Method and device for rapid entry and exit of solid materials in high-pressure containers

A technology for high-pressure containers and materials, which is applied in the field of fast entry and exit of solid materials in high-pressure containers, and can solve the problems of inconvenient use, complex mechanism, and high power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The method and device for rapid entry and exit of solid materials in high-pressure containers disclosed by the invention can be used in intermittent steam explosion tanks.

[0030]Steam explosion technology, referred to as steam explosion technology, is a method of using saturated steam at high temperature and high pressure to process raw materials such as biomass. These raw materials are placed in a high-pressure container, saturated steam is introduced to a certain pressure and maintained for a period of time, and then the high pressure is quickly released. The valve of the container opens to burst the material. The steam explosion pots currently used are basically intermittent. The intermittent small steam explosion pots are mostly installed with high-pressure ball valves at both ends of a cylinder, one for feeding and one for discharging, while the production type intermittent The structure adopted by the steam explosion tank is mostly a cylindrical tank body with b...

Embodiment 2

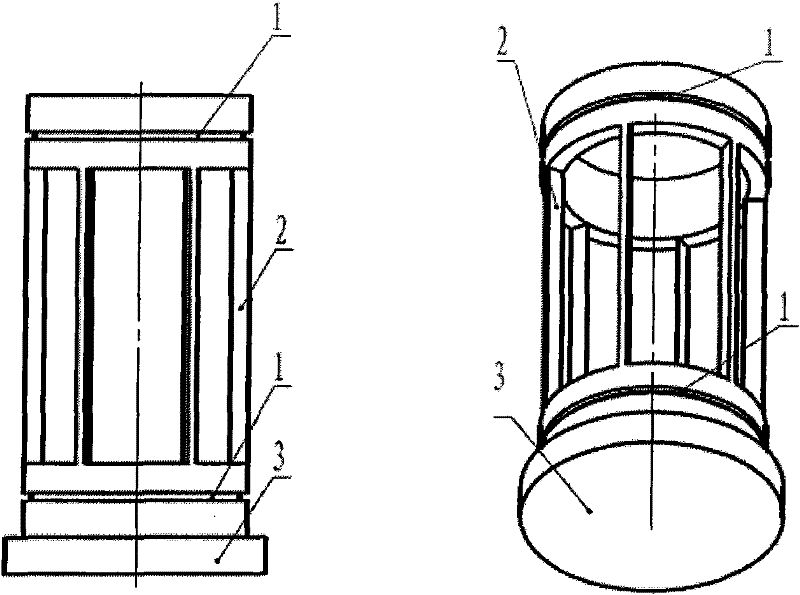

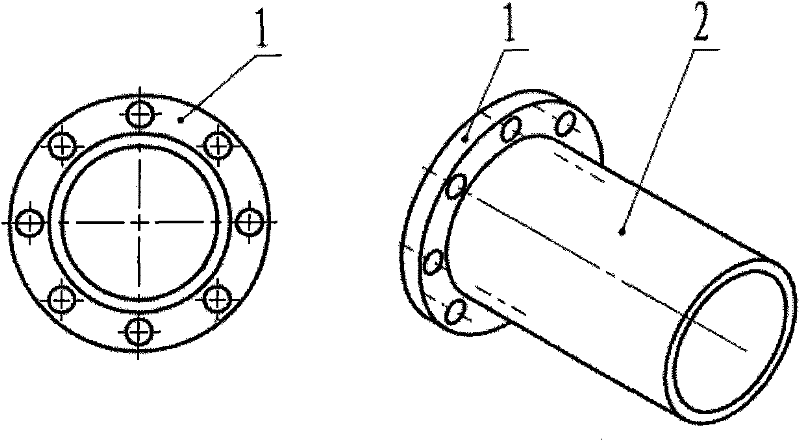

[0033] When the present invention is used in the intermittent steam explosion tank, the following configuration can also be adopted, the tank body is 10m 3 , the height-to-diameter ratio is 3.5:1, the inlet valve adopts an inverted V-type inlet valve, the diameter of the inlet cylinder is selected as 300mm, the outlet valve adopts a lantern-type outlet valve, and the number of pillars of the inner core structure of the outlet valve is selected For 4.

Embodiment 3

[0035] The method and device for quickly entering and exiting solid materials in a high-pressure container disclosed by the invention can be used in a solid material steaming tank. The cooking of solid materials is widely used in the brewing industry. For example, the materials of solid-state fermentation liquor generally need to be cooked for 1-2 hours before entering the cellar. The traditional cooking method mostly uses atmospheric pressure cooking, which takes longer time and consumes less energy. High, low production efficiency. The present invention can be configured as a solid material steaming tank.

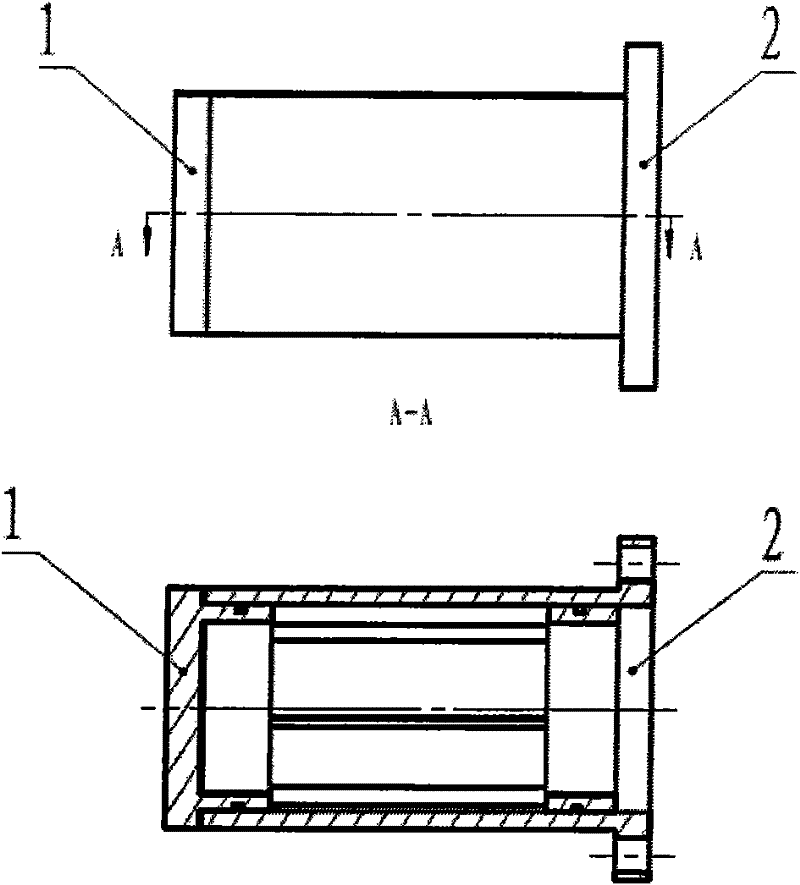

[0036] When the present invention is used for the solid material steaming tank, the tank body is 6m 3 , the height-to-diameter ratio is 3:1, the feed valve adopts box-type feed valve, the discharge valve adopts r-type discharge valve, and the diameter of the discharge cylinder of the discharge valve is selected as 200mm, which can be directly connected from the processin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com