand an inverted V-shaped network closing arm connected with the rear pull hydraulic cylinder; and the support table is disposed at a free end of the network closing arm. During the installation process, the action is stable and reliable, a jamming phenomenon is not easy to occur, and the structure is stable and reliable; the construction workload is saved, the network closing time is shortened andthe engineering cost is reduced; the repeated adjustment of the two sides during the construction process is prevented; the network closing speed is fast, the mechanical failure rate is low, the network closing time is guaranteed, the network closing boom adopts a lattice structure, the structure is stable, and network closing protection is carried out through a hard network closing holding pole,in comparison with the traditional soft network closing, the advantages of strong impact resistance, high safety, high reliability and the like can be achieved.

Owner:CHINA ELECTRIC POWER RES INST +3

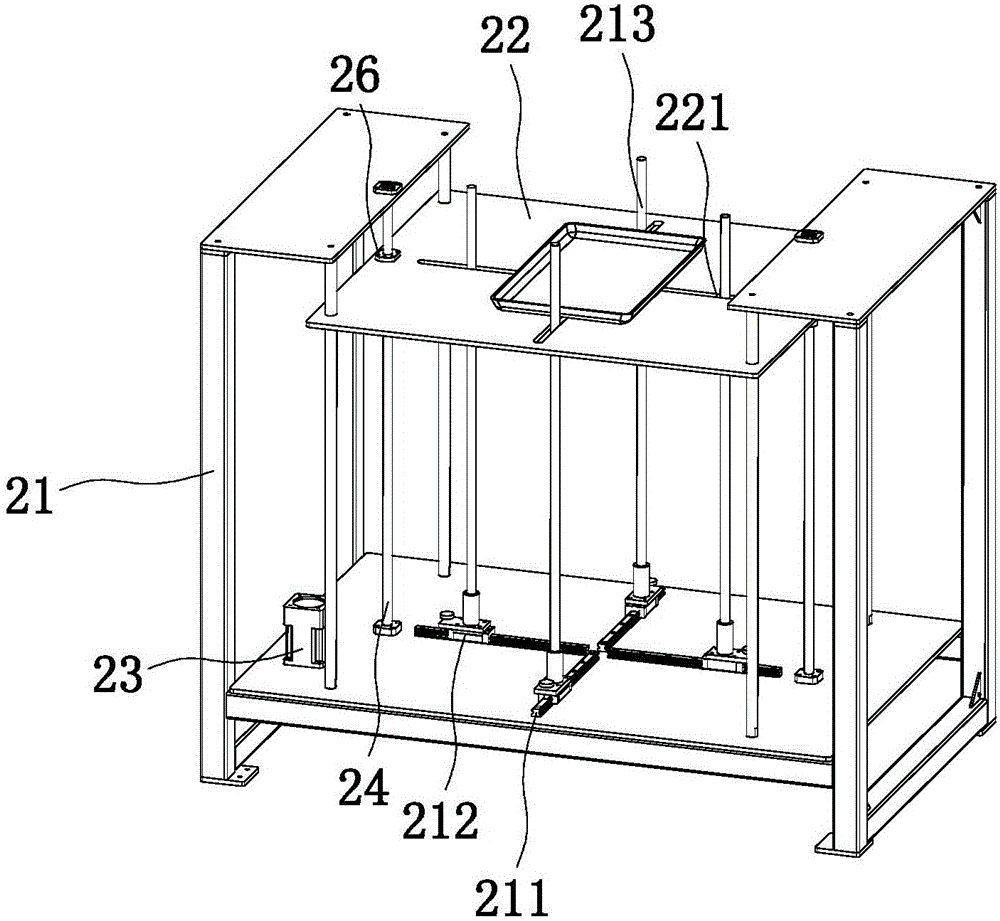

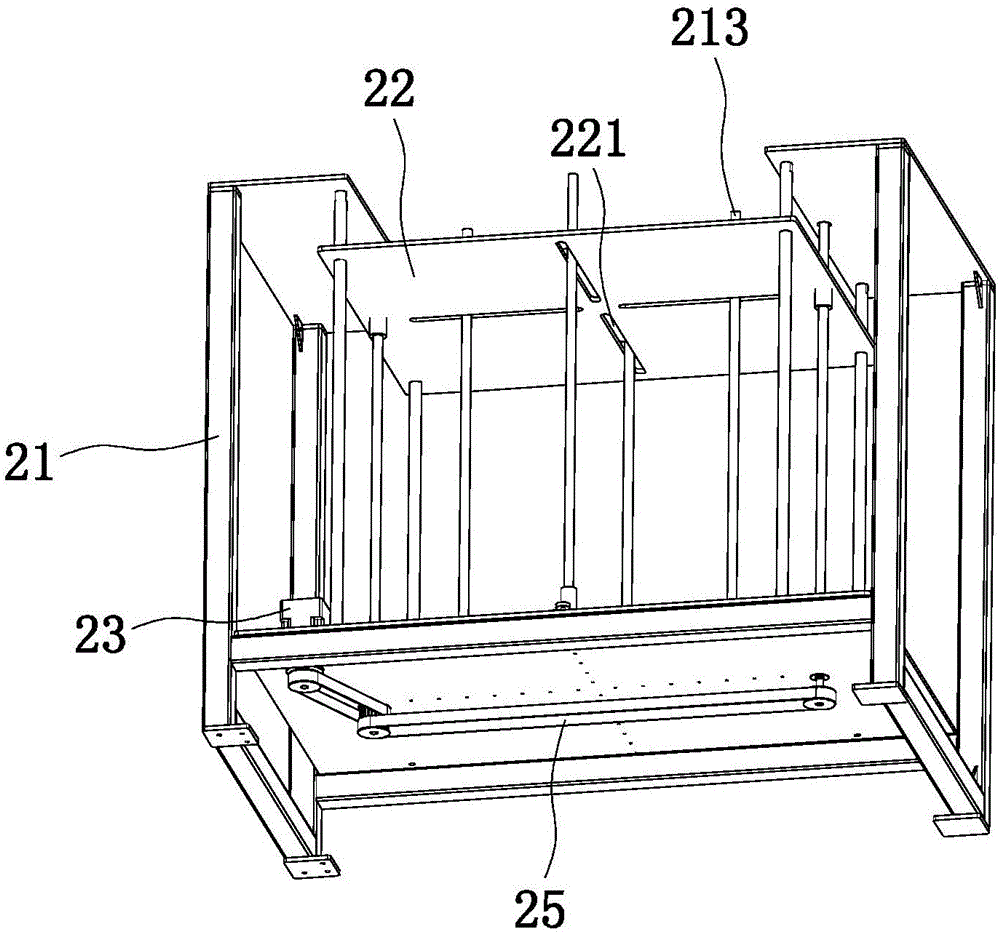

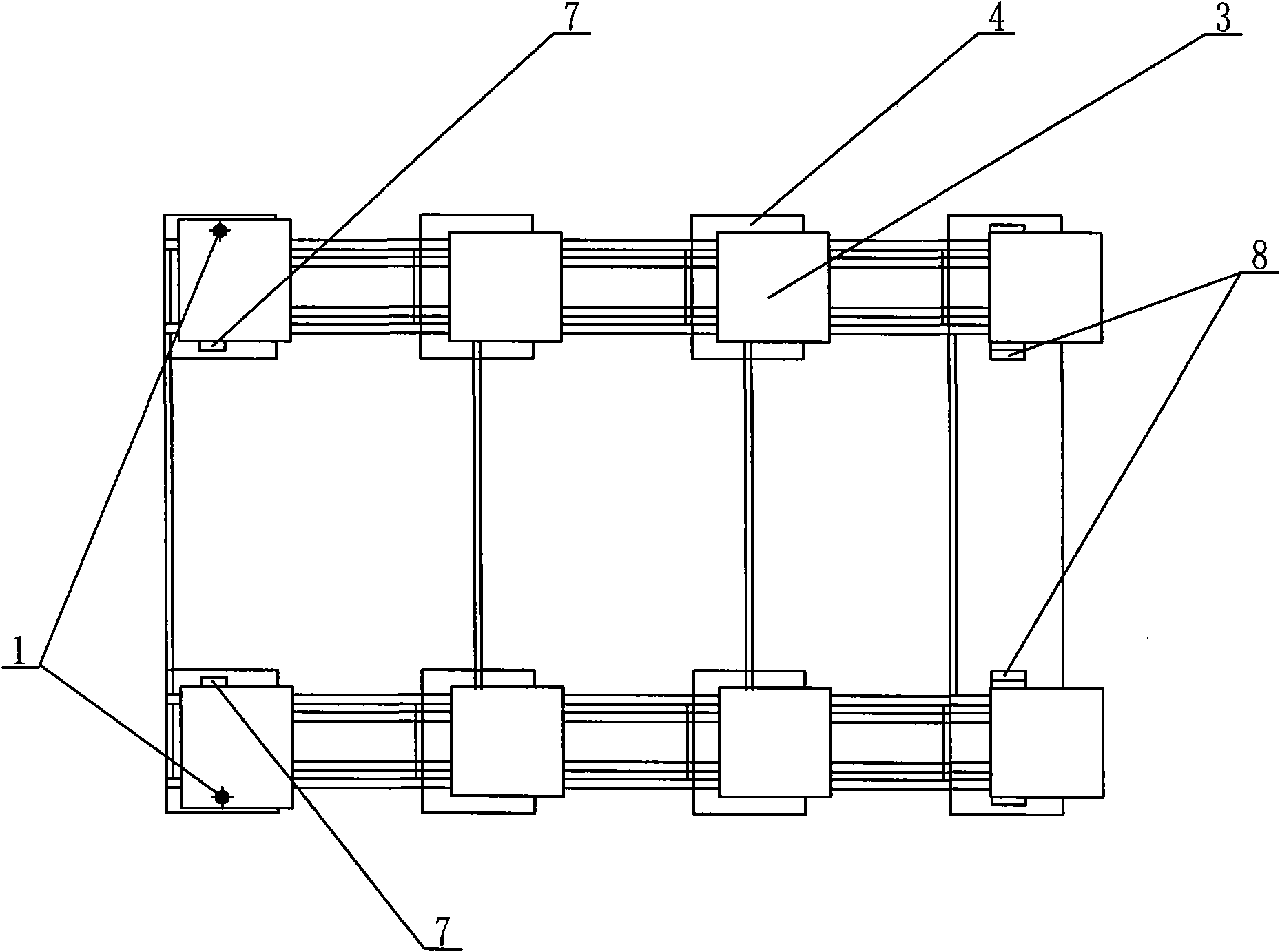

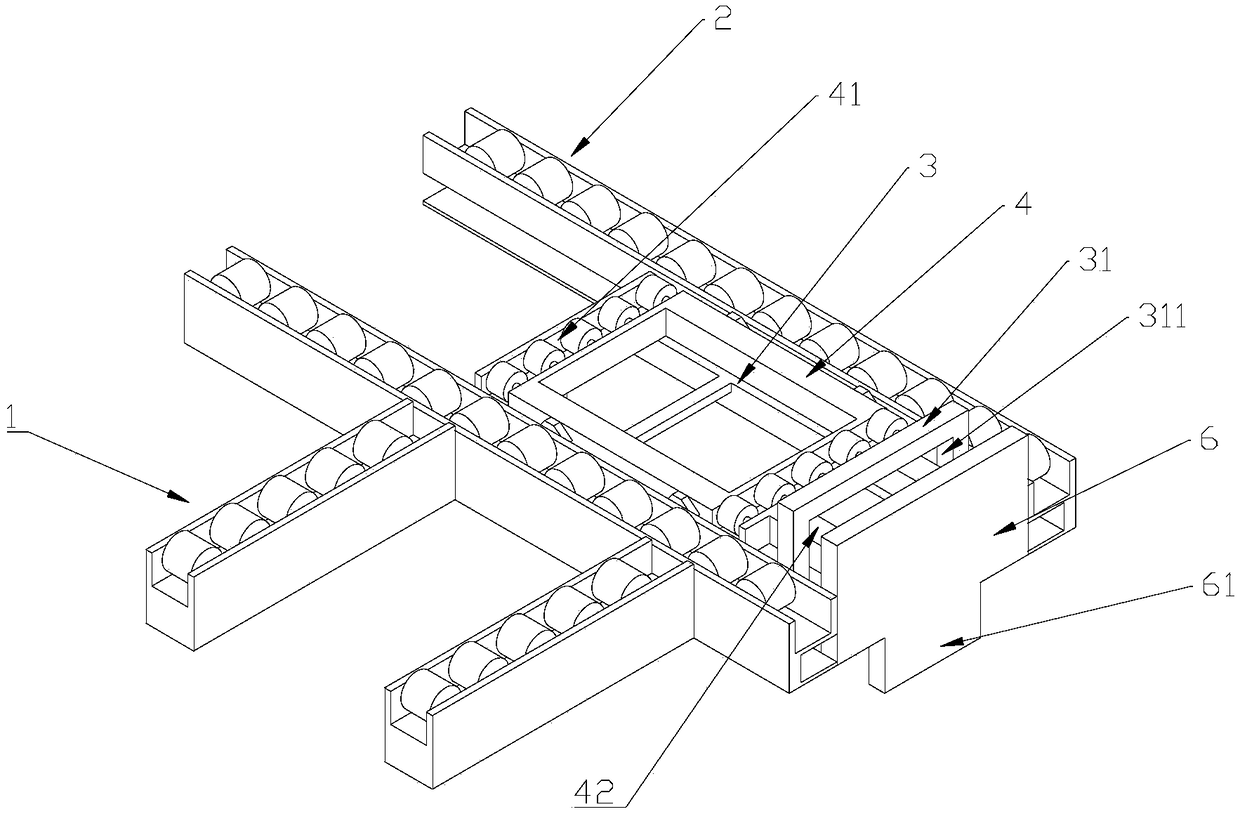

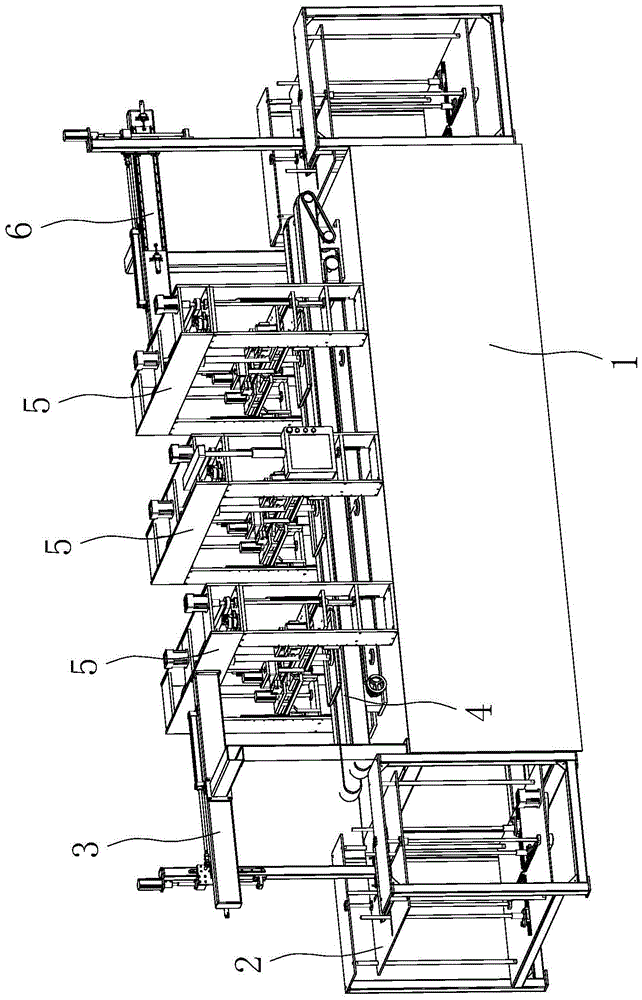

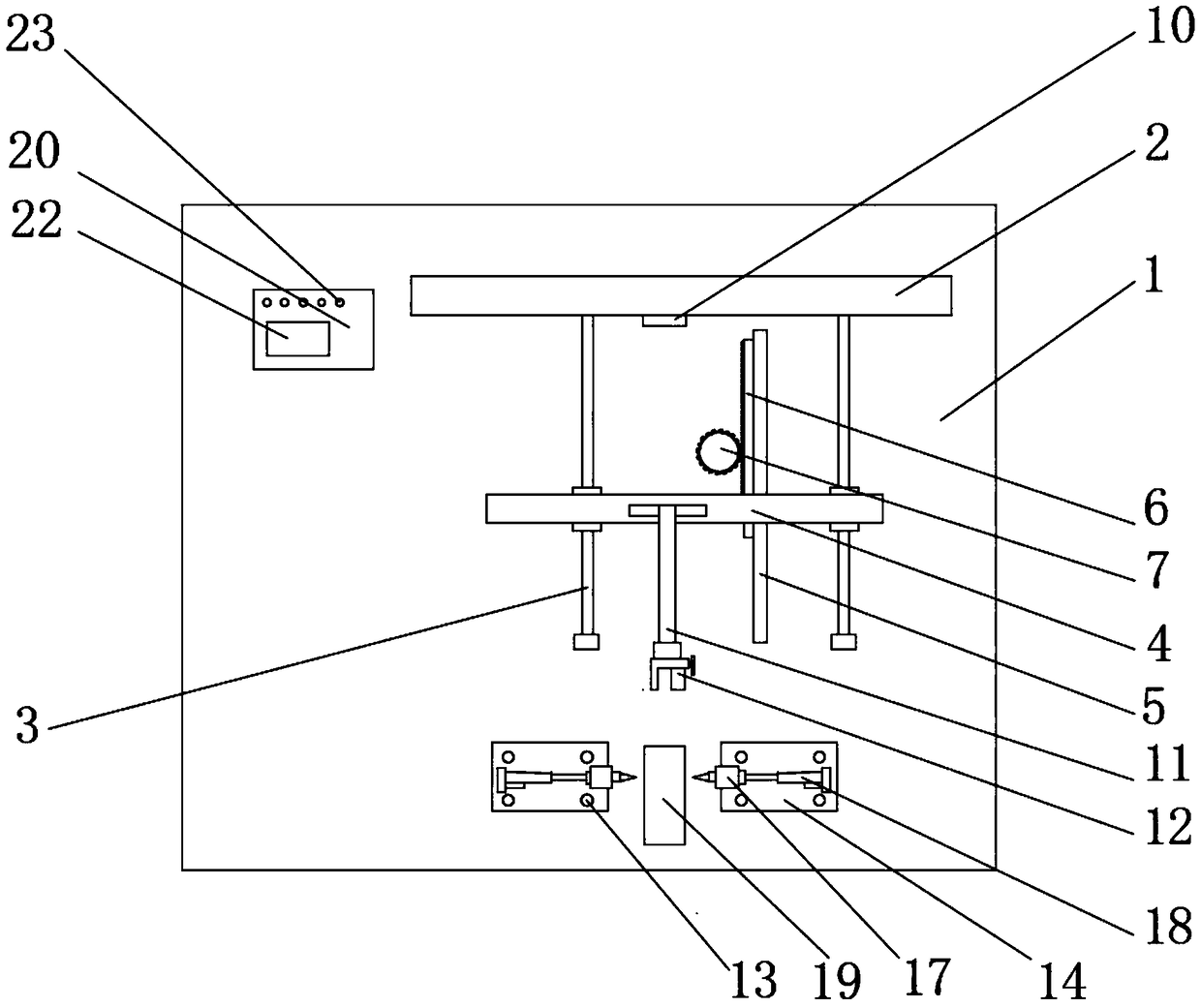

A quarter-turn system for a production line

ActiveCN106429273BCompact structureSmall footprintMechanical conveyorsProduction lineReciprocating motion

The invention provides a right-angle turning system for a production line. The right-angle turning system for the production line comprises mould feeding tracks and mould conveying tracks, wherein the conveying directions of the mould feeding tracks are perpendicular to the conveying directions of the mould conveying tracks; a conveying surface of the mould feeding tracks is higher than the conveying surface of the mould conveying tracks; a carrying cart is arranged in the mould conveying tracks; the carrying cart performs reciprocating movement in the length direction of the mould conveying tracks under the driving of a driving device; a lifting track frame is arranged above the carrying cart; short tracks in the same conveying direction as the mould feeding tracks are arranged on the lifting track frame; the mould conveying track is fixedly connected with a baffle; collision blocks which are protruded from the side wall is arranged on the side wall, close to the baffle, of the lifting track frame; the collision blocks extend in the direction of the baffle; the lifting track frame is connected with the carrying cart through lifting connecting rods; the lifting connecting rods are respectively hinged to the lifting track frame and the carrying cart. Through the right-angle turning system for the production line, the production line is simple and compact in structure and small in occupied area; power is provided for the overall production line by taking a hydraulic oil cylinder as the driving device; the energy consumption is low; the economical efficiency is high.

Owner:WUWEI JINWEI ENVIRONMENT TECH

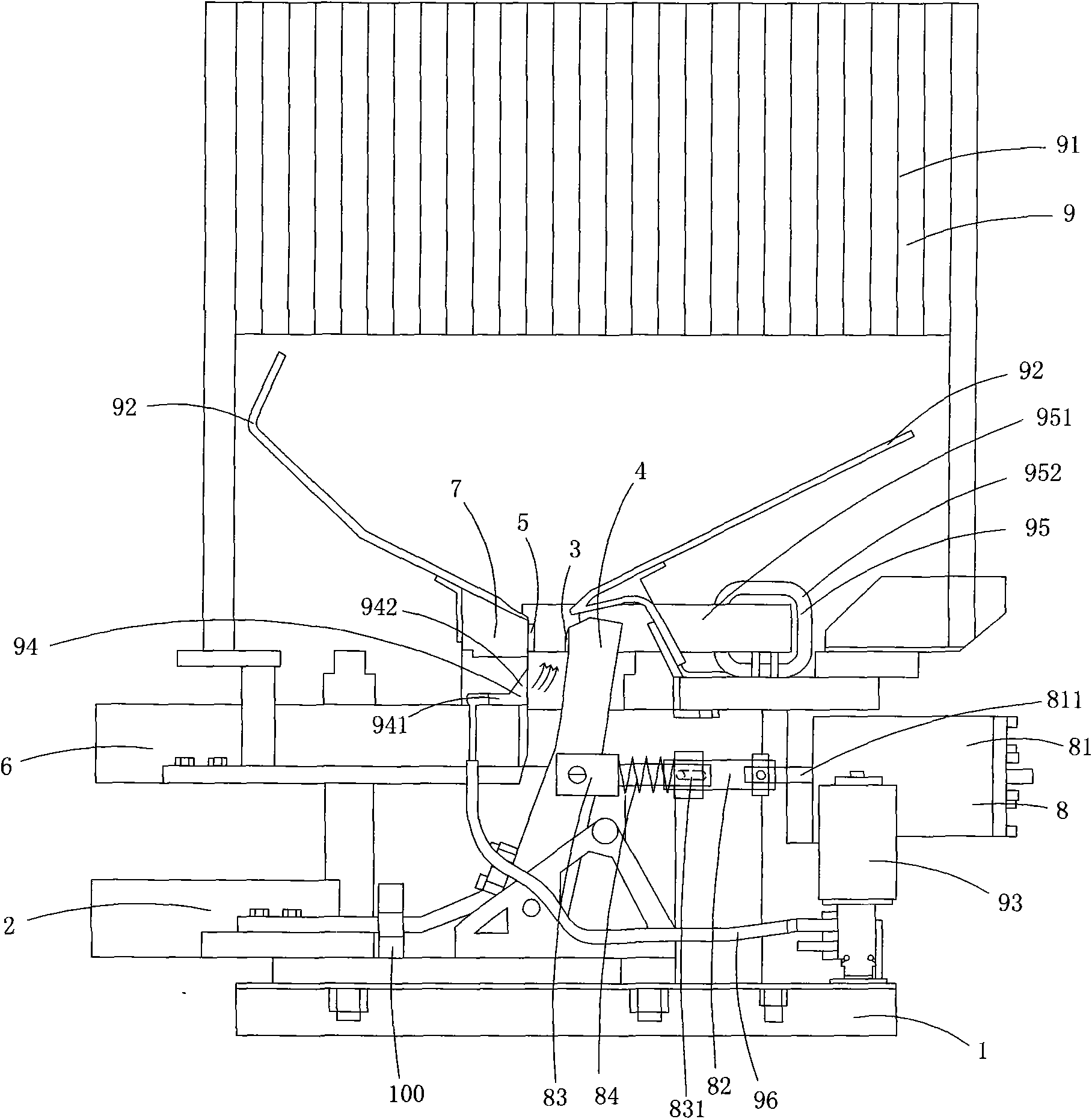

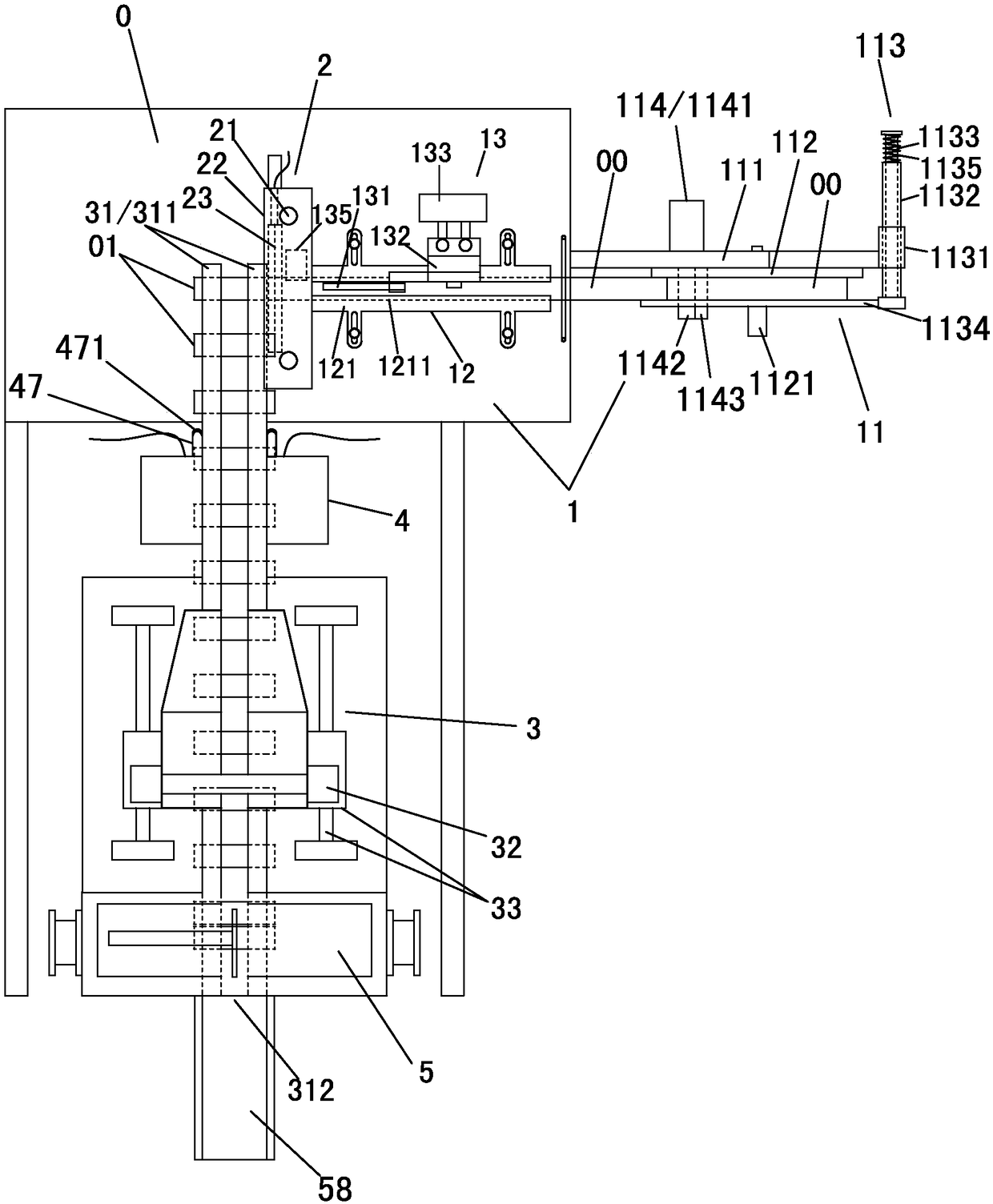

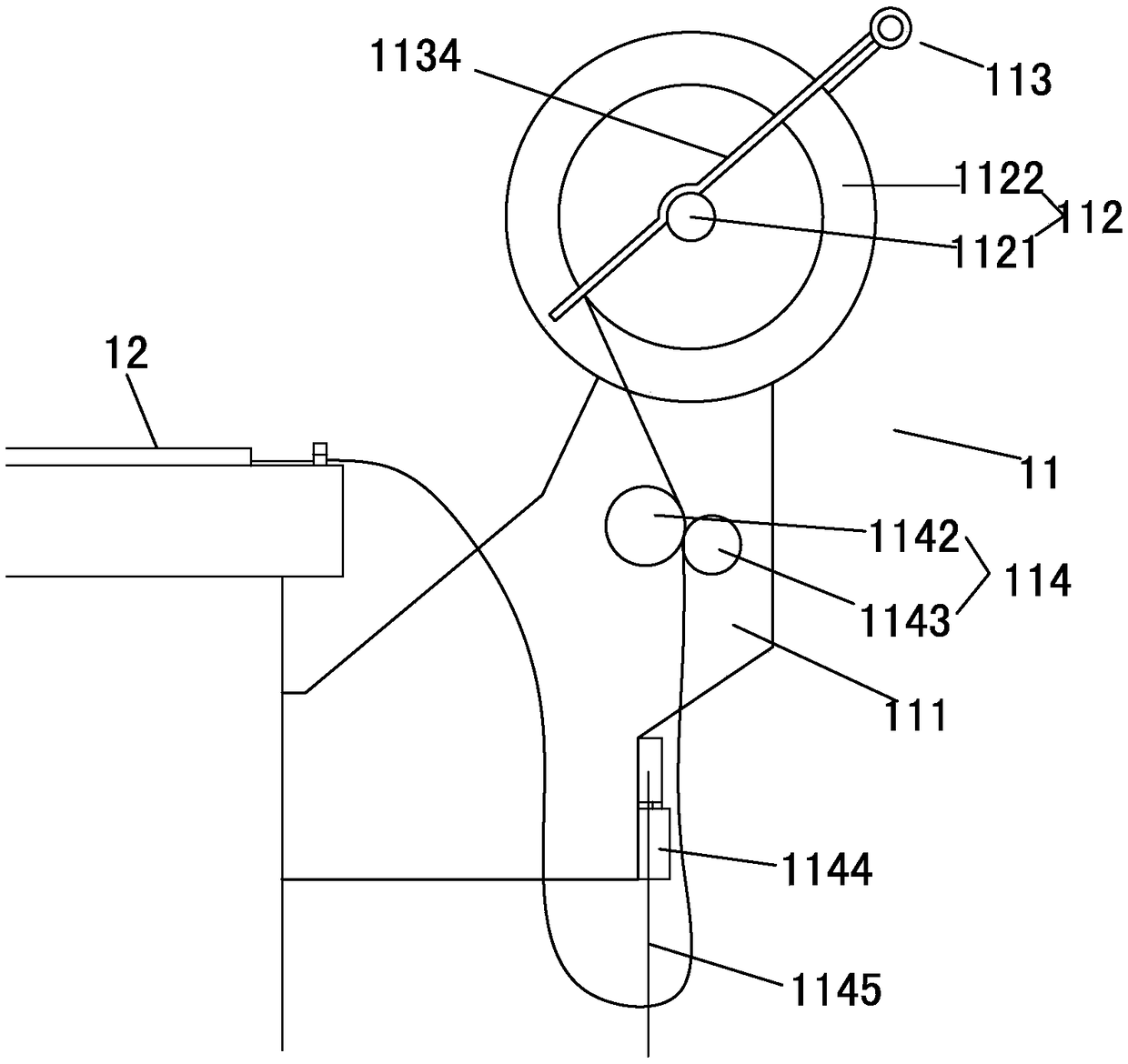

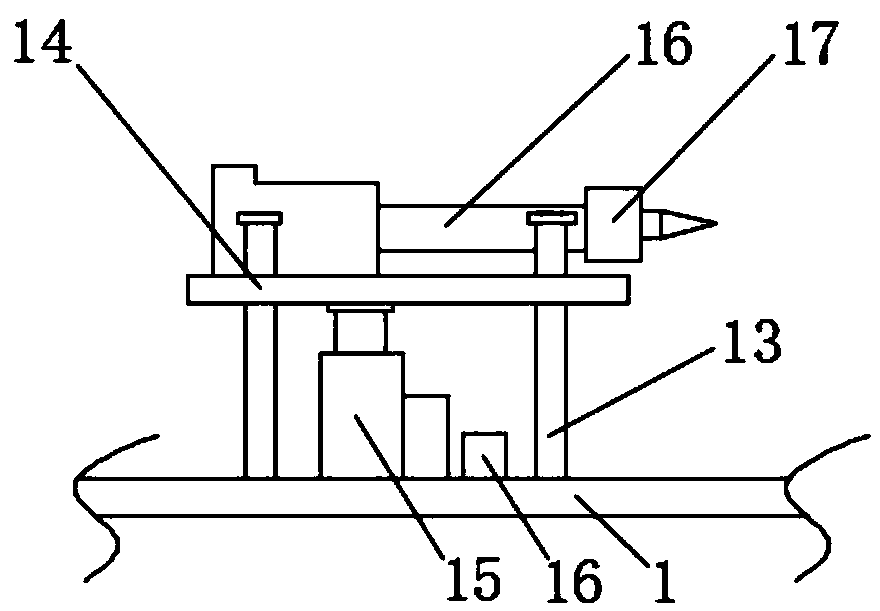

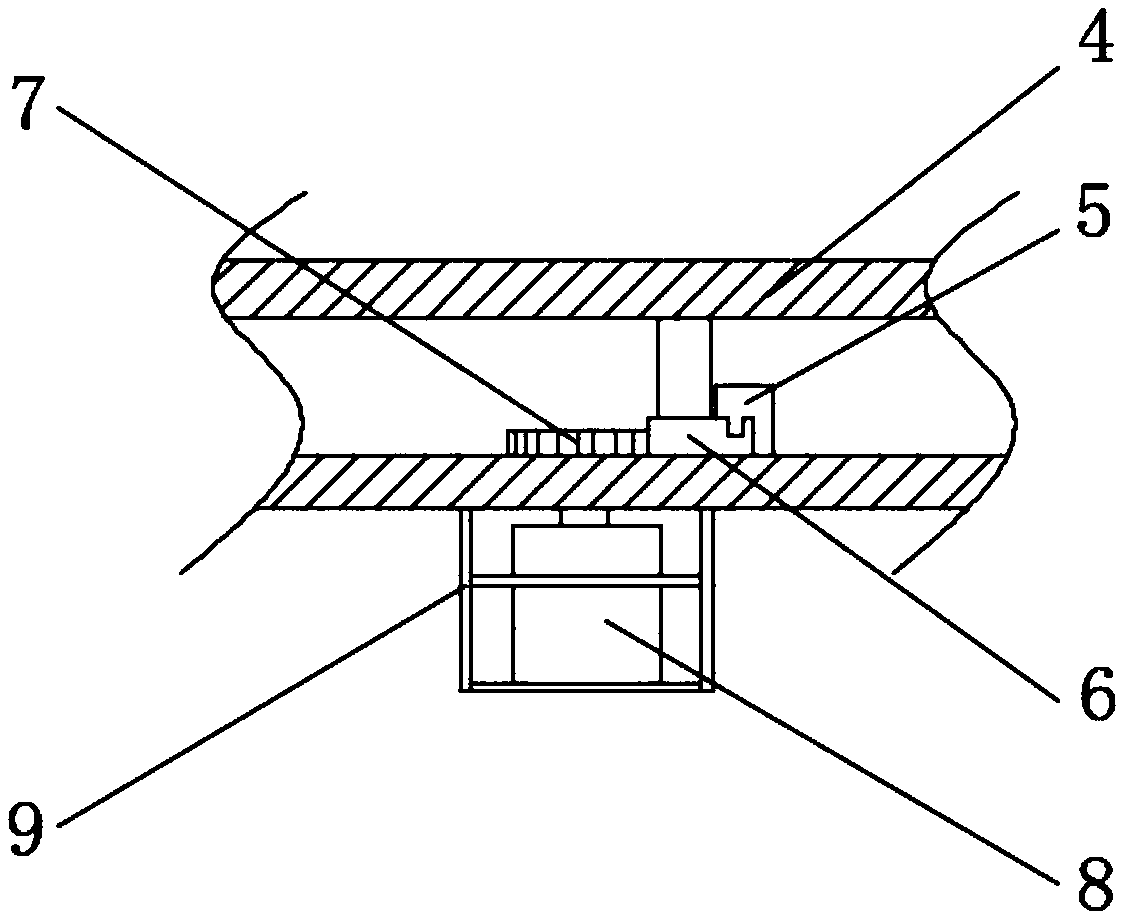

A special-shaped edging machine

ActiveCN105058210BImprove stabilityAccurate displacementEdge grinding machinesGrinding drivesProduction lineConveyor belt

The invention relates to an edge grinding machine for special-shaped articles. The edge grinding machine for the special-shaped articles comprises a machine frame, a feeding device, a taking device, two conveyor belts and one or more edge grinding devices, wherein the feeding device, the taking device, the conveyor belts and the edge grinding devices are arranged on the machine frame according to a production line. The articles are transferred between the feeding device and the conveyor belts through the taking device. The two conveyor belts are arranged on the front and rear sides of the machine frame respectively. A lifting air cylinder is arranged at the position, between the two conveyor belts, of the machine frame. An ejector rod is arranged on a piston rod of the lifting air cylinder in a rotating mode. A lower rotating disc supporting and holding the articles is arranged at the upper end of the ejector rod. Each edge grinding device comprises a support arranged on the machine frame, a rotating motor arranged on the support and located above the lower rotating disc and a grinding base arranged on the support in a vertically-sliding mode. A rotating shaft of each rotating motor is fixedly connected with an upper rotating disc which is used in cooperation with the lower rotating disc for clamping the articles. Each grinding base is provided with a sliding base in a horizontally-sliding mode. Each sliding base is provided with a grinding motor. Each grinding motor is in transmission connection with a grinding roller.

Owner:JINJIANG LIDA MACHINERY

Plate grinding device

InactiveCN107457638AReasonable structureEasy to useEdge grinding machinesGrinding carriagesEngineeringControl switch

The invention discloses a plate grinding device, comprising a workbench, a main body and a clamping seat, the workbench is fixedly installed on the upper end of the main body, the clamping seat is located The upper end is fixedly connected with a vacuum suction cup through the first air pressure rod, a control switch is installed on one side of the clamping seat, a chute is opened on the end surface of the workbench, and the inner cavity of the chute is slidably connected with a first lift Platform and the second lifting platform, the upper end surface of the first lifting platform is rotatably connected with support wheels, the upper end of the second lifting platform is fixedly equipped with a grinder, and the grinder includes a first grinding roller, a second grinding roller Rollers and troughs. The plate grinding device is reasonable in structure and easy to use, and is mainly used for edge grinding of circular plates, and has the advantages of high efficiency and high precision.

Owner:LIANGXI HAOXING IND DESIGN OFFICE

Double-station high-precision drilling robot of office chair

InactiveCN109333649AEasy to controlImprove stabilityMetal working apparatusElectric machineMeasuring instrument

The invention discloses a double-station high-precision drilling robot of an office chair. The double-station high-precision drilling robot comprises an operation platform and a connecting block, wherein a feeding groove is formed in the middle of the operation platform, a feeding device fixing frame is arranged on the rear side wall of the operation platform, sliding rods are symmetrically arranged on the feeding device fixing frame, one ends of the sliding rods are connected with the feeding device fixing frame, the other ends of the sliding rods are connected with the operation platform through a connecting rod, and one ends of the connecting blocks are in sliding connection with the sliding rods on the left side, so that accurate control on Y-axis displacement can be achieved through aservo motor and a first infrared distance measuring instrument; accurate control of the X-axis and Z-axis displacement of a perforating machine can be realized through a first electric push rod and asecond electric push rod; and a rack is driven by the servo motor to move, so that the stability is higher in the working process, the mechanical faults caused by overweight of clamped workpieces donot easily occur, and the drilling robot is suitable for drilling and processing of office chairs.

Owner:嘉善中佳电路板有限公司

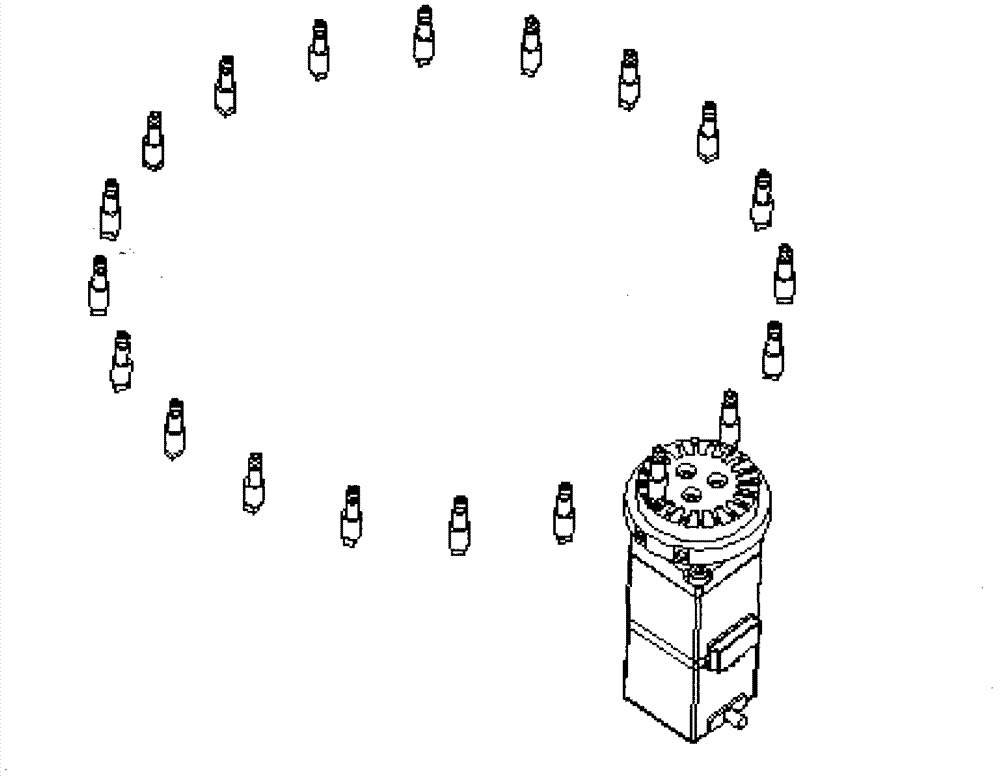

Ultrasonic cleaning machine used for production of LED lamp

InactiveCN109013511APrecise processSmall footprintCleaning using liquidsMegasonic cleaningEngineering

The invention provides an ultrasonic cleaning machine used for production of an LED lamp. The ultrasonic cleaning machine used for production of the LED lamp comprises a rotary lifting device, a cleaning device, a base and a control circuit. The rotary lifting device is composed of a motor base arranged on the base, a servo motor arranged on the motor base, a speed reducer connected with a spindleof the servo motor, an indexing turntable arranged on an output shaft of the speed reducer and a cable box arranged at the center of the indexing turntable. The structure that a synchronous electricpush rod is mounted on the indexing turntable to pull an LED lamp frame is adopted, so that common parallel working troughs are replaced by circularly-distributed working troughs; the indexing turntable is driven by the servo motor and the speed reducer jointly, so that the clear water spraying procedure, the ultrasonic cleaning procedure, the draining procedure and the air-drying procedure are conducted more accurately; the occupied area is small, and the structure is simple; and the LED lamp is driven by the indexing turntable to be transferred between the working troughs in the circumferential direction, so that a conveying belt or a horizontal moving mechanism is not needed anymore, and thus, mechanical faults are unlikely to happen.

Owner:TIANJIN TIANXING ELECTRONICS

Clutch system for automobile and automobile having same

Owner:GREAT WALL MOTOR CO LTD

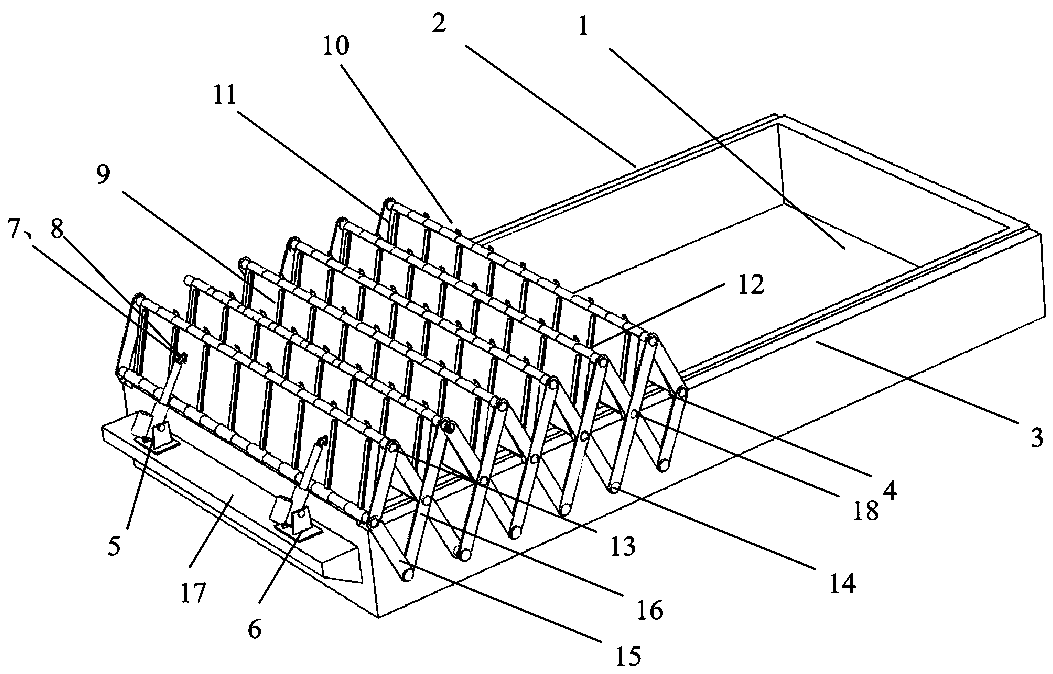

Automatic telescopic type sludge storage bin sealing cover plate device

ActiveCN111573033AEasy to operateSmooth motionLarge containersAgricultural engineeringStructural engineering

The invention discloses an automatic telescopic type sludge storage bin sealing cover plate device. The automatic telescopic type sludge storage bin sealing cover plate device comprises a sludge storage bin, a hydraulic transmission mechanism arranged on the upper part of the sludge storage bin and a telescopic cover plate mechanism, wherein the telescopic cover plate mechanism comprises travelling wheels, scissors forks, matched scissors forks, a steel cover plate, a matched steel cover plate, central shafts, upper central shafts and connecting shaft pins, the scissors forks and the matched scissors forks separately pass through the upper central shafts, the central shafts and the connecting pin rolls and then are connected to form a scissors fork structure; the steel cover plate and thematched steel cover plate are separately in matched connection to the scissors forks and the matched scissors forks; wheel rails are arranged on positions, along surfaces, of bin portions on the two side walls of the sludge storage bin; the travelling wheels are arranged among the scissors forks, the matched scissors forks, the steel cover plate and the matched steel cover plate; the hydraulic transmission mechanism is arranged at one end of the sludge storage bin; and after the hydraulic transmission mechanism is started, the scissors forks at the front end are stressed to move, so that the travelling wheels roll along the wheel rails, and therefore, the whole telescopic cover plate mechanism is driven to accomplish shrinkage and expansion motion.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com