Electromagnetic reverse heat sealing machine

A sealing machine and electromagnetic technology, applied in packaging sealing/fastening, external support, transportation packaging, etc., can solve the problems of high noise, high failure rate, complex structure, etc., and achieve the effect of low noise, stable operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

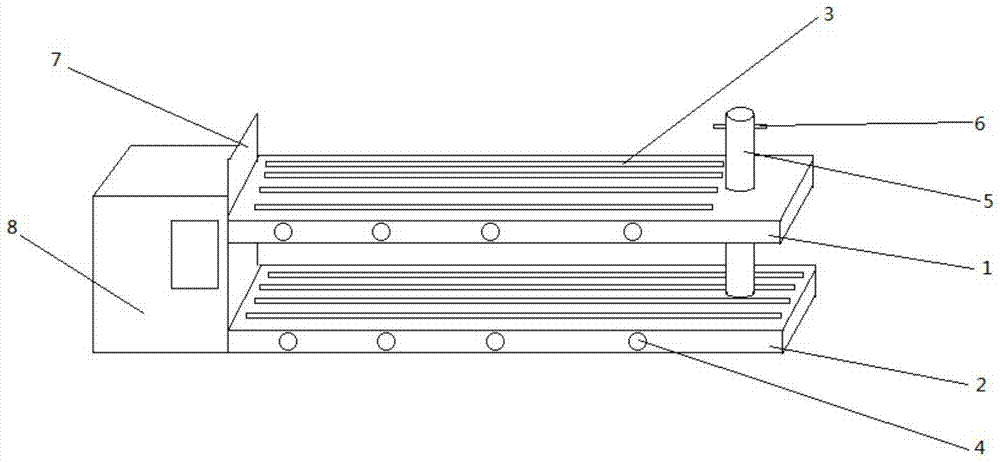

[0013] An electromagnetic reverse hot-press sealing machine, comprising an upper hot-press plate 1, a lower hot-press plate 2, a sliding support 5, a limit rod 6, an electromagnet 4, a heating rod 3, a slide rail plate 7, and a reverse transformer 8, The lower heat pressing plate 2 is fixed on the lower end of the slide rail plate 7, and the upper heat pressing plate 1 is installed in the slide rail of the slide rail plate 7, and is relatively parallel to the lower heat pressing plate 2, and can move up and down along the slide rail plate 7. The electromagnet 4 is installed in the hot pressing plate 1 and the lower hot pressing plate 2, the heating rod 3 is installed on the opposite surface of the upper hot pressing plate 1 and the lower hot pressing plate 2, the slide rail plate 7 is connected with the reverse transformer 8, and the sliding support 5 One end is fixed on the lower heat press plate 2, and passes through the upper heat press plate 1, and the other end of the slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com