Flexible portal blanking machine

A flexible and blanking technology, which is applied in the direction of presses, metal processing, manufacturing tools, etc., can solve the problems of poor stability, cumbersome operation, difficult to place stably, etc., and achieve mechanical failure, wide application range, and convenient material cutting. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

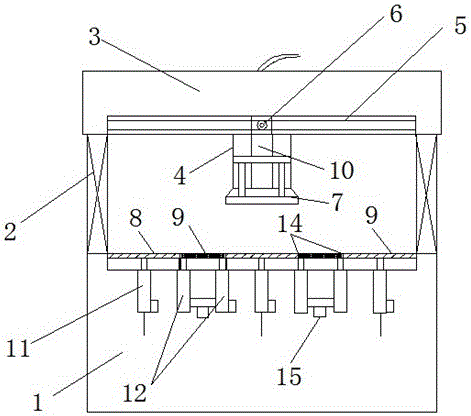

[0014] Embodiment 1: as figure 1 and 2 A flexible gantry blanking machine is shown, the gantry blanking machine includes a frame base 1, a support frame 2, a position adjustment bracket 3, a blanking die head 4 and a feeding mechanism, and the position adjustment The bracket 3 is fixedly installed on the top of the frame base 1 through two support frames 2, the bottom of the position adjustment bracket 3 is provided with a transverse slide rail 5, and the blanking die head 4 is movably installed through the driving roller 6 on the top On the horizontal slide rail 5, the top of the frame base 1 is provided with a horizontal support platform, and the horizontal support platform is composed of a plurality of horizontal platforms 8 and an adjustable platform 9, and the adjustable platform 9 is installed on the horizontal platform. 8, the bottom of the horizontal platform 8 is provided with a single hydraulic jack 11, and the bottom of the adjustable platform 9 is provided with tw...

Embodiment 2

[0015] Embodiment 2: as figure 1 and 2 As shown, the hydraulic ejector 11 or 12 at the bottom of the horizontal platform 8 and the adjustable platform 9 is provided with a displacement detector 15, and the displacement detector 15 is connected to the control system through a control line; centralized control by the control system The working height of each hydraulic ejector rod 11 or 12 makes the horizontal platform 8 and the adjustable platform 9 fixed at different working heights to meet the working requirements of different shaped materials or molds.

Embodiment 3

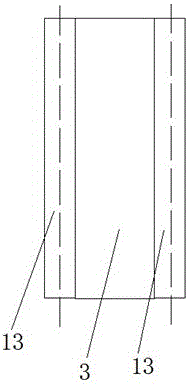

[0016] Embodiment 3: as figure 1 and 2 As shown, the feeding mechanism is composed of two feeding rollers 13, and the two feeding rollers 13 are respectively installed on both sides of the frame base 1; the feeding and discharging work is respectively completed through the feeding rollers 13 on both sides, which is convenient Streamlined production of enterprises.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com