Automatic telescopic type sludge storage bin sealing cover plate device

A technology of automatic expansion and sealing of cover plates, used in packaging, transportation, packaging, containers, etc., can solve the problems of occupying more space, limited sealing area, poor sealing performance, etc., to achieve mechanical failure, environmental adaptation. Strong and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

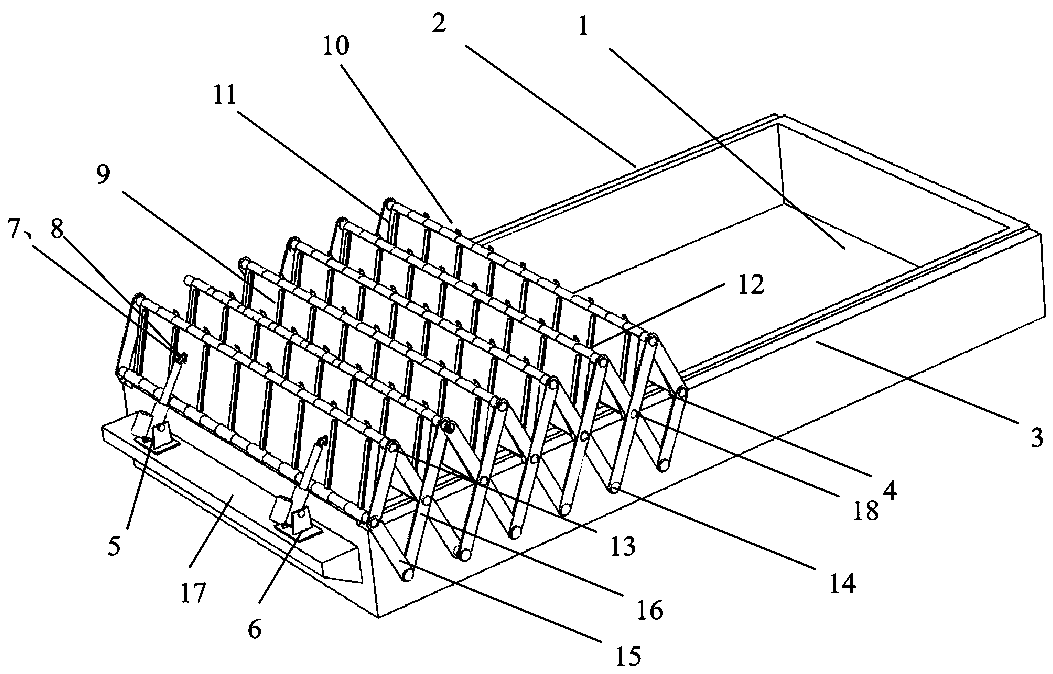

[0034] Such as figure 1 As shown, the automatic telescopic sludge storage bin sealing cover device of an embodiment of the present invention includes a sludge storage bin 1 and a hydraulic transmission mechanism and a telescopic cover plate mechanism arranged on the upper part of the sludge storage bin 1;

[0035] The telescopic cover plate mechanism includes traveling wheels 4, a scissor structure and a cover plate structure, the scissor structure is arranged on the two side walls of the sludge storage bin 1, the cover plate structure is arranged on the scissor structure and After the fork structure is fully unfolded, it covers the mouth of the sludge storage bin 1. The walking wheels 4 are arranged on the scissor structure. The wheels 4 are placed on the wheel track 3 on the top of the sludge storage bin 1; the hydraulic transmission mechanism is arranged at one end of the sludge storage bin 1 and drives the scissor structure to perform scissor movement. After the hydraulic ...

Embodiment 2

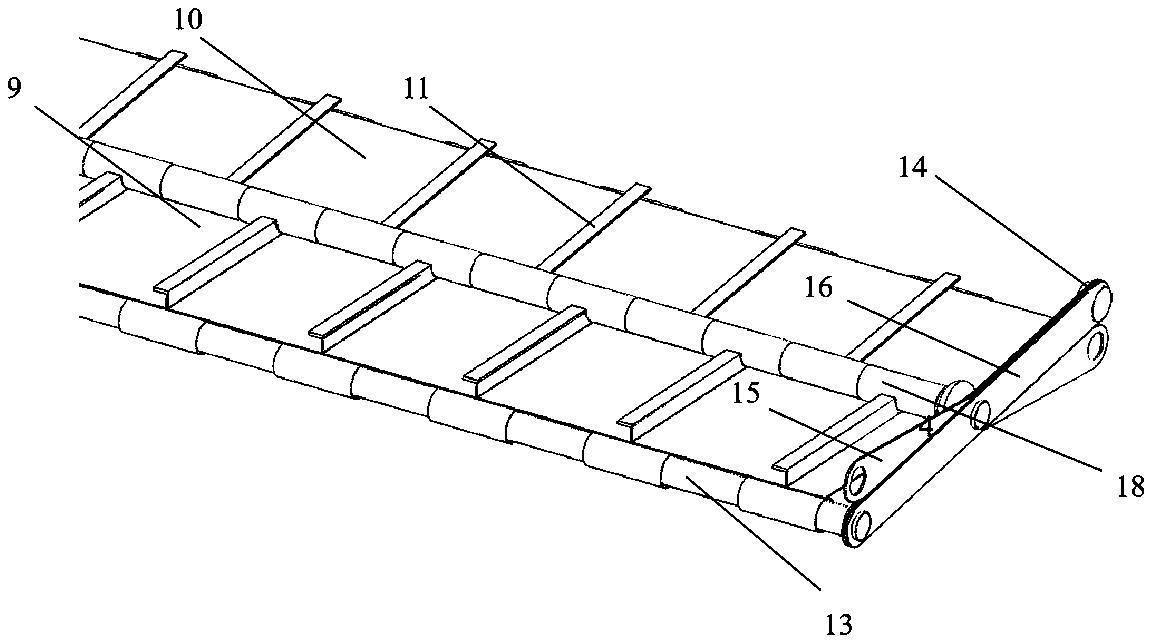

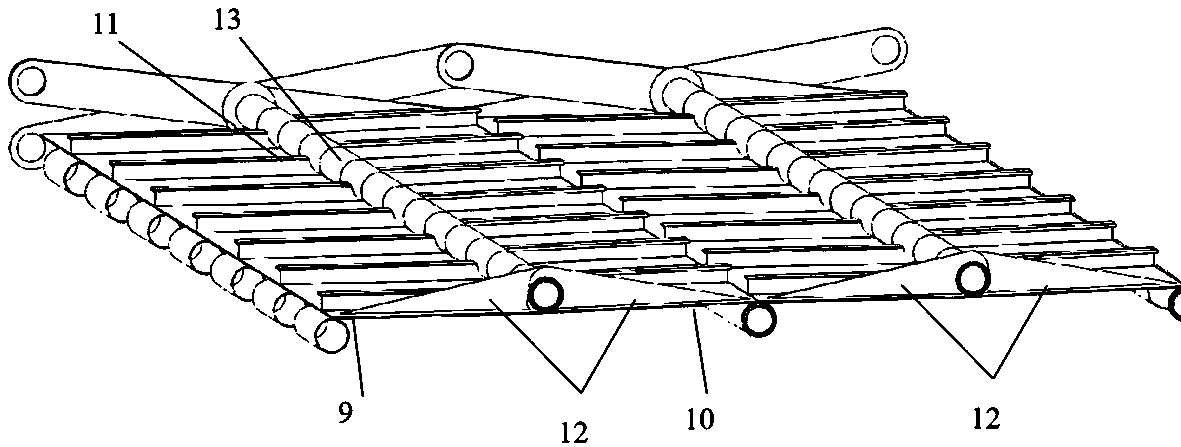

[0038] Such as Figure 1-5 As shown, the automatic retractable sludge storage bin sealing cover device of the above-mentioned embodiment of the present invention can also be described in detail as follows. The upper, middle and lower parts of 16 are respectively connected by the upper central shaft 13, the central shaft 18 and the connecting pin shaft 14 to form a scissor structure, and the upper central shaft 13, the central shaft 18 straddle the two Between the side walls, the cover plate structure includes a steel cover plate 9 and a matching steel cover plate 10, the steel cover plate 9 and the matching steel cover plate 10 are respectively connected with the scissors fork 15 and the pairing scissors fork 16, and the steel cover plate 9 and the matching steel cover plate 10 are connected with the upper central shaft 13 to form a hinge structure, and the bottom of the steel cover plate 9 and the matching steel cover plate 10 are connected with the central shaft 18; Fork 16...

Embodiment 3

[0041] Such as Figure 1-5 As shown, the automatic retractable sludge storage bin sealing cover device of the above-mentioned embodiment of the present invention can also be improved as follows, and also includes a top sealing device, and the top sealing device includes The warehouse roof rubber contact plate 2 along the surface of the wall, the roof rubber contact plate 2 is located on both sides of the wheel track 3, and the steel cover plate 9 and the matching steel cover plate 10 are tiled to the warehouse roof rubber when fully unfolded. The contact plate 2 is compacted. When the sludge storage bin 1 is in the closed state, the steel cover plate 9 on the telescopic cover plate mechanism is attached to the rubber contact plate 2 on the top of the bin, so as to realize the sealed state when the sludge storage bin 1 is closed. , Effectively realize the sealing of the sludge bin body, and isolate harmful substances such as odor and dust.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com