Angle rotary table for mechanical processing

A technology of mechanical processing and rotary table, which is applied in the direction of metal processing equipment, metal processing machine parts, manufacturing tools, etc. It can solve the problems of difficult control of precision, difficult adjustment, waste of manpower, etc., and achieves short adjustment time and high precision , the effect of convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

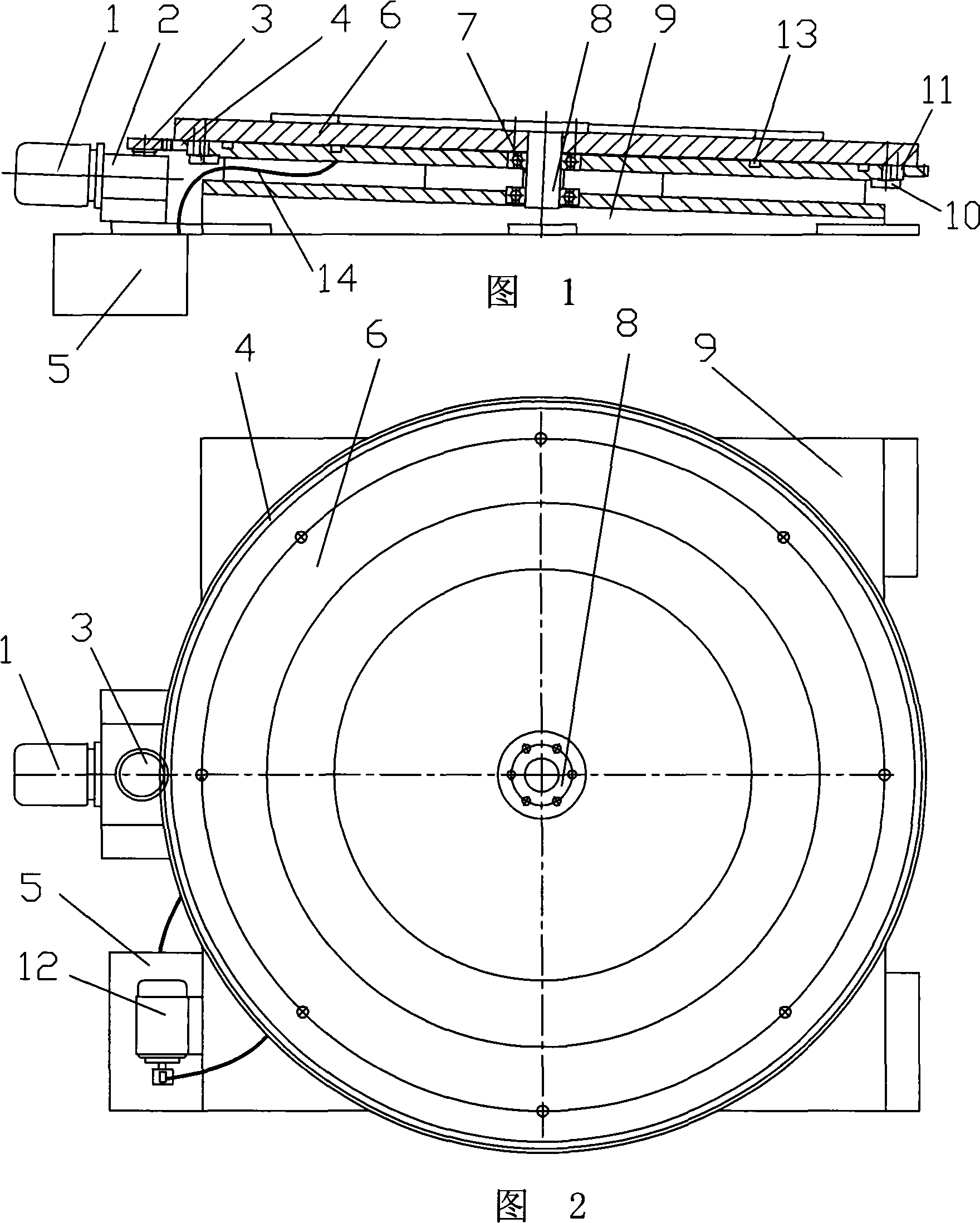

[0010] Below the present invention will be further described in conjunction with the example in the accompanying drawing:

[0011] As shown in Figure 1: speed regulating motor 1, reducer 2, pinion gear 3, bull gear 4, oil tank 5, upper table panel 6, bearing spacer 7, rotary positioning shaft 8, seat cushion 9, pressure plate 10, pressure plate pad 11, Hydraulic station 12.

[0012] Above the seat cushion 9 there is an upper platform panel 6, which is characterized in that: the center of the seat cushion 9 utilizes a bearing to install a rotary positioning shaft 8, and the upper end of the rotary positioning shaft 8 is fixedly connected with the upper platform panel 6; the seat cushion 9 is connected to the upper platform panel 6 are arranged parallel to each other and inclined; there is a large gear 4 on the edge of the upper platform panel 6, and the large gear 4 is engaged with the pinion 3 at the output end of the reducer 2; the upper surface of the cushion 9 is provided f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com