Automatic fiber liquid adding and drying equipment

A drying equipment and automatic technology, applied in liquid/gas/vapor fiber/sliver/roving processing, textile and papermaking, solvent processing, etc., can solve the problems of waste of resources, large consumption, etc. The effect of small dosage of medicine and flexible formulation of medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

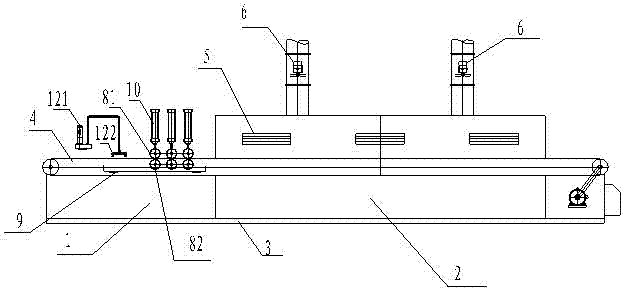

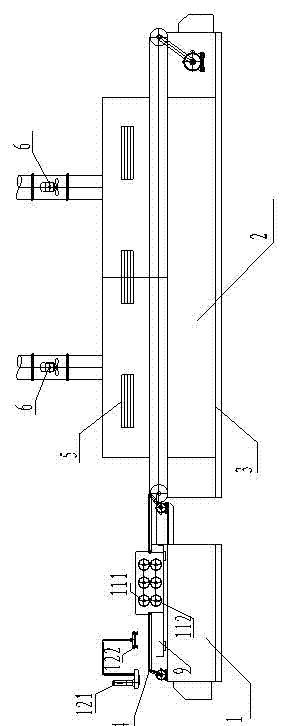

[0013] A fiber automatic feeding and drying equipment, the automatic feeding and drying equipment includes a liquid feeding area 1 and a drying area 2, the drying area 2 includes a frame 3, and the upper surface of the frame 3 is set There is a conveyor belt 4 connecting the drying zone 1 and the liquid addition zone 2. A low-temperature oven 5 for drying materials is arranged above the conveyor belt 4. The low-temperature oven 5 is connected to an axial flow fan 6. The liquid addition zone 1 is provided with a The mixing device is evenly infiltrated by the liquid medicine. In this embodiment, the mixing device is a pressure roller 81 and a supporting roller 82 arranged oppositely, a tray 9 is arranged below the supporting roller 81, and the cylinder 10 is connected to the pressure roller 81, and the conveyor belt 4 passes through the pressing roller 81 and the supporting roller. Between the rollers 82. The liquid adding area 1 is also provided with a liquid adding pump 121 a...

specific Embodiment 2

[0015] In this embodiment, another mixing device is used, specifically, the mixing device is a mixing chamber with an upper gear set 111 and a lower gear set 112 inside. The material is fully mixed with the liquid medicine by stirring or spiral in the mixing chamber, and the fiber containing the liquid medicine is sent to the automatic oven by the conveyor belt to be dried according to the temperature required for drying the material.

[0016] The heating method of the low-temperature oven in the present invention is far-infrared heater, electric heating, thermal oil heating, steam heating, or gas heating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com