Energy-saving type heat treatment heating furnace for grinding balls

A heating furnace and energy-saving technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of affecting the heat treatment quality of casting ball production, unstable casting ball temperature, and complicated operation of casting balls in and out of the furnace, so as to improve production. Efficiency and effect of heat treatment quality, good refractory thermal insulation, excellent chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

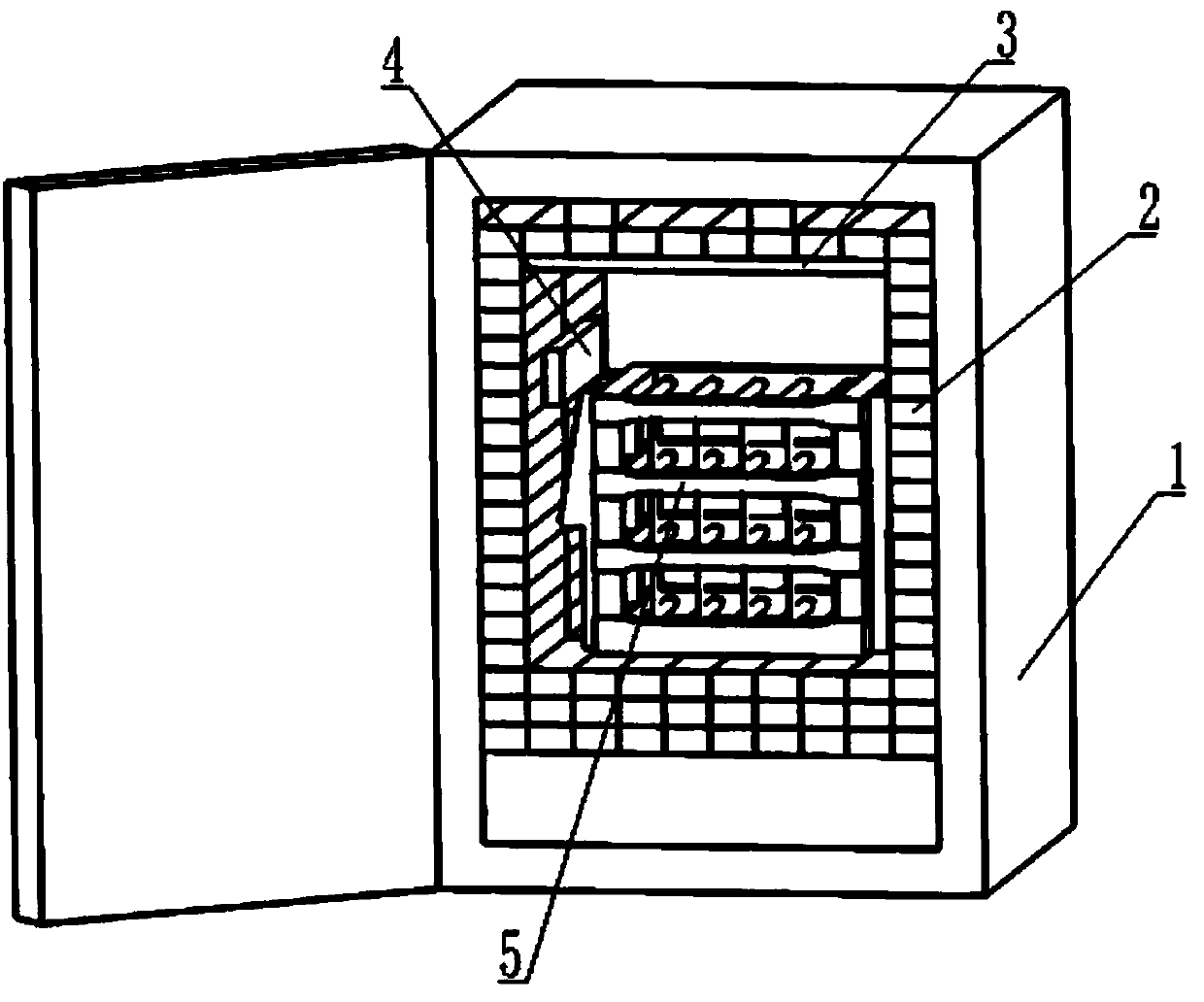

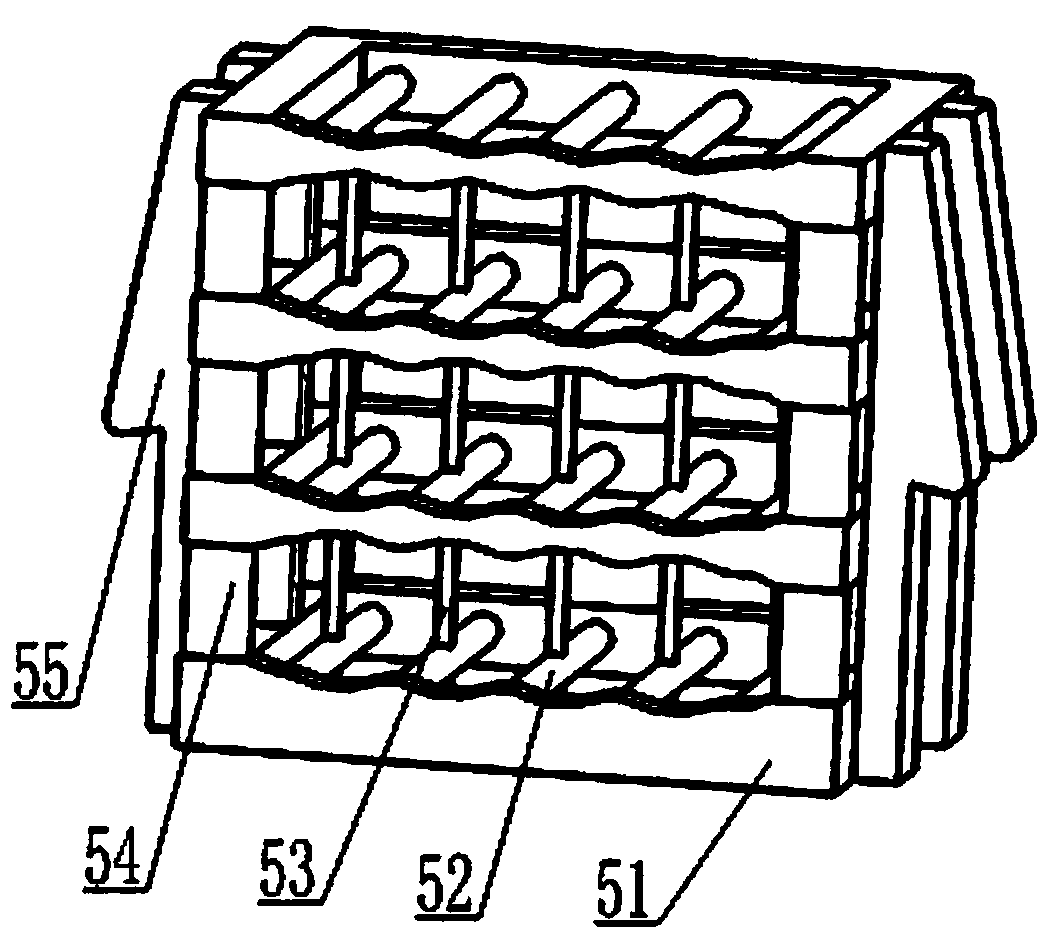

[0012] Refer to the attached figure 1 to attach image 3 An energy-saving cast ball heat treatment heating furnace according to the present invention will be described in detail below.

[0013] An energy-saving cast ball heat treatment heating furnace is characterized in that it includes a furnace body 1, a furnace lining 2, a boom 3, a heater 4 and a furnace frame 5; the boom 3 is installed on the top of the inner wall of the furnace body 1, and the furnace lining 2 is installed on the furnace On the inner wall of the body 1, the heater 4 is installed in the furnace lining 2, and the furnace frame 5 is placed in the furnace body.

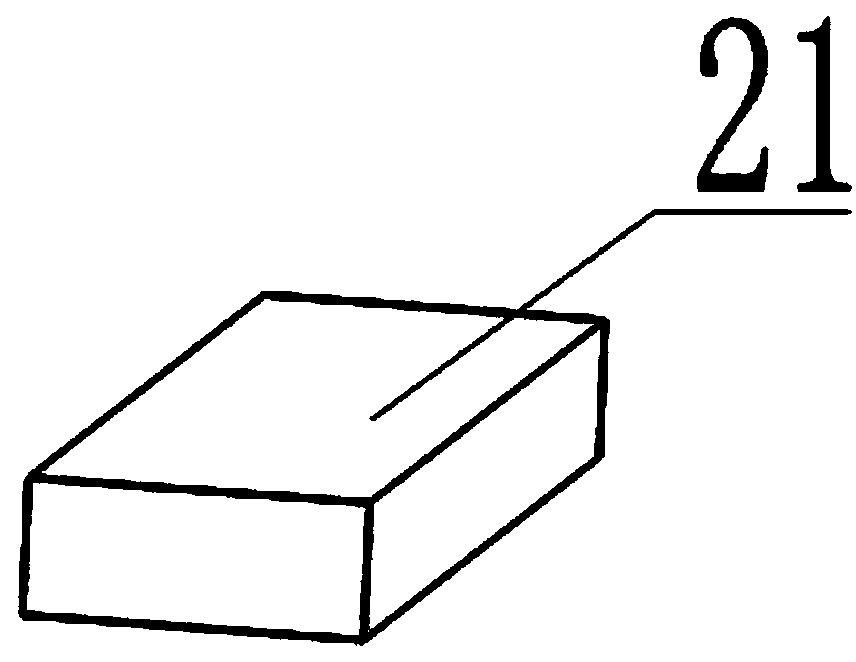

[0014] The furnace lining 2 is made of strip-shaped aluminum silicate insulation cotton with a length of 60 cm, a width of 15 cm, and a height of 10 cm. The inner wall of the furnace body 1 is installed layer by layer perpendicular to the inner wall of the furnace body 1. The furnace body 1 The furnace lining 2 at the top is supported by a boom 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com