Upper-opening-type filling valve with central small flow rate

A small flow, filling valve technology, used in packaging, bottle filling, liquid bottling, etc., can solve the problems of broken wire of viscous materials, lateral splashing of materials, mutual restriction of large and small flow, etc. The effect of filling accuracy and improving filling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

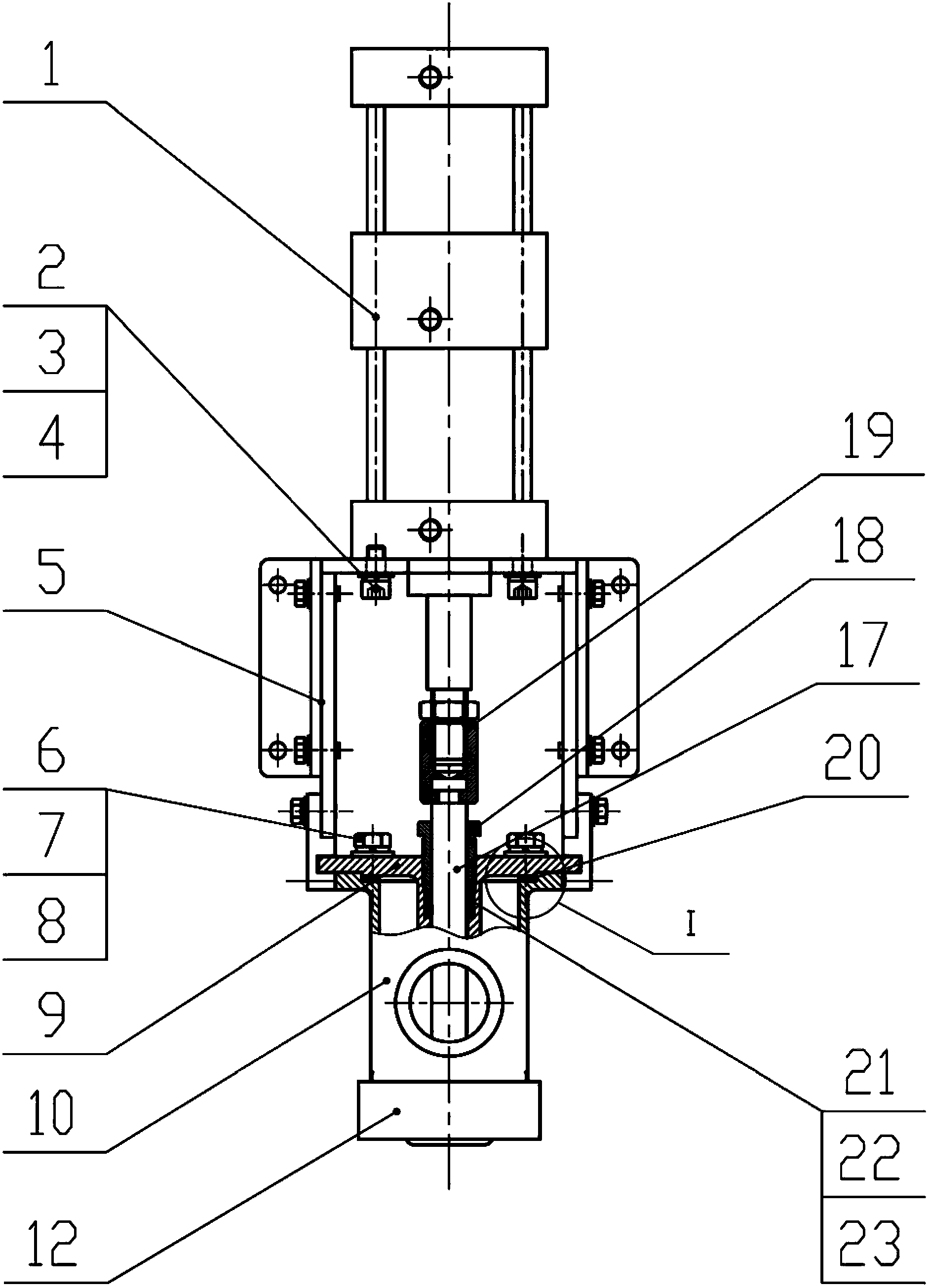

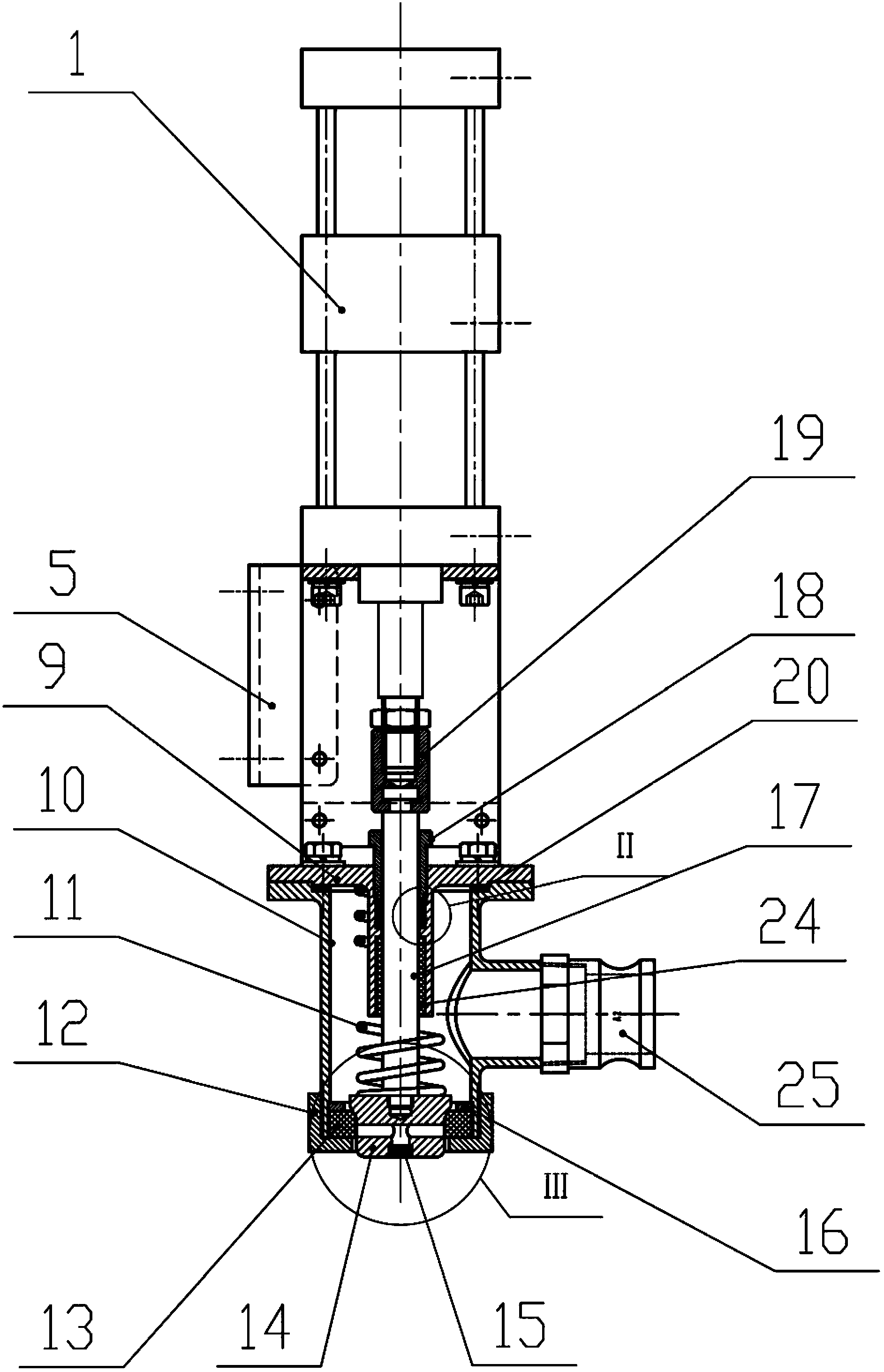

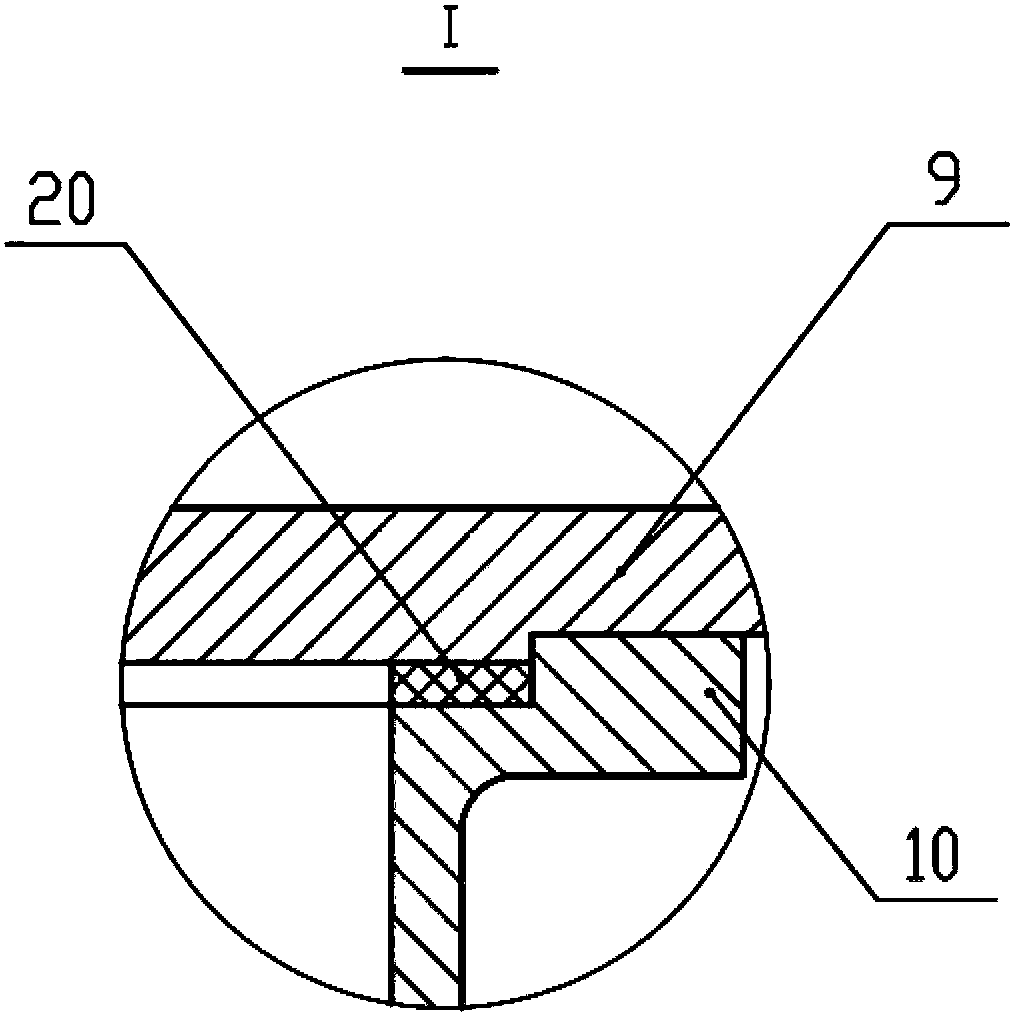

[0032] Such as figure 1 with figure 2 As shown, the connecting frame 5 is a mounting bracket for the filling head, and the connecting frame 5 installs the filling head on the filling host. The flange plate at the bottom of the double-stroke cylinder 1 is fixedly connected to the top of the connecting frame 5 through the inner hexagon screw 2, the flat washer 3 and the spring washer 4, and the bottom of the connecting frame 5 and the top of the upper flange 9 are connected through the bolt 6, the flat washer 7 and the spring The washer 8 is fixedly connected. The upper flange 9 is a cylinder with a flange on the top, and the flange of the upper flange 9 is fixed on the top of the valve body 10 by bolts; image 3 As shown, a gasket 20 is provided between the lower surface of the flange of the upper flange 9 and the top of the valve body 10 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com