Nozzle arrangement

A nozzle device and nozzle technology, applied in the direction of spraying device, spraying device, liquid spraying device, etc., can solve the problems of increasing operating costs, etc., and achieve the effect of improving operation rate and improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

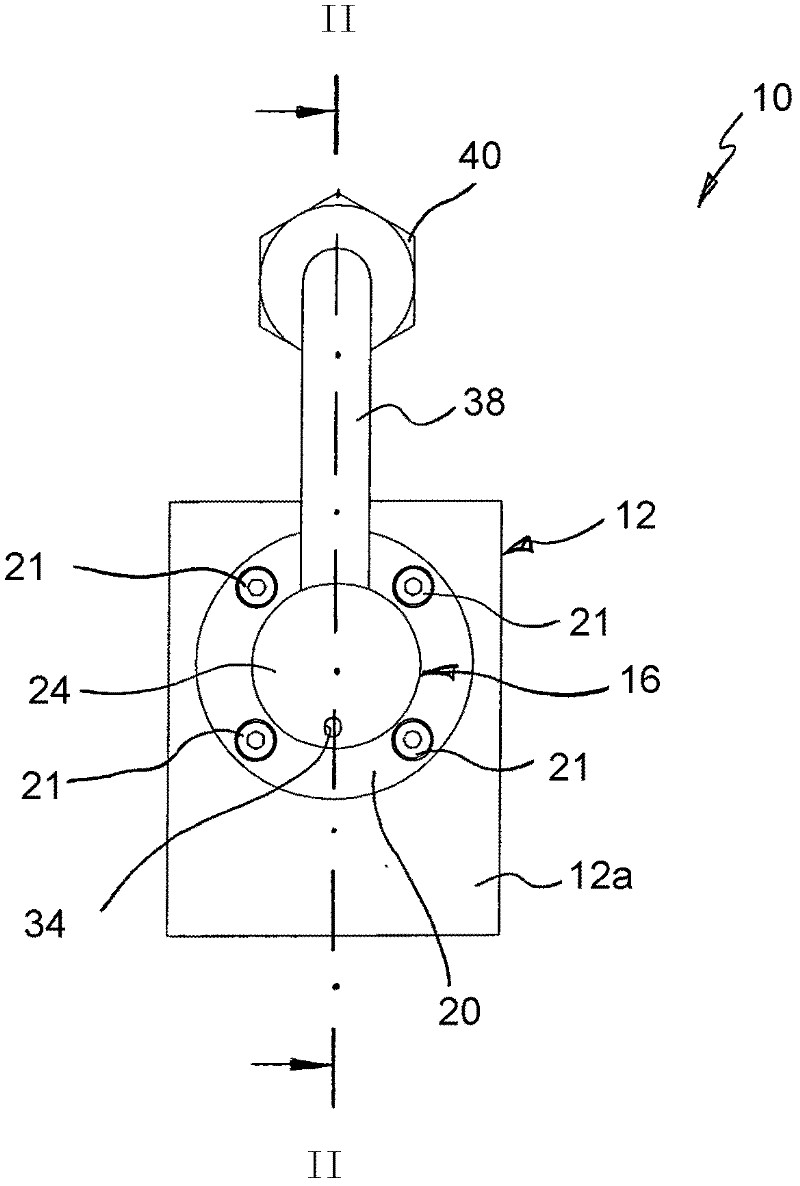

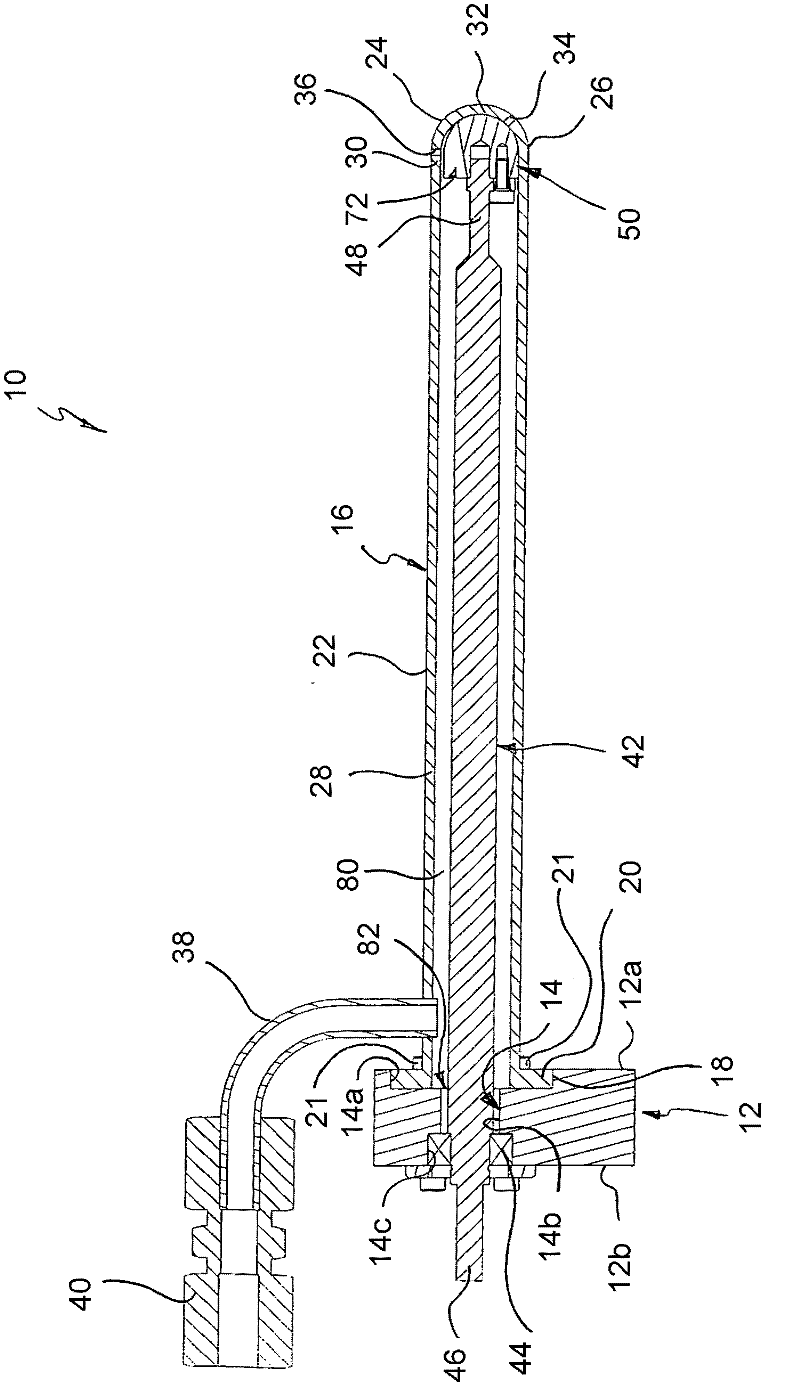

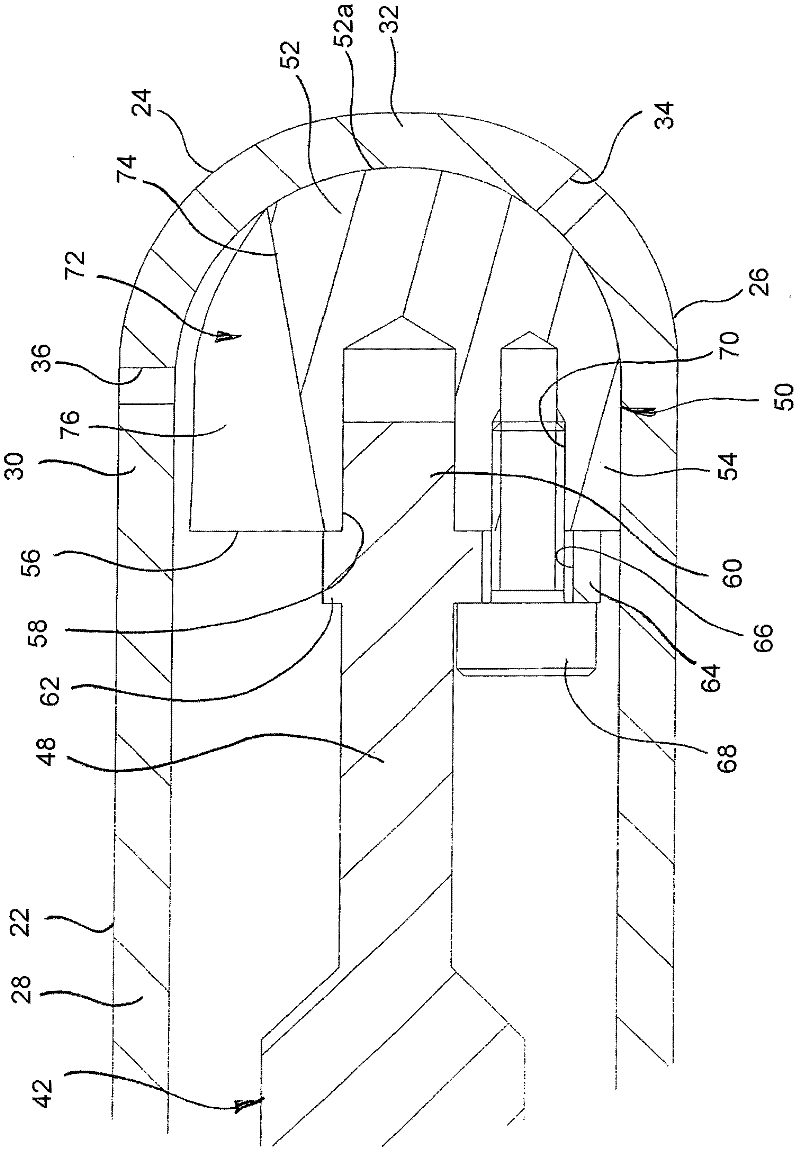

[0040] see first figure 1 with 2 , wherein 10 generally indicates a nozzle arrangement, by means of which anticorrosion wax can be sprayed into the cavity of the vehicle body.

[0041] The nozzle arrangement 10 comprises a support block 12 having two opposite and mutually parallel outer surfaces 12a, 12b. A stepped through hole 14 passes through the support block 12 perpendicular to the outer surface. From the outer surface 12a to the outer surface 12b, the through hole 14 comprises three sections 14a, 14b, 14c each having a circular cross-section, but they have different diameters, wherein the section 14a has the largest diameter and the middle section 14b has the smallest diameter. Diameter, segment 14c has a diameter in between.

[0042] The nozzle assembly 10 also includes a cylindrical lance 16 . The lance 16 has at its axially open fixed end 18 a fixing flange 20 extending in the peripheral direction. The fixing flange 20 fits in the section 14 a of the through hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com