Nut assembling machine and using method

A technology for assembly machines and nuts, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of low production efficiency, reduced precision, low efficiency, etc., to avoid danger and inefficiency, and ensure reliability Requirements, effects of technology maturity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

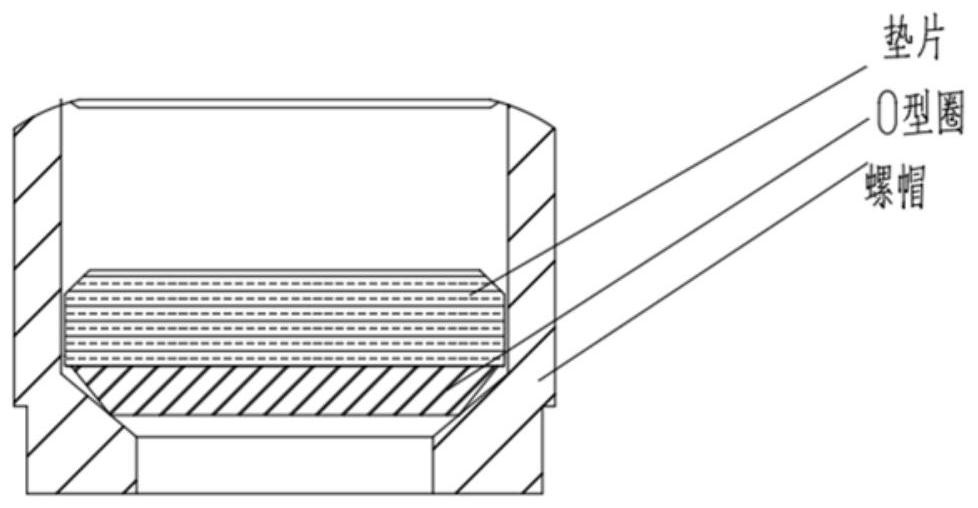

[0075] Embodiment 1. The nut assembly machine is used to assemble the O-ring and gasket into the inner hole of the nut. The effect of the assembly is as follows figure 2 As shown, the outer diameter of the nut is D, and the inner diameter of the bottom is R 1 , the inner diameter of the top and bottom is R 2 , the height is H, and satisfies H>D, R 1 2 ; The O-ring is a plastic frustum-shaped ring, that is, the outer diameter of the bottom is larger than the outer diameter of the top. When installing, the end with the smaller diameter needs to be put down into the inner hole of the nut; the gasket is a rubber ring. The inner diameters of the O-ring and the gasket are both R;

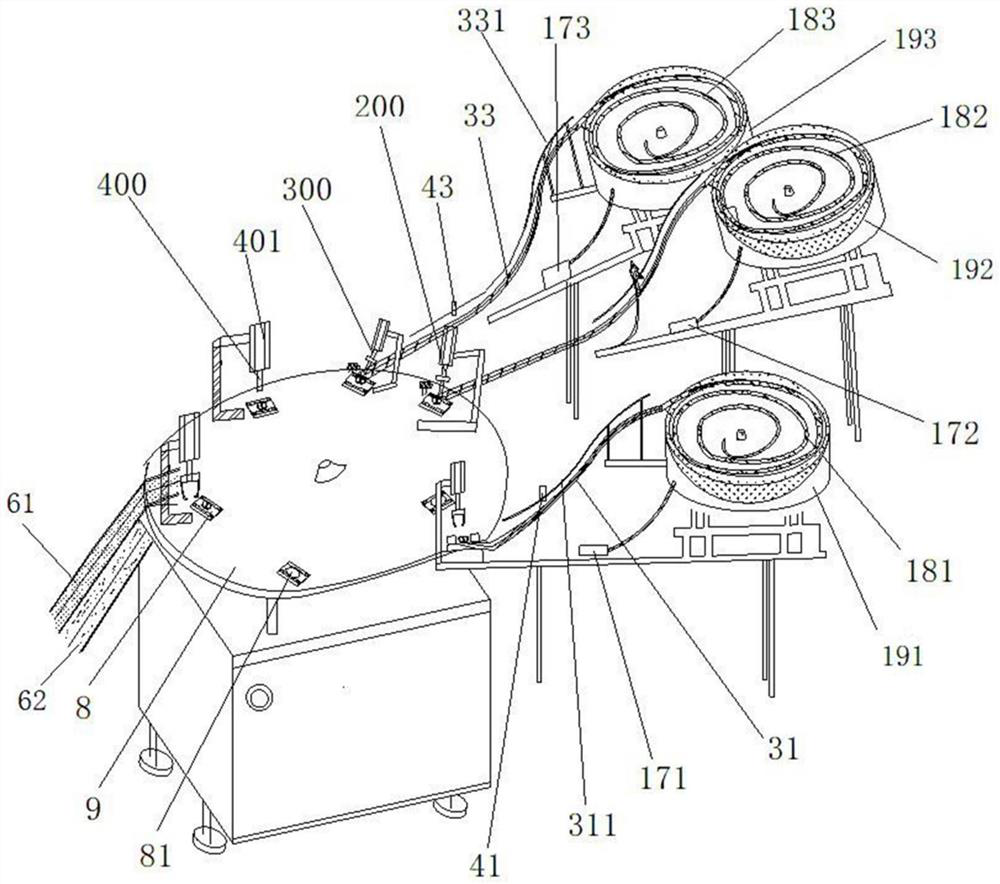

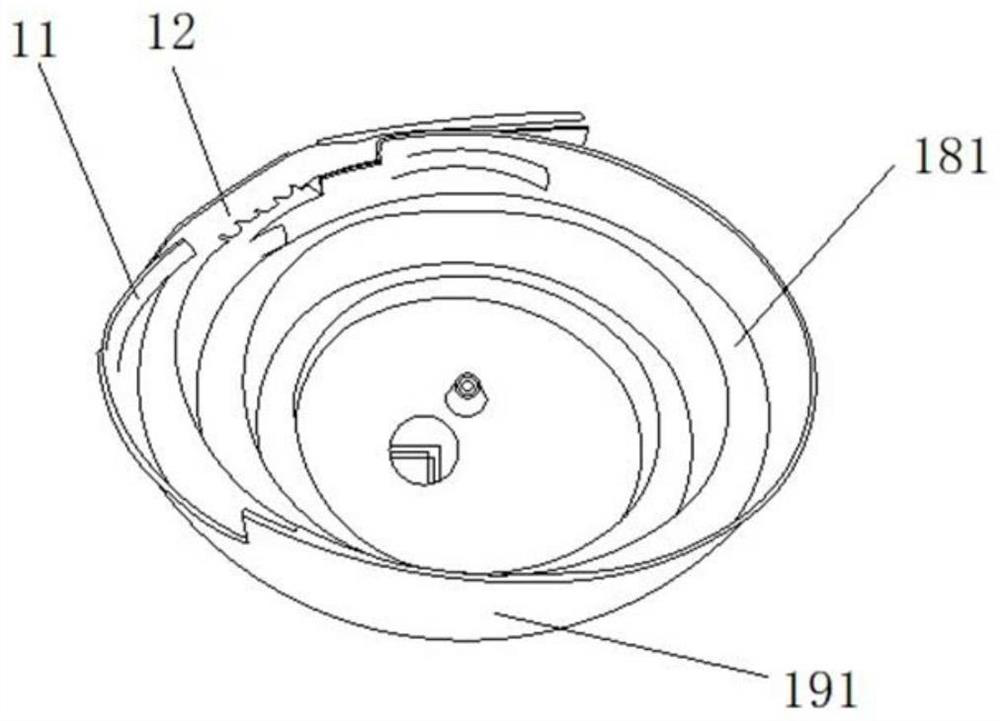

[0076] The nut assembly machine includes a nut feeding mechanism, an O-ring feeding mechanism, a gasket feeding mechanism and an assembly turntable 9, such as Figure 1-7 As shown, the assembly turntable 9 includes a circular turntable driven by a motor. On the assembly turntable 9, six stations are e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com