Full-automatic cutting edging machine for clothing trademarks

A fully automatic, folding machine technology, applied in the cutting of textile materials, textiles and papermaking, fabric surface trimming, etc., can solve the problems of irregular manual cutting, time-consuming, sewing distortion, etc., to improve sewing efficiency and sewing quality , Reduce human labor, improve the effect of cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

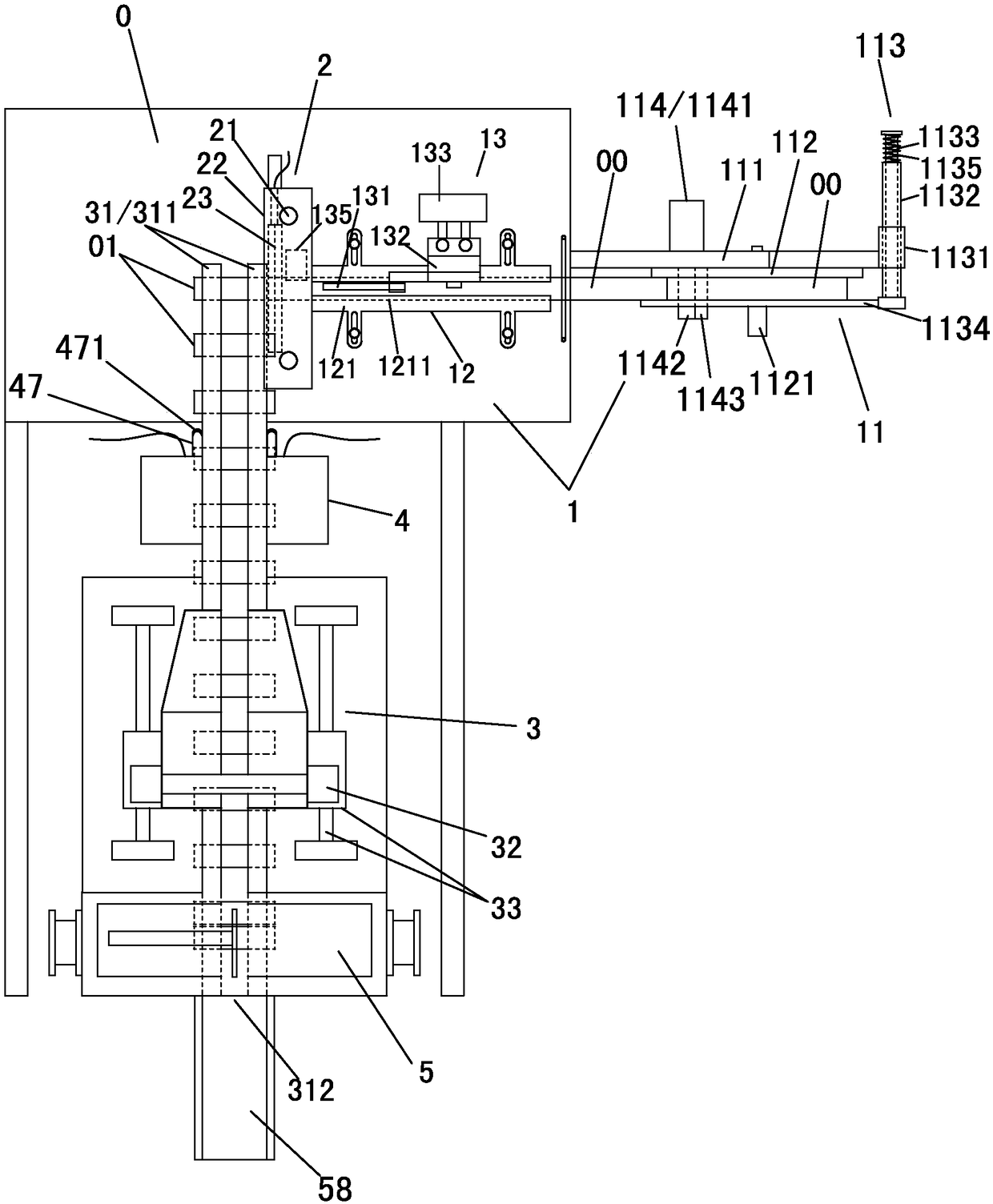

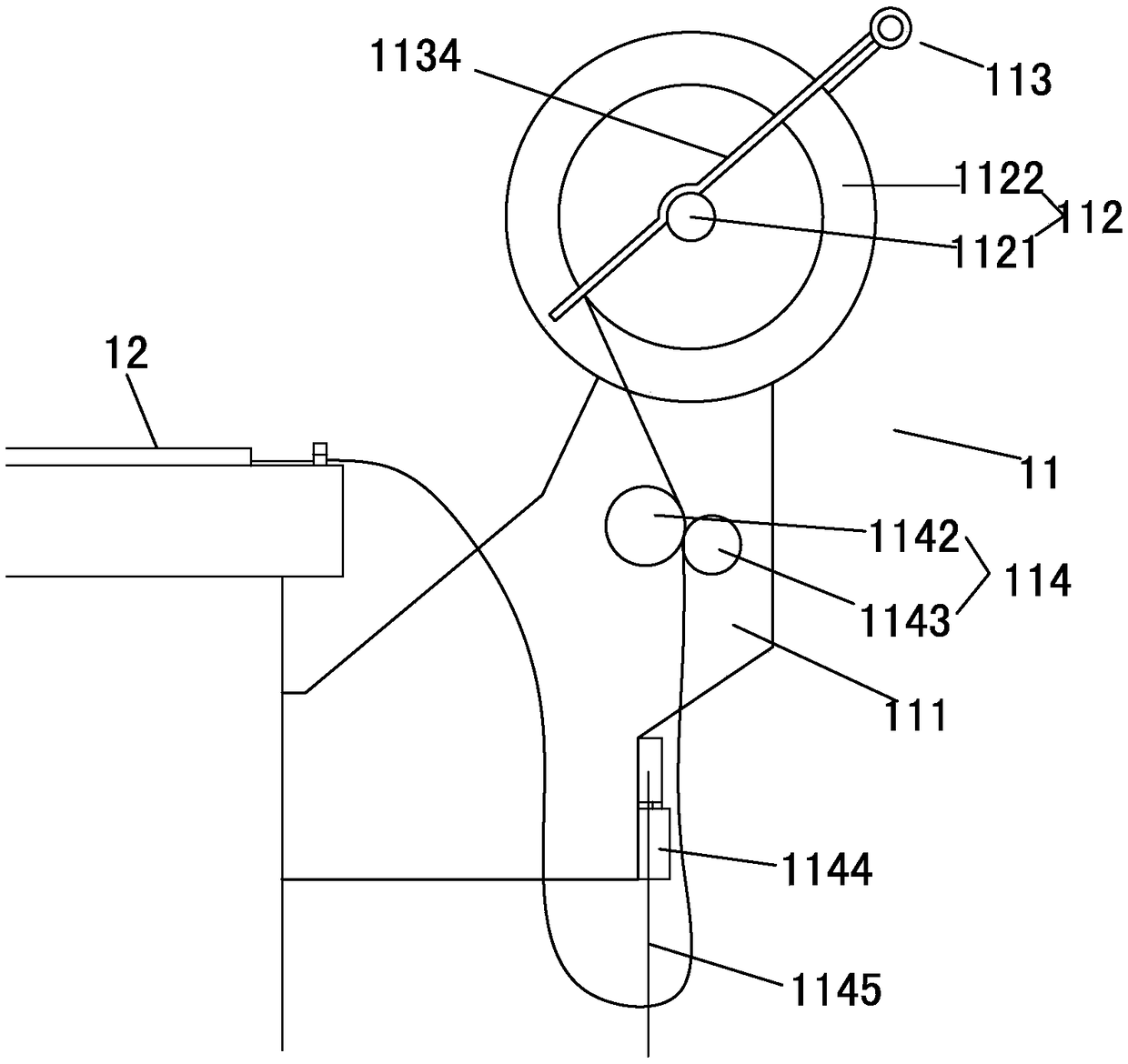

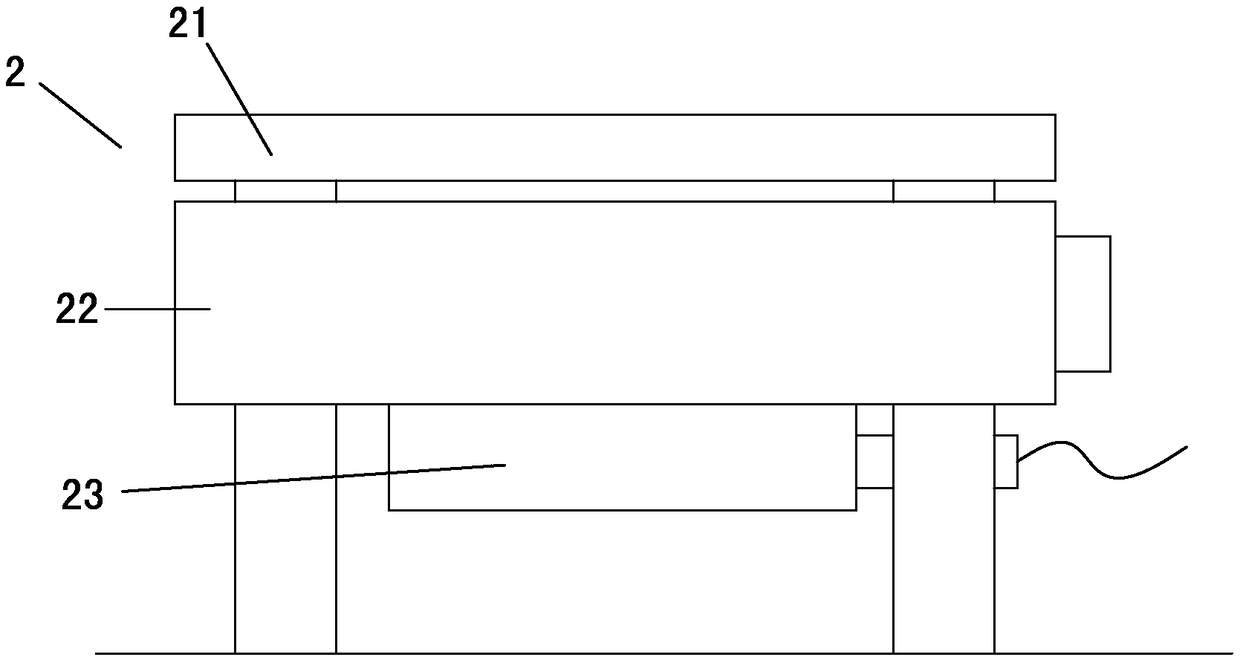

[0049] The fully automatic garment trademark cutting and folding machine disclosed by the present invention, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, it includes a machine base 0 and a roll feeding device 1, a cutting device 2, a pressing device 3, a hemming device 4, a stacking device 5 and a control system (not shown in the figure) arranged on the machine base 0. The roll-feeding device 1 is used to transport the rolled clothing trademark tape 00 to the cutting device 2, and the cutting device 2 is used to cut the clothing trademark tape 00 into sections, and the pressure feeding device 3 is used to cut the clothing trademark tape 00 into sections. The clothing trademark 01 cut into sections is transported to the hemming d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com