Air exhausting method of high-pressure casting die and die

A technology of high-pressure casting and exhaust method, applied in the field of high-pressure casting molds, can solve the problems of decreased product strength, reduced product compactness, increased rejection rate, etc., to strengthen product strength, improve compactness, production efficiency and product qualification rate boosted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A high-pressure casting mold can realize the method of the present invention, and it is composed of a movable mold and a fixed mold.

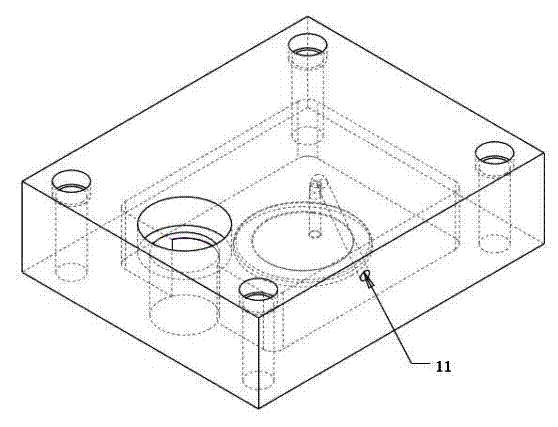

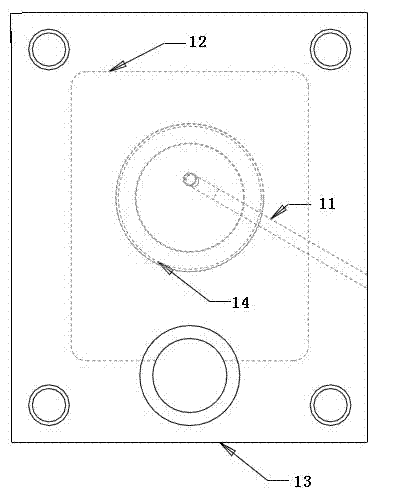

[0020] Among them: such as figure 1 , 2 As shown, the vent hole 11 provided on the fixed mold (with the cavity 14 ) directly penetrates the fixed mold core 12 , and then opens obliquely downward on the mold frame 13 at the bottom of the mold core 12 .

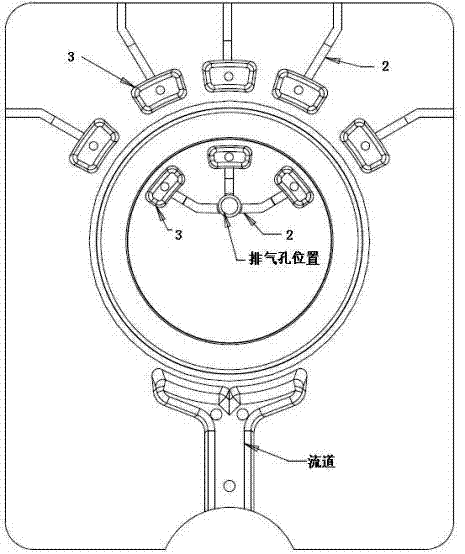

[0021] Such as image 3 As shown, a blind hole with a depth of 5-8 mm is opened on the moving mold. This structure is mainly to allow a part of aluminum chips to stop in the blind hole when exhausting, and to blow away the aluminum chips from the blind hole when spraying. This prevents the aluminum chips from clogging the vent. In order to avoid interference with the cooling water channel and to facilitate the blowing away of aluminum chips during spraying, the blind hole cannot be opened too deep.

[0022] During use, an exhaust groove 2 is opened in the middle of the slag bag 3 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap