Gear M-value rapid diameter measuring jaw linkage mechanism

A linkage mechanism, M value technology, applied in the direction of mechanical diameter measurement, measuring devices, instruments, etc., can solve the problems of unsuitable workpiece online inspection, difficult to promote and use on production sites, poor repeatability, etc., to reduce the production and operation cost of enterprises, The effect of low manufacturing cost and avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific drawings and embodiments.

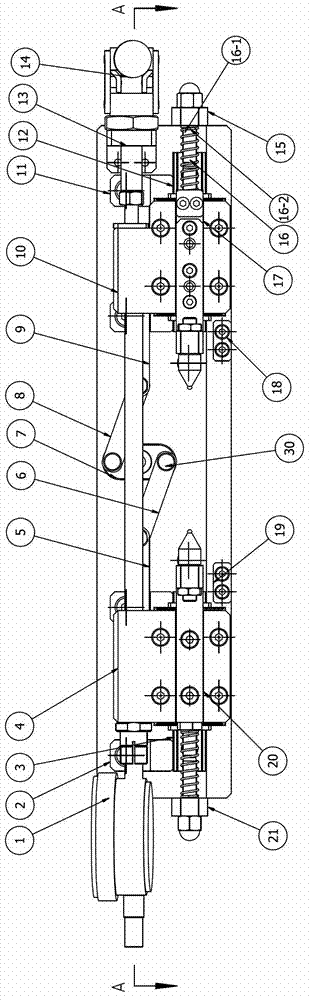

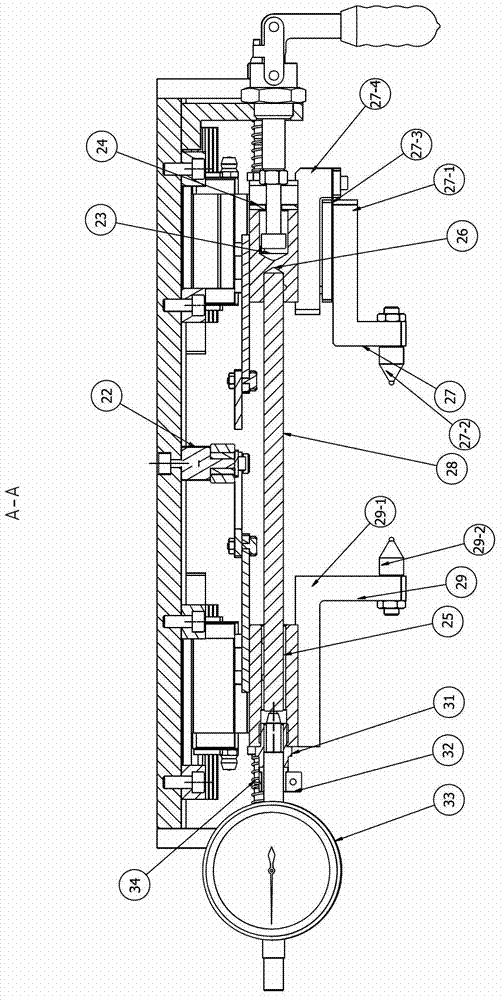

[0019] Such as figure 1 , figure 2 As shown, it includes the bottom plate 1, the second guide rail limit block 2, the second guide rail 3, the second slider 4, the second fixed link 5, the second spread link 6, the eccentric wheel 7, the first spread link Rod 8, first fixed connecting rod 9, first slider 10, first guide rail limit block 11, first guide rail 12, clamp hand bracket 13, clamp hand 14, first compression spring fixing seat 15, first spring device 16. Stud 16-1, spring 16-2, first chute 17, first slider limit block 18, second slider limit block 19, second chute 20, second compression spring fixing seat 21 , eccentric wheel seat 22, inner long hole 23, cover plate 24, second inner hole 25, first inner hole 26, movable measuring rod device 27, first measuring rod 27-1, first measuring head 27-2, sheet Spring 27-3, connecting block 27-4, and differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com