Tire-punctured pushing device for electric vehicles

A technology for electric vehicles and flat tires, which is applied in the direction of vehicle control devices, vehicle maintenance, shunting equipment, etc., can solve the problems of increasing the use cost of electric vehicles, limited load capacity, and laborious electric vehicles, so as to reduce the use cost, simple structure, Portable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

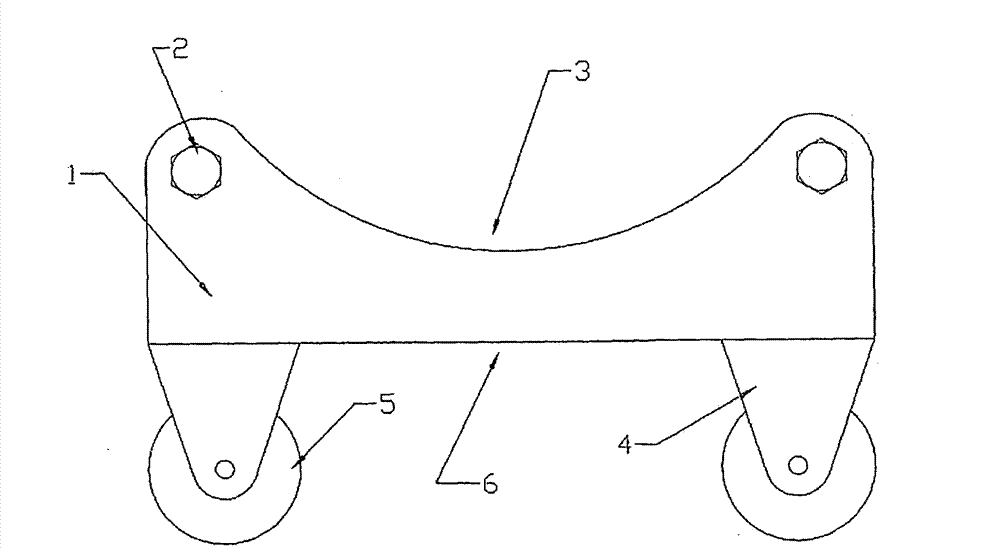

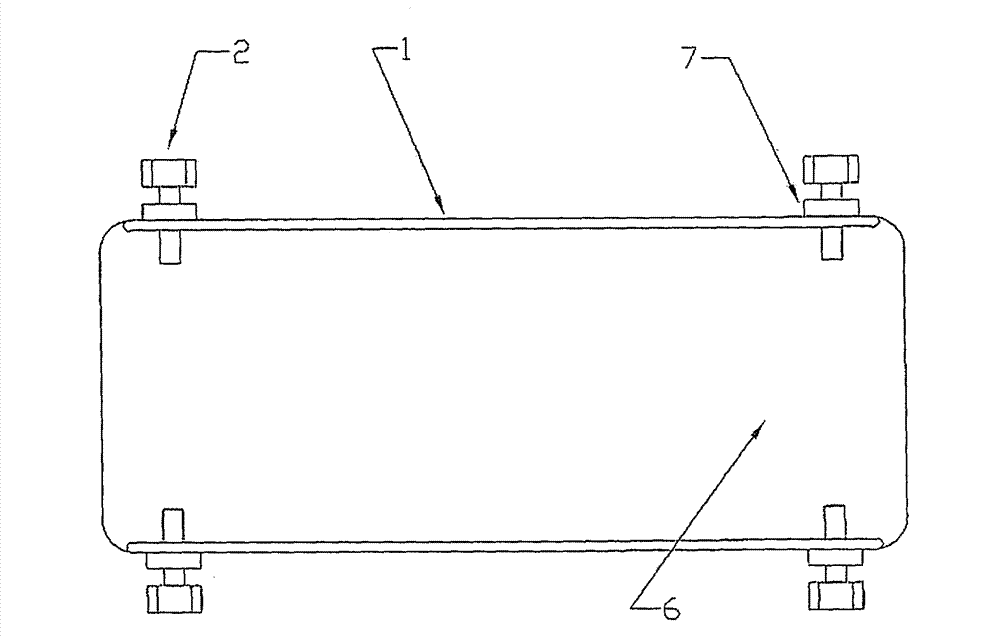

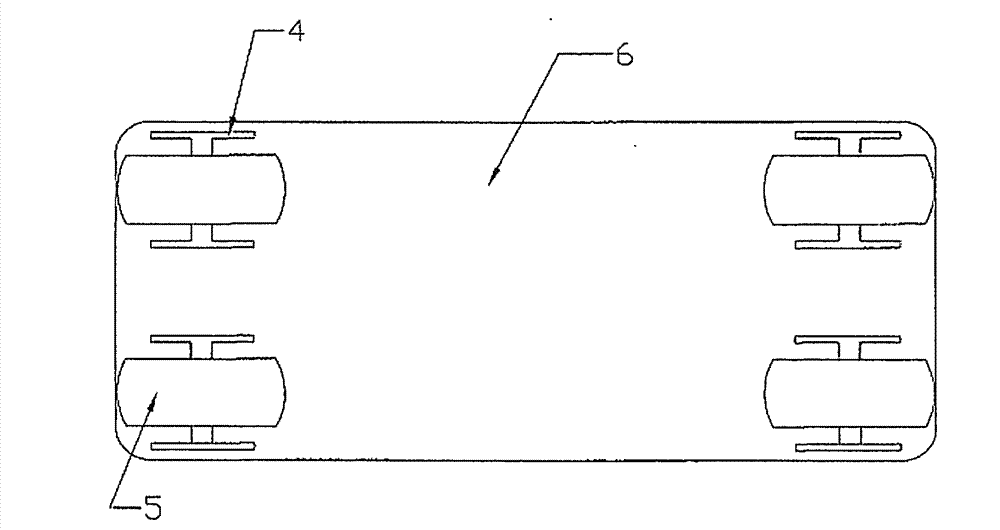

[0022] Such as figure 1 , 2 As shown in , 3, a tire blowout pushing device for an electric vehicle includes a base plate 6, the base plate 6 is rectangular, and pulleys 5 are provided at the concave apexes thereof, and the pulleys 5 are fixedly connected to the base plate 6 through the pulley seat 4 .

[0023] The bottom plate 6 is provided with a clamping device for clamping on the wheel of the electric vehicle. Under the action of the clamping device, the pushing device and the tire of the electric vehicle have better connection firmness during the pushing process.

[0024] The base plate 6 is provided with a support piece 1, and the support piece 1 is located at both side edges in the length direction of the base plate 6. The base plate 6 and the support piece 1 can be formed by bending a whole plate, and are also connected together by welding. The supporting piece 1 generally consists of two pieces, which protrude toward the direction facing away from the pulley 5 , and ...

Embodiment 2

[0028] Such as Figure 4 , 5 As shown, the main structure of pushing the electric vehicle tire blowout is substantially the same as that described in Embodiment 1, except for the specific structure of the clamping device. In this embodiment, the clamping device is an arc-shaped groove formed between the bottom plate 6 and the two support pieces 1 , the arc of the arc-shaped groove coincides with the arc of the wheel of the electric vehicle.

[0029] The support piece 1 is rectangular and has no gaps on it. An arc-shaped piece 8 can be welded between the two support pieces 1, and the bottom of the arc-shaped piece 8 can be in contact with the bottom plate 6, or there is a gap between them, which will be determined according to the actual use . An arc-shaped groove for accommodating the wheel of the electric vehicle can be formed between the two support pieces 1 and the arc-shaped piece 8. When the wheel of the electric vehicle is placed in the arc-shaped groove, the wheel pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com