Rear pull rotary crossing-over frame

A cross-frame, rotating technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of increased workload of construction personnel, unstable power output process, long construction time, etc., to avoid repeated adjustment work, stable recovery process, The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the present invention, the content of the present invention will be further described below in conjunction with the accompanying drawings and examples.

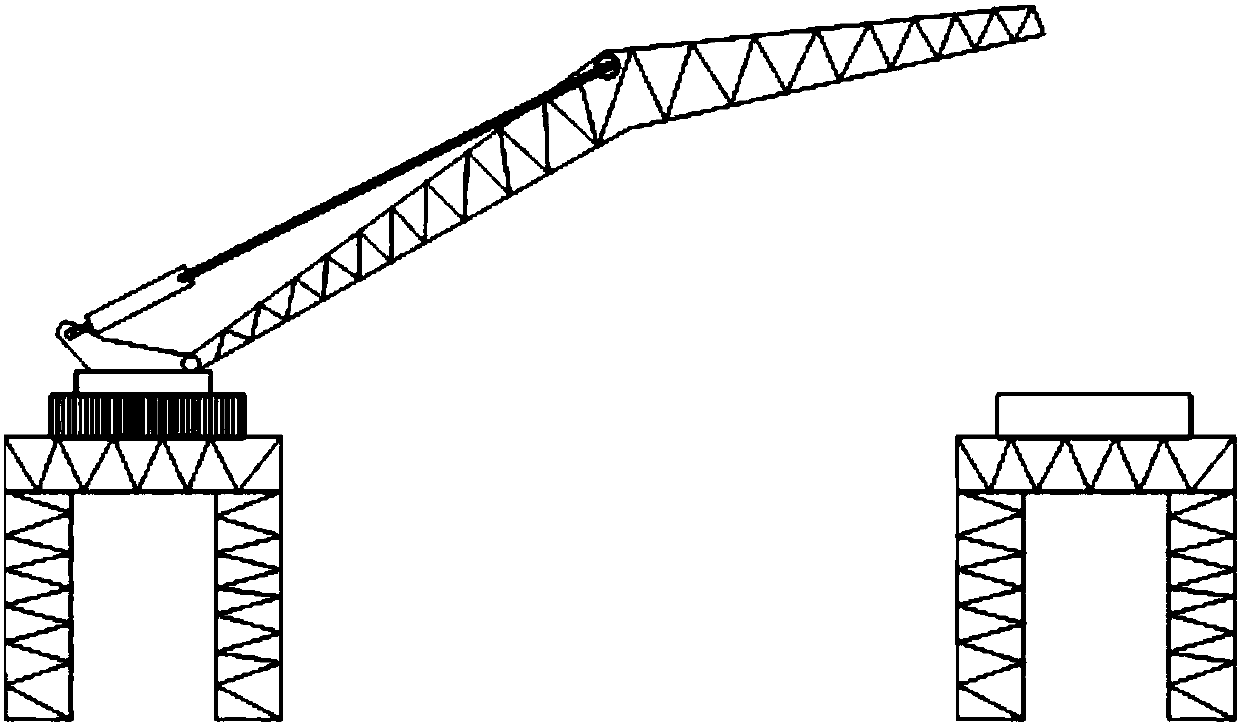

[0025] Such as figure 1 As shown, it is a schematic diagram of overlapping of the back-pull rotating span frame provided by the present invention. In the initial installation state, the back-pull hydraulic cylinder 3 is used to raise the net-sealing arm 4 along the direction of the object to be spanned, and the rotating platform 2 is rotated to the spanning direction, and then the back-pull hydraulic cylinder 3 is used to adjust the raising of the net-sealing arm 4 The angle is overlapped to the support platform 6 on the opposite side. The installation process is realized through the rotating platform and the back-pull hydraulic cylinder, which avoids the way of docking on both sides, prevents uneven docking, and ensures the sealing time.

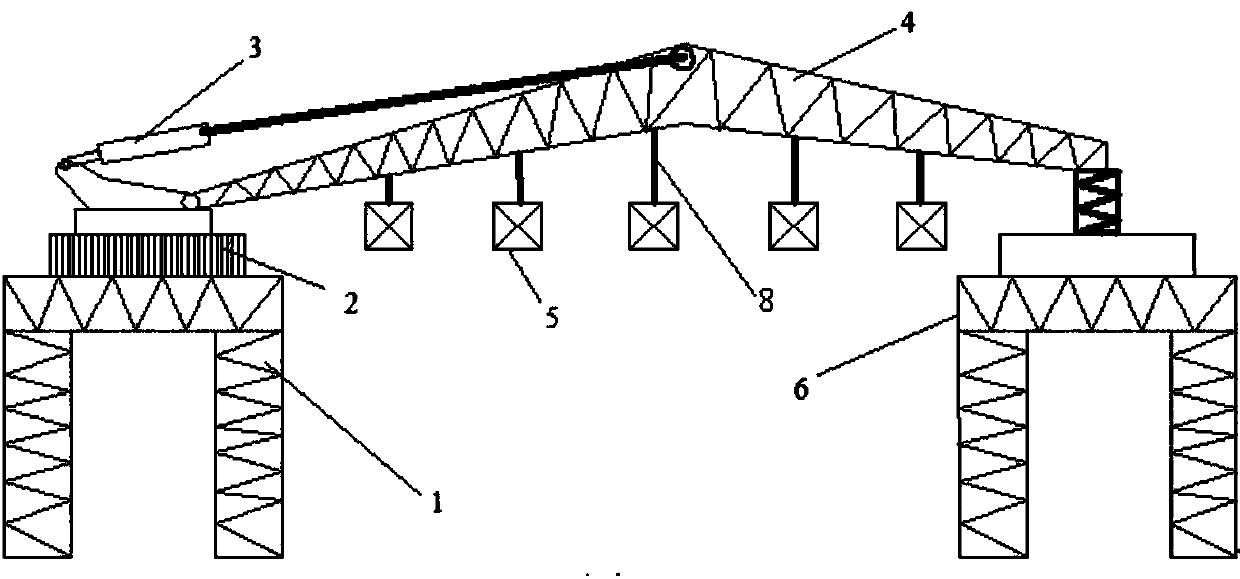

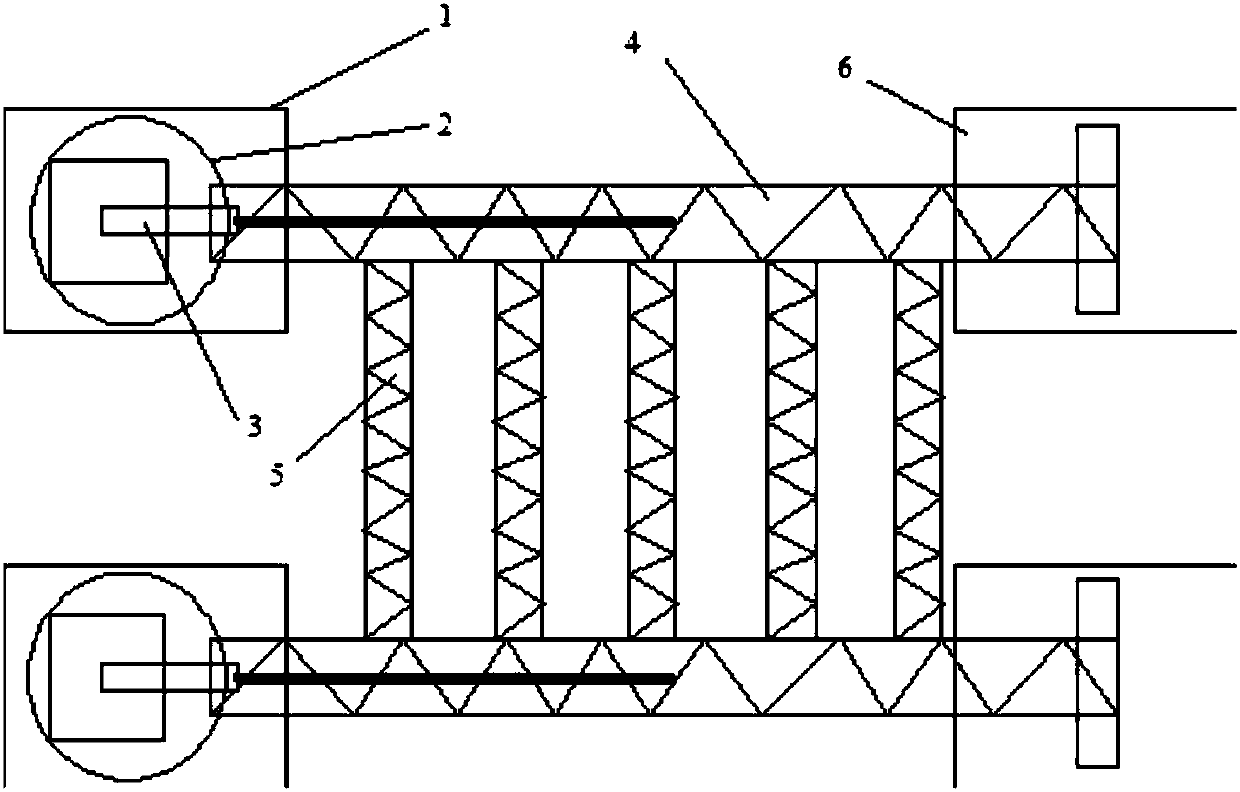

[0026] Such as Figure 2~3 As shown, it is a sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com