Anti-self-locking anchor-bolt support plate

A self-locking bolt and supporting plate technology, which is applied to the installation of bolts, mining equipment, earthwork drilling and mining, etc., can solve the problems of reducing the service life of the bolt supporting plate, thread damage, and bolt breakage, so as to avoid the bolt Thread breakage, improved service life, and construction cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

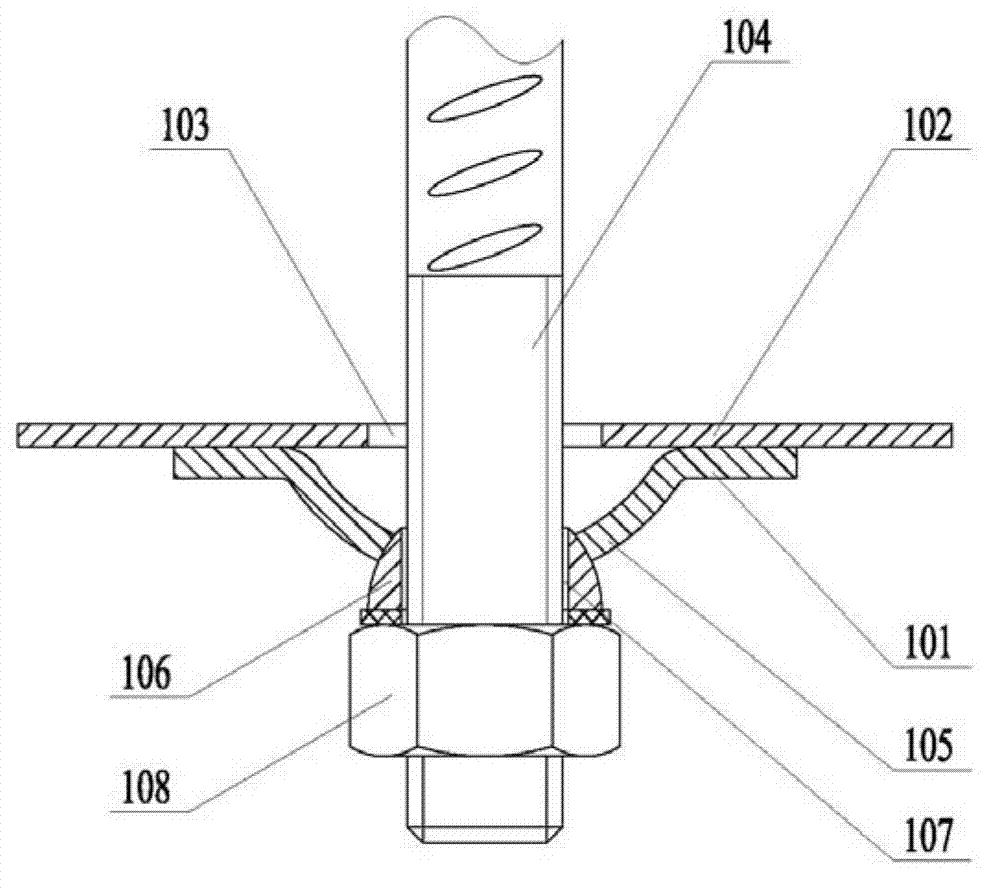

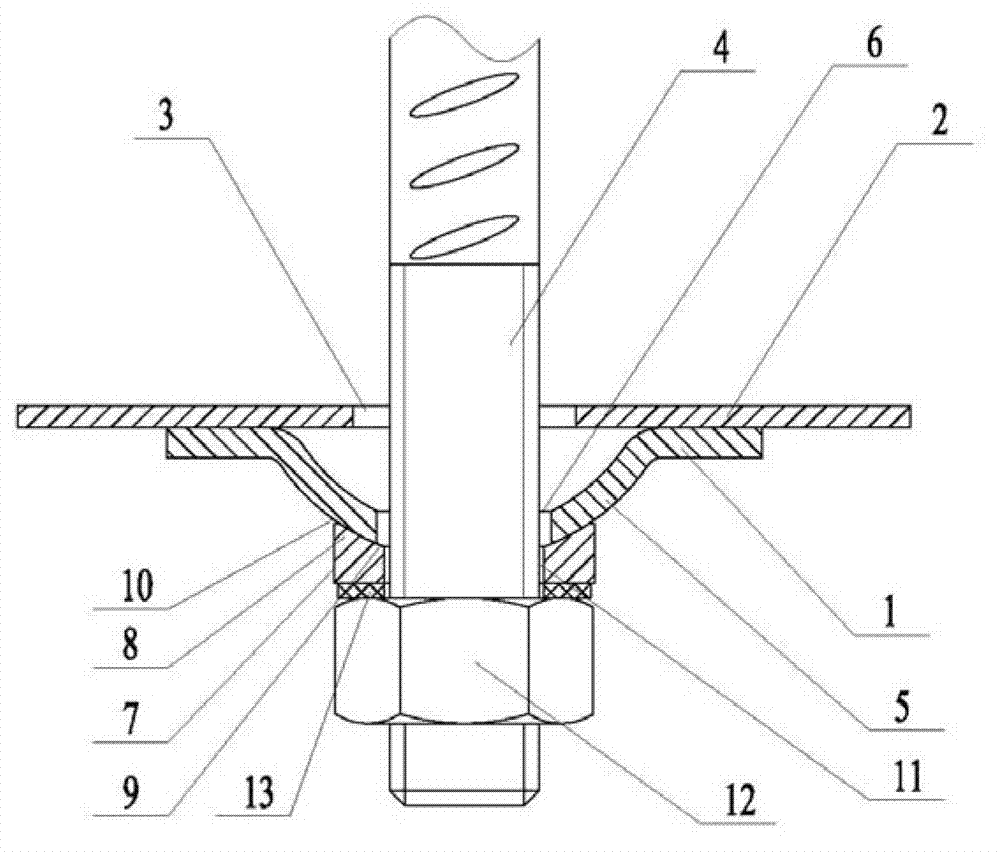

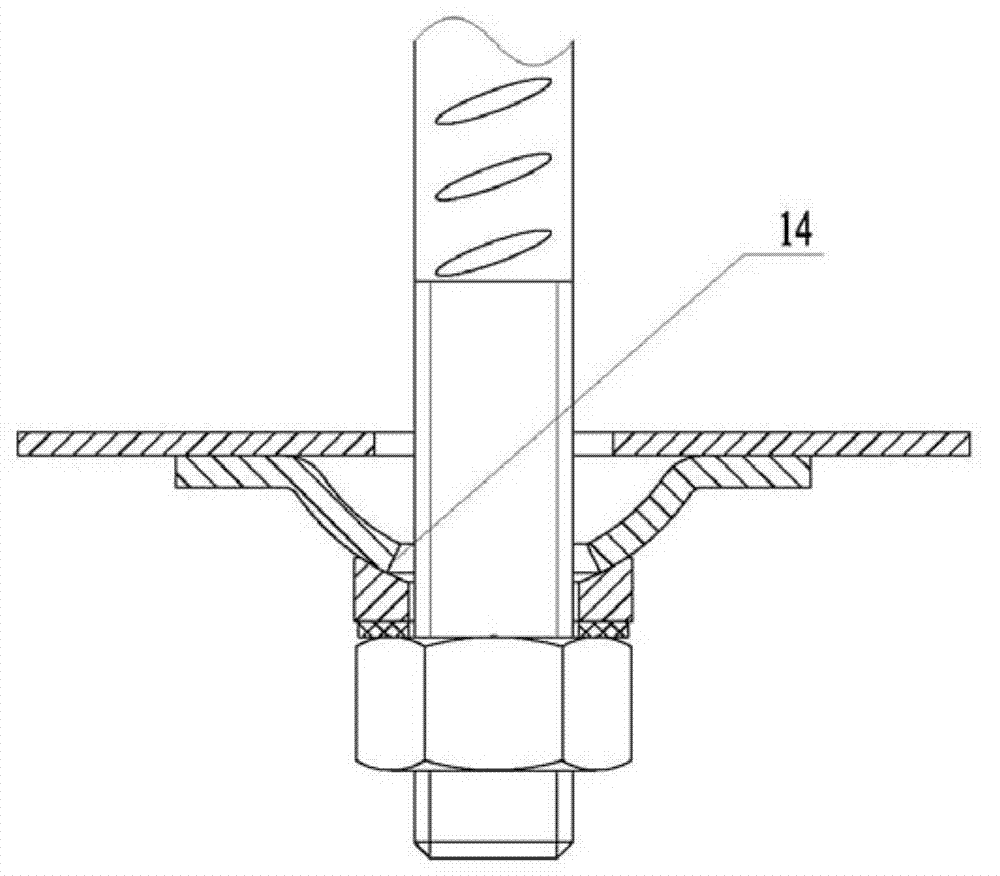

[0022] see figure 2 , image 3 As shown, an anti-self-locking anchor supporting plate of the present invention has an arched tray 1, and a steel belt 2 is arranged on the arched tray. The steel belt in this embodiment adopts w Shaped steel strip; the steel strip is provided with an anchor hole 3, and an anchor 4 is arranged in the anchor hole. In this embodiment, the anchor hole is arranged along the center line of the anchor; the arched tray The round arch portion 5 of the anchor rod is provided with a stress through hole 6 along the centerline direction of the anchor rod, and the arched tray is worn with the anchor rod through the stress through hole; a self-aligning ball pad is arranged under the arched tray 7. A central rotating part 8 is provided on the upper part of the self-aligning ball pad, and the inner rotating surface 9 of the central rotating part is arranged in cooperation with the outer rotating surface 10 of the circular arch; the bottom end surface of the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com