A segmented sealing high pressure sealing member

A technology of high pressure bearing and sealing glass, which is applied in the direction of weapon accessories, offensive equipment, blasting barrels, etc., can solve the problems of structural damage, poor sealing performance, and increased product weight, and achieve a high degree of miniaturization and light weight. Sealing and pressure-bearing properties, the effect of ensuring safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and preferred embodiments.

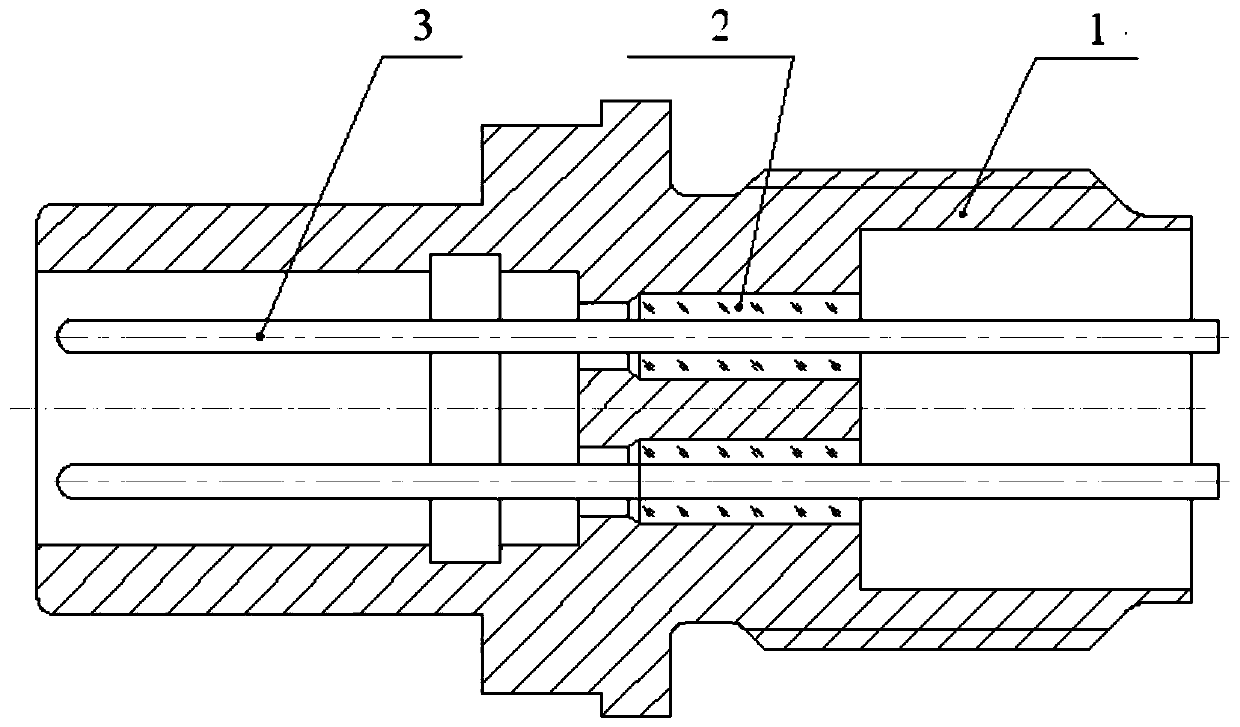

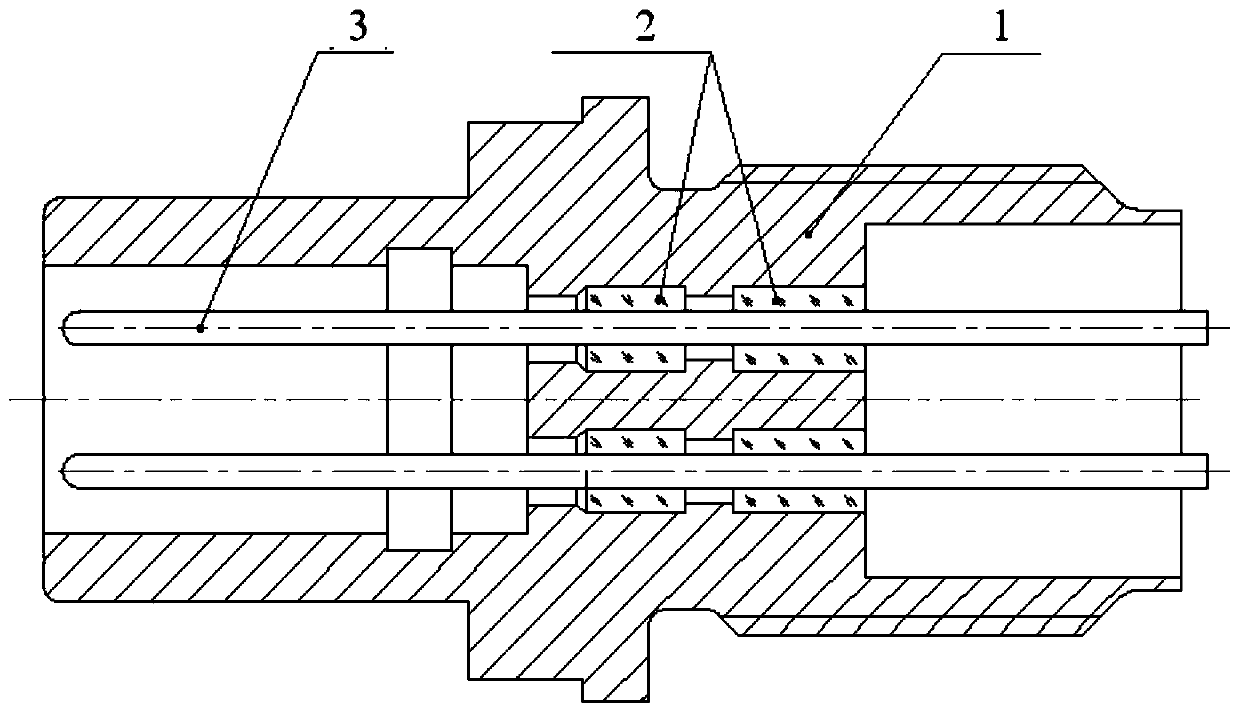

[0023] The invention provides a section-sealed high-pressure-bearing sealing piece, which is applied to an electric detonator outputting detonation. The structure of the sealed component is as follows figure 2 As shown, it consists of housing 1, sealing glass 2, and pin 3.

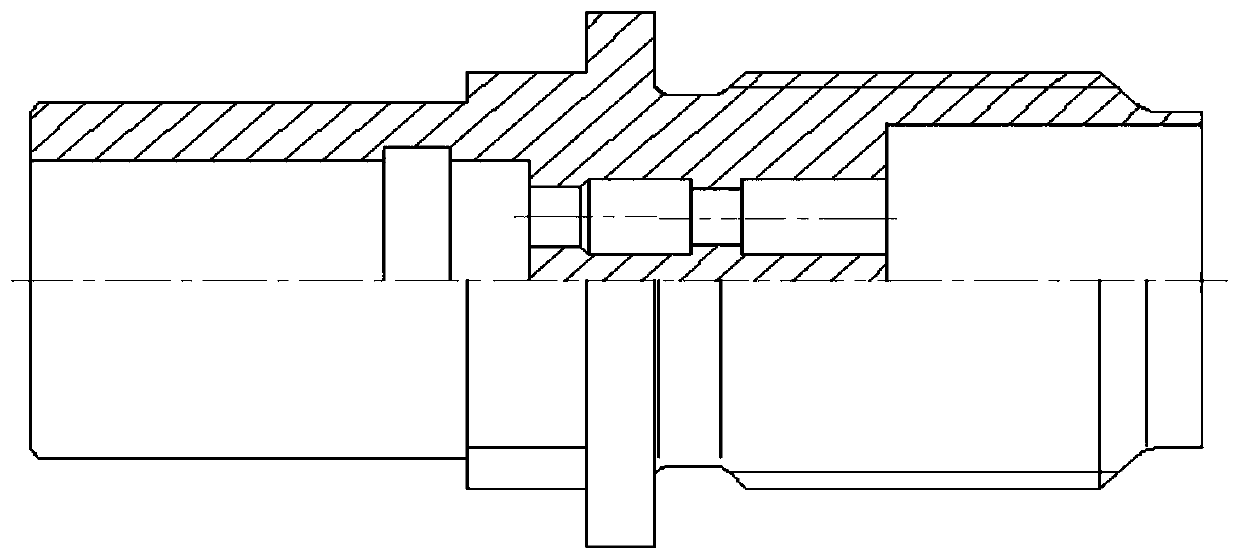

[0024] The shell structure is as image 3 As shown, the shell material is 12Cr18Ni9. This material has the characteristics of high strength and environmental adaptability. When it is subjected to high temperature and high pressure gas, it can ensure the integrity of the structure. A boss is designed in the through hole of the shell to facilitate the control of sealing. The end face and the pressure bearing capacity are improved. The linear expansion coefficient of this shell material is larger than that of glass, and it has good wettability with glass.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com