Pipe fitting pressing sleeve perforating machine and using method thereof

A technology of pressing sleeve and punching machine, applied in the direction of boring/drilling, drilling/drilling equipment, parts of boring machine/drilling machine, etc. Reliability requirements, avoidance of control devices, effect of ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

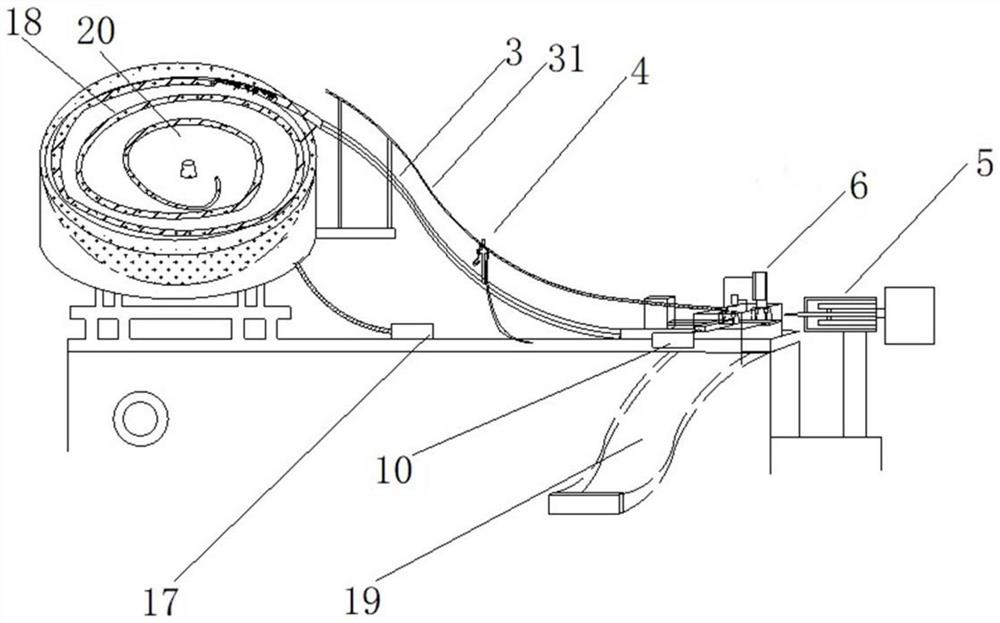

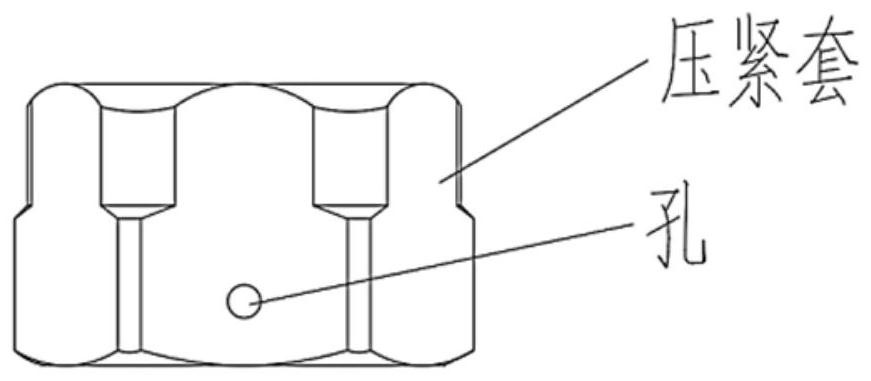

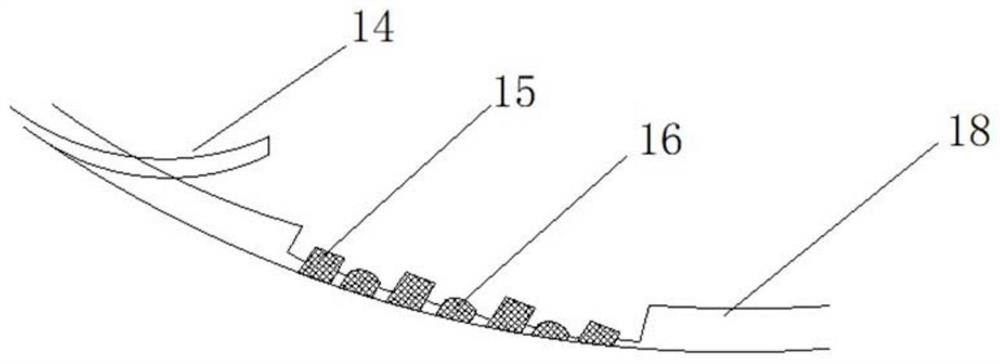

[0051] Embodiment 1. The pipe fitting compression sleeve punching machine is used for automatic feeding and punching of the compression sleeve used for bellows joints. The compression sleeve is a nut type hardware, such as figure 2 As shown, the inner diameter of the top surface is D 1 , the inner diameter of the bottom surface is D 2 , the outer diameter is D, the height is H, and H1 2 , the pipe fitting compression sleeve punching machine includes a compression sleeve feeding vibration plate, a compression sleeve screening mechanism, a feeding mechanism and a compression punching device; the vibration plate technology used in the compression sleeve feeding vibration plate includes a conical hopper 20. Pulse electromagnet 17, spiral track 18, spiral track 18 is arranged spirally along the inner wall of the conical hopper 20, the width of the spiral track 18 is slightly larger than the outer diameter of the compression sleeve, and a compression sleeve is provided on the spira...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com