A Method for Precisely Locating Defects on Materials in Ultrasonic Testing

An ultrasonic detection and precise positioning technology, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, can solve the problems of difficulty in accurately distinguishing the same defect, unsuitable for batch operation, low efficiency, etc., to reduce positioning errors, avoid mistakes, high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

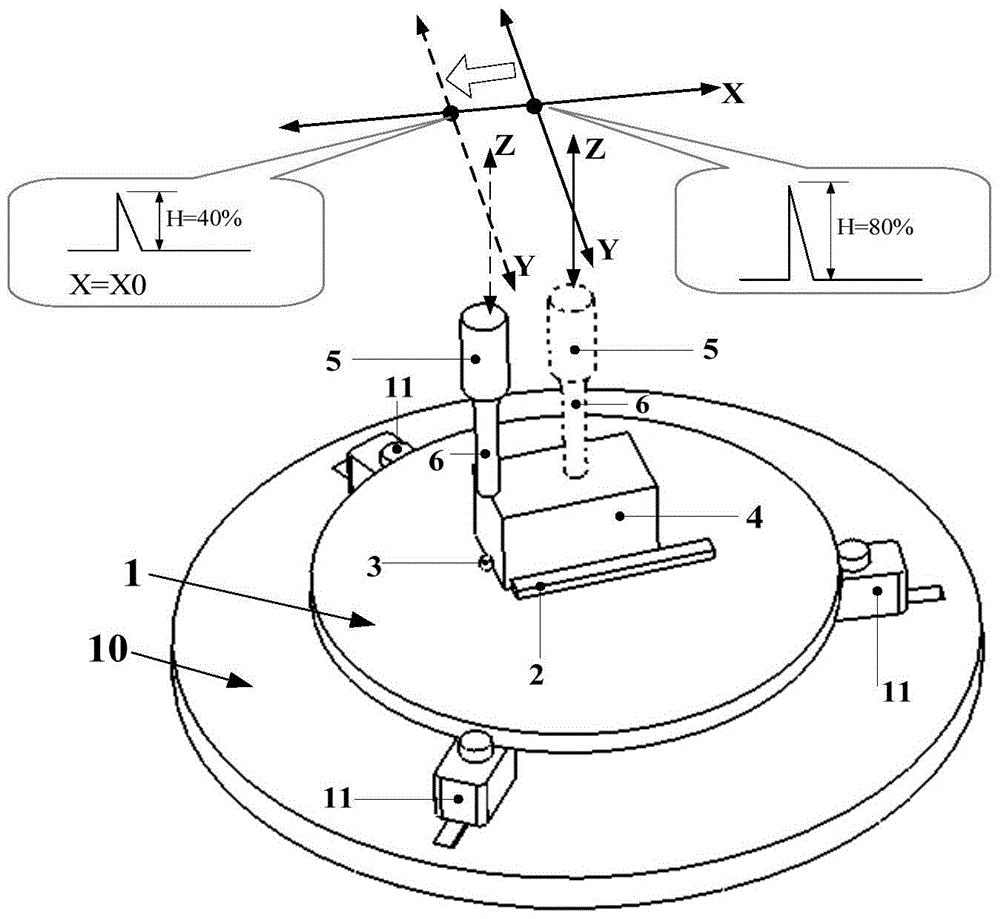

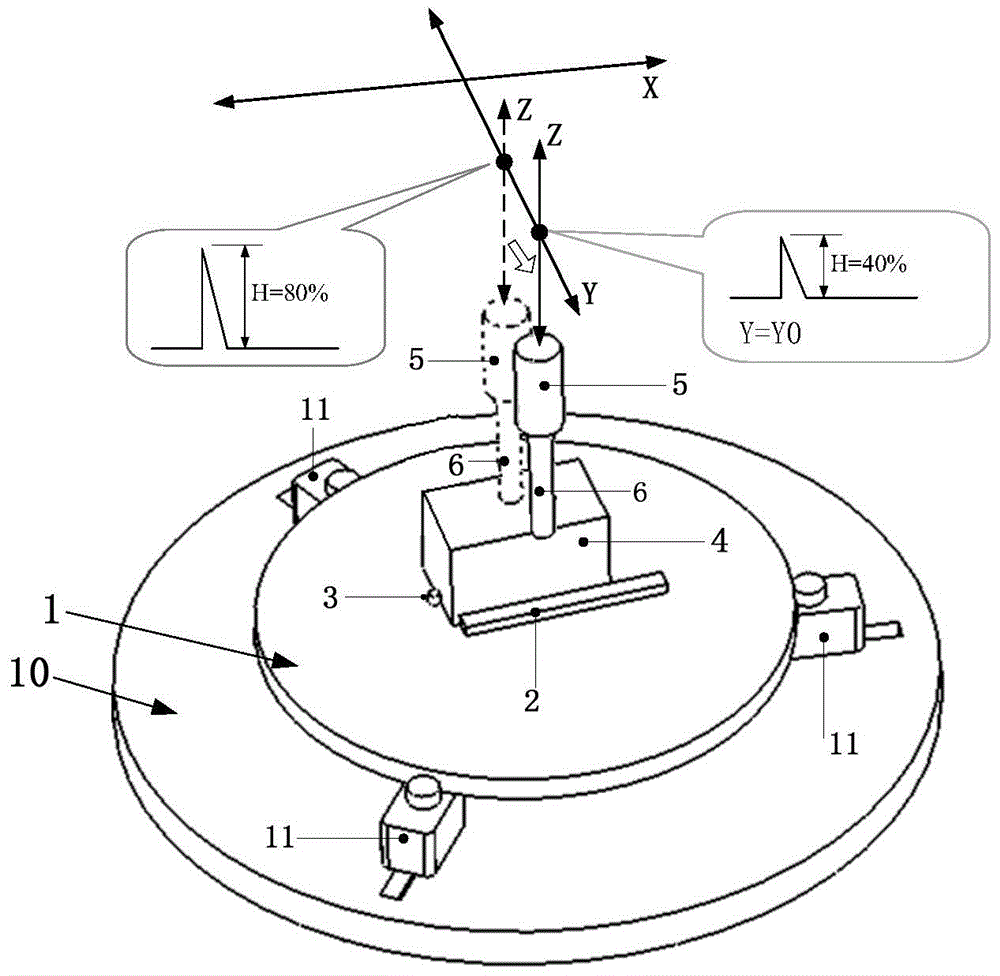

[0030] Example 1: Positioning of dense small defects during metallographic dissection of rings

[0031] Combine below Figure 1 ~ Figure 4 , taking the location of a defect in a superalloy ring as an example to illustrate the specific implementation process of the present invention.

[0032] A large number of dense defect signals were found by ultrasonic testing of a high-temperature alloy ring, and it was necessary to determine the nature of the defect through metallographic anatomy. In order to improve the accuracy of defect metallographic sampling, after cutting a section of material containing defects from the ring, the The defect location of segment material is carried out according to the following methods and steps:

[0033] Step 1. On the horizontal working surface of a circular stainless steel horizontal tray 1 with a diameter of 300mm, a rectangular stainless steel gauge block 2 with a length, width, and height of 100mm, 10mm, and 10mm is fixedly placed, and the lengt...

Embodiment 2

[0042] Example 2: Location of weld defects during mechanical performance testing of welded parts containing defects

[0043] Combine the following Figure 1 ~ Figure 3 , Figure 5 , taking the positioning of defects in a titanium alloy weldment as an example to illustrate the specific implementation process of the present invention.

[0044] In order to establish the acceptance standard for ultrasonic testing of a certain titanium alloy weldment, it is necessary to carry out the mechanical performance test of the defective weld part of the titanium alloy weldment according to the relevant standards. The weld defect of interest is located at the center of the cross-section near half the length of the mechanical performance sample. Since the diameter of the mechanical performance sample at this part is only 5 mm, there is a high requirement for the positioning accuracy of the defect. In view of the above situation, the following defect location methods and steps are adopted:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com