Machine tool spindle reliability test bed based on mixed loading of electro-hydraulic servo and dynamometer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is described in detail below in conjunction with accompanying drawing:

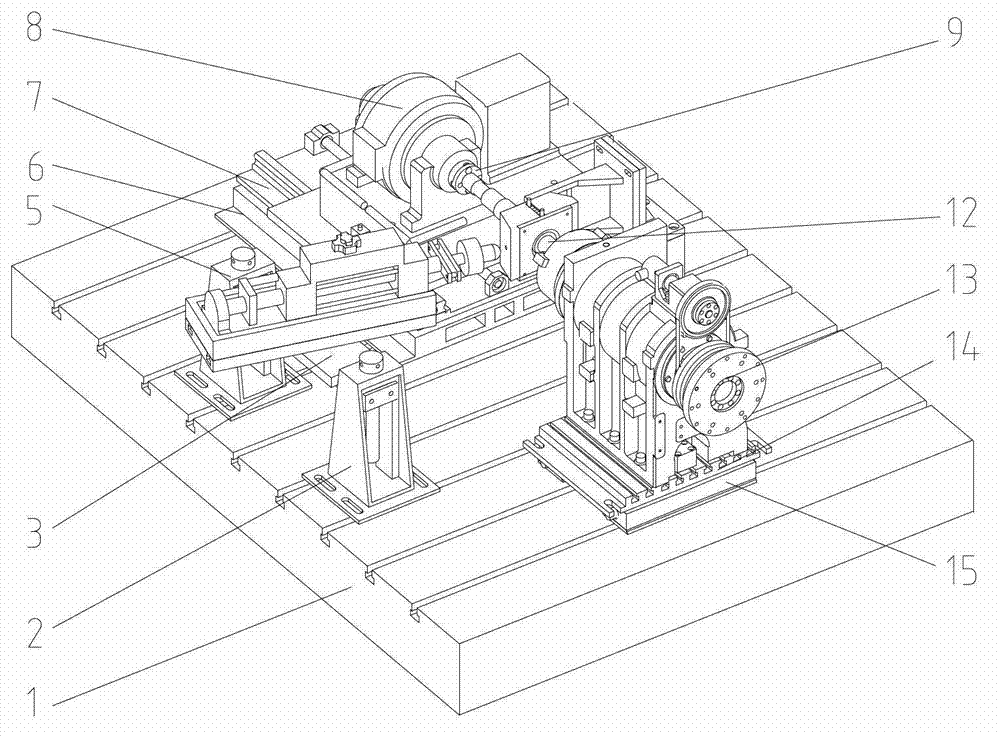

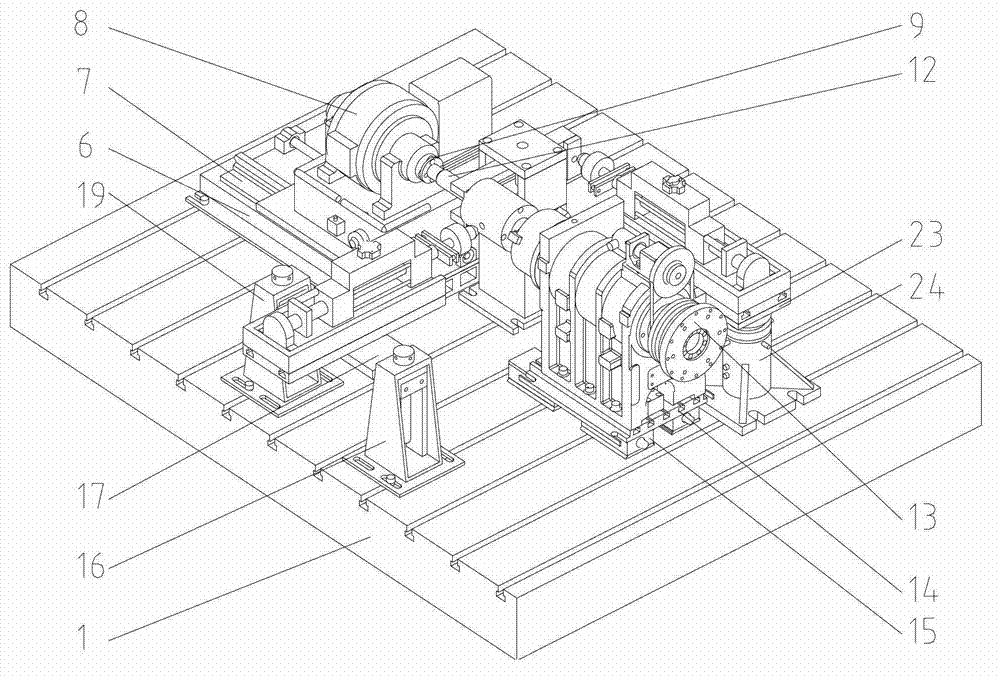

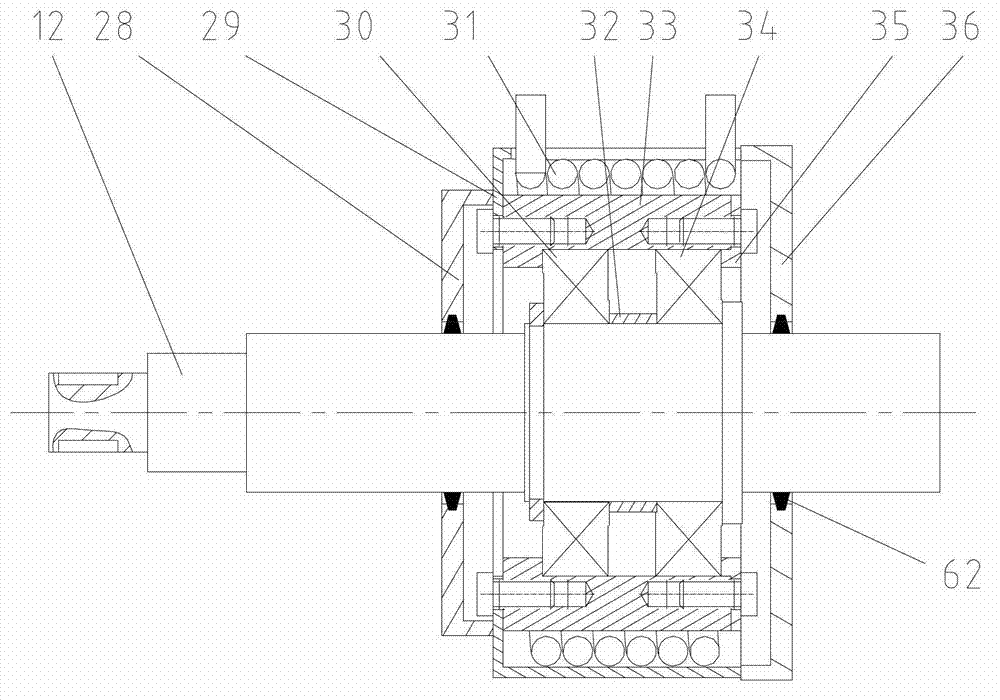

[0040] refer to figure 1 , figure 2 According to the present invention, the machine tool spindle reliability test bench loaded by electro-hydraulic servo and dynamometer includes a machine tool spindle support part, a torque loading part, and a cutting force loading part.

[0041] 1. Spindle support part of machine tool

[0042] The supporting part of the machine tool spindle includes a headstock backing plate 14 and a shim assembly 15 .

[0043] The headstock backing plate 14 is a plate structure, and there are T-shaped grooves parallel to each other on the upper plane. 15 is four sets of NC milling machine pads of the same specification, the model is S83-2, the machine tool spindle 13 is assembled on the headstock through the flange, and together with the three-jaw chuck is used as the test object of this test bench; Bolts and T-shaped nuts are fixed on the headstock ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com