Patents

Literature

32results about How to "Avoid self-locking phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

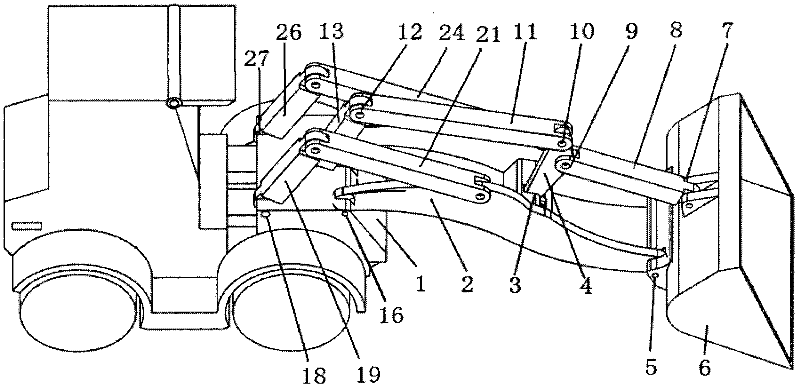

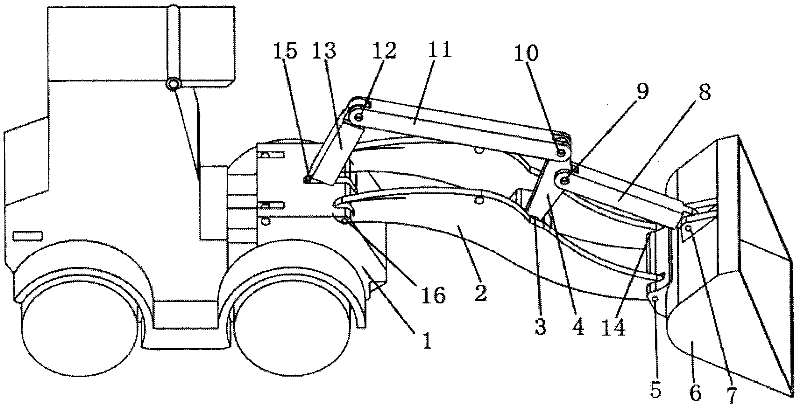

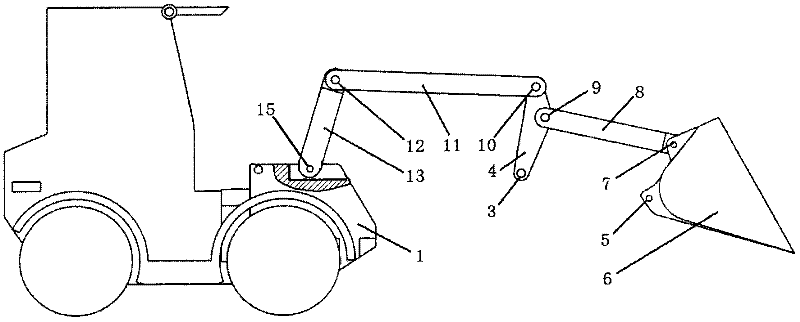

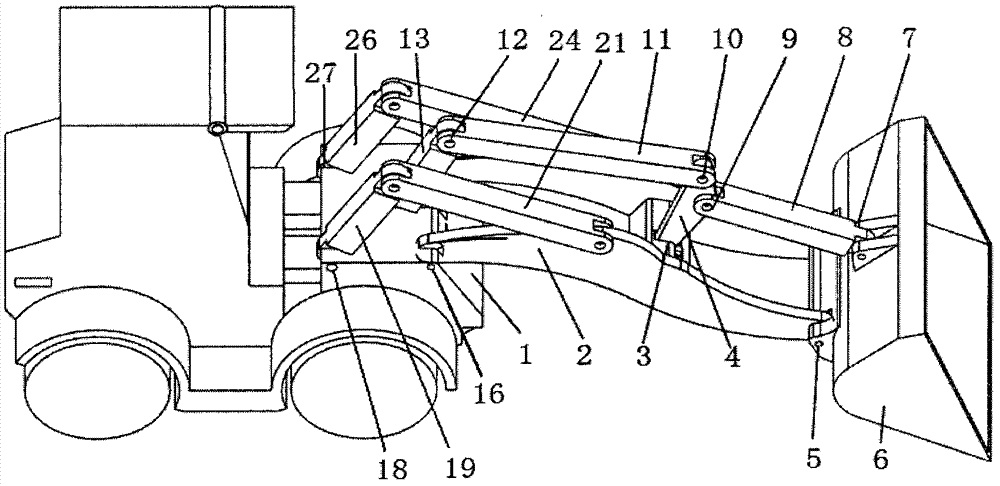

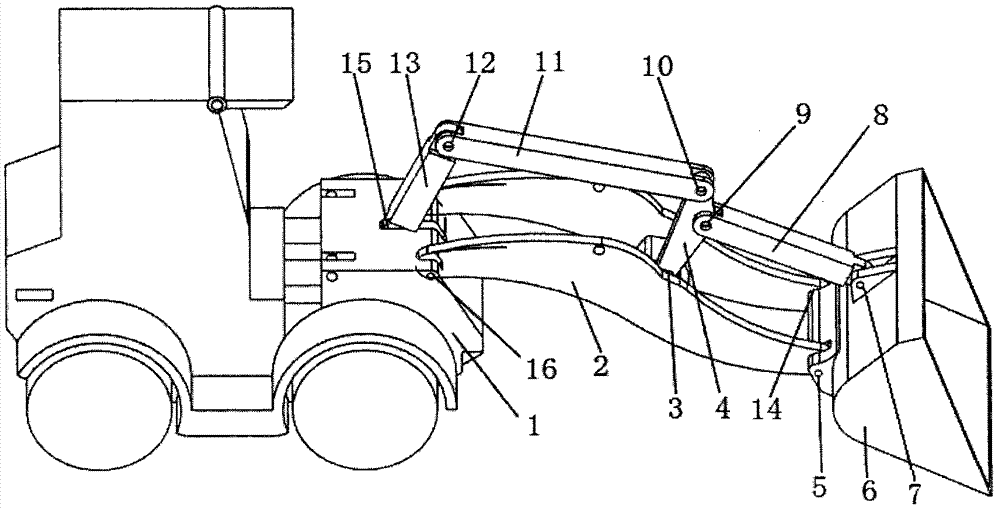

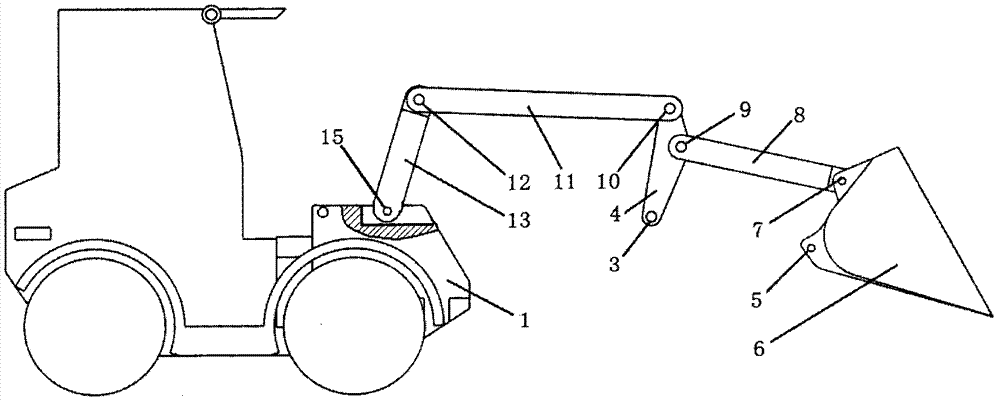

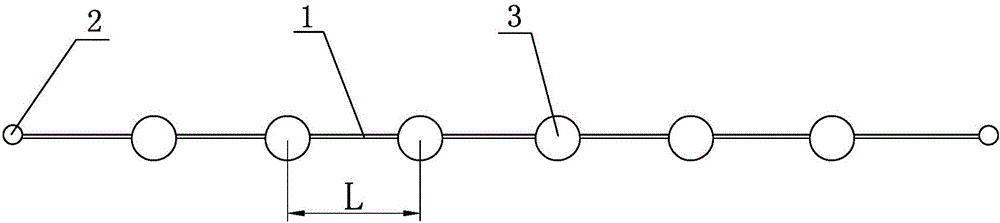

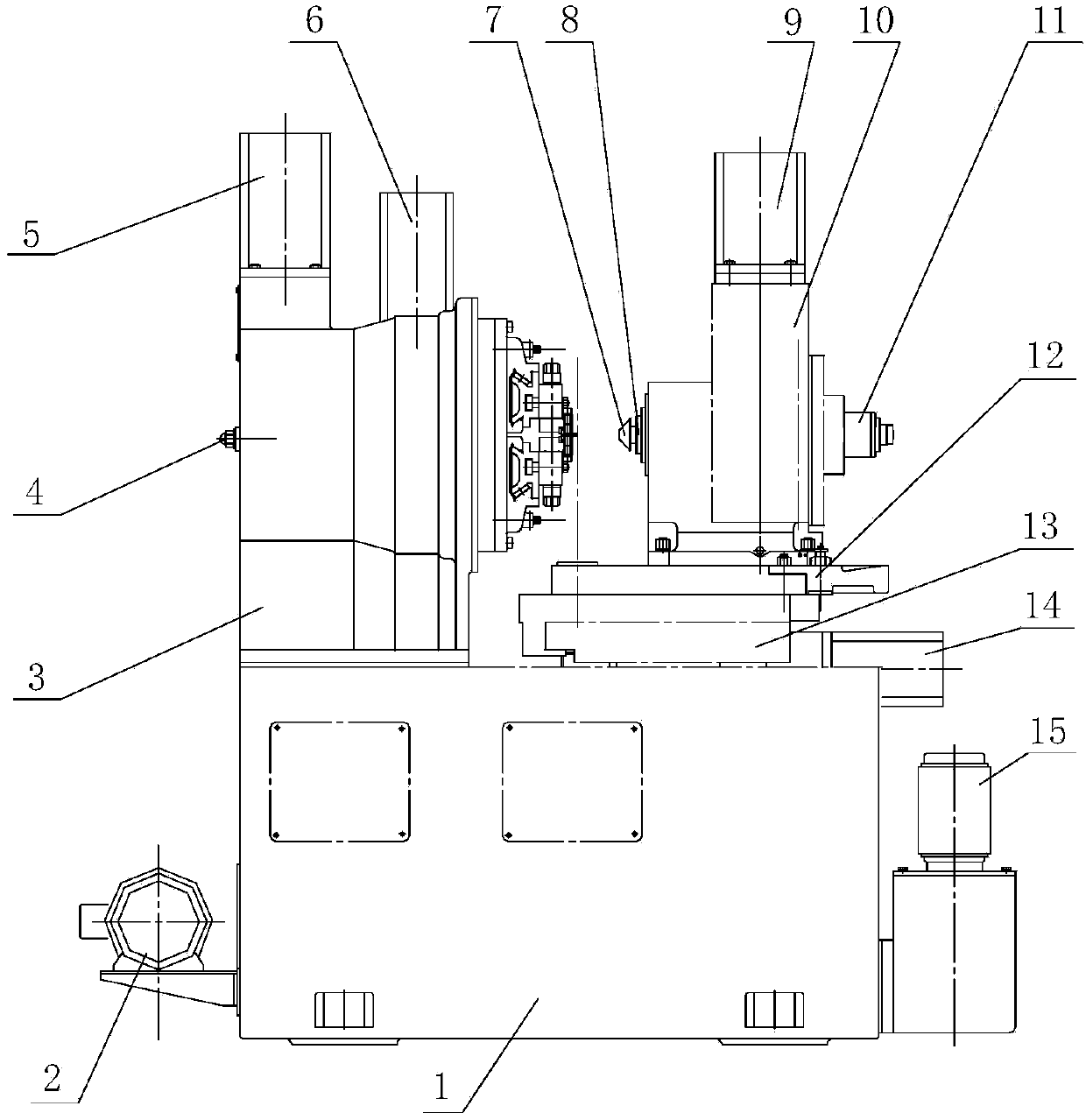

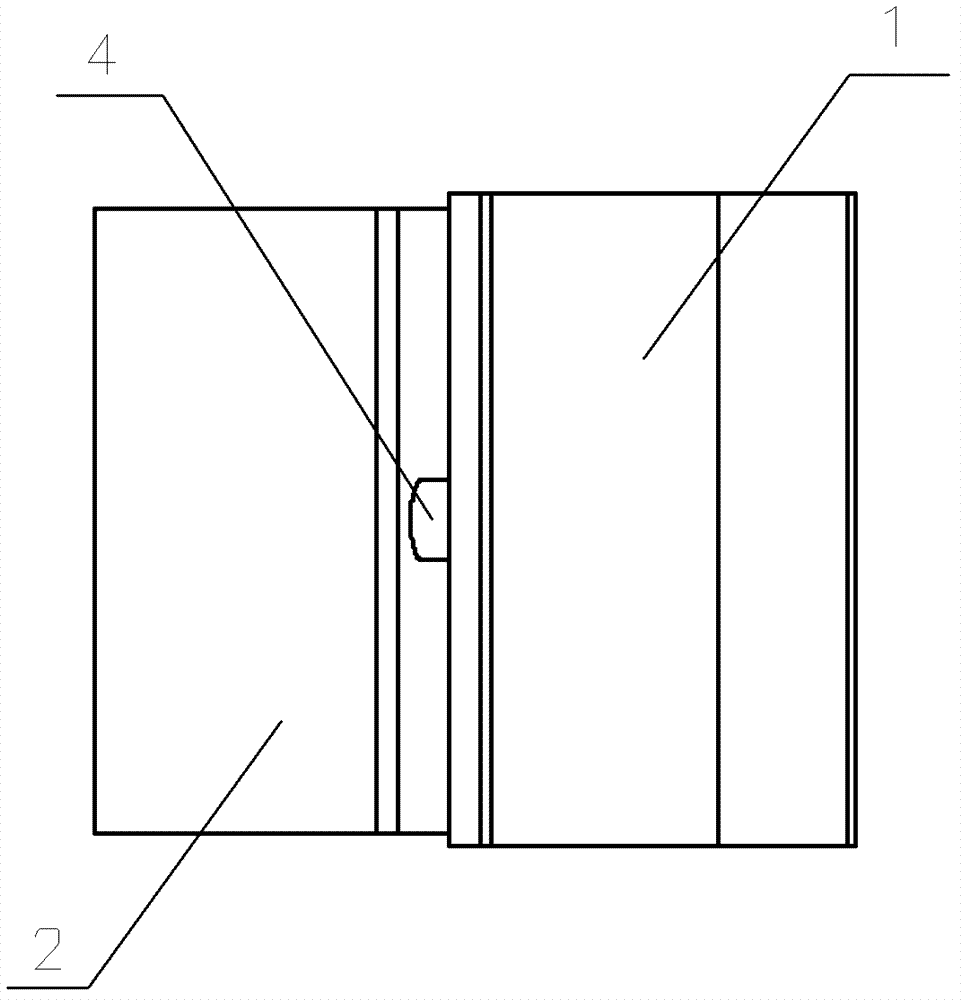

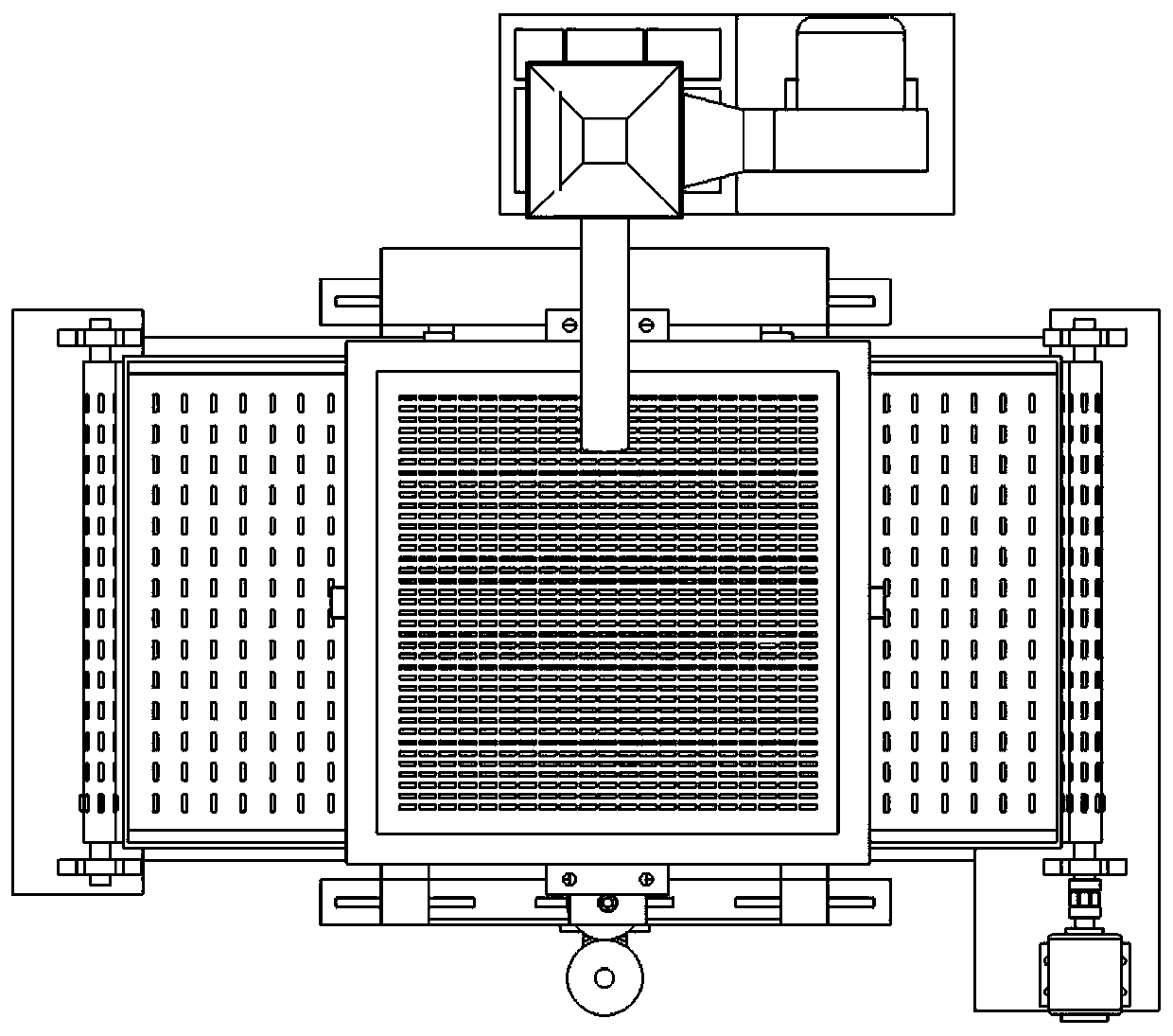

A multi-link loading mechanism

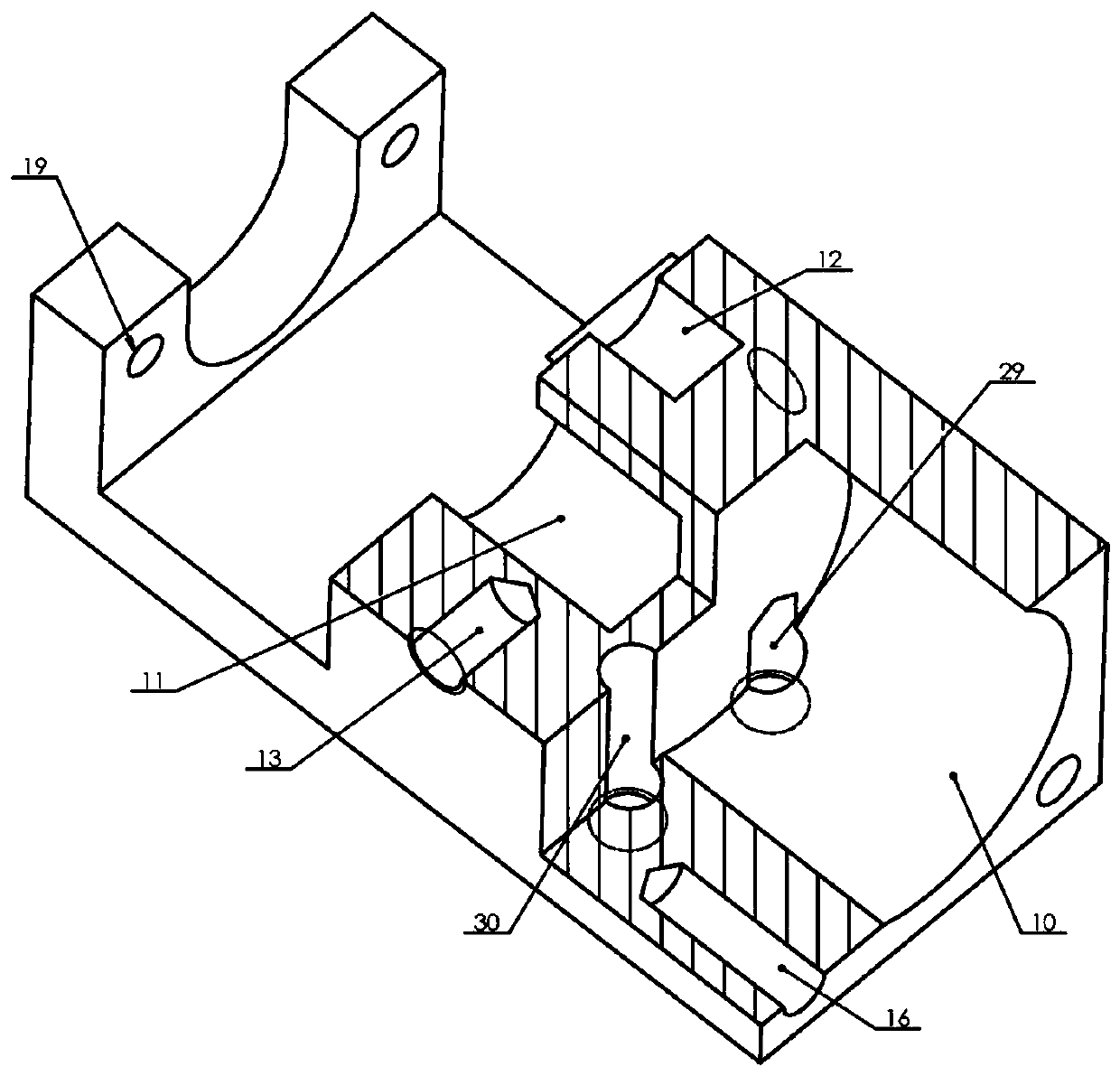

The invention discloses a multi-connecting rod loading mechanism, which comprises a first driving rod, a first connecting rod, a swinging arm, a pull rod, a movable arm, a movable arm elevating mechanism and a scraper bucket, wherein one end of the movable arm is connected with a frame, and the other end of the movable arm is connected with the scraper bucket and is elevated and lowered under theaction of the movable arm elevating mechanism; one end of the first driving rod is connected with the frame, and the other end of the first driving rod is connected with the first connecting rod; thefirst connecting rod is connected with the swinging arm; one end of the swinging arm is connected to the movable arm, and the other end of the swinging arm is connected with the pull rod; the other end of the pull rod is connected with the scraper bucket; and the first driving rod is used for controlling the scraper bucket to rotate around the movable arm under the driving action of a motor. In the invention, a hydraulic transmission system is replaced by the multi-connecting-rod loading mechanism, so that the defects of high maintenance cost and the like of a hydraulic excavator are overcome; and simultaneously, the first connecting rod, the swinging arm and the pull rod are connected with one another, so that the strange phenomenon and an oversize or undersize transmission angle among the first connecting rod, the swinging arm and the pull rod due to the approach or reach of the scraper bucket of a mechanical loader to a limit position can be avoided easily on the premise of meetingthe requirement of loading, and the reliability of an electric loader is improved.

Owner:GUANGXI UNIV

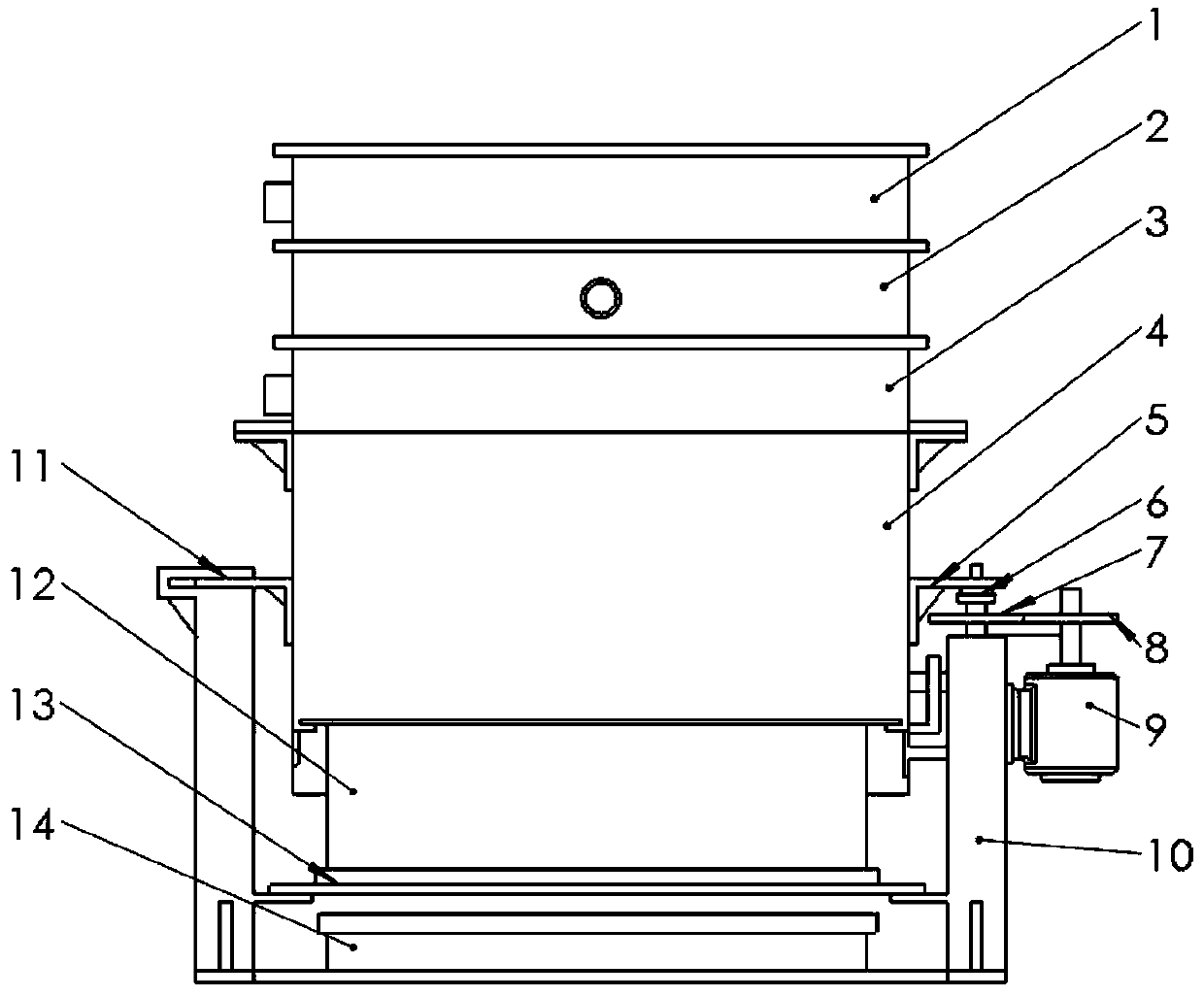

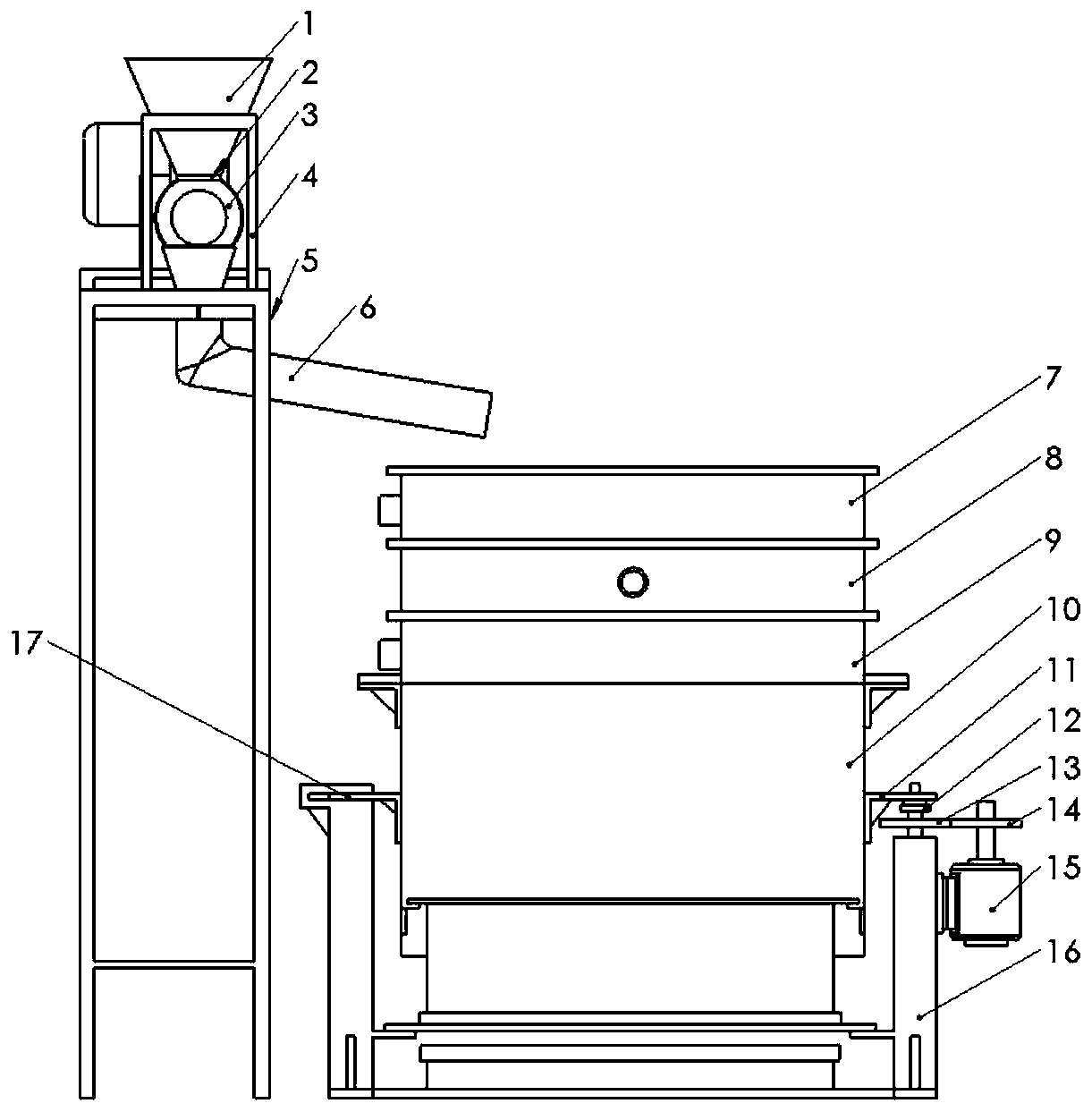

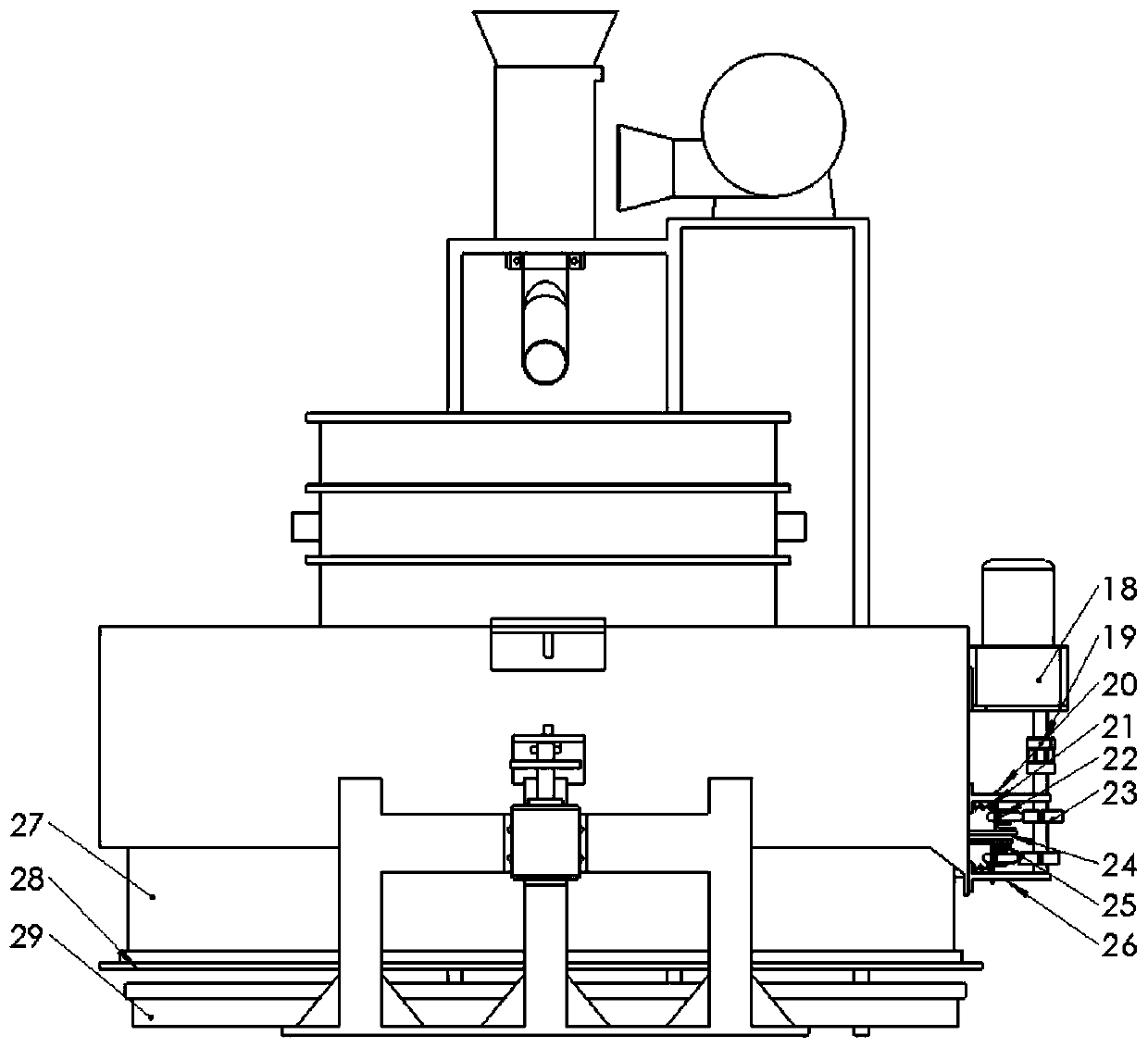

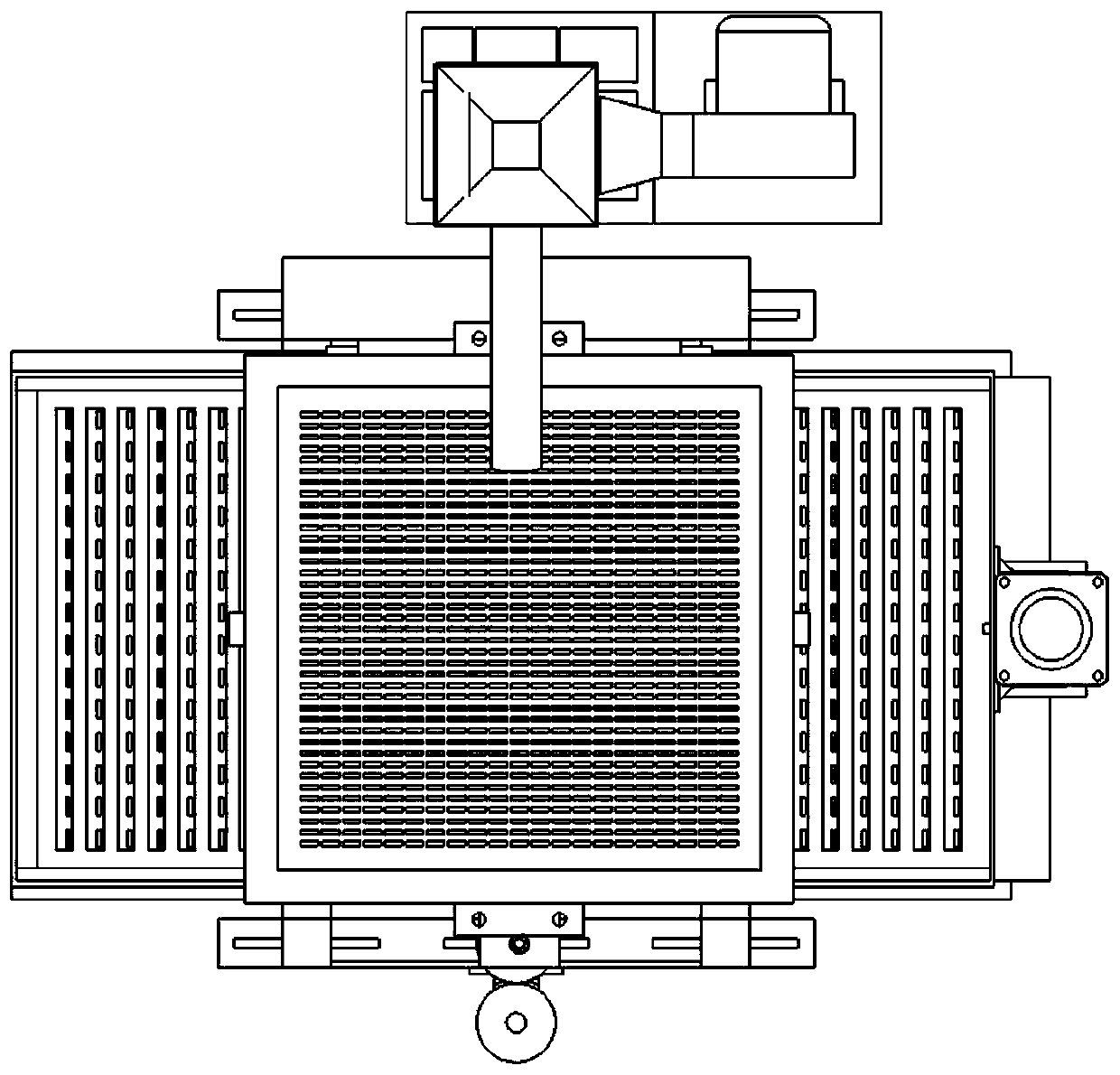

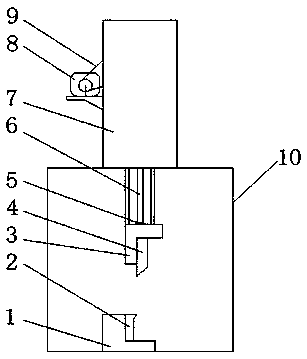

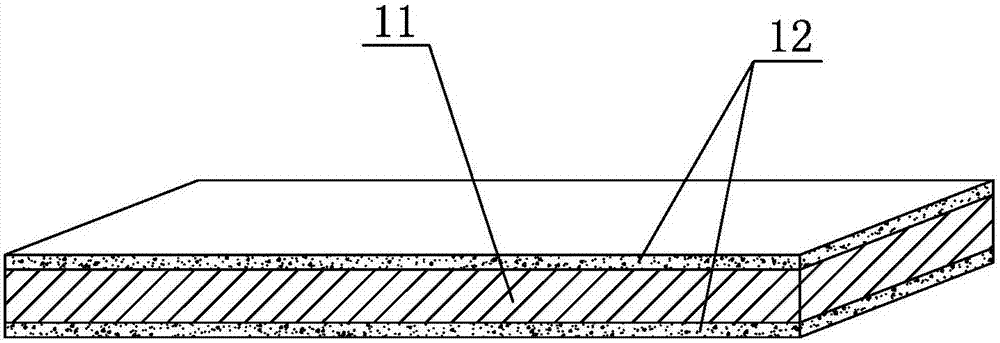

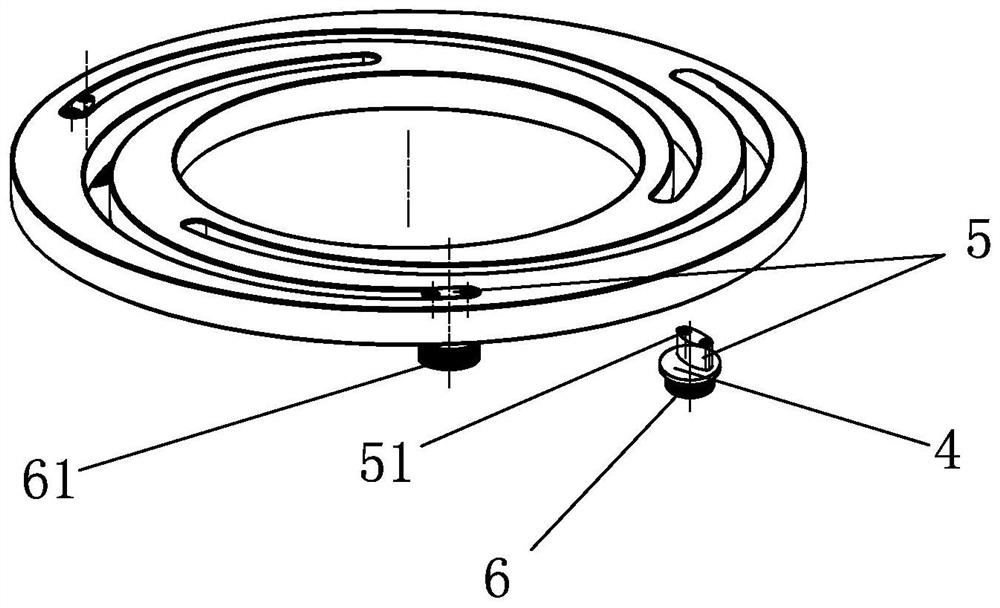

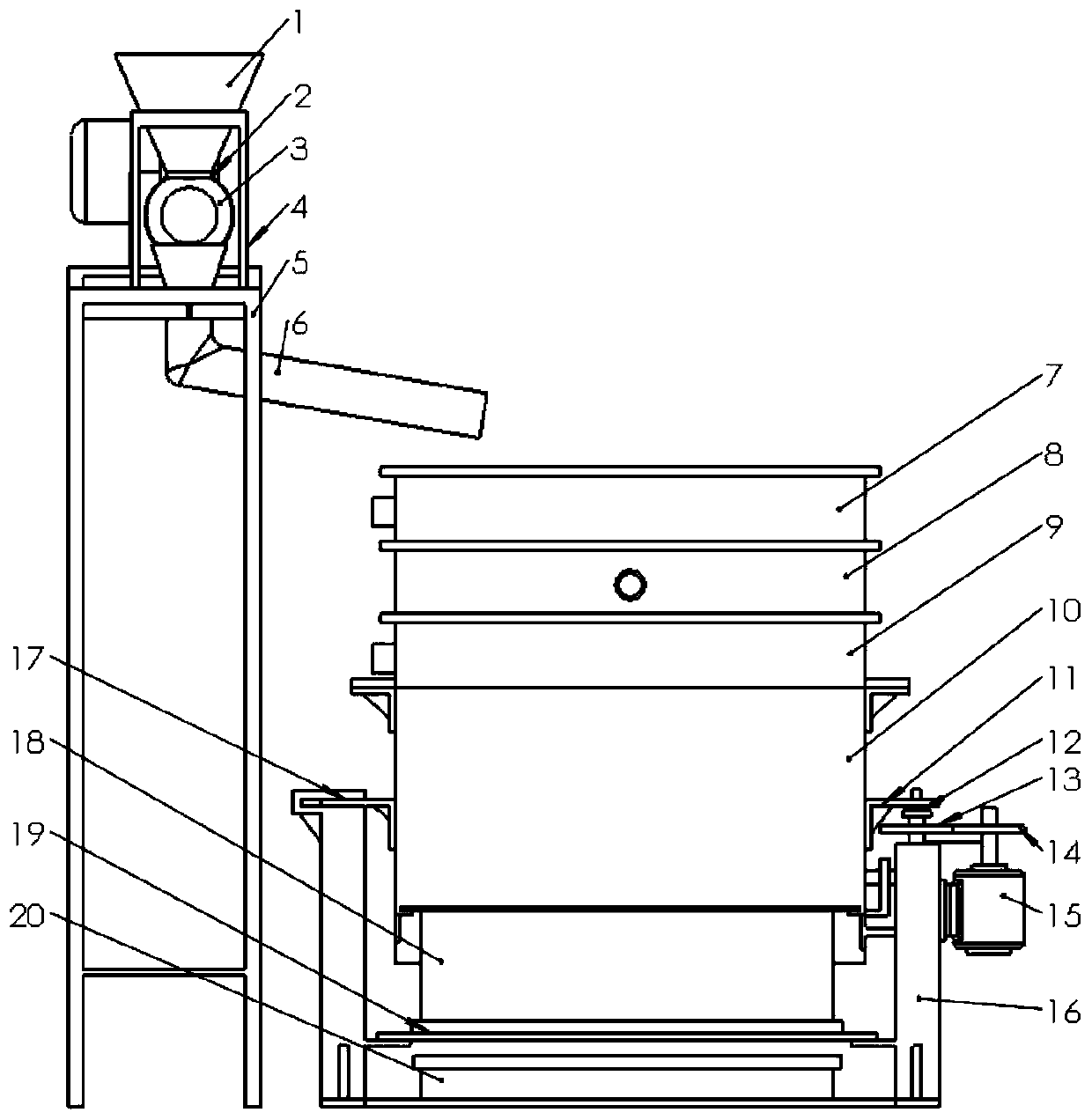

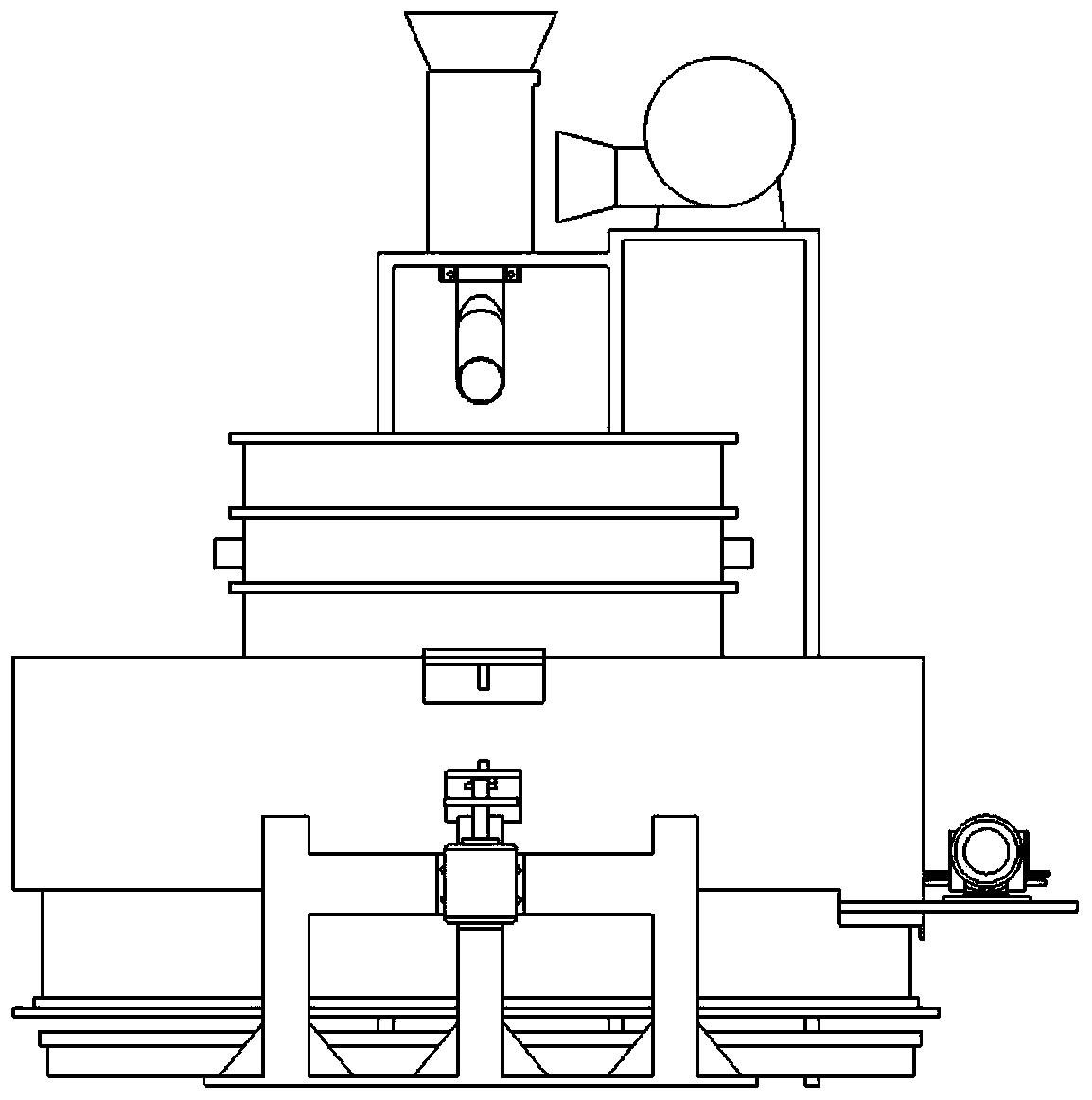

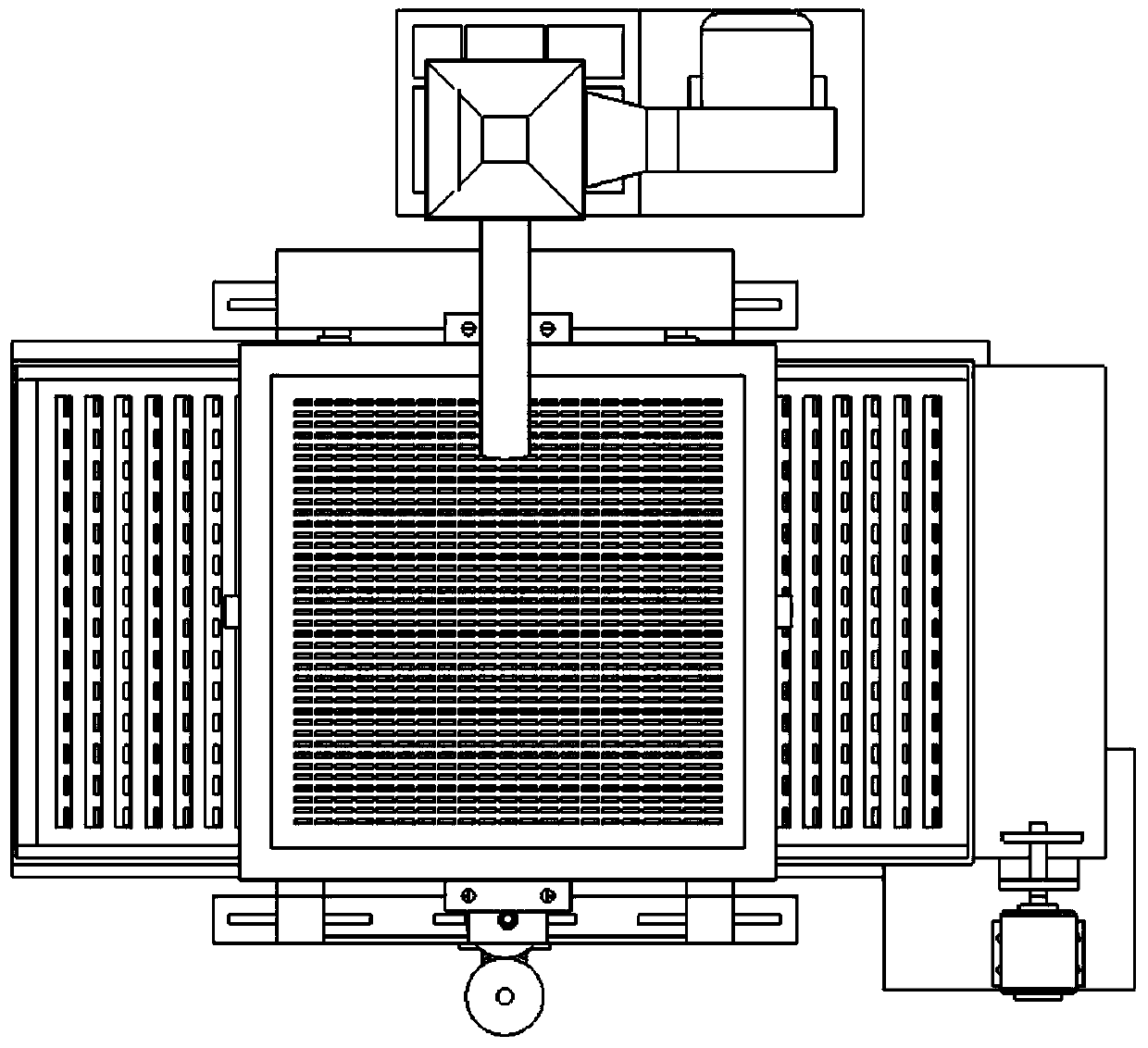

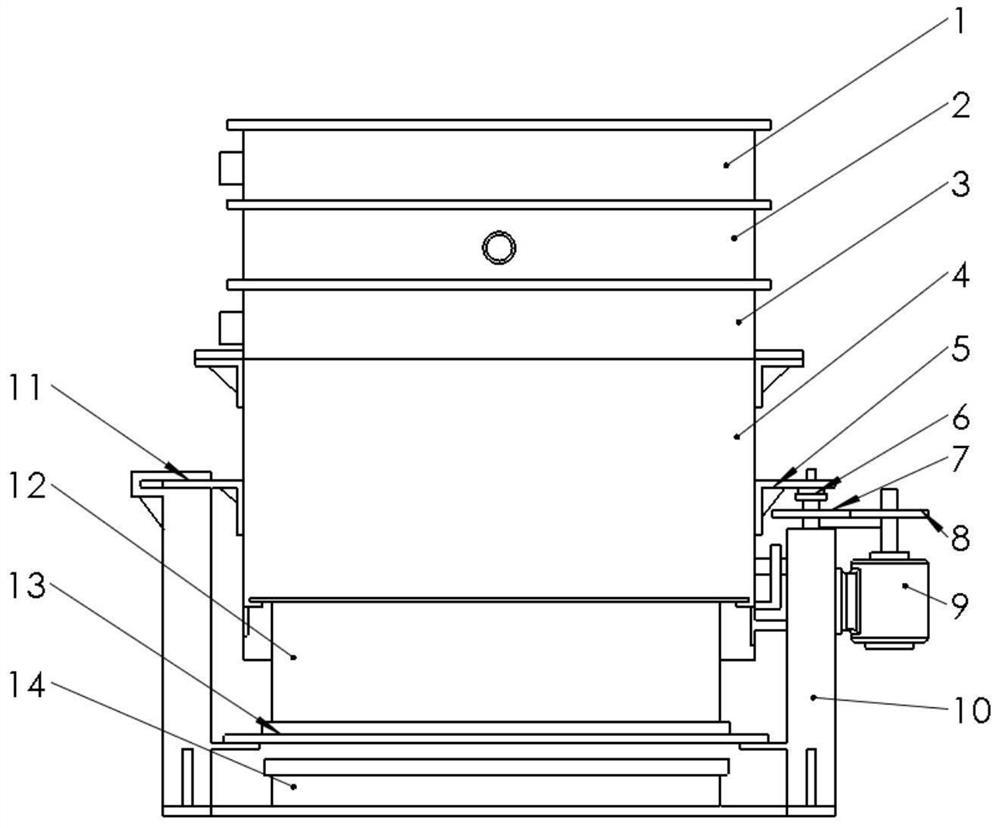

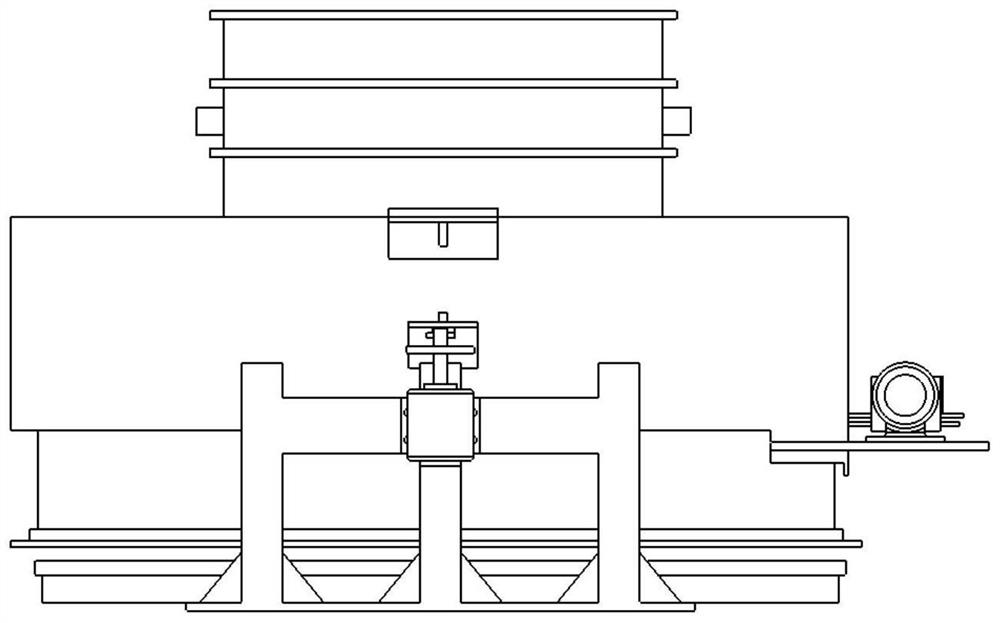

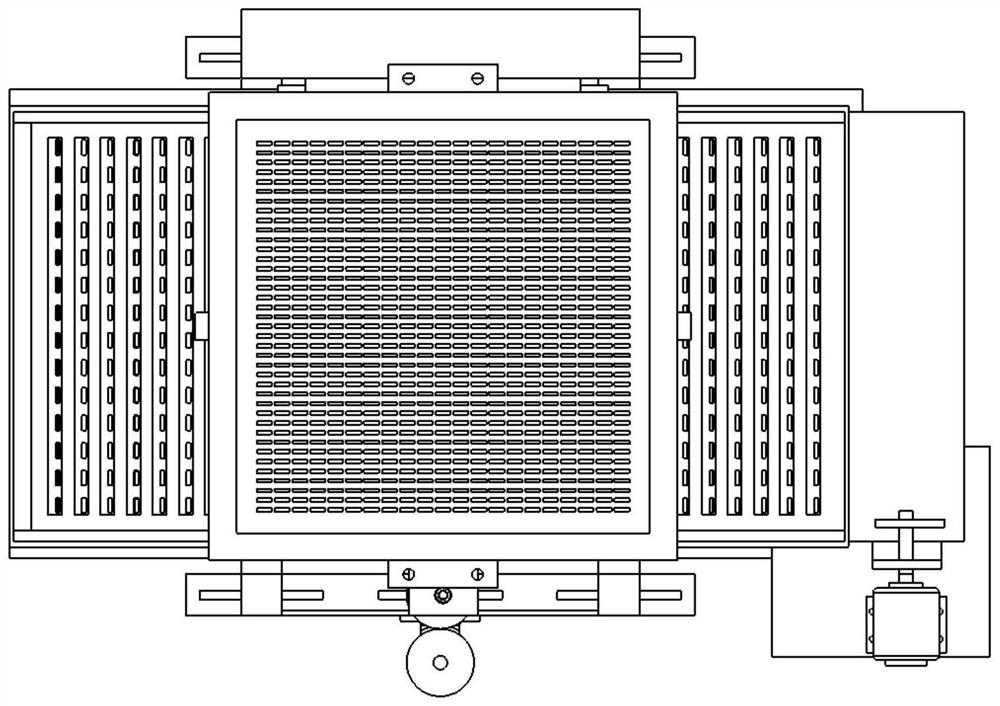

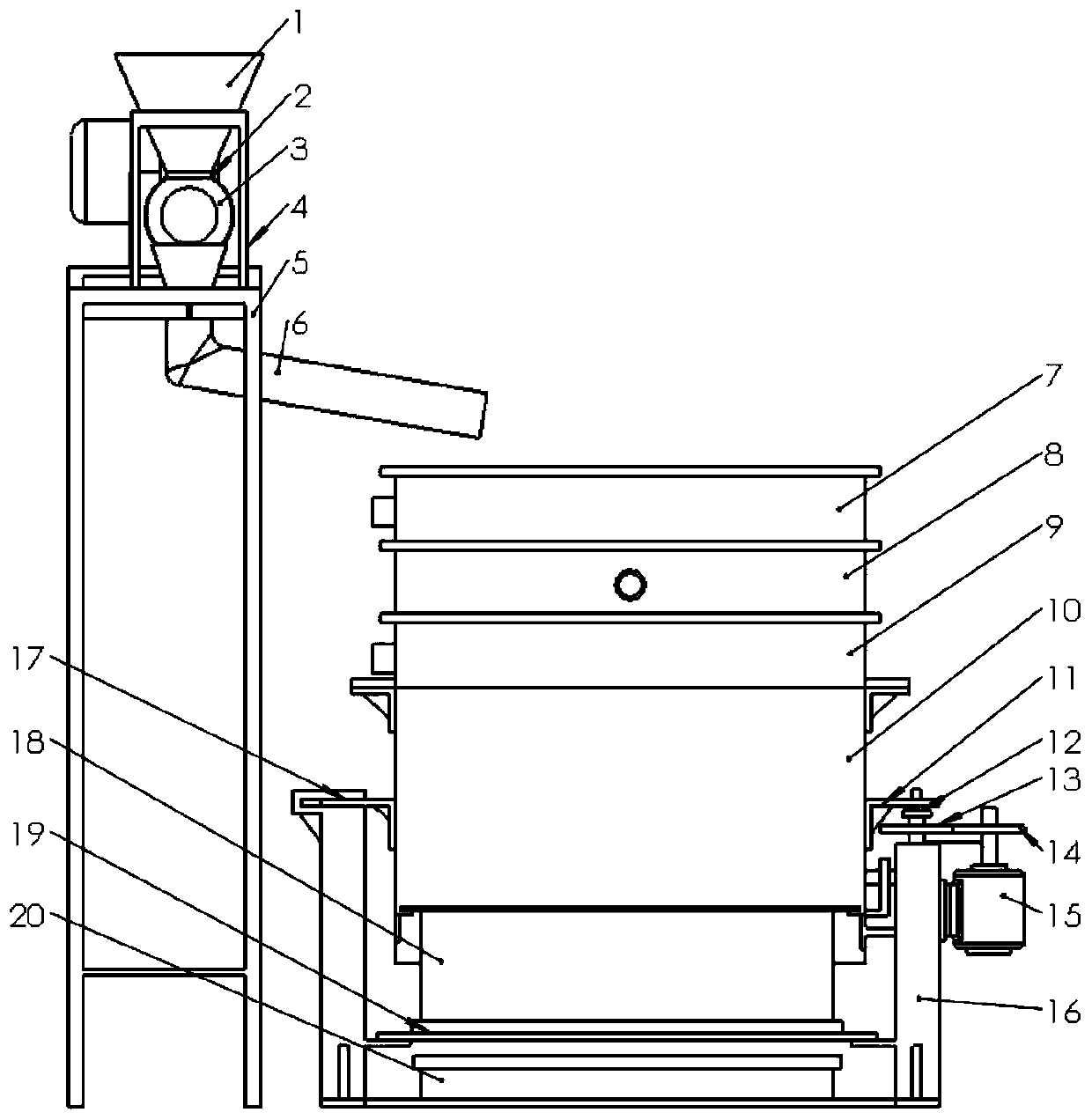

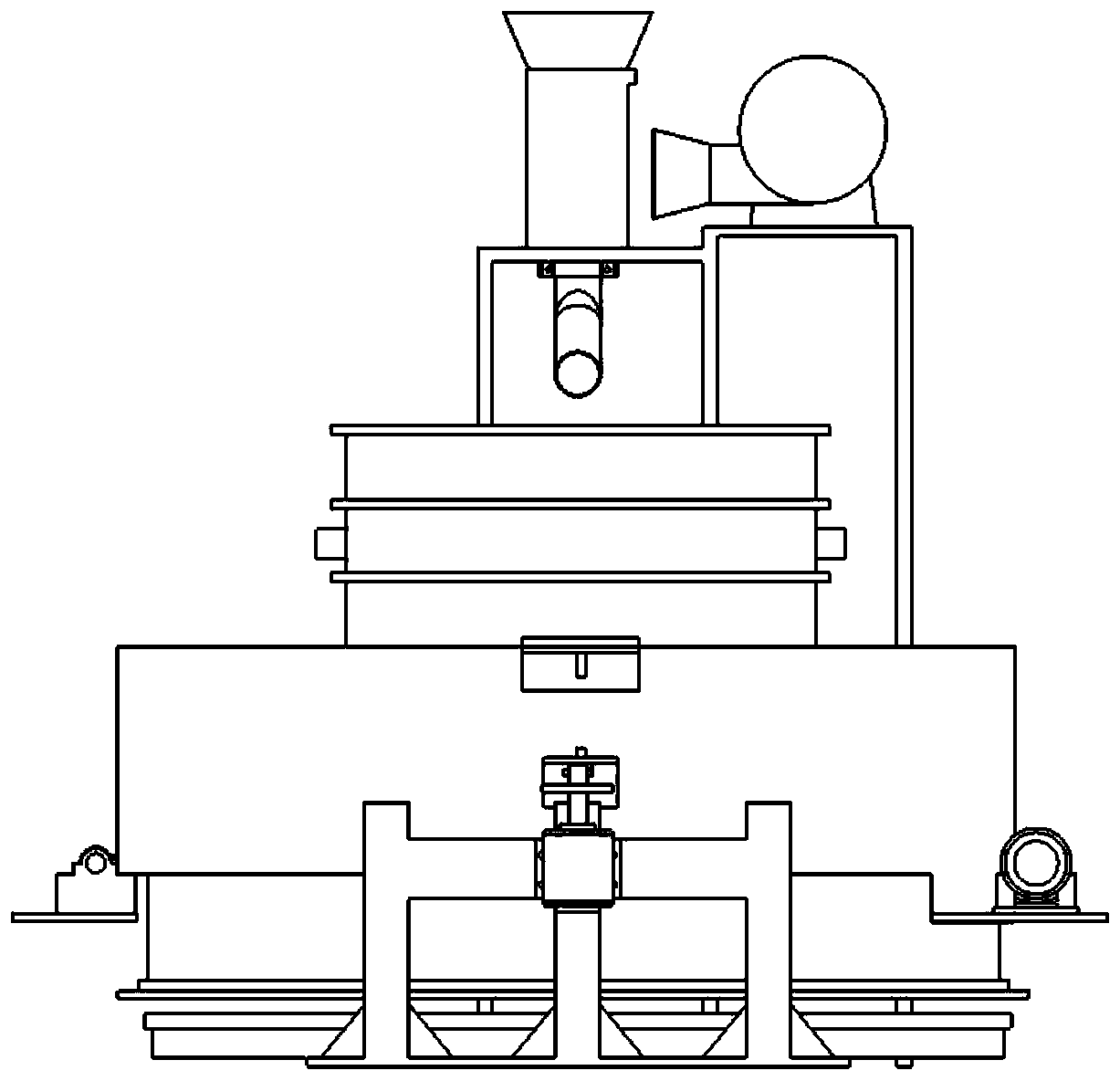

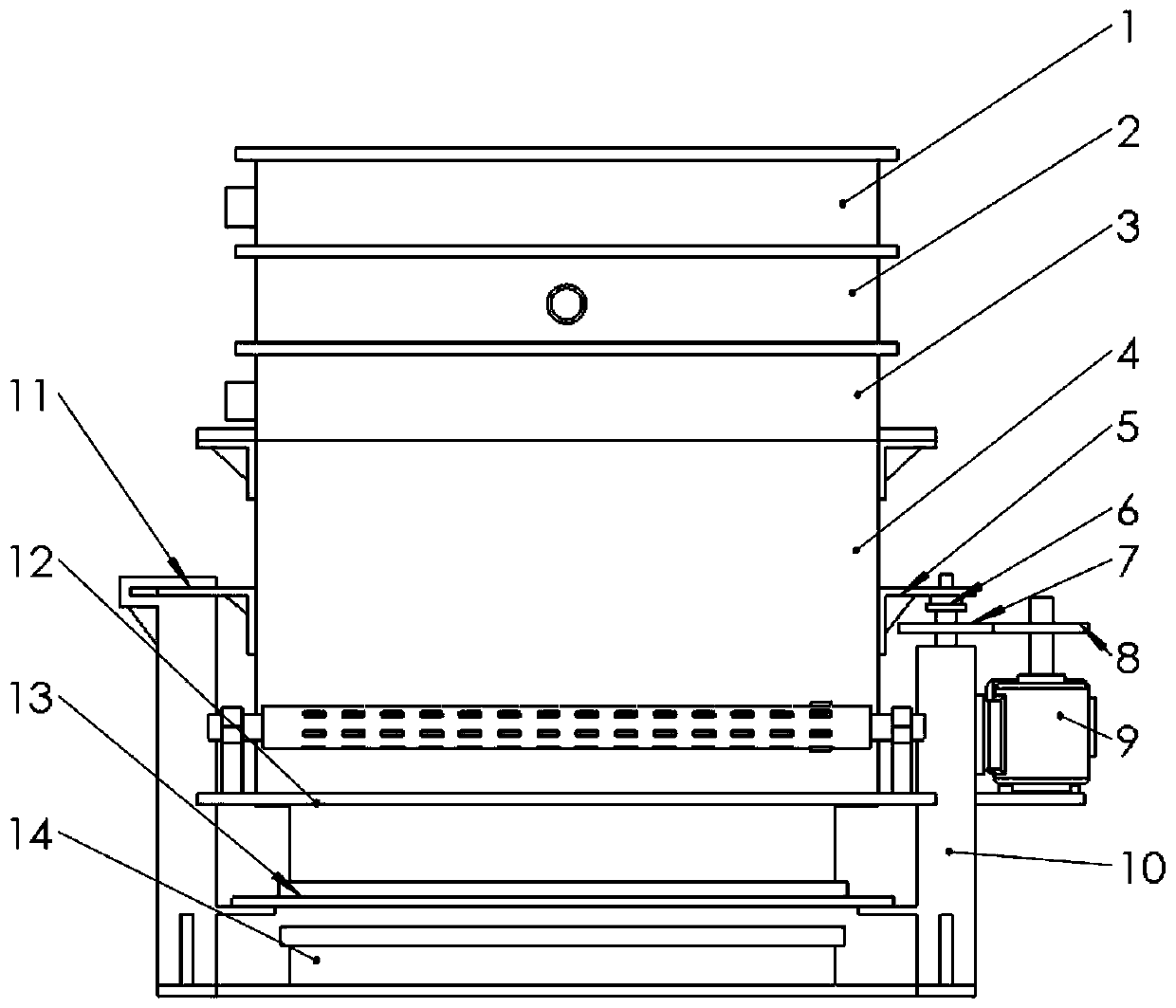

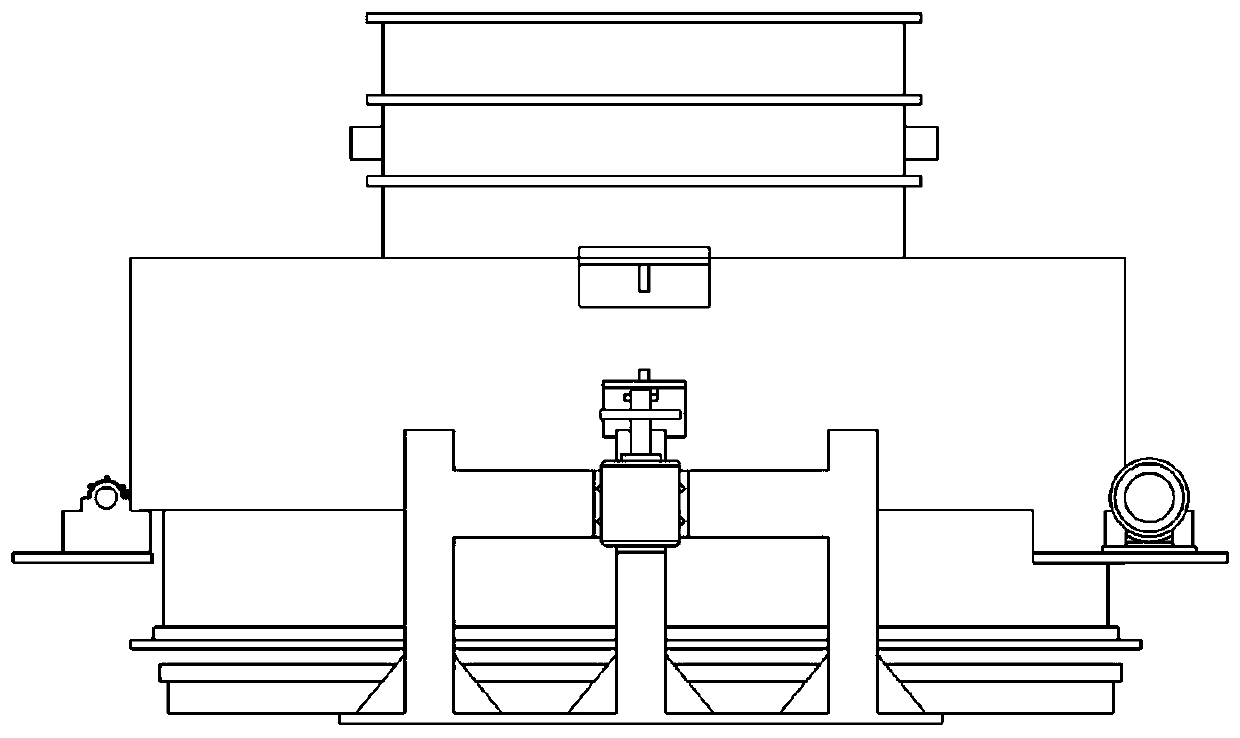

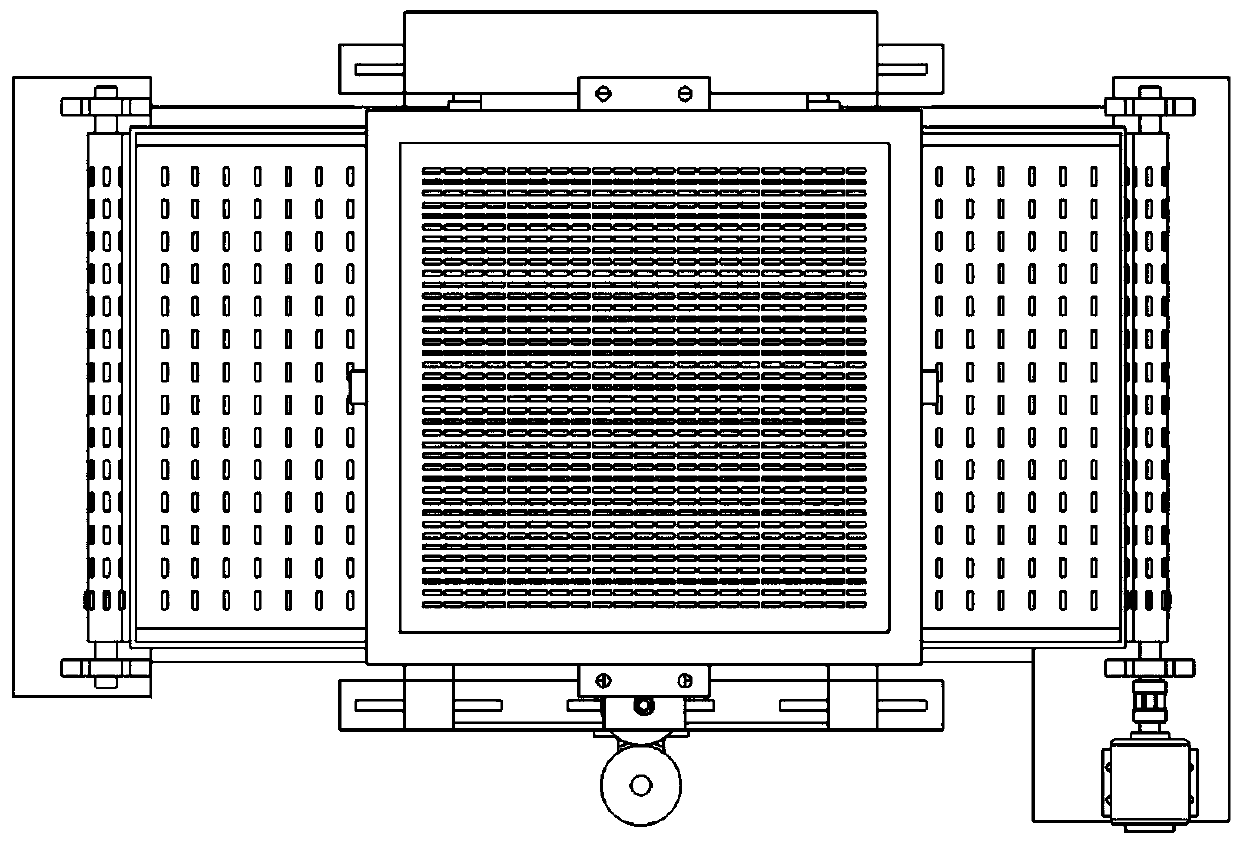

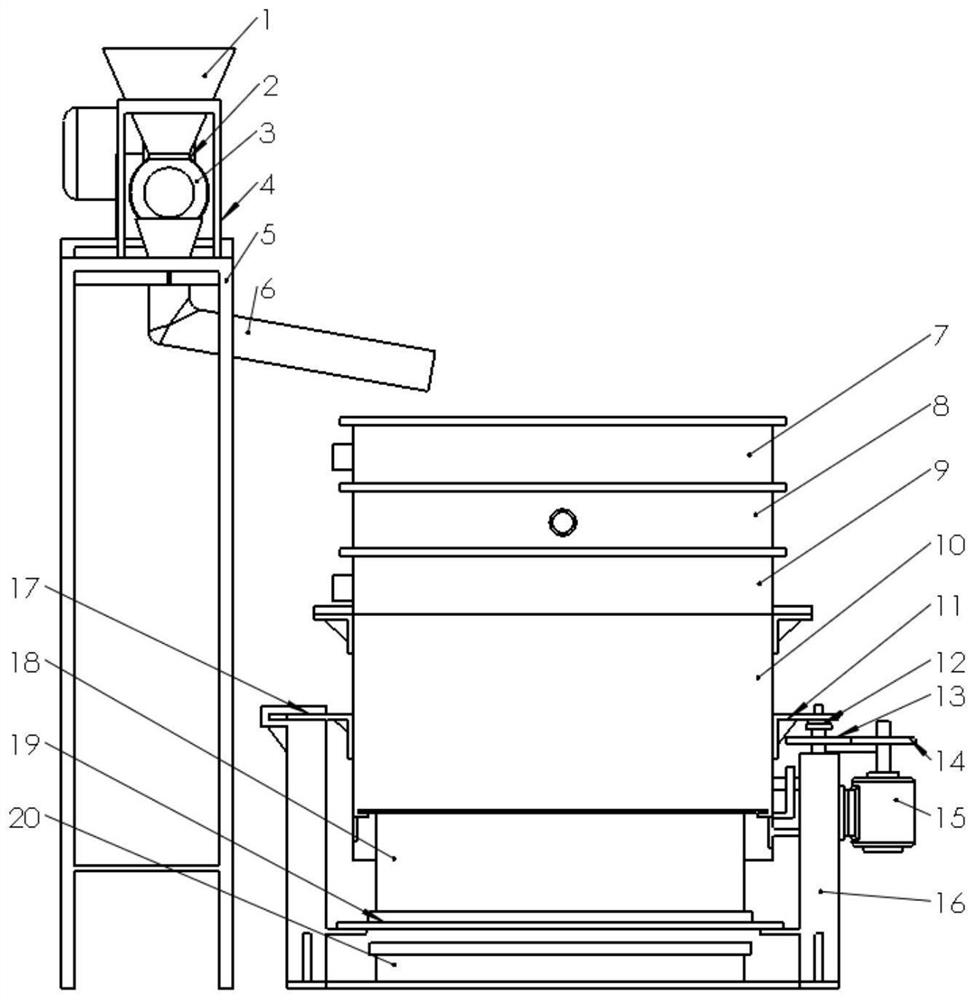

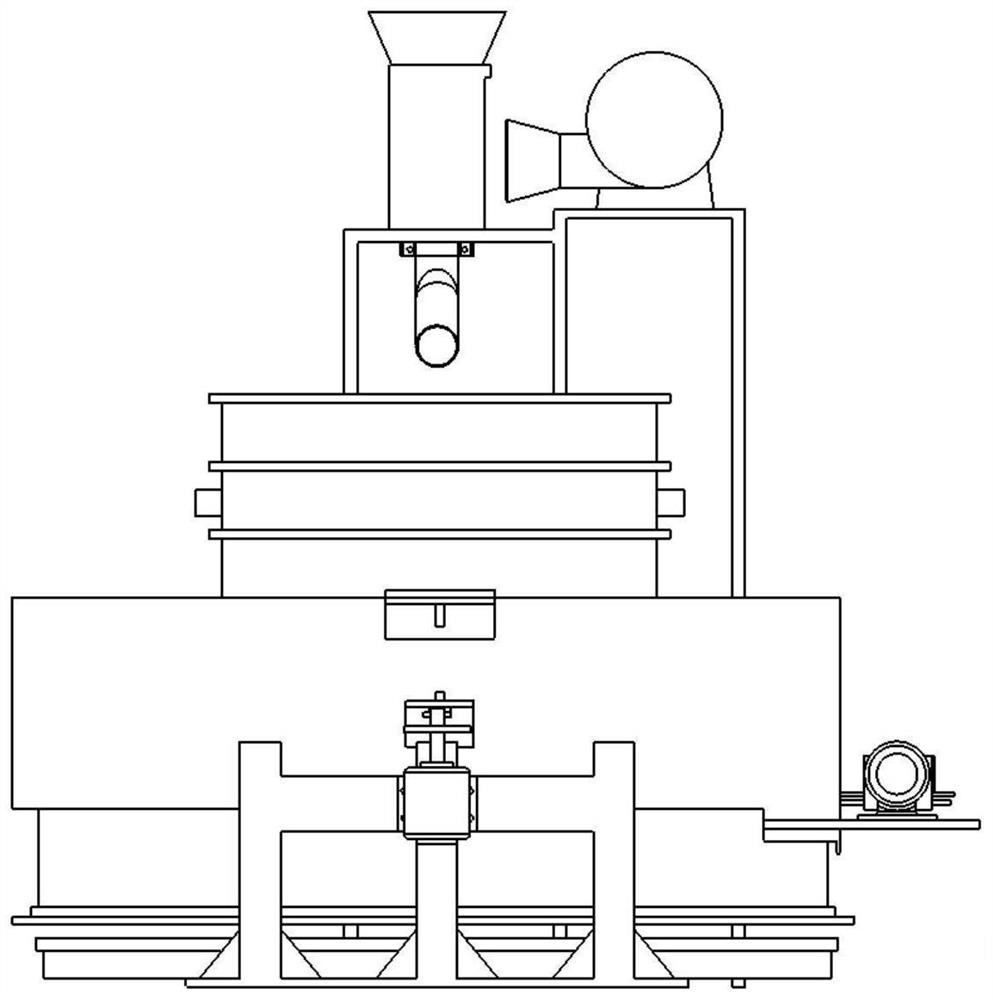

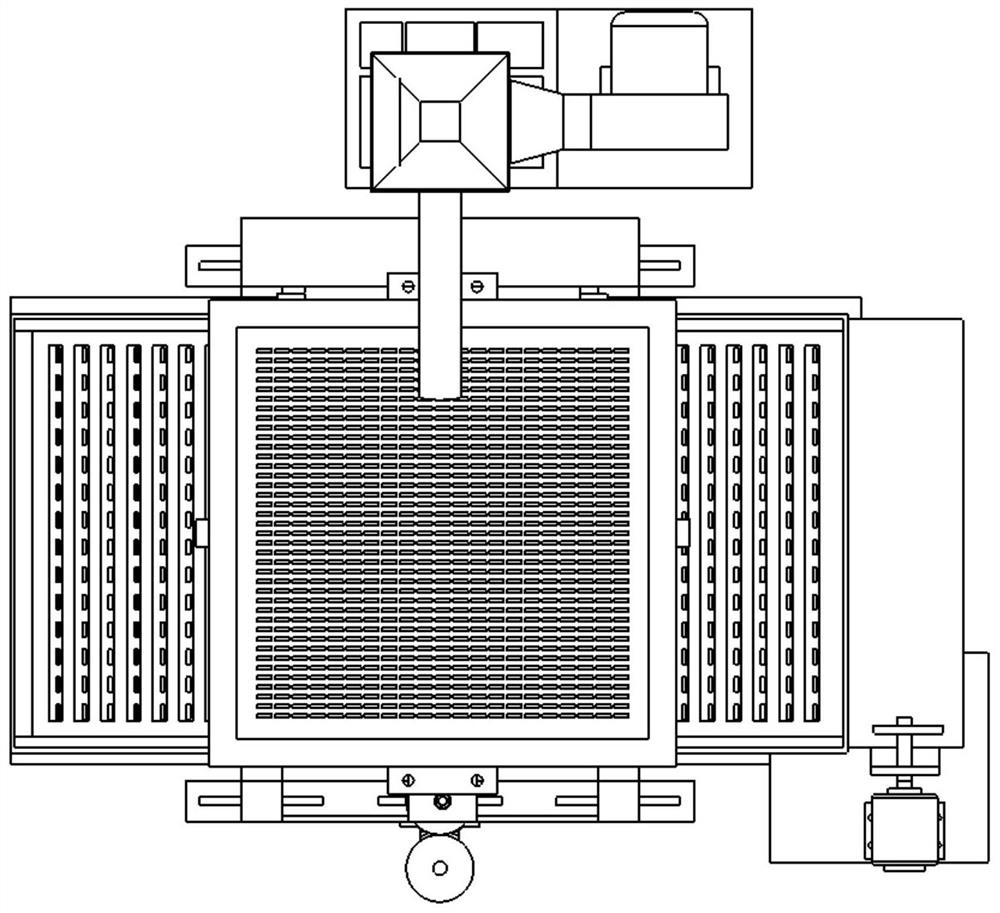

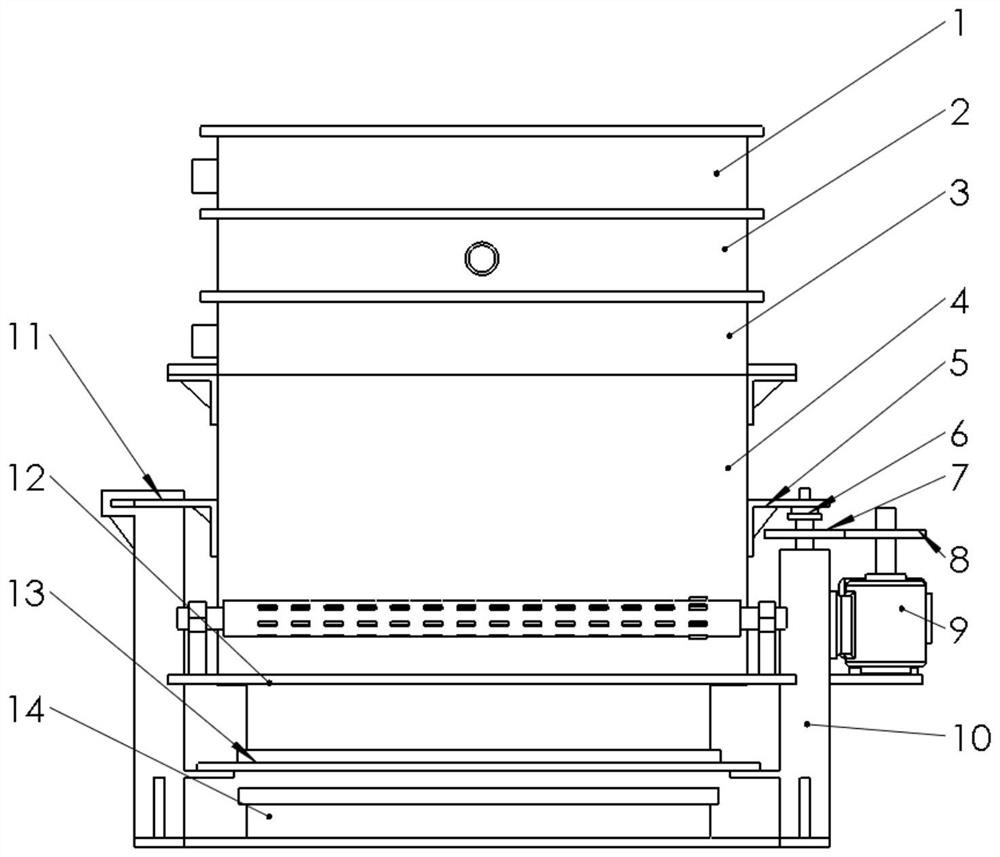

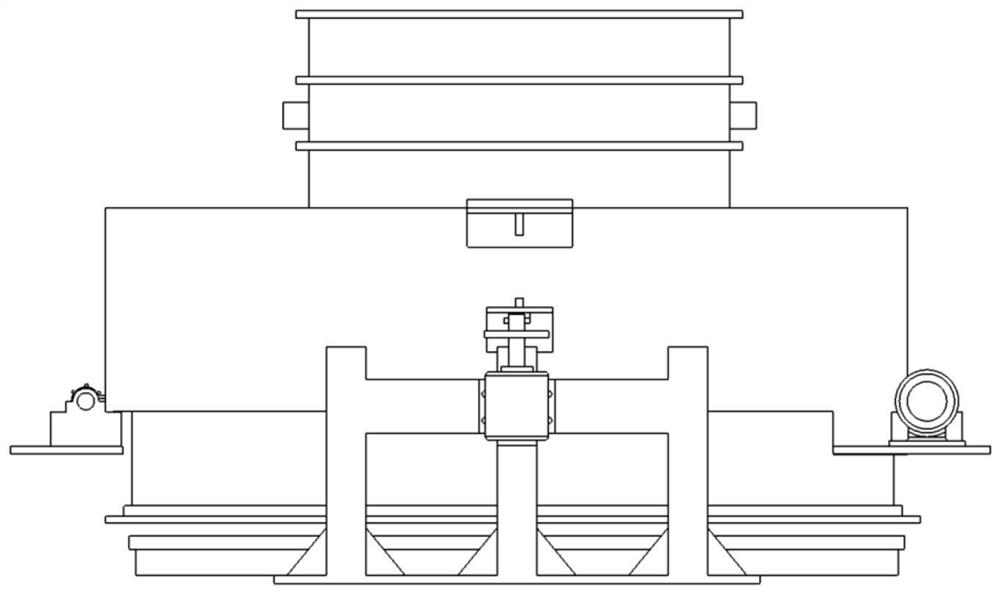

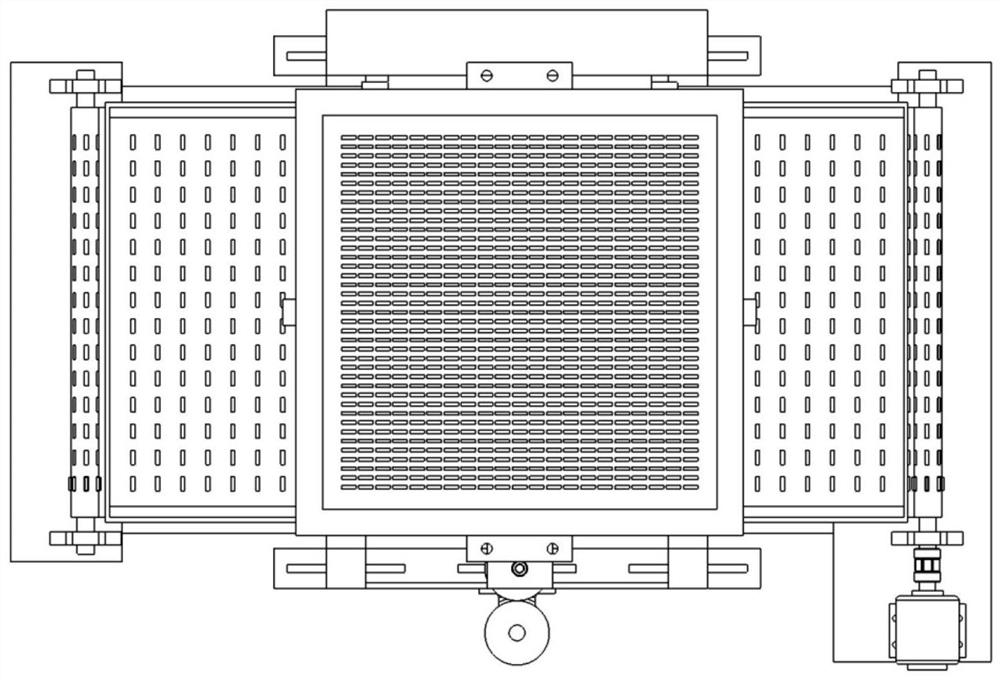

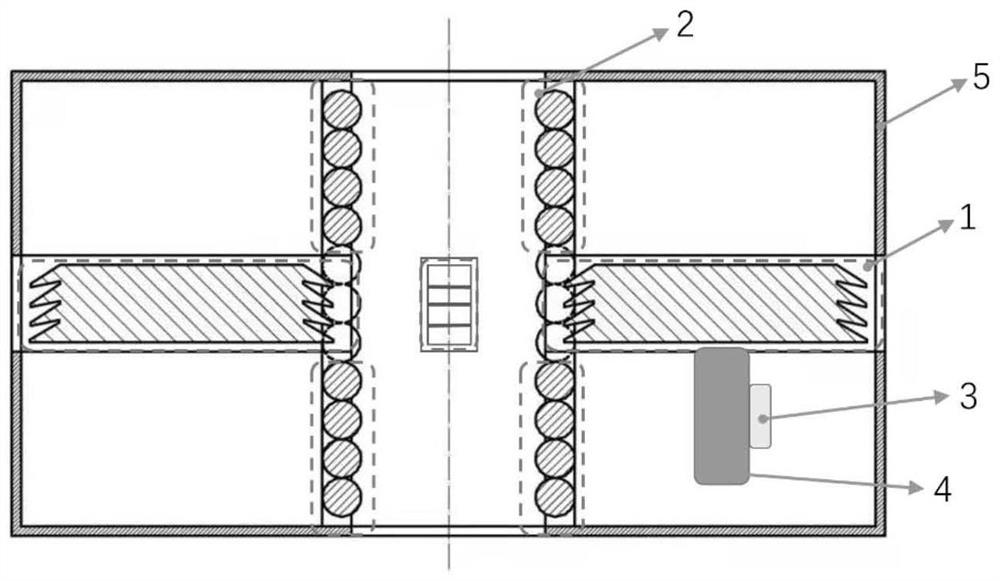

Mechanical sliding sheet translation type precise seeding mechanism

ActiveCN110291872ATake advantage ofAvoid shortageDibble seedersSeed depositing seeder partsGear wheelReciprocating motion

The invention relates to a mechanical sliding sheet translation type precise seeding mechanism which comprises a seed selecting mechanism, a seed filling mechanism and a seed filling-discharging mechanism. The seed filling mechanism comprises a mechanical translation driving mechanism fixedly connected with the side wall of a seed filling box, a translation sliding sheet structure is arranged on one side opposite to the mechanical translation driving mechanism and comprises a U-shaped sliding groove in fixed arrangement and a supporting sliding sheet, and one horizontal end of the supporting sliding sheet is fixed on the side wall of the seed filling box while the other end of the same can slide in the U-shaped sliding groove; a power output shaft of a small motor of the seed filling-discharging mechanism is horizontal, an upper linkage gear is meshed with an upper rack frame, a lower linkage gear is meshed with a lower rack frame, the upper rack frame is fixedly connected with an upper cover plate, and the lower rack frame is fixedly connected with a lower bottom plate; each of the upper linkage gear and the lower linkage gear is a non-full-tooth gear, and only one of the upper linkage gear and the lower linkage gear is in a meshed state; the small gear respectively drives the upper cover plate and the lower bottom plate to be in reciprocating motion through the two rack frames to realize seed filling and seed discharging.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

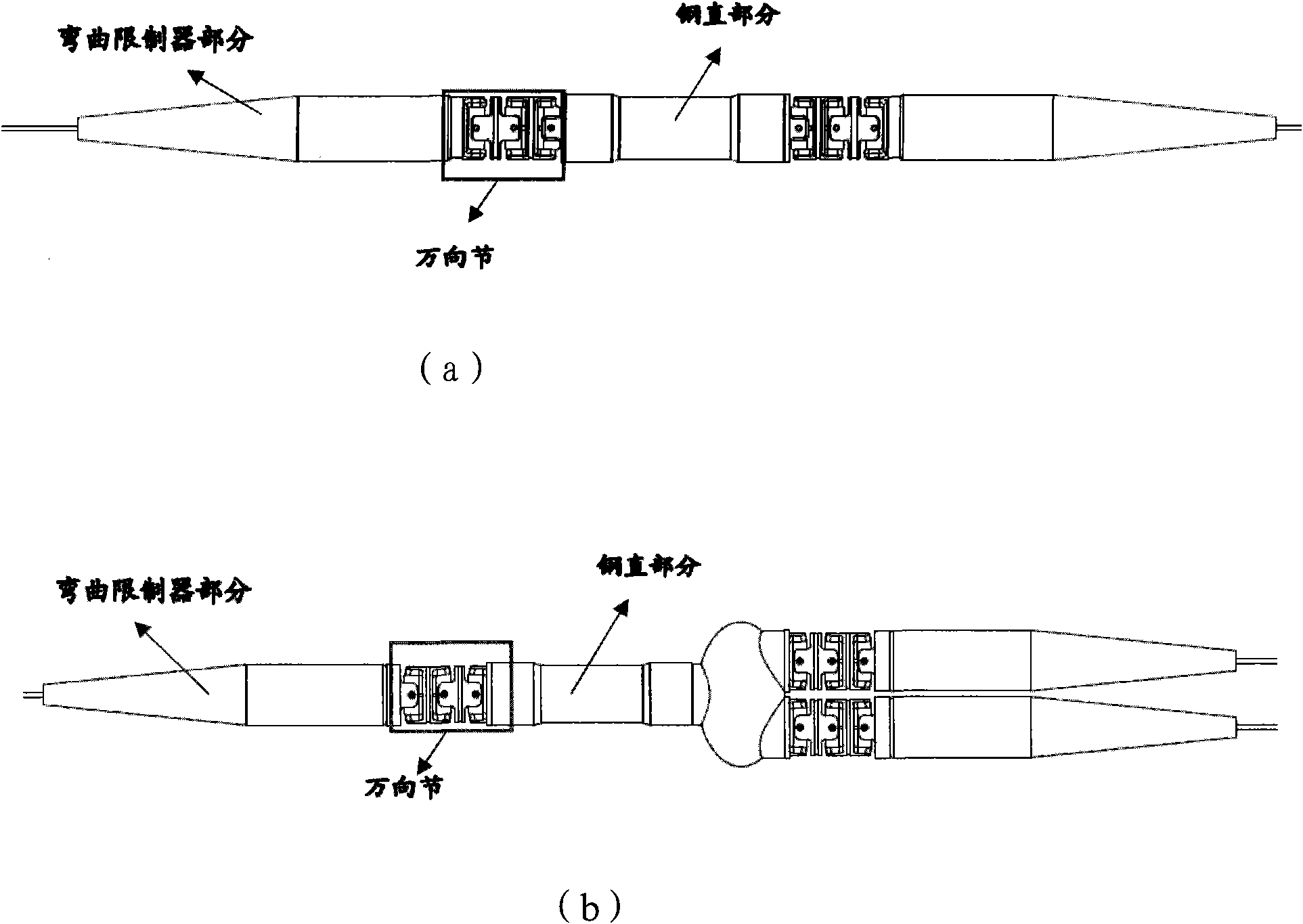

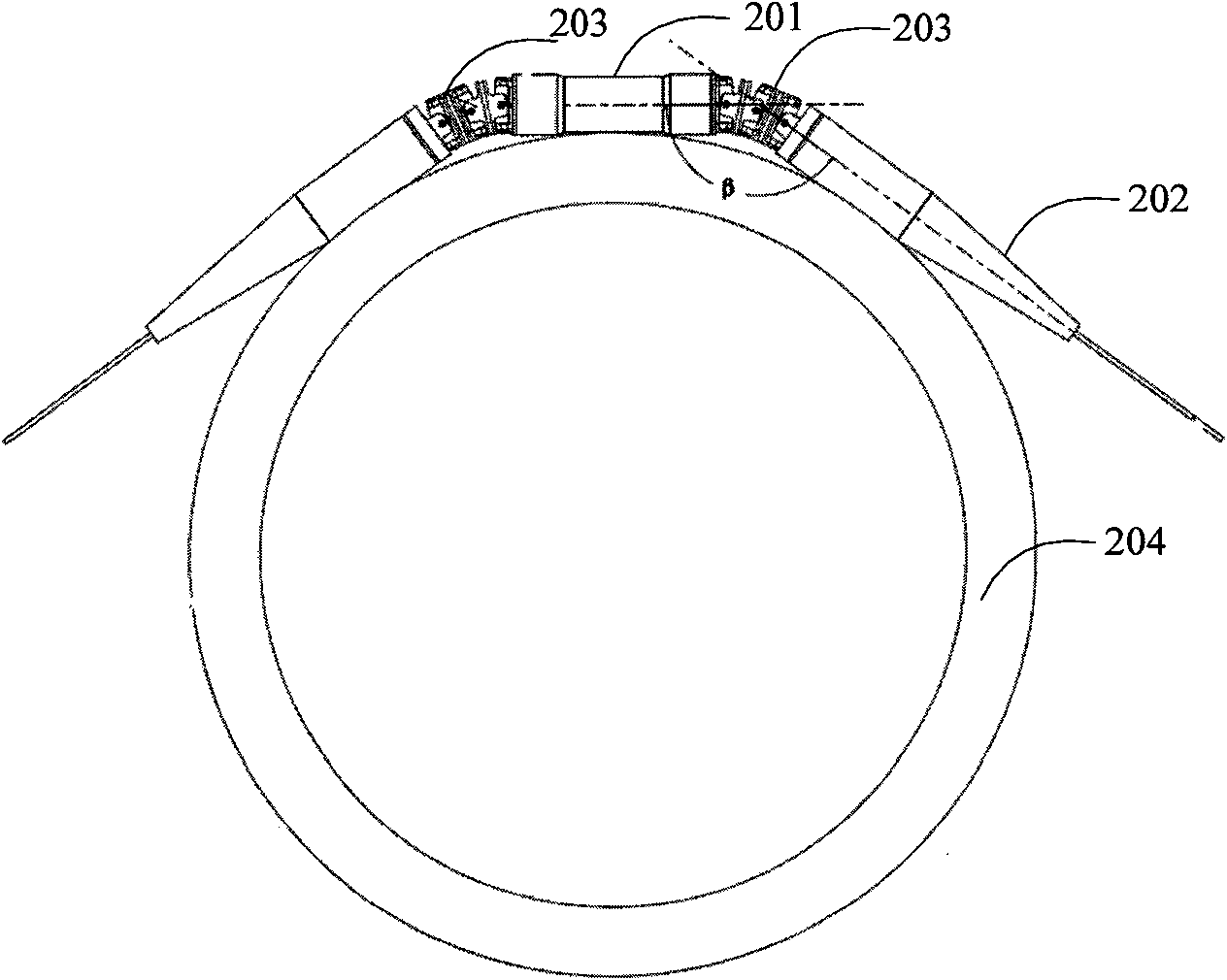

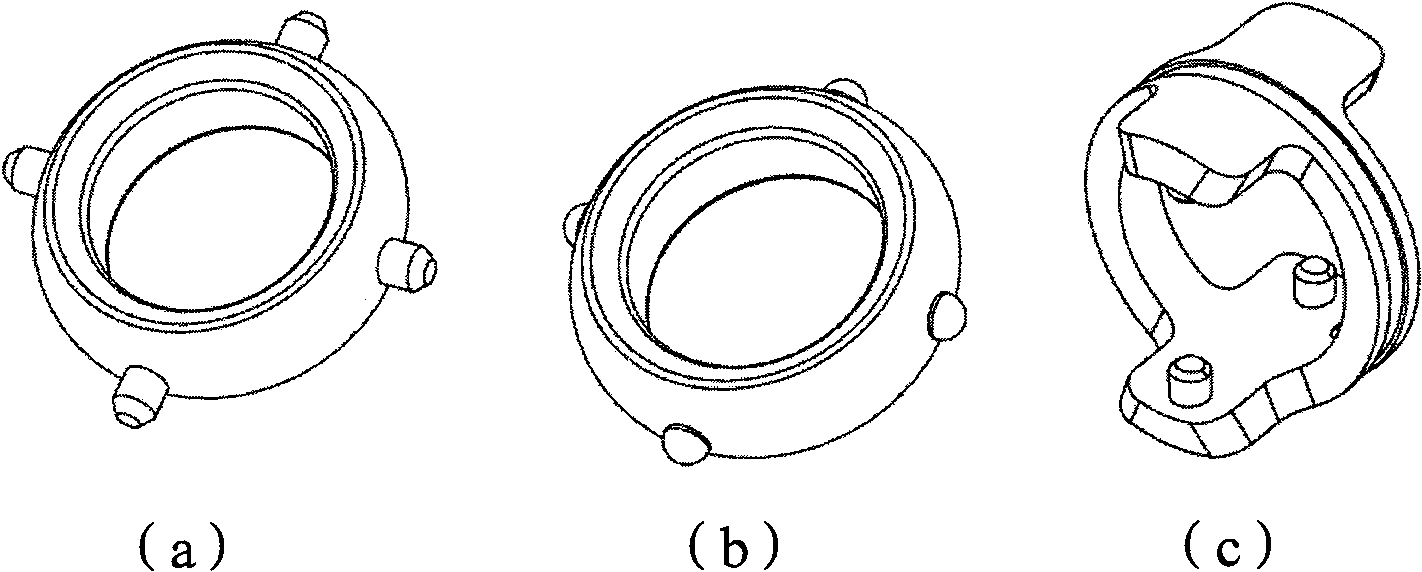

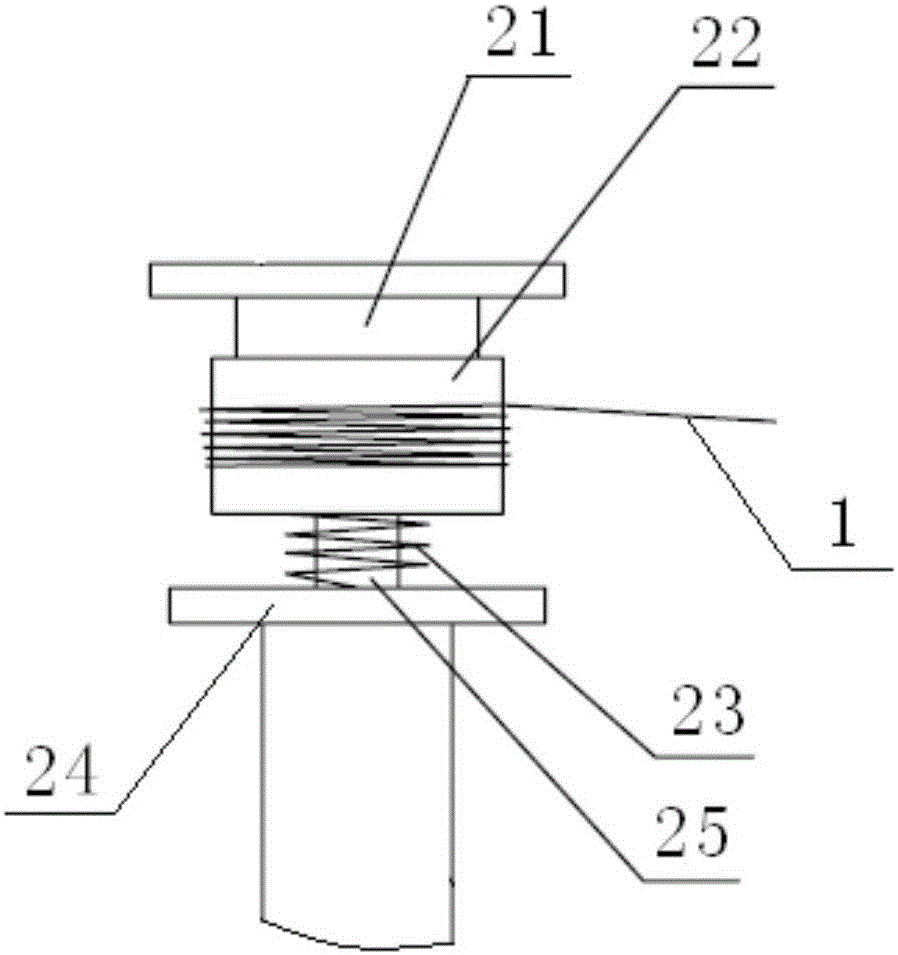

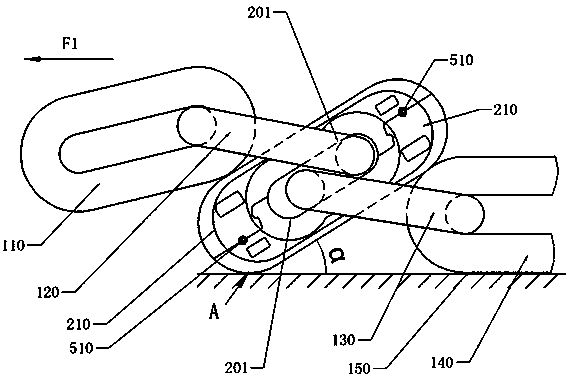

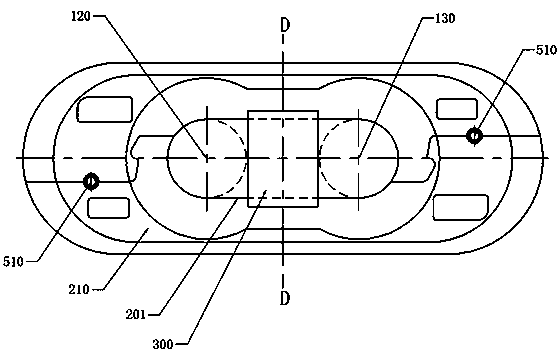

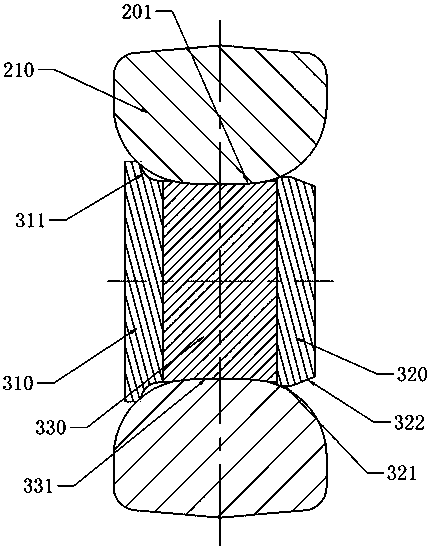

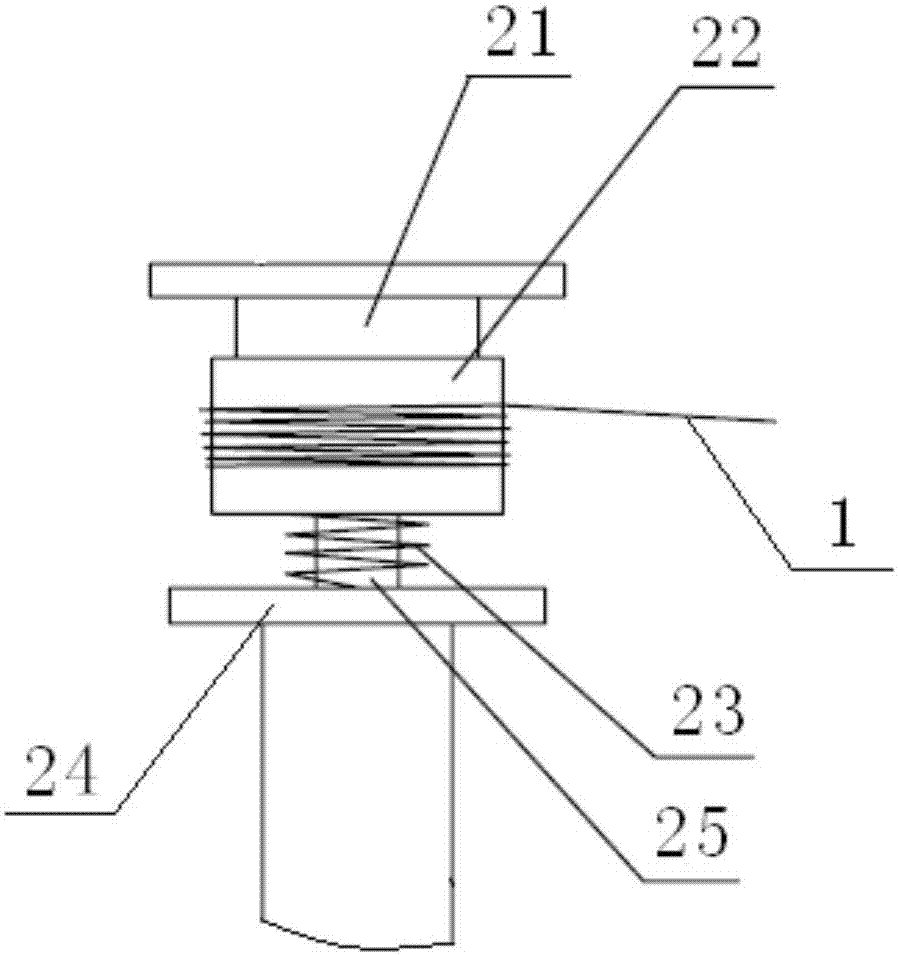

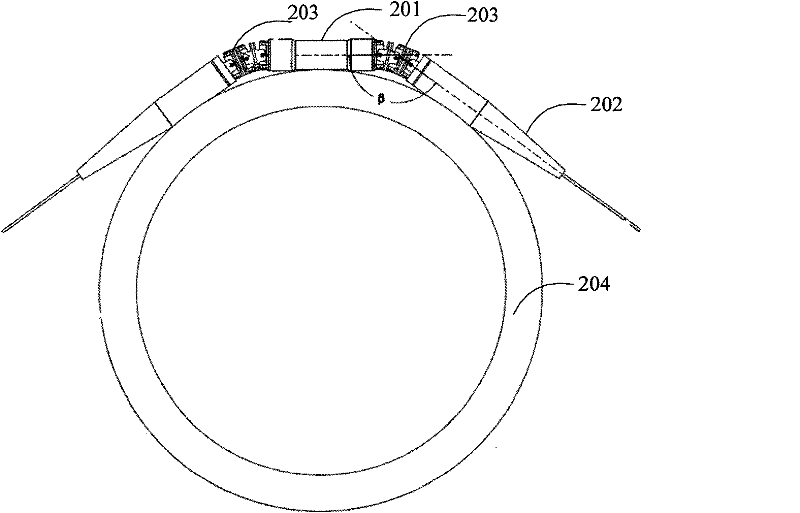

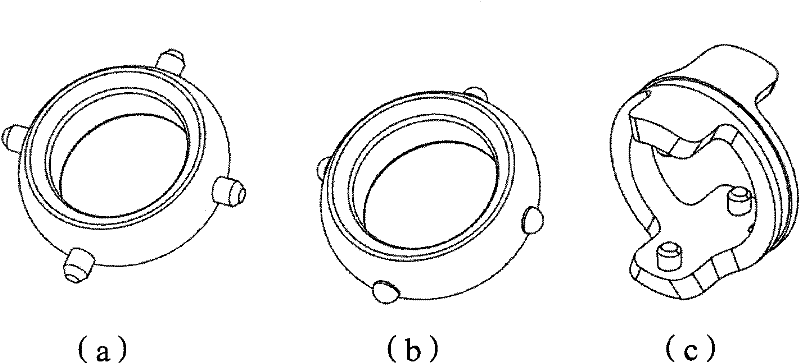

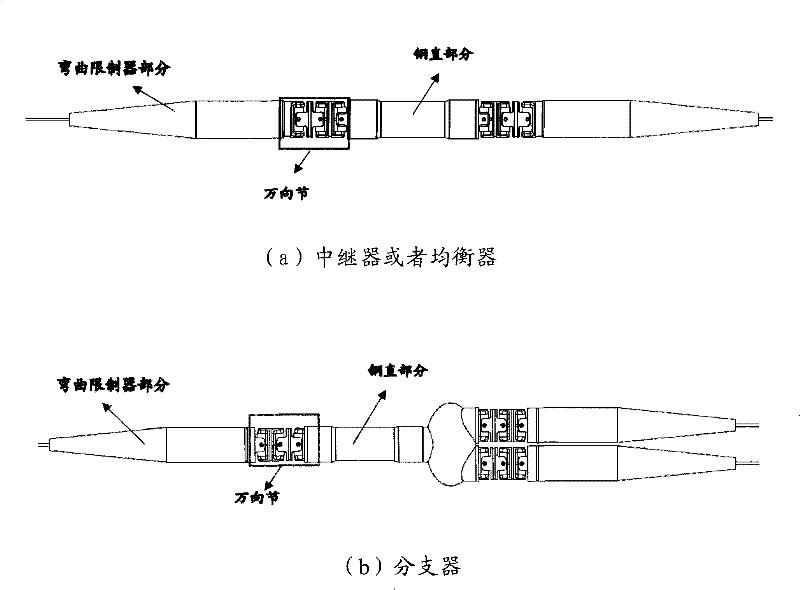

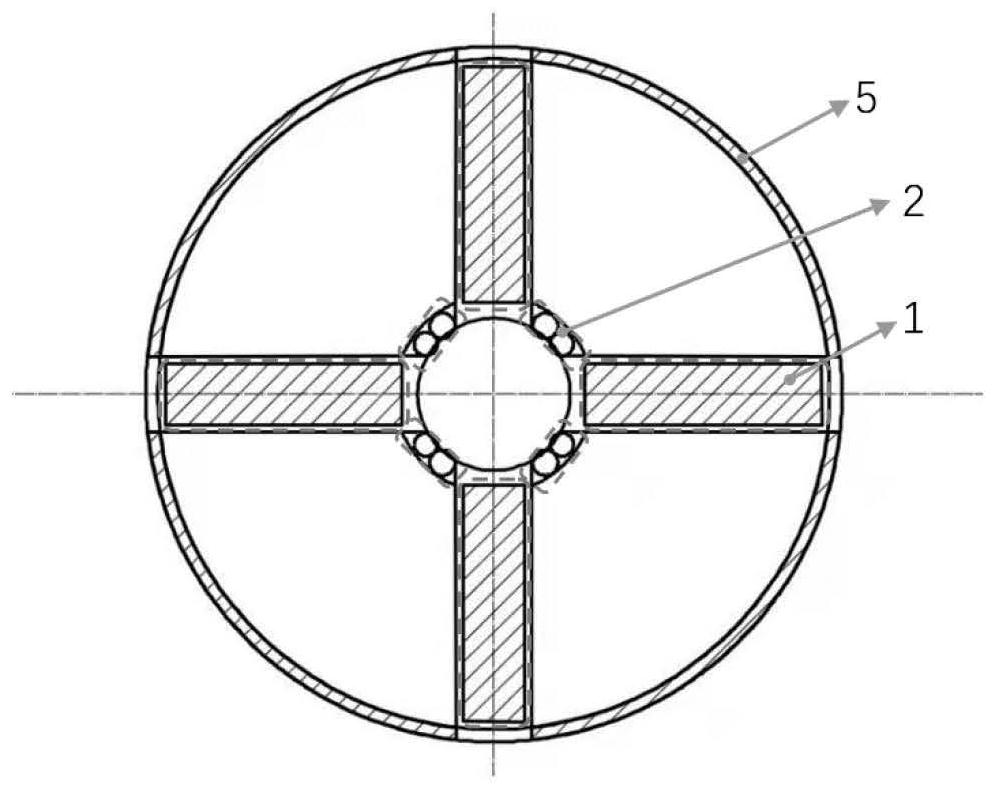

Universal joint and equipment realized by using the universal joint

ActiveCN101561015AAvoid self-locking phenomenonYielding couplingOptical fibre/cable installationUniversal jointSelf locking

The embodiment of the invention discloses a universal joint and equipment realized by using the universal joint. The universal joint comprises at least two rotating rings, at least one joint and at least four rotating pins, wherein one end of the joint is connected with the first rotating ring through two embedded rotating pins with certain angle in between; the other end of the joint is connected with the second rotating ring through the other two embedded rotating pins with certain angle in between, wherein the value selection range of certain angle includes 180 degrees, two rotating pins at one end of the joint are parallel to the other two rotating pins at the other end of the joint. While avoiding a self-locking phenomenon, the universal joint provided by the embodiment effectively protects the rotating pins.

Owner:HUAWEI MARINE NETWORKS CO LTD

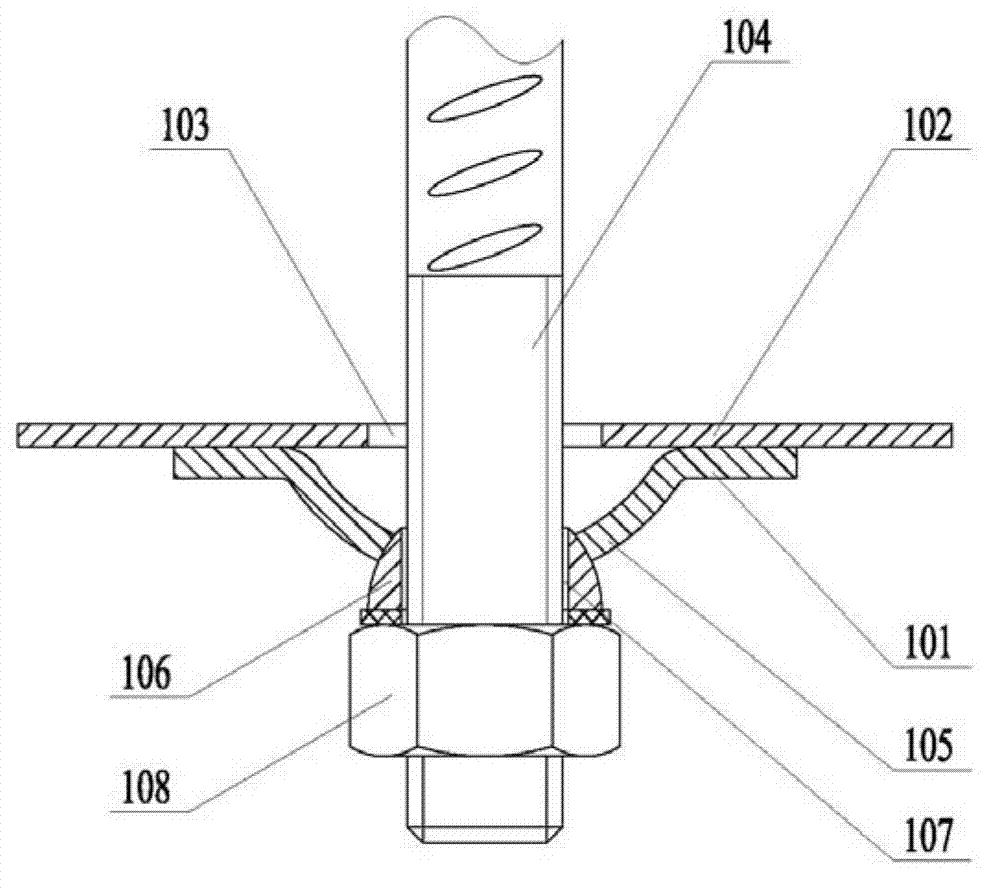

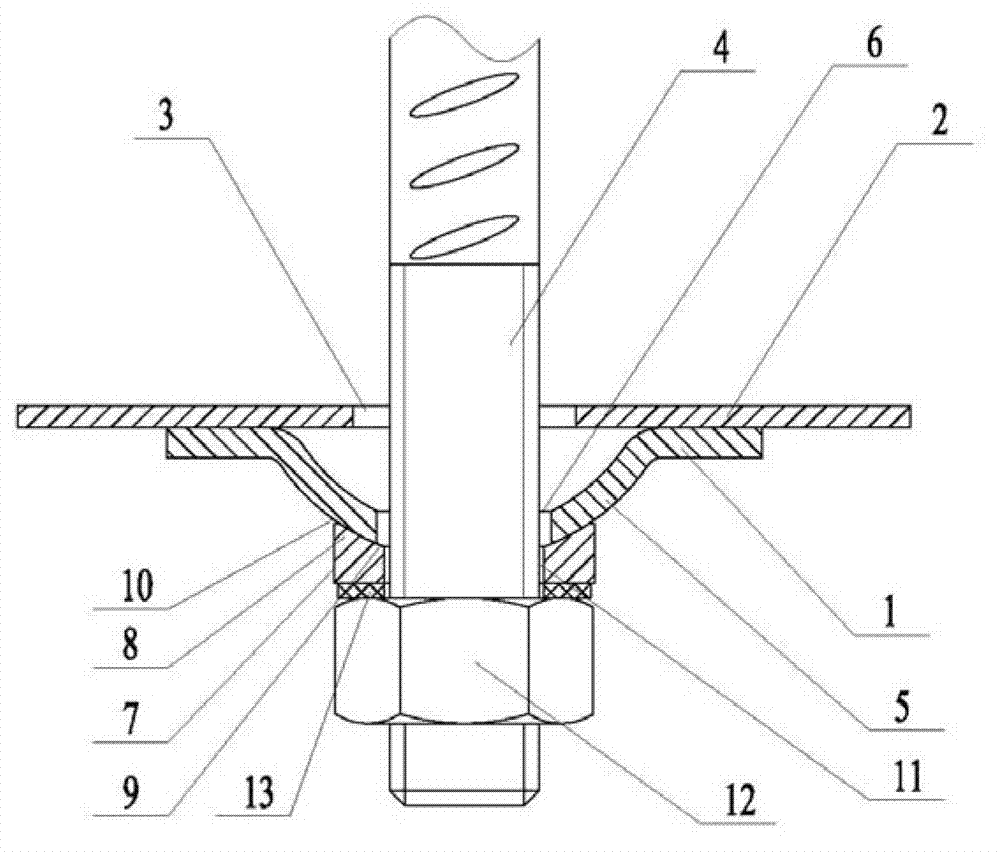

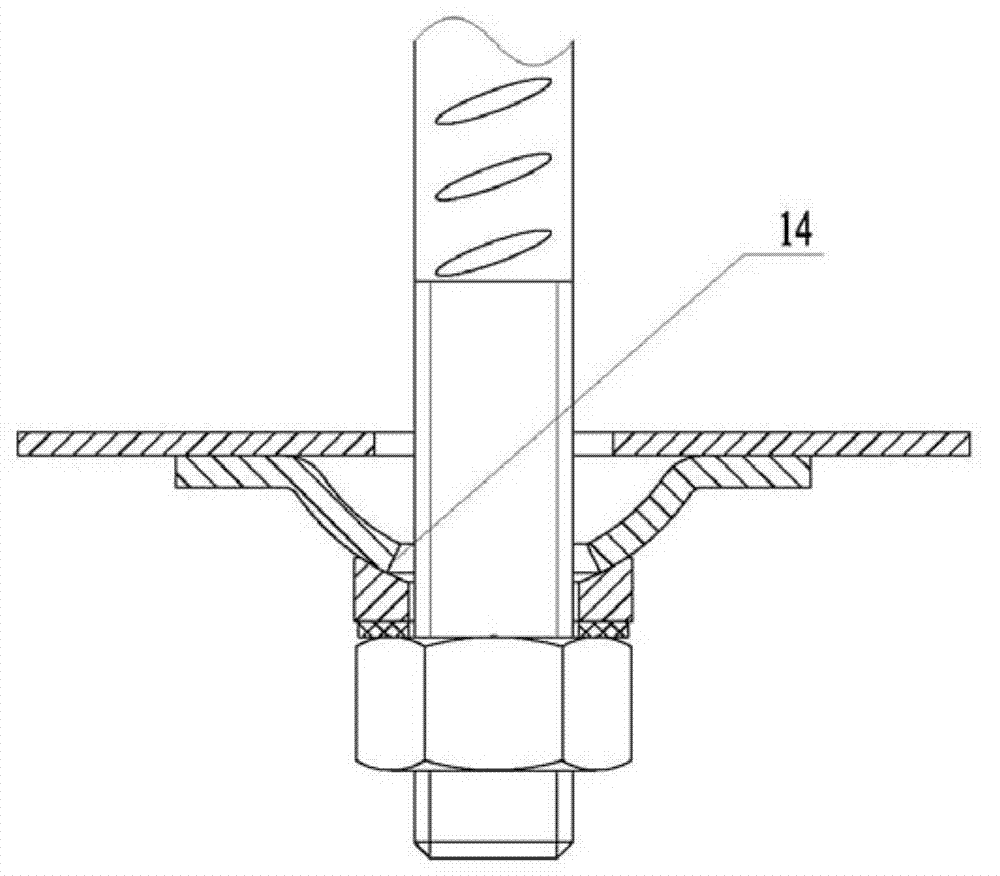

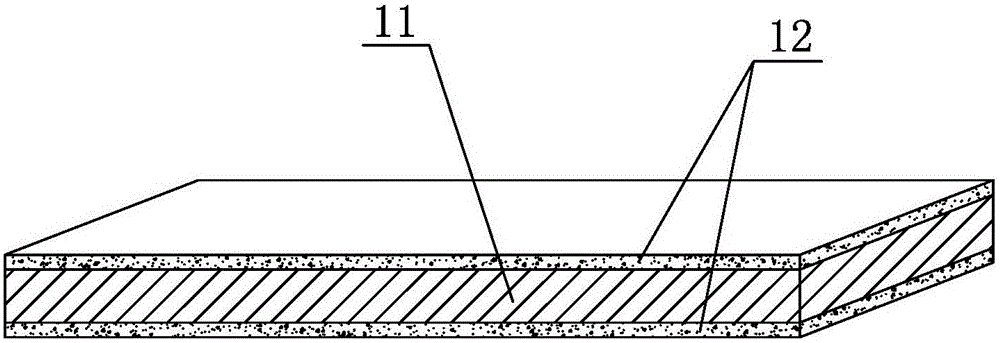

Anti-self-locking anchor-bolt support plate

InactiveCN102900448AAvoid anchor thread breakageAvoid bolt breakageAnchoring boltsSelf lockingSteel belt

The invention provides an anti-self-locking anchor-bolt support plate. A self-aligning ball pad is arranged below an arched tray of the anchor-bolt support plate, the upper part of the self-aligning ball pad is provided with a central rotary component, and the internal rotary surface of the central rotary component and the external rotary surface of a circular arch part are cooperatively arranged. According to the invention, by adopting a design of cooperatively arranging the internal rotary surface of the central rotary component and the external rotary surface of the circular arch part, the occurrence of a phenomena that the self-aligning ball pad is self-locked because a stress generated by the downward bending of a steel belt acts on the self-aligning ball pad can be effectively prevented.

Owner:TIANDI SCI & TECH CO LTD

Multi-connecting-rod loading mechanism

The invention discloses a multi-connecting rod loading mechanism, which comprises a first driving rod, a first connecting rod, a swinging arm, a pull rod, a movable arm, a movable arm elevating mechanism and a scraper bucket, wherein one end of the movable arm is connected with a frame, and the other end of the movable arm is connected with the scraper bucket and is elevated and lowered under theaction of the movable arm elevating mechanism; one end of the first driving rod is connected with the frame, and the other end of the first driving rod is connected with the first connecting rod; thefirst connecting rod is connected with the swinging arm; one end of the swinging arm is connected to the movable arm, and the other end of the swinging arm is connected with the pull rod; the other end of the pull rod is connected with the scraper bucket; and the first driving rod is used for controlling the scraper bucket to rotate around the movable arm under the driving action of a motor. In the invention, a hydraulic transmission system is replaced by the multi-connecting-rod loading mechanism, so that the defects of high maintenance cost and the like of a hydraulic excavator are overcome; and simultaneously, the first connecting rod, the swinging arm and the pull rod are connected with one another, so that the strange phenomenon and an oversize or undersize transmission angle among the first connecting rod, the swinging arm and the pull rod due to the approach or reach of the scraper bucket of a mechanical loader to a limit position can be avoided easily on the premise of meetingthe requirement of loading, and the reliability of an electric loader is improved.

Owner:GUANGXI UNIV

High-friction-resistance ship arresting method

ActiveCN105696524AAvoid self-locking phenomenonSimple structureClimate change adaptationShipping equipmentBuoy

Owner:NINGBO UNIV

Mechanical sliding piece translational motion type precise sowing device with air channel seed selecting function

InactiveCN110402647AAvoid shortagePrevent fallingDibble seedersSeed depositing seeder partsCharge dischargeMechanical engineering

The invention relates to a mechanical sliding piece translational motion type precise sowing device with an air channel seed selecting function. The precise sowing device comprises a seed selecting mechanism, a seed charging mechanism and a seed charging-discharging mechanism. The seed selecting mechanism comprises a seed cleaning part and a sorting part; a funnel of the seed cleaning part is installed on a seed cleaning rack, the bottom of the funnel is provided with a guide groove, a poking amount adjusting plate is installed in the guide groove, a fan is arranged below the poking amount adjusting plate, one end of a conveying pipe is connected with an air outlet of the fan, and the other end of the conveying pipe extends to a position above the sorting part; the sorting part comprises aplurality of stacked sorting boxes, and the bottommost sorting box is arranged above the seed charging mechanism. The seed charging mechanism comprises a mechanical translational motion driving mechanism fixedly connected with the side wall of a seed charging box, a translational motion sliding piece mechanism is arranged on the opposite side of the mechanical translational motion driving mechanism, the translational motion sliding piece mechanism comprises a U-shaped sliding groove and a supporting sliding piece which are fixedly arranged, the supporting sliding piece is horizontal, one endof the supporting sliding piece is horizontally fixed on the side wall of the seed charging box, and the other end of the supporting sliding piece can slide in the U-shaped sliding groove.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

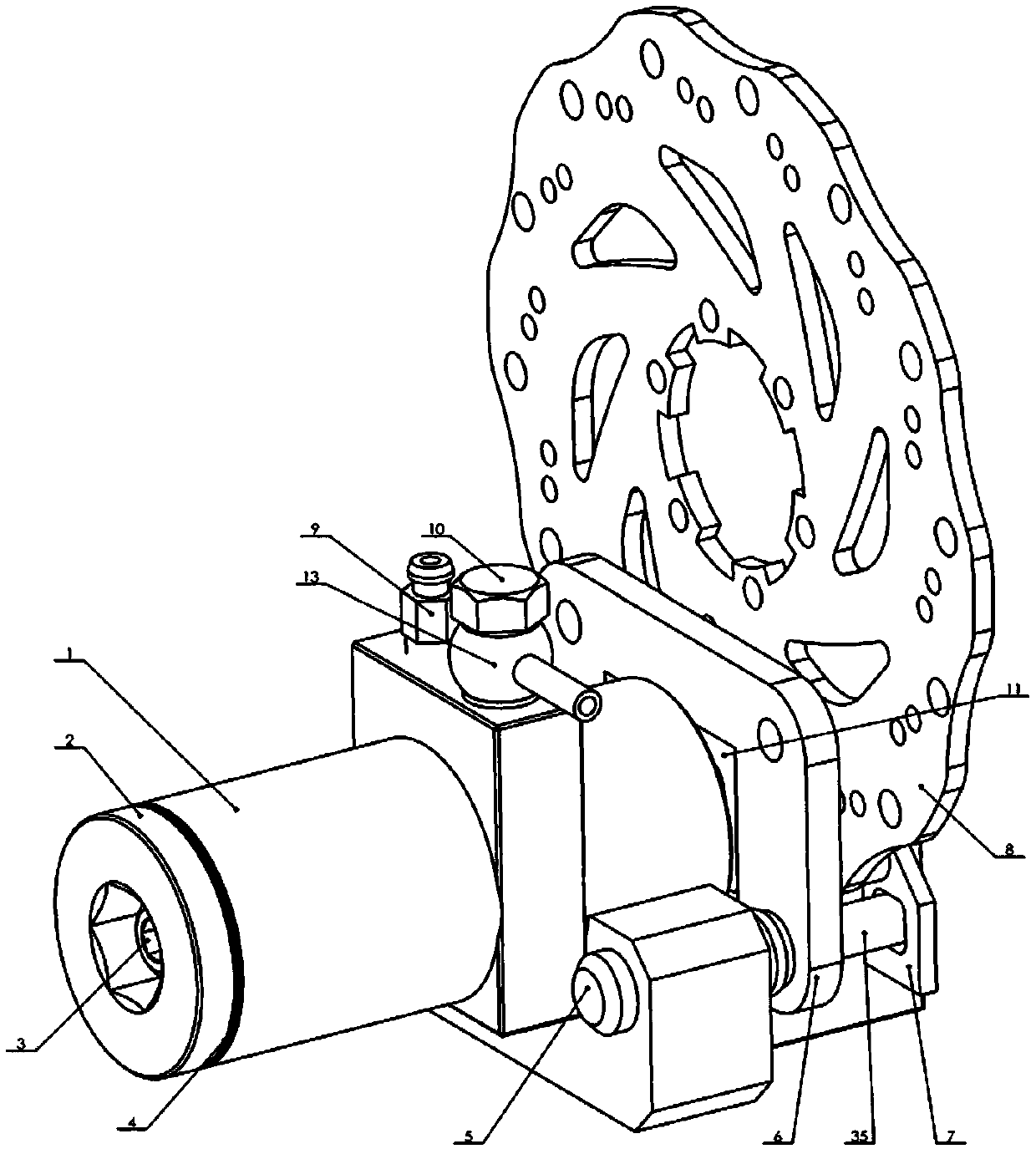

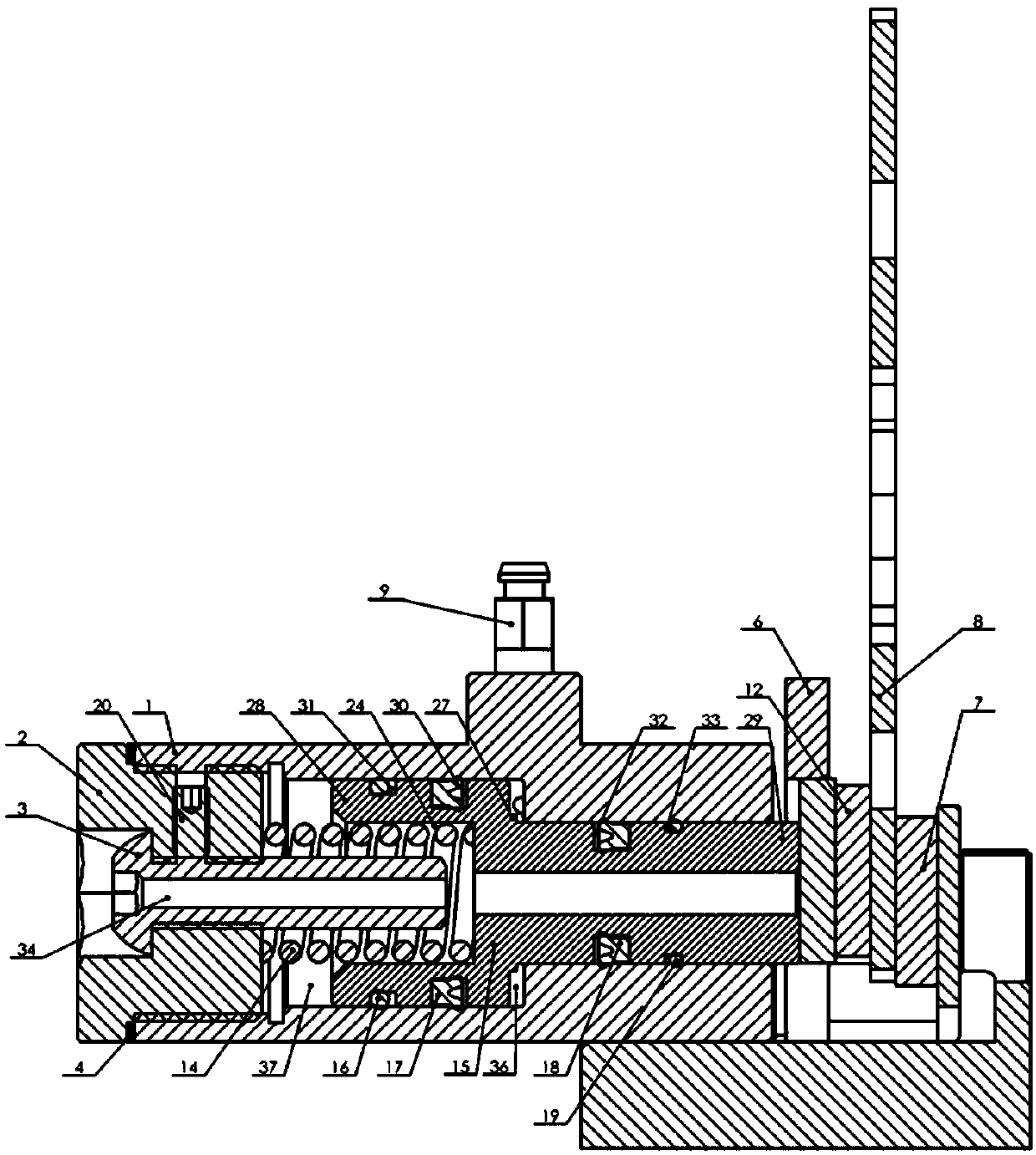

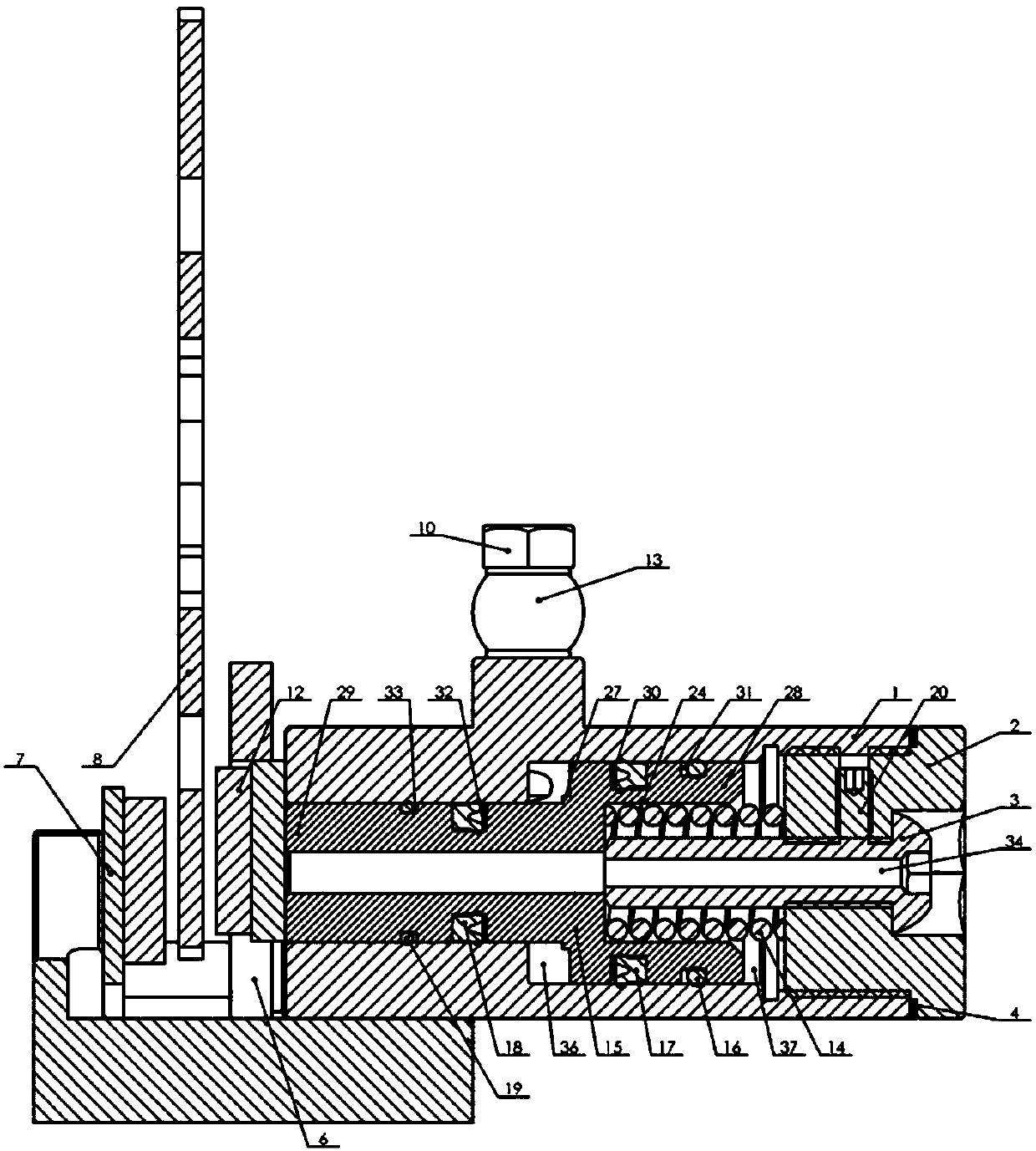

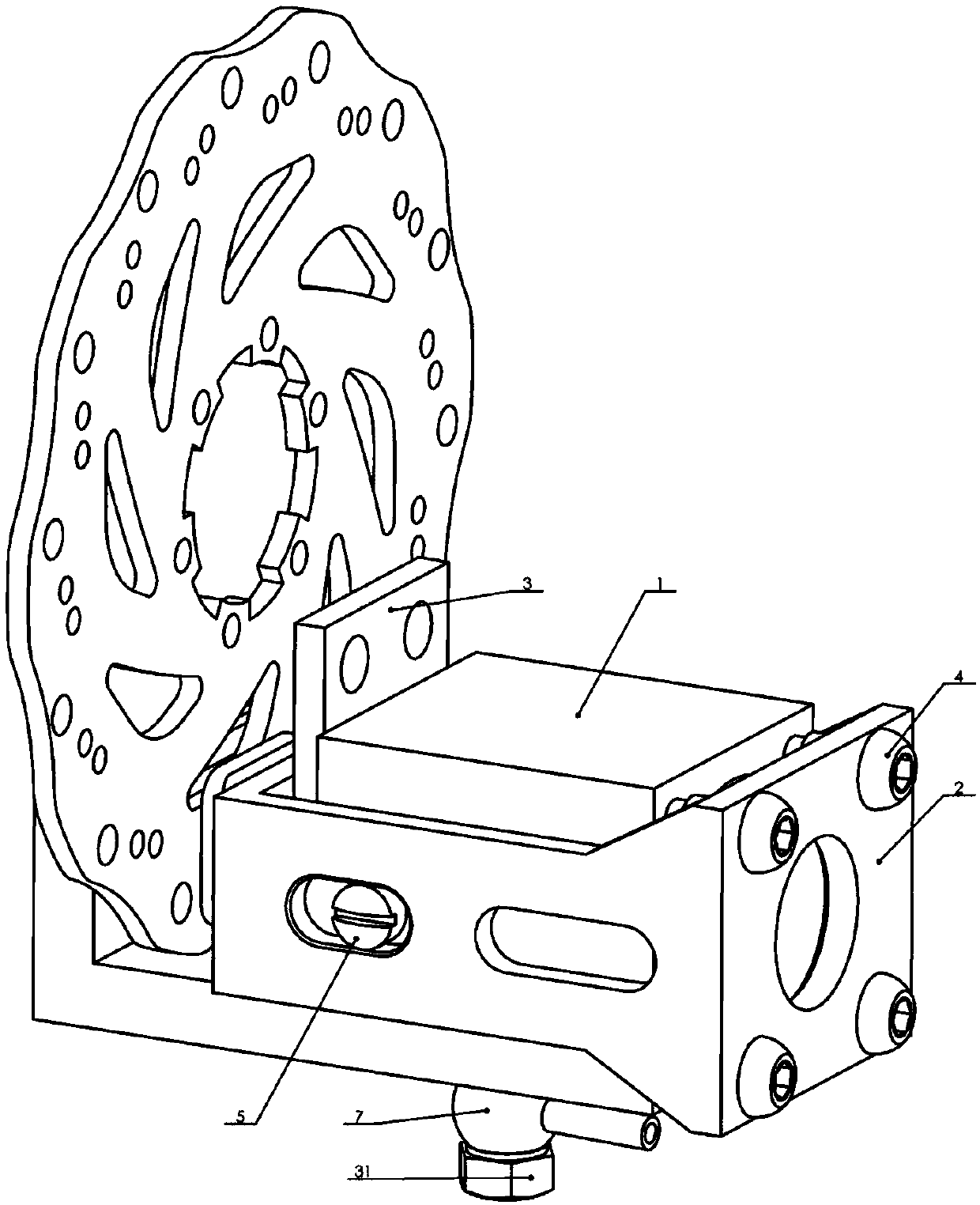

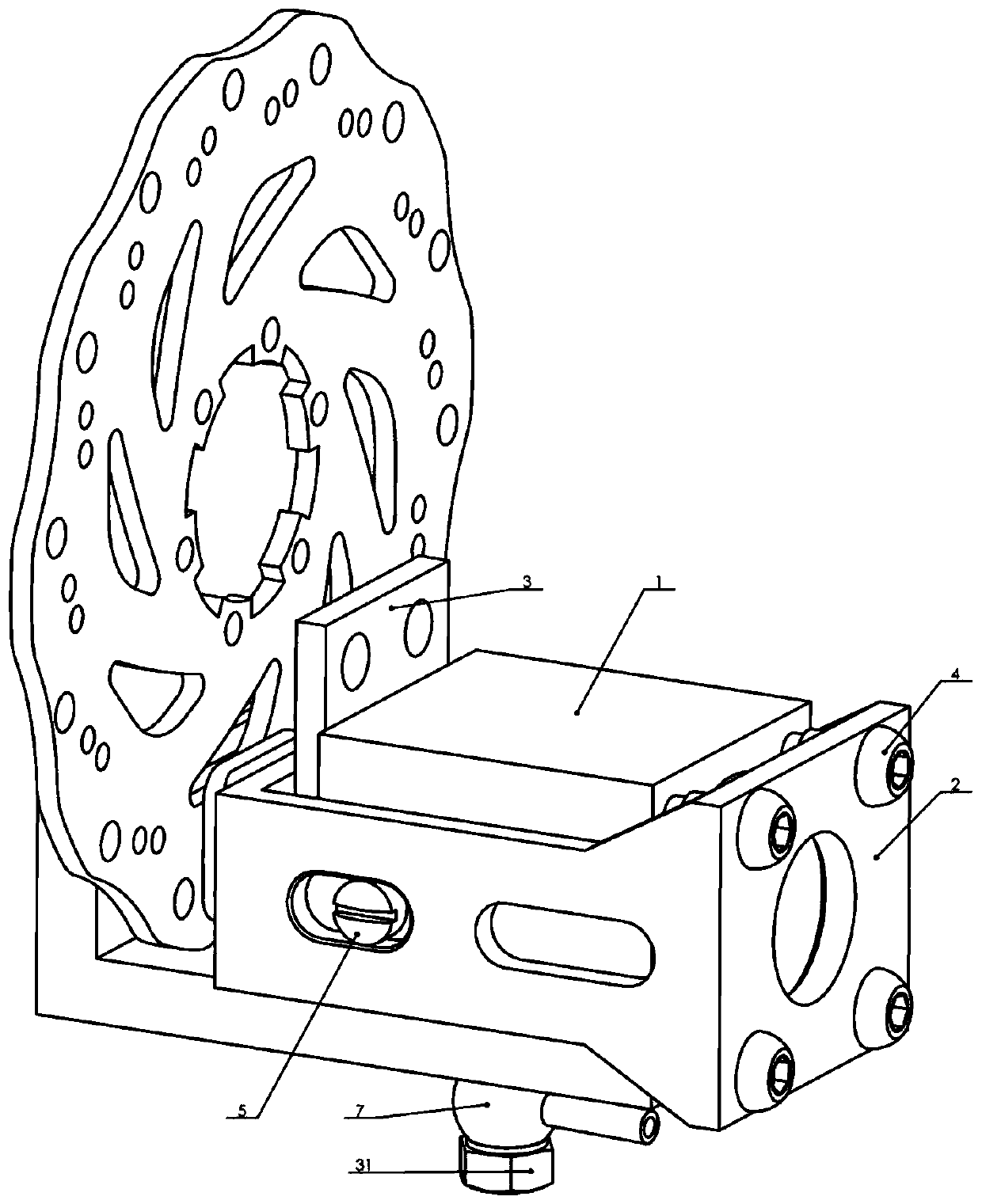

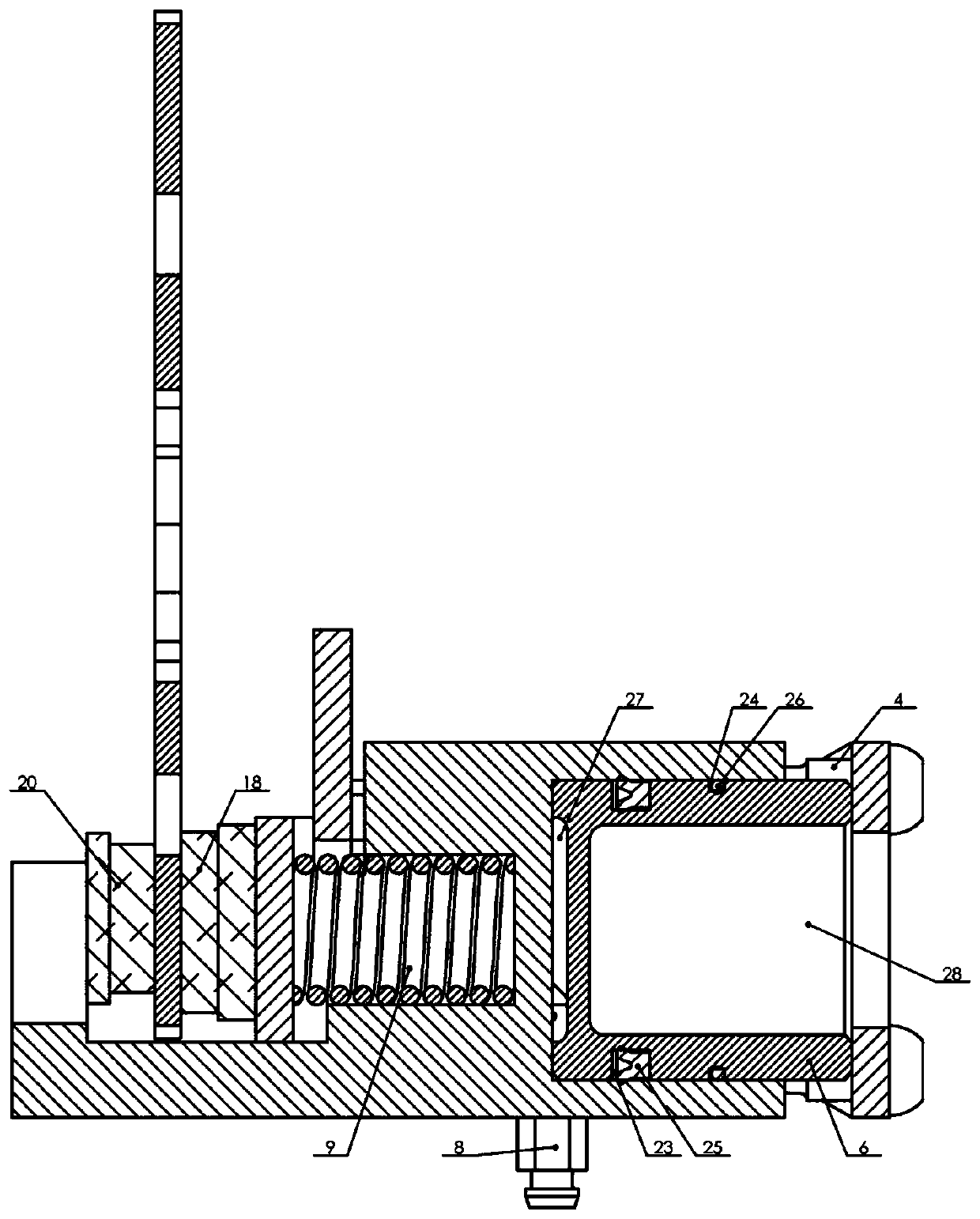

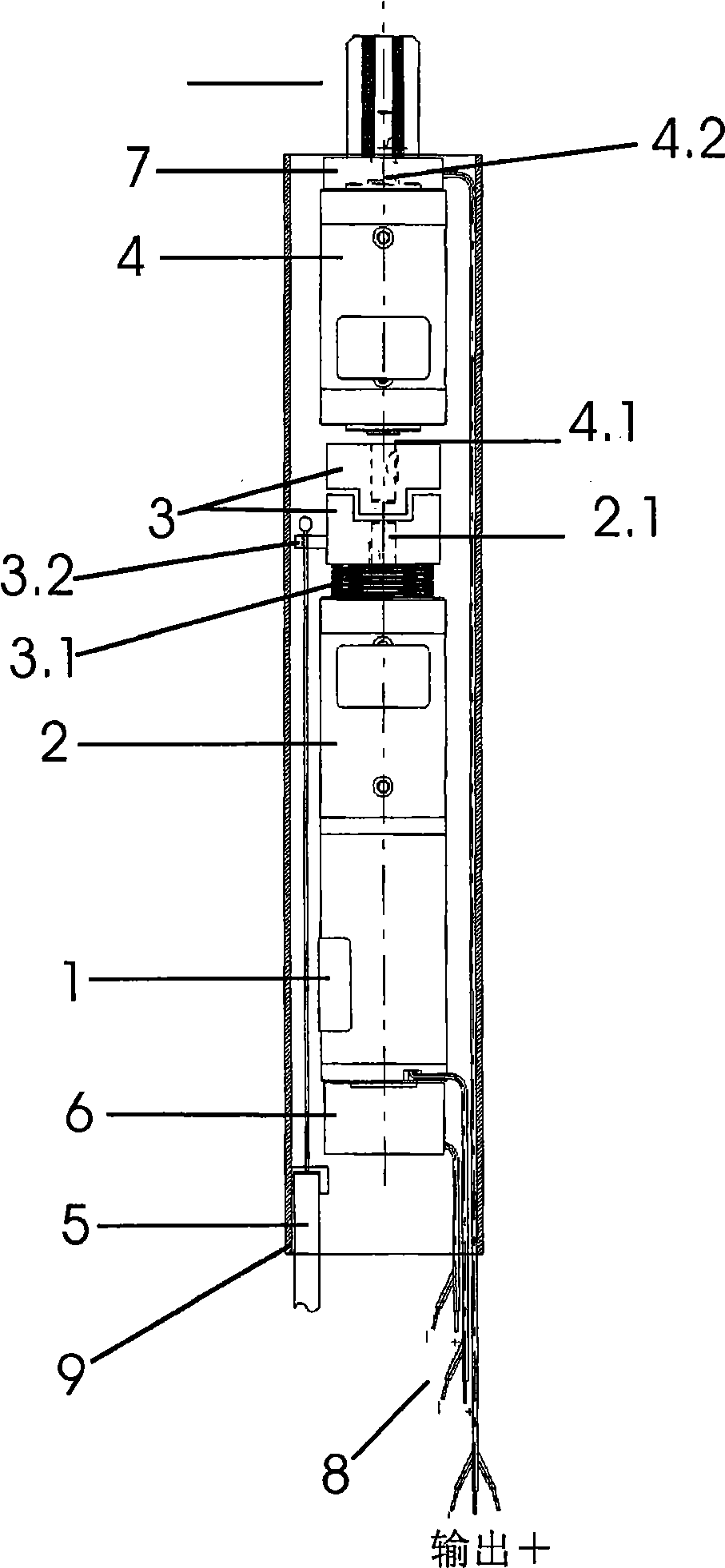

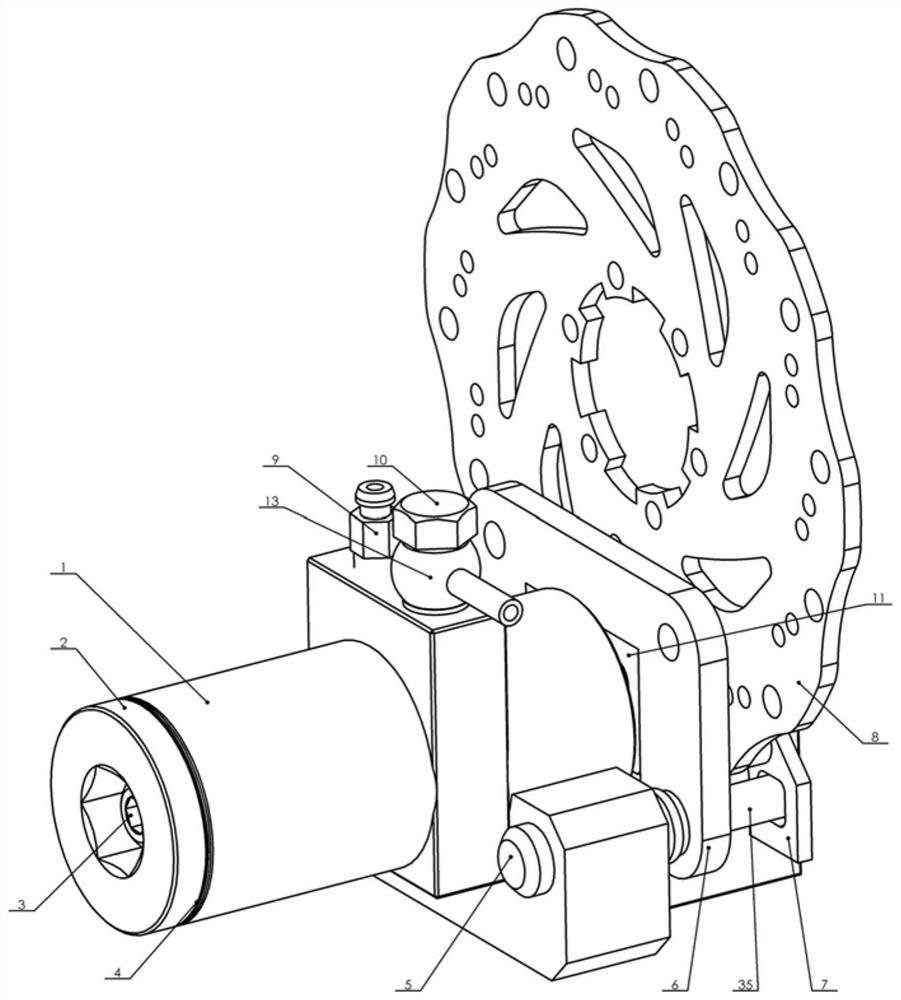

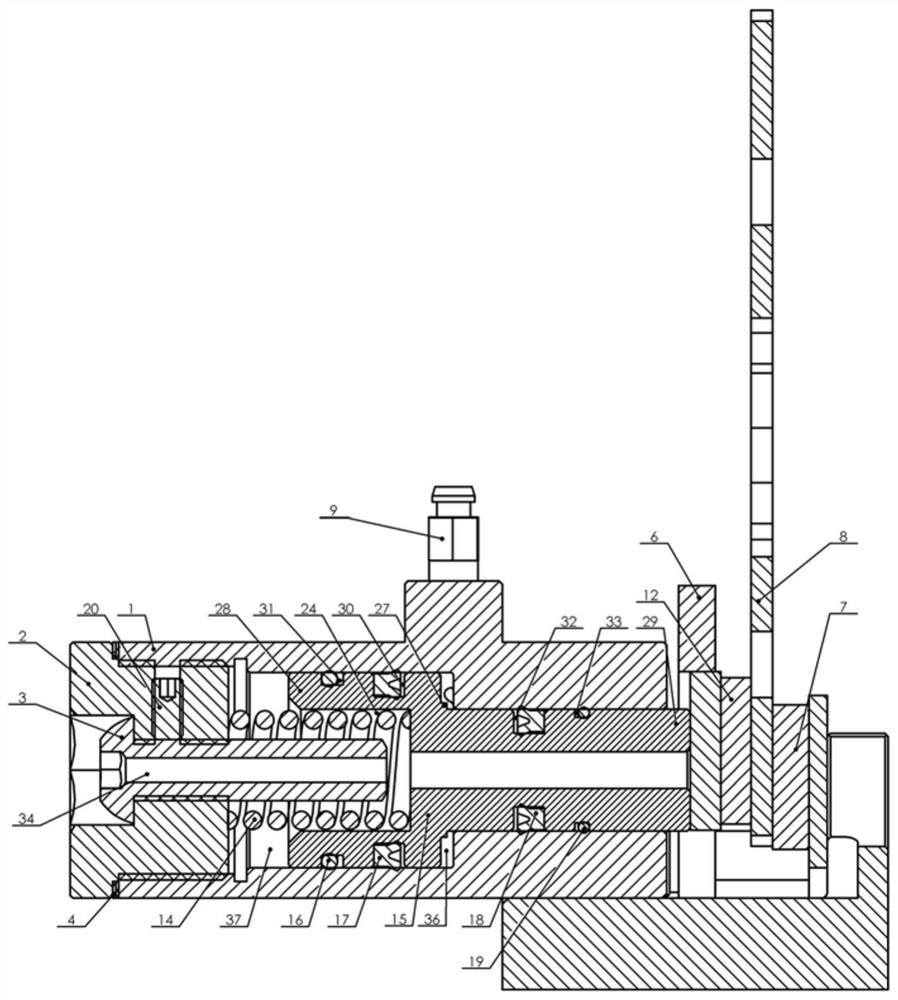

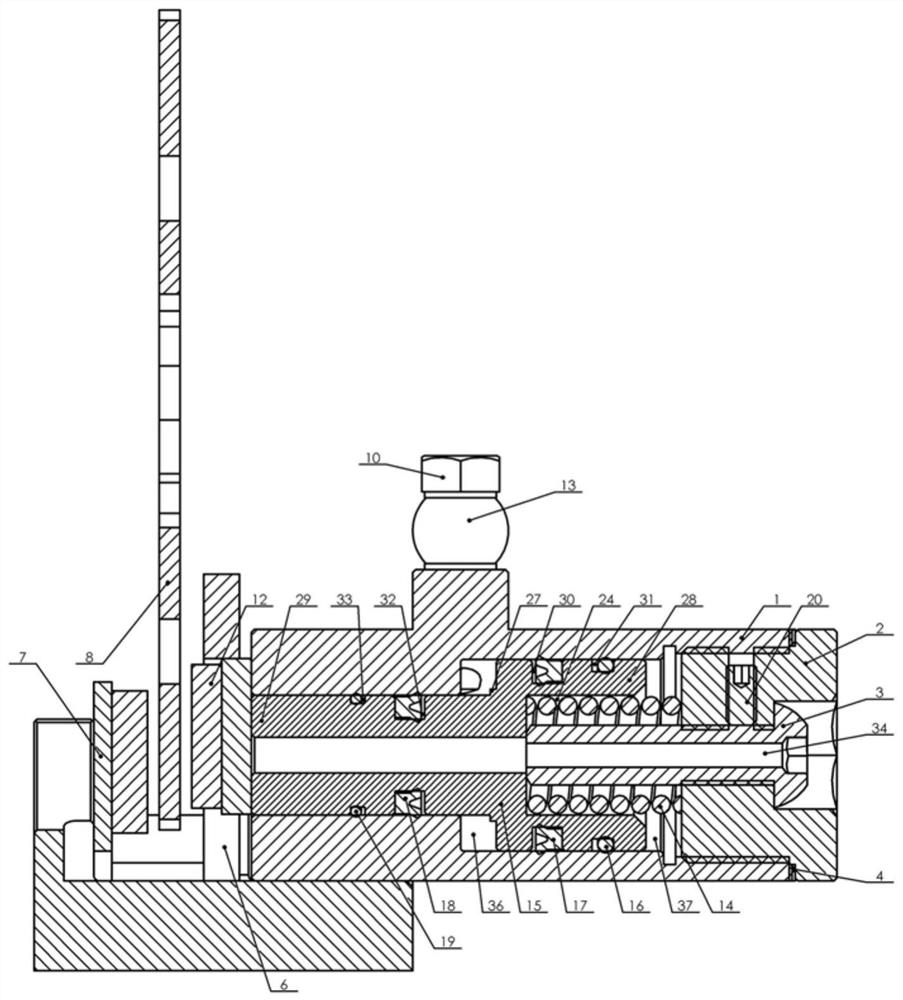

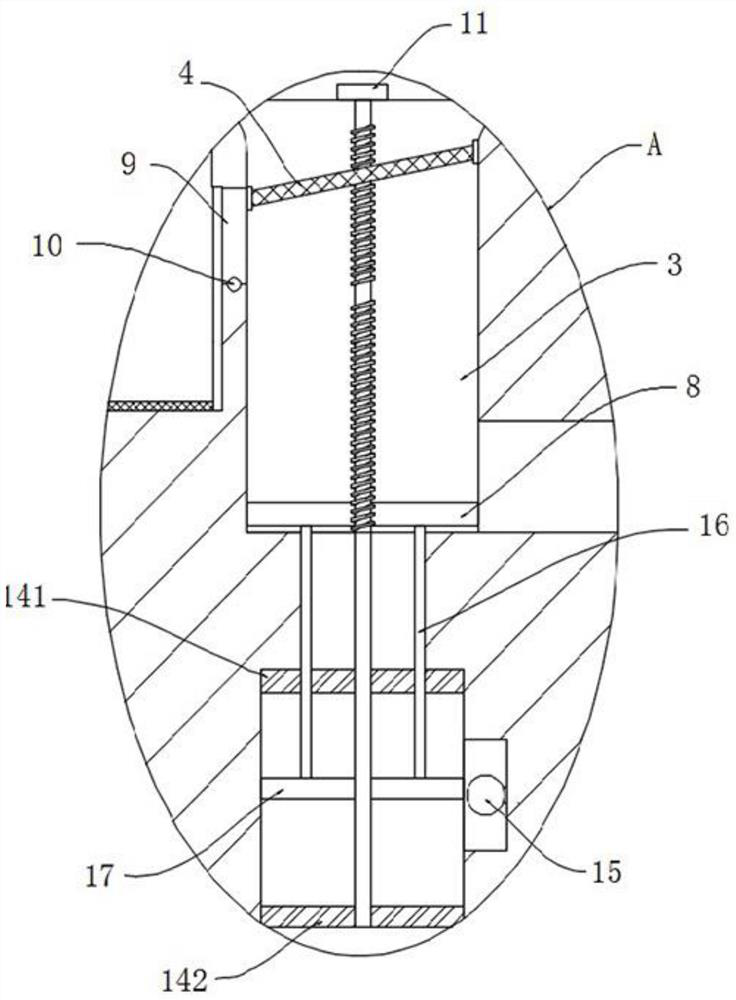

Normally-locked hydraulic disc brake device

ActiveCN109532998AAvoid instabilityRelieve stressCarriage/perambulator accessoriesHand cart accessoriesEngineeringScrew thread

The invention discloses a normally-locked hydraulic disc brake device which comprises main clamp body, adjusting screw plug, limit screw, piston, limit location step, first sealing ring, second sealing ring, spring, third sealing ring, fourth sealing ring and positioning screw, step guiding hole and threaded hole are arranged in the main clamp body, adjusting screw plug is connected at bottom of the main clamp body through the threaded hole, adjusting gasket is arranged between the adjusting screw plug and the main clamp body, piston is pressed into the step guiding hole through matching, limit screw is connected at bottom of the adjusting screw plug through threads, spring is arranged in step guiding hole of the large shaft end, the piston is provided with first groove and second groove outside the large shaft end, first sealing ring and second sealing ring are respectively arranged in the first groove and the second groove, the piston is provided with third groove and fourth groove outside the small shaft end, and third sealing ring and fourth sealing ring are respectively arranged in the third groove and the fourth groove. The overall structure design of the invention is ingenious and convenient to use.

Owner:YANSHAN UNIV

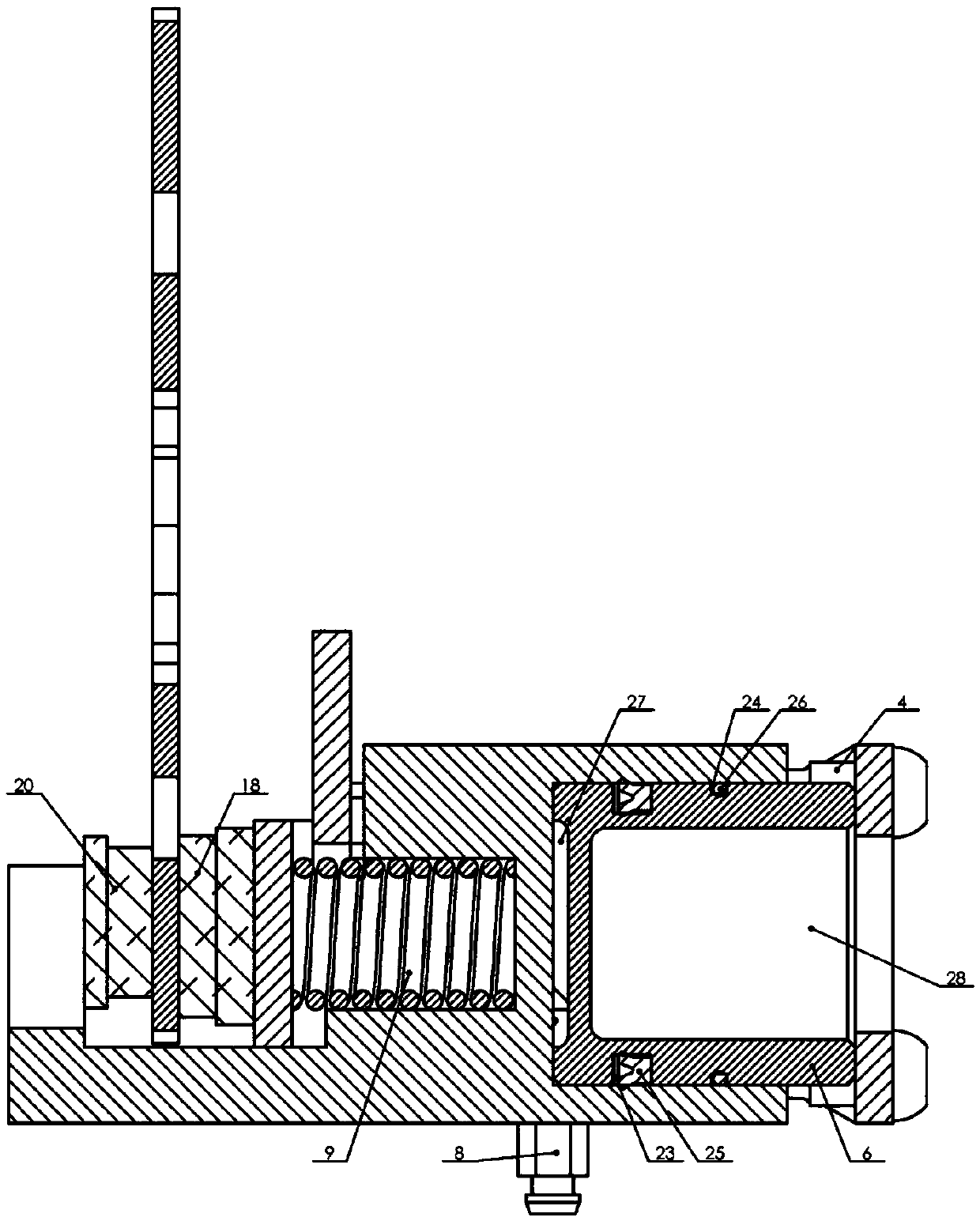

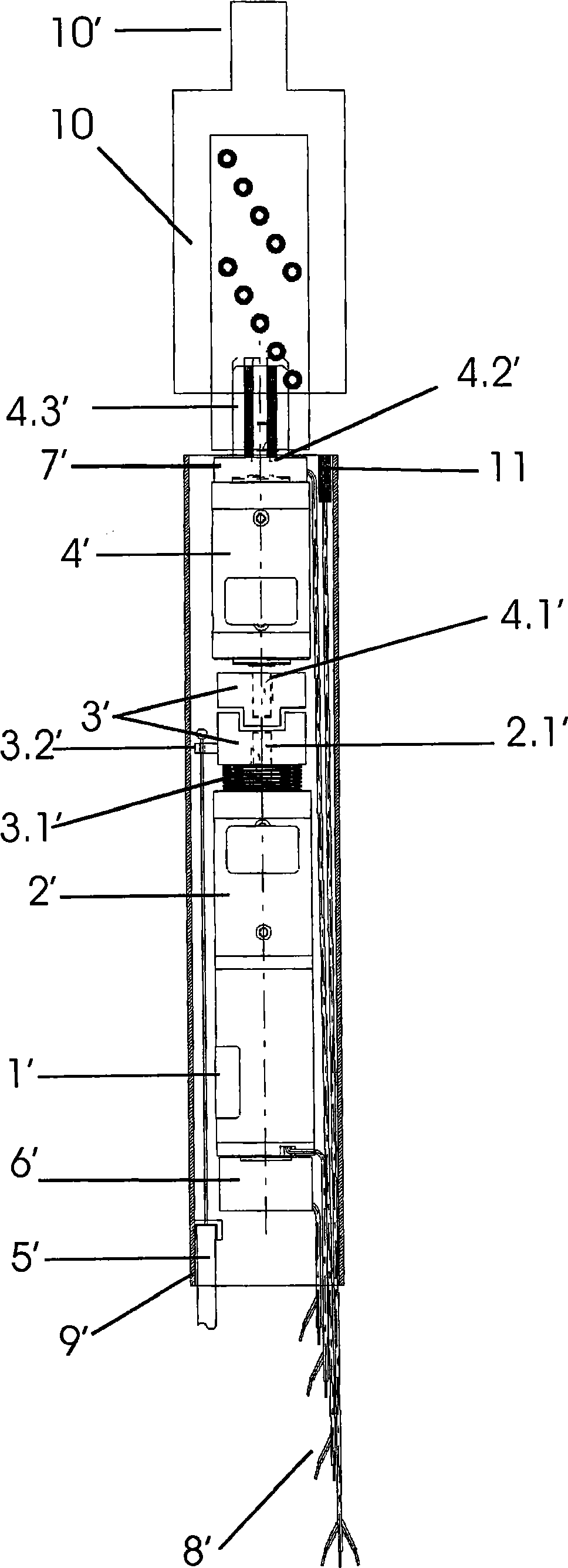

External connection type normal-locking hydraulic disc brake device

ActiveCN109538661AAvoid instabilityAvoid self-locking phenomenonAxially engaging brakesEngineeringPiston

The invention discloses an external connection type normal-locking hydraulic disc brake device. The device comprises a main clamp body, an external connecting frame, a mounting plate, jackscrews, guide screws, a piston and a spring; and the device is characterized in that a piston hole is formed in the bottom of the main clamp body, the piston is pressed in the piston hole in a matched mode, a spring guide hole is formed in the middle of the main clamp body, the spring is compressed in the spring guide hole, guide threaded holes are formed in the middles of the left side face and the right side face of the main clamp body respectively, guide groove holes are formed in the left side face and the right side face of the external connecting frame respectively, the front ends of the guide screws are installed in the guide threaded holes through threads, the rear ends of the guide screws are clamped in the guide groove holes, four threaded mounting holes are uniformly distributed in the rearend face of the external connecting frame, four guide unthreaded holes are uniformly distributed in the end face of the bottom of the main clamp body, the rear ends of the jackscrews are connected into the threaded mounting holes through threads, the front ends of the jackscrews are installed in the guide unthreaded holes, a supporting guide column is fixedly connected to the mounting plate through riveting, the supporting guide column is installed in a guide hole, and a pit is formed in the end face of the outer side of the piston.

Owner:YANSHAN UNIV

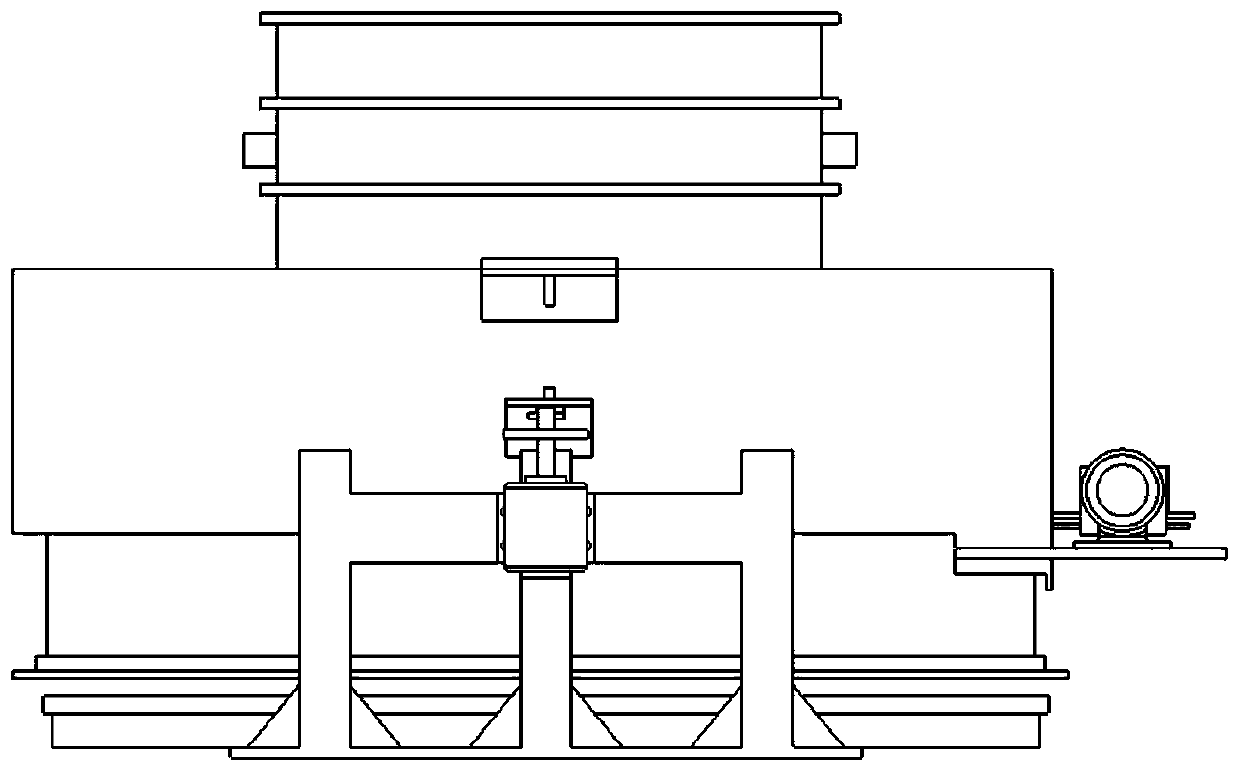

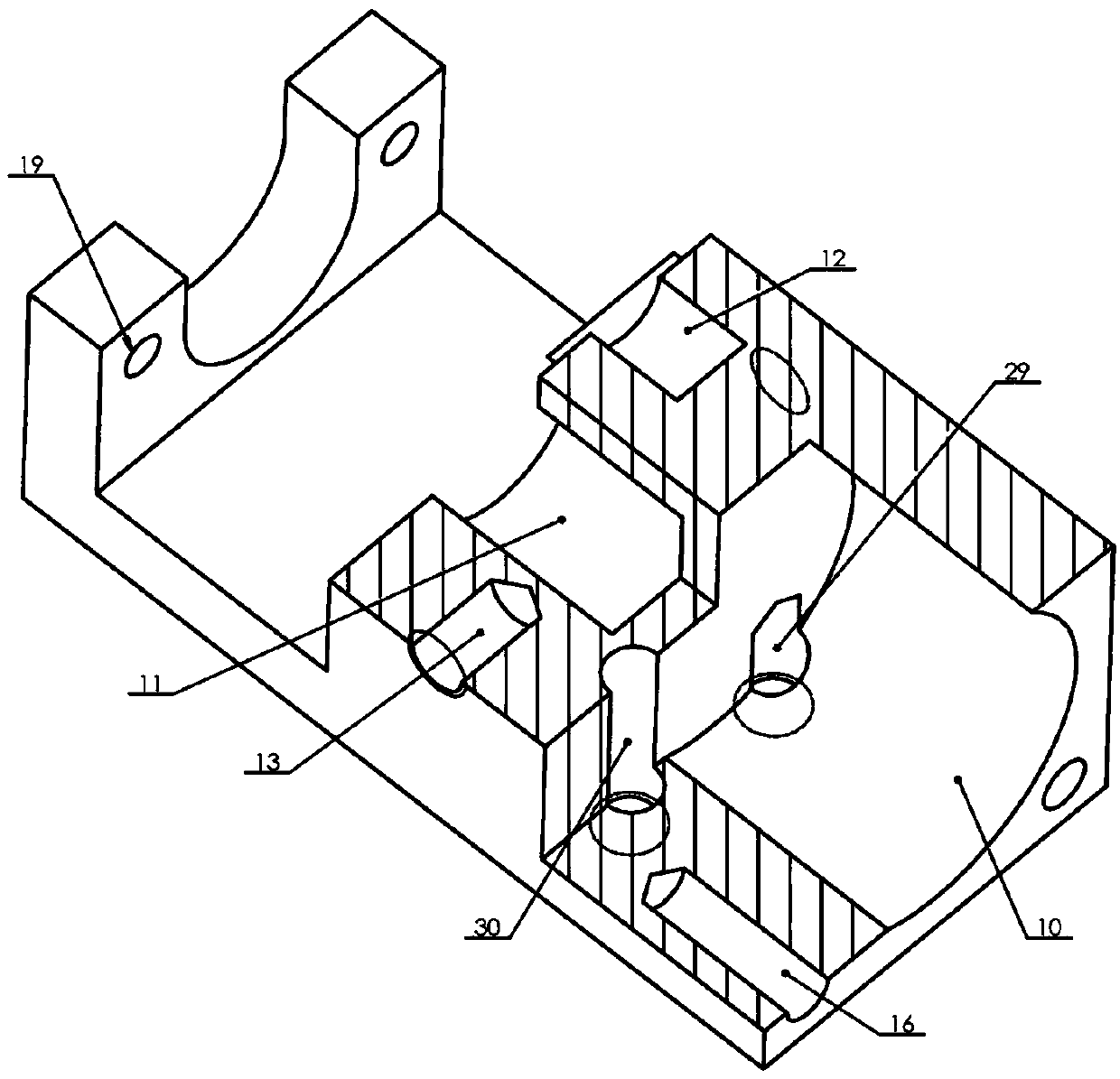

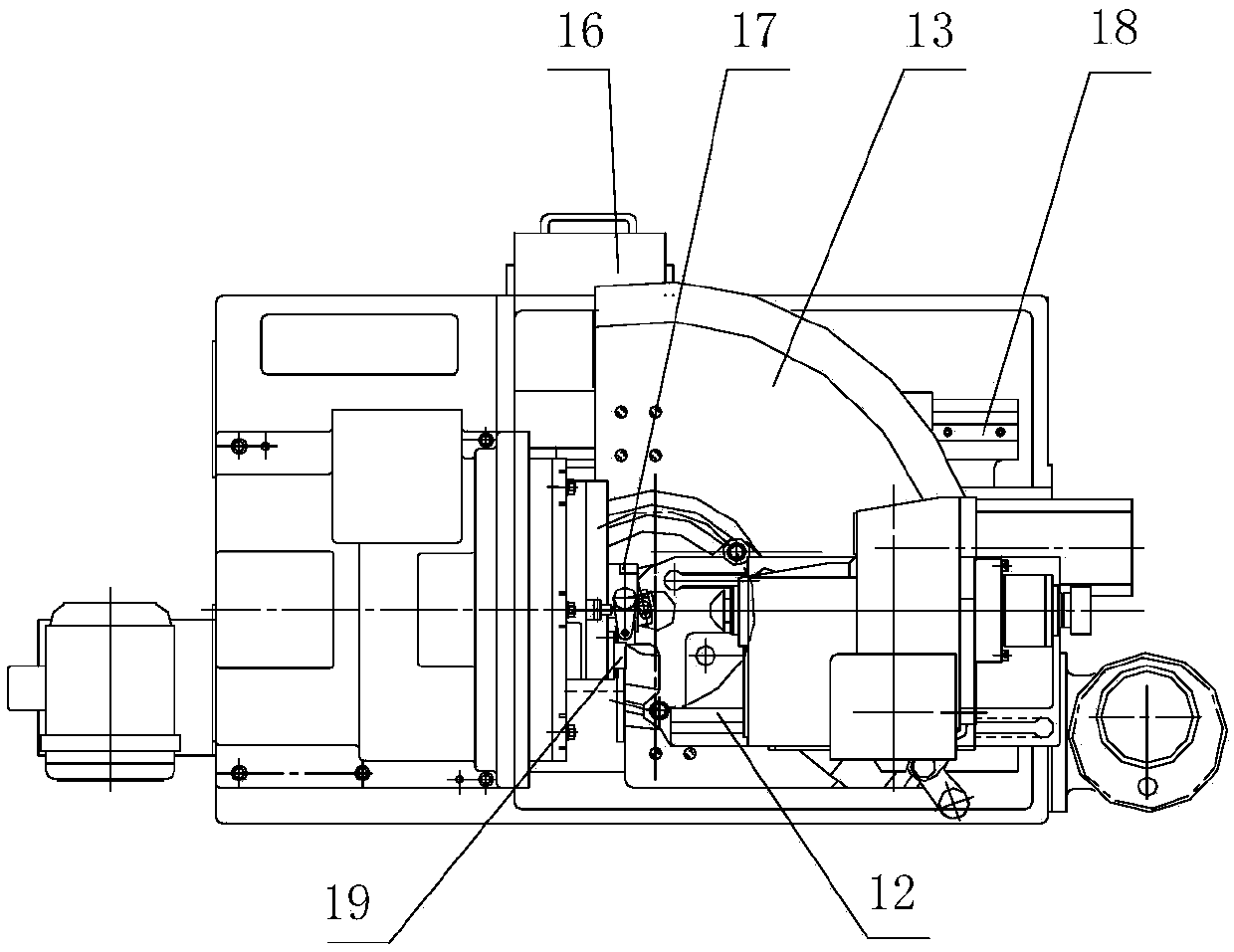

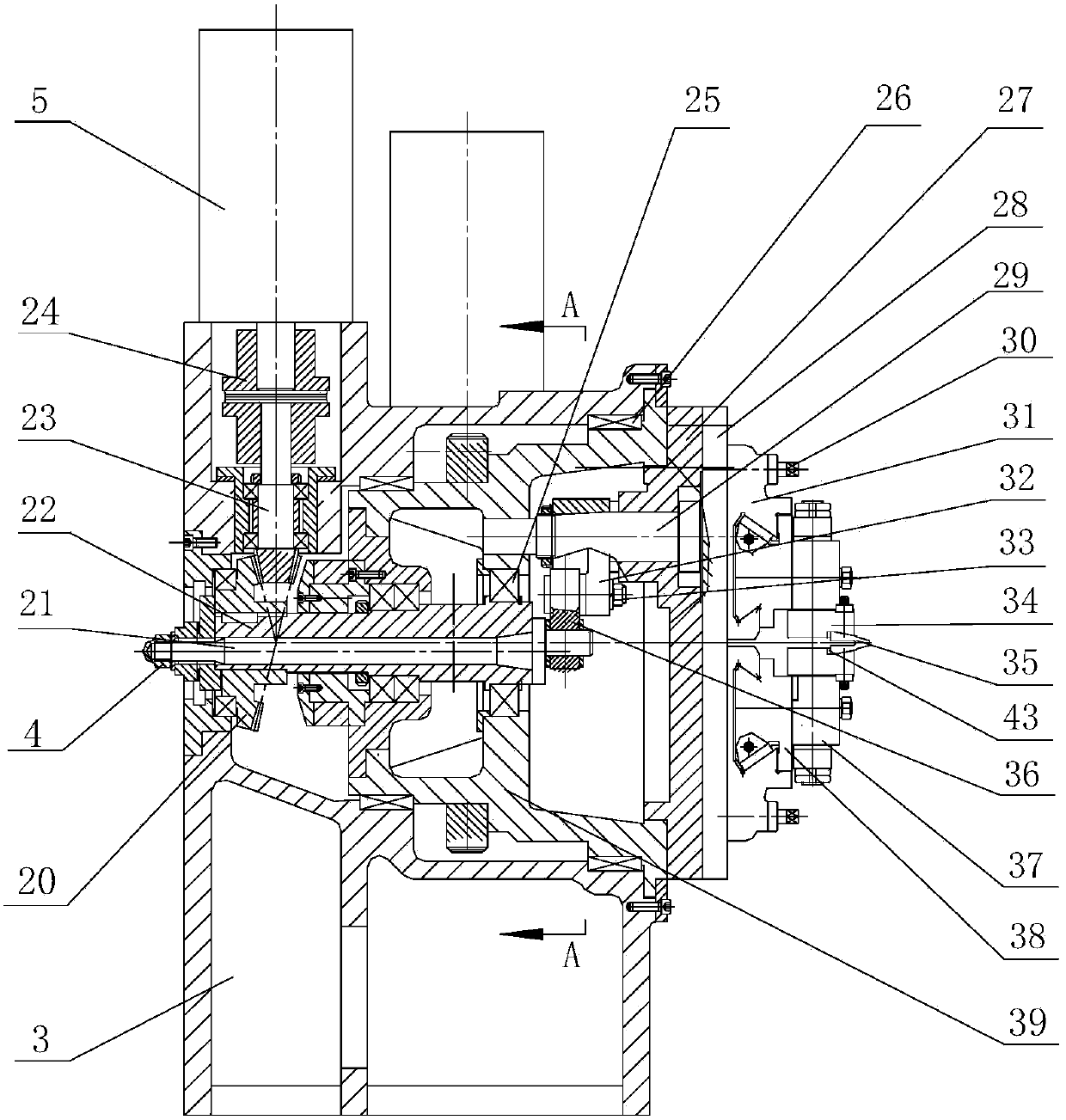

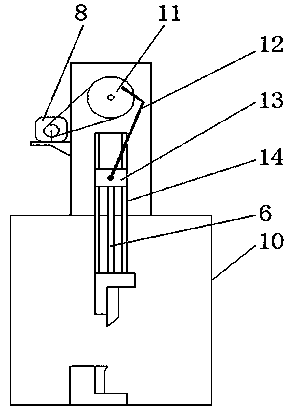

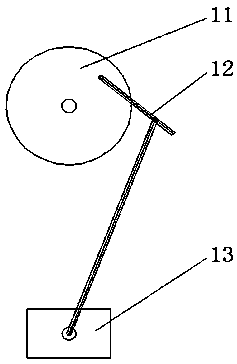

CNC small modulus straight bevel gear planer

ActiveCN105965106BImprove machining accuracyMovement precisionGear-cutting machinesGear teethSelf lockingBevel gear

The invention relates to a numerical control small-modulus straight bevel gear shaper comprising a lathe bed, a rocking table assembly, a workpiece box assembly, a hydraulic system and a numerical control system. The lathe bed is provided with the rocking table assembly and the workpiece box assembly; and the hydraulic system is arranged on the two sides of the lathe bed. The rocking table assembly comprises a rocking table support, a tool holder transmission mechanism, a rocking table drum wheel, a tool holder device, a stroke adjusting mechanism, a gear shaping cutter movement main shaft servo motor, a rocking table rotating servo motor and a rocking table rotating worm gear and worm mechanism connected with the rocking table rotating servo motor and is characterized in that the tool holder device comprises a tool holder base, a ram, a tool base support, a tool base, a tool back-off movement adjusting device, a gear angle adjusting mechanism, a gear shaping tool, a tool height adjusting mechanism and a pressure angle adjusting mechanism. The numerical control small-modulus straight bevel gear shaper has the beneficial effects of being compact in structural layout, easy and convenient to adjust and operate, large in tool back-off amount, wide in adjusting range, accurate in tool back-off movement and capable of avoiding the self-locking phenomenon, improving the gear machining precision and meeting the machining requirements of high-precision small-modulus straight bevel gears.

Owner:通用技术集团天津第一机床有限公司

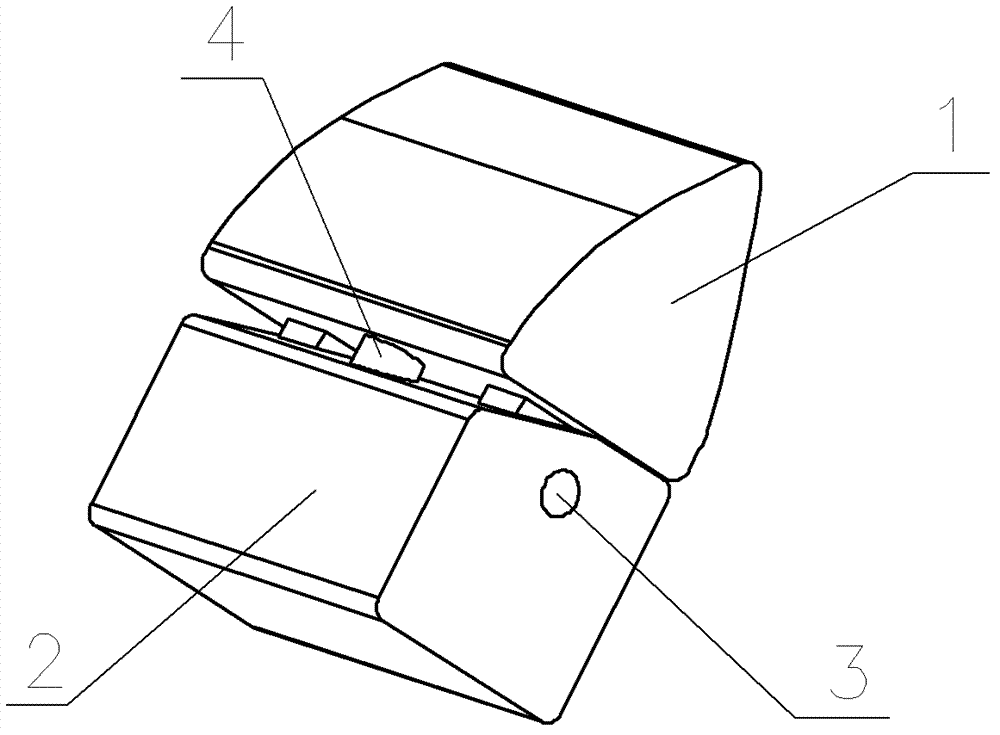

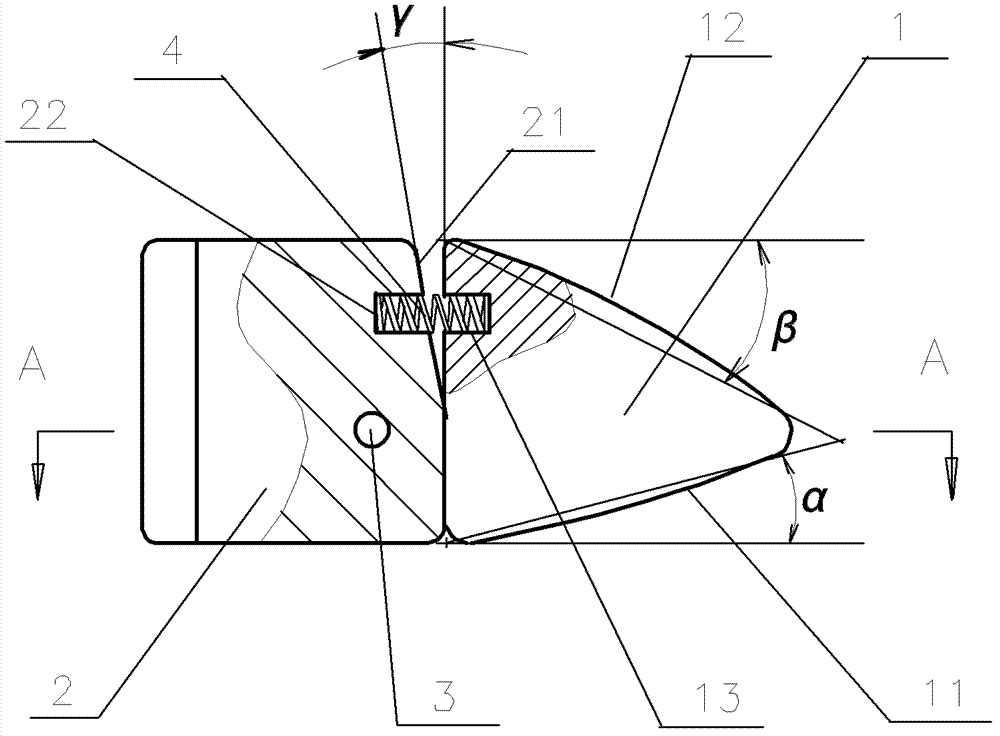

Oscillating spring bolt for door lock

ActiveCN102817497AAvoid self-locking phenomenonReduce door push forceBuilding locksSelf lockingEngineering

An oscillating spring bolt for a door lock is arranged on a lock body and comprises a bolt body, a bolt base, a pin shaft and elastic elements, wherein the bolt base is arranged on the lock body, and the bolt body is hinged onto the bolt base through the pin shaft and can oscillate around the pin shaft. A front bolt surface and a back bolt surface are respectively arranged on two sides of the bolt body, the front bolt surface and a door leaf plane form a front oblique angle alpha, and the back bolt surface and the door leaf plane form a back oblique angle beta. A second blind hole is arranged at the position on one side of the bolt base deviating from the pin shaft, a bolt base inclined surface is arranged on the bolt base on the periphery of the second blind hole, and the bolt base inclined surface and the vertical surface of the door leaf plane form a bolt base oblique angle gamma. A first blind hole is arranged on the bolt body at the position corresponding to the second blind hole, and the elastic elements are respectively arranged in the first blind hole and the second blind hole and push and press the bolt base and the bolt body toward two sides. The oscillating spring bolt reduces door push force, avoids door leaf self locking, ensures door leaf positioning reliability, and can be applied to various door locks, especially special unlatched doors.

Owner:SHANGHAI YANGYANG DADUOLI HARDWARE PROD CO LTD +1

Packaging machine shearing mechanism

InactiveCN107838963ACompact structureImprove securityMetal working apparatusArticle deliveryTransmission beltEngineering

The invention discloses a packaging machine shearing mechanism which comprises a lower knife base, an upper knife rest, a protection cover, a crank connection rod and a travel rod. A lower knife is fixed above the lower knife base, an upper knife is fixed below the upper knife rest, a connection rod is arranged above a connection nut, a motor is arranged outside the protection cover, a support isconnected to the bottom of the protection cover, a transmission belt is connected to the outer side of the motor, a fly wheel is connected to the top of the transmission belt, a fly wheel is connectedto the top of the crank connection rod, a piston pin is connected to the bottom of the crank connection rod, and a piston pin is arranged inside the travel rod. According to the packaging machine shearing mechanism, the lower knife base and the upper knife reset are of an L-shaped structure and have the different sizes, the lower knife base is conveniently fixed to the support through the L-shaped structure, the lower knife base is better in stability, the lower knife and the upper knife are aligned in a staggered mode, the upper knife moves perpendicular to the lower knife base, blades are staggered when the mechanism is used for shearing so as to be prevented from collision, and mechanism safety is improved.

Owner:王虹

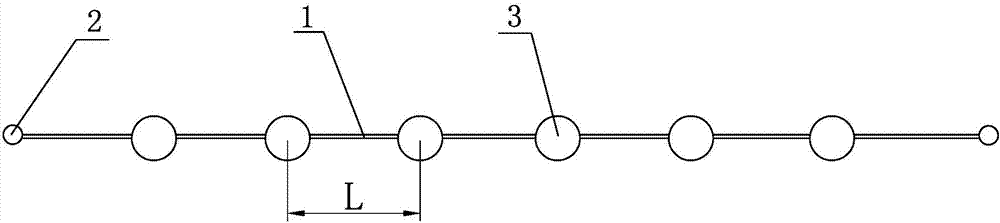

Upright chain connecting ring used for mine chain and capable of preventing self-locking during chain piling

The invention discloses an upright chain connecting ring used for a mine chain and capable of preventing self-locking during chain piling. Self-locking can be prevented from occurring at the chain connecting ring by means of the upright chain connecting ring. The upright chain connecting ring comprises two half rings; the two half rings are in head-tail clamp fit to be assembled, a spring pin is hit into the assembled position of the two half rings, and thus the chain connecting ring is achieved by integrating the two half rings; a hollow chain connecting groove is formed in the inner side ofthe chain connecting ring; the chain connecting groove is buckled with a second chain ring body and a third chain ring body of the ends, needing to be connected, of two chain portions; and a clampingblock is mounted in the position, located between the second chain ring body and the third chain ring body, in the chain connecting groove, and the second chain ring body is separated from the third chain ring body through the clamping block. By means of the upright chain connecting ring, the cost can be greatly reduced, and disassembling is convenient. A main body of the chain connecting ring isnot changed, the middle space is large, and thus the chain portions of the two ends can be conveniently and easily mounted. During usage, the positions of the chain portions of the two ends are basically fixed, piled chain portions can be easily pulled apart even during chain piling, and thus phenomena like self-locking are avoided.

Owner:上海力直得输送装备有限公司

A high-friction ship arresting method

ActiveCN105696524BAvoid self-locking phenomenonSimple structureClimate change adaptationShipping equipmentBuoyBlock method

Owner:NINGBO UNIV

An external connection type constant lock hydraulic disc brake device

ActiveCN109538661BAvoid instabilityAvoid self-locking phenomenonAxially engaging brakesEngineeringPiston

The invention discloses an external connection type normal-locking hydraulic disc brake device. The device comprises a main clamp body, an external connecting frame, a mounting plate, jackscrews, guide screws, a piston and a spring; and the device is characterized in that a piston hole is formed in the bottom of the main clamp body, the piston is pressed in the piston hole in a matched mode, a spring guide hole is formed in the middle of the main clamp body, the spring is compressed in the spring guide hole, guide threaded holes are formed in the middles of the left side face and the right side face of the main clamp body respectively, guide groove holes are formed in the left side face and the right side face of the external connecting frame respectively, the front ends of the guide screws are installed in the guide threaded holes through threads, the rear ends of the guide screws are clamped in the guide groove holes, four threaded mounting holes are uniformly distributed in the rearend face of the external connecting frame, four guide unthreaded holes are uniformly distributed in the end face of the bottom of the main clamp body, the rear ends of the jackscrews are connected into the threaded mounting holes through threads, the front ends of the jackscrews are installed in the guide unthreaded holes, a supporting guide column is fixedly connected to the mounting plate through riveting, the supporting guide column is installed in a guide hole, and a pit is formed in the end face of the outer side of the piston.

Owner:YANSHAN UNIV

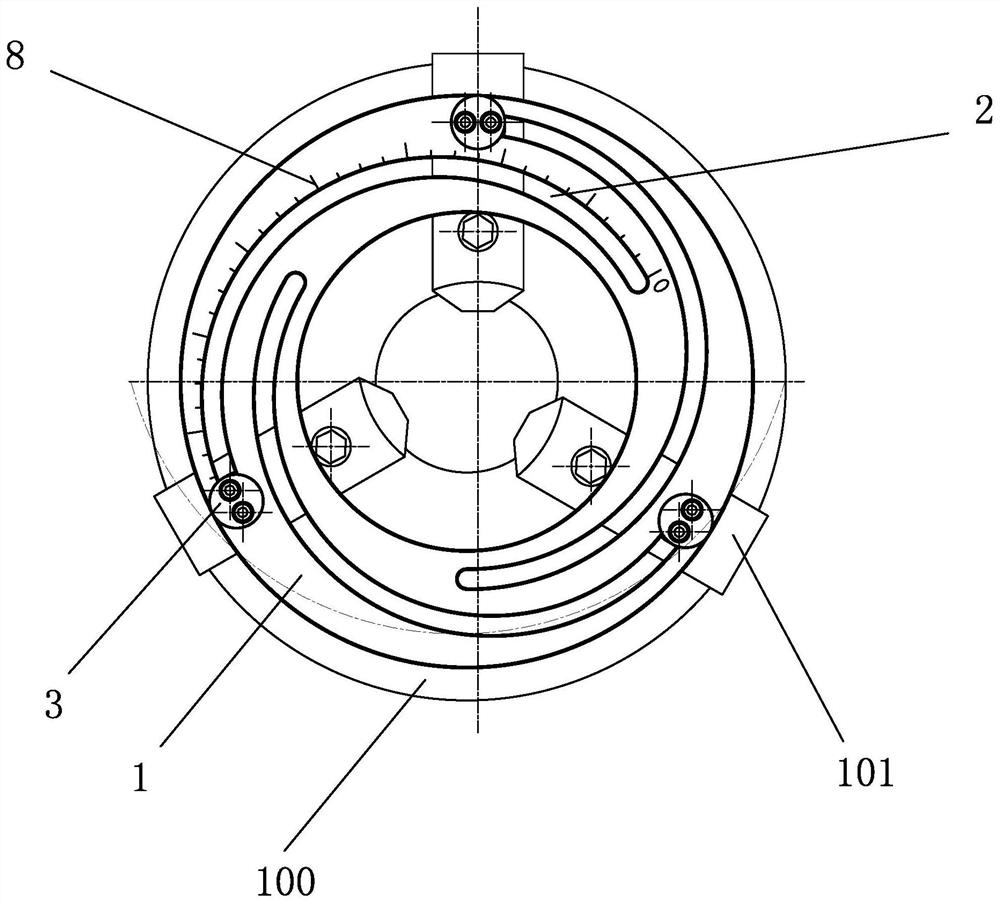

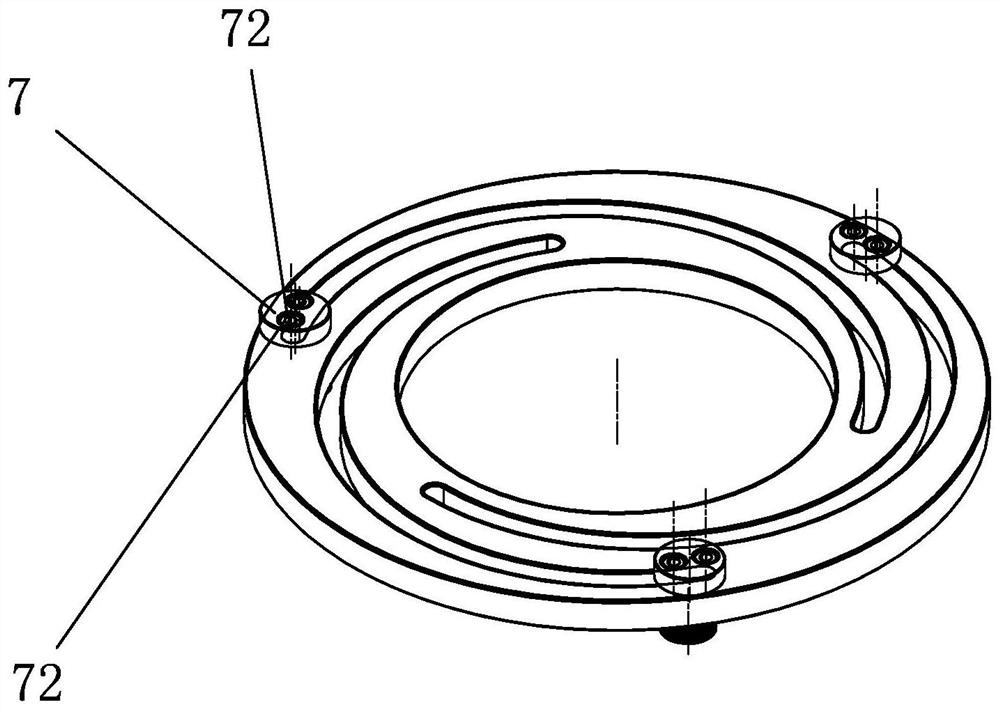

Adjusting tool for machining lathe claw

PendingCN114523320AHigh dimensional accuracyAccurate feedPositioning apparatusMetal-working holdersPhysicsEngineering

The adjusting tool for machining the lathe claw comprises an adjustable base disc arranged on an equipment spindle, a sliding groove set is arranged on the adjustable base disc, the sliding groove set comprises at least two sliding grooves with gradually-changed radians, and the sliding grooves of the sliding groove set are arranged in a central symmetry mode along the disc center of the adjustable base disc; a tool sliding block is arranged in each sliding groove in a sliding mode, and the bottom of each tool sliding block can be connected with a lathe claw to be machined. The whole set of lathe claws to be machined are uniformly and radially adjusted through the adjustable base disc provided with the sliding groove with the gradient radian, it is ensured that machining parameters of the lathe claws are highly consistent, and it can also be ensured that in the process that the lathe claws to be machined slide in the sliding groove along with a tool sliding block, a lathe to be machined can adjust the distance in the radial direction of an equipment spindle at a constant speed; therefore, the positions of the inner contour line and the outer contour line of the lathe claw to be machined are accurately controlled, accurate feeding of a machining tool is achieved, and the accuracy degree of claw forming and the consistency of the claws are effectively improved.

Owner:HANGZHOU DAHE THERMO MAGNETICS CO LTD

Air duct seed selection translational precision seeding device

ActiveCN110337865AAvoid shortagePrevent fallingSeed depositing seeder partsMotor driveReciprocating motion

The invention relates to an air duct seed selection translational precision seeding device. The device comprises a seed selection mechanism, a seed filling mechanism and a seed filling and dischargingmechanism; the seed selection mechanism comprises a seed cleaning part and a sorting part; the seed filling mechanism comprises a mechanical translation driving mechanism fixedly connected with the side wall of a seed filling box, the opposite side of the mechanical translation driving mechanism is provided with a translation sliding sheet structure, the translation sliding sheet structure comprises a U-shaped sliding groove and a support sliding sheet which are fixedly arranged, and one end of the support sliding sheet can slide in the U-shaped sliding groove; a power output shaft of the seed filling and discharging mechanism is provided with a lower connecting gear and an upper connecting gear, the upper connecting gear is meshed with an upper rack frame, and the lower connecting gear is meshed with a lower rack frame; a small motor drives an upper cover plate and a lower bottom plate to reciprocate through the two rack frames separately to achieve seed filling and discharging.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Mechanical sliding plate translational seed precision sowing device

ActiveCN110291872BTake advantage ofAvoid shortageDibble seedersSeed depositing seeder partsReciprocating motionGear wheel

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

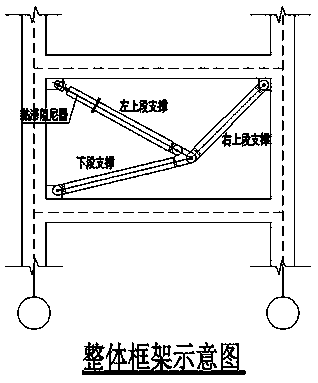

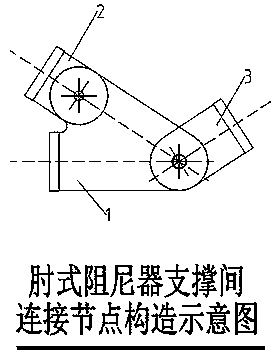

Connection joint between elbow-type damper supports

InactiveCN109898682AAvoid self-locking phenomenonAvoid stressProtective buildings/sheltersShock proofingSelf lockingControl theory

The invention discloses a connection joint between elbow-type damper supports. The connection joint between the elbow-type damper supports comprises a lower end supporting connecting end head, an upper left section supporting connecting end head and an upper right section supporting connecting end head. The end heads are connected through pin shafts, the three elbow-type supports are convenientlyconnected into a whole, a self-locking phenomenon generated by the structure of the connection joint between the multiple supports is avoided, a design force transmission path is consistent with the connection joint between the elbow-type damper supports, and the connection joint between the elbow-type damper supports is a convenient and reliable connection joint form.

Owner:ZHEJIANG JIANKE DAMPING SCI & TECH CO LTD

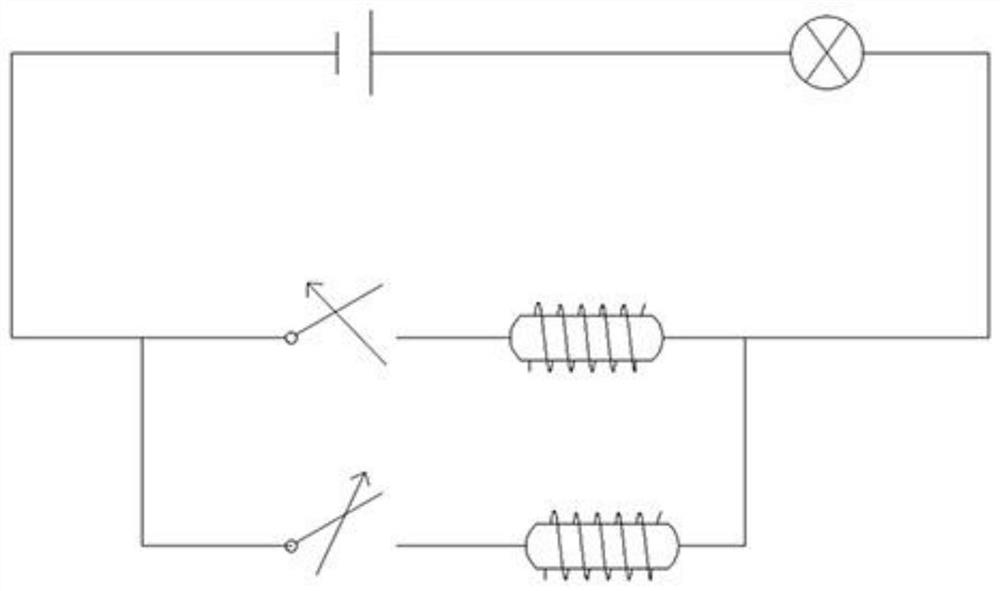

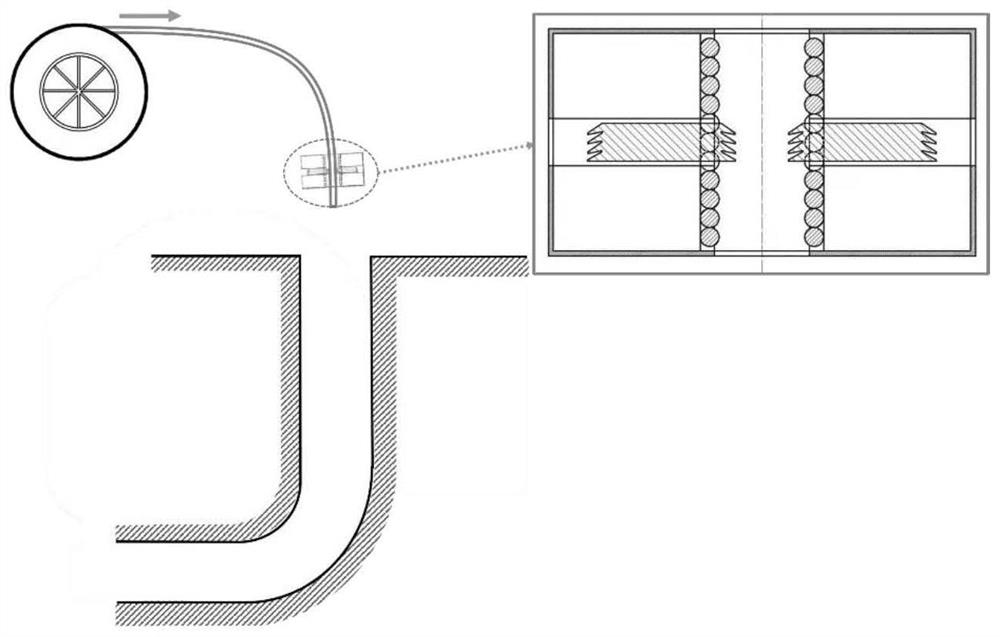

Drive unit for entrance and exit systems

InactiveCN101535589AAvoid self-locking phenomenonImplement manual operationMechanical apparatusPower-operated mechanismEngineeringElectric drive

A drive apparatus for boarding and unboarding devices, in particular for passenger doors, boarding ramps, retractable steps and the like on public transport vehicles having an electric drive motor the driven element of which is connected to the input element of a first reduction gear the output element of which is coupled to the actuation devices for the boarding and unboarding devices where the drive apparatus is constructed as a compact drive where the electric drive motor, the first reduction gear and a second reduction gears as well as an energizable clutch are disposed axially behind each other inside a tubular housing between the first reduction gear and the second reduction gear.

Owner:GEBR BODE GMBH & CO KG

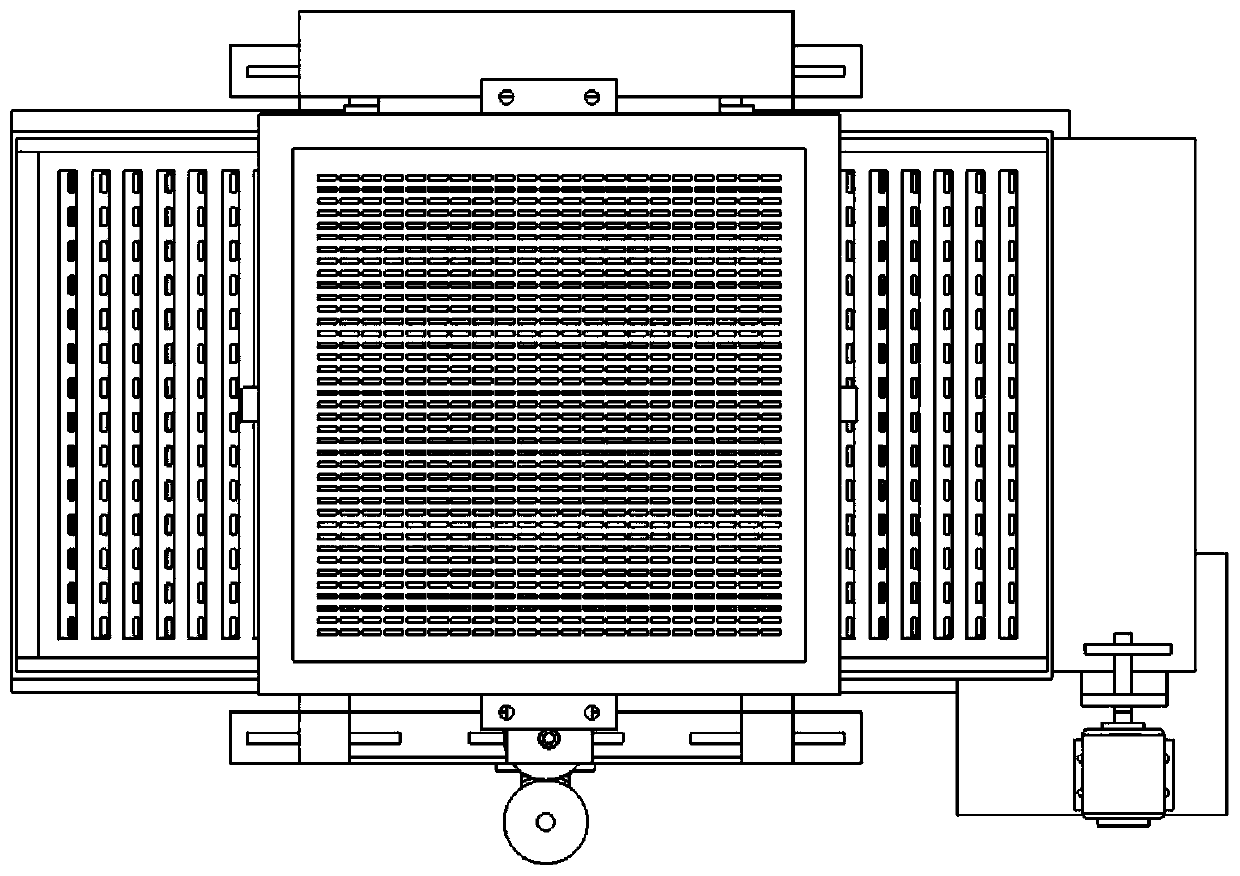

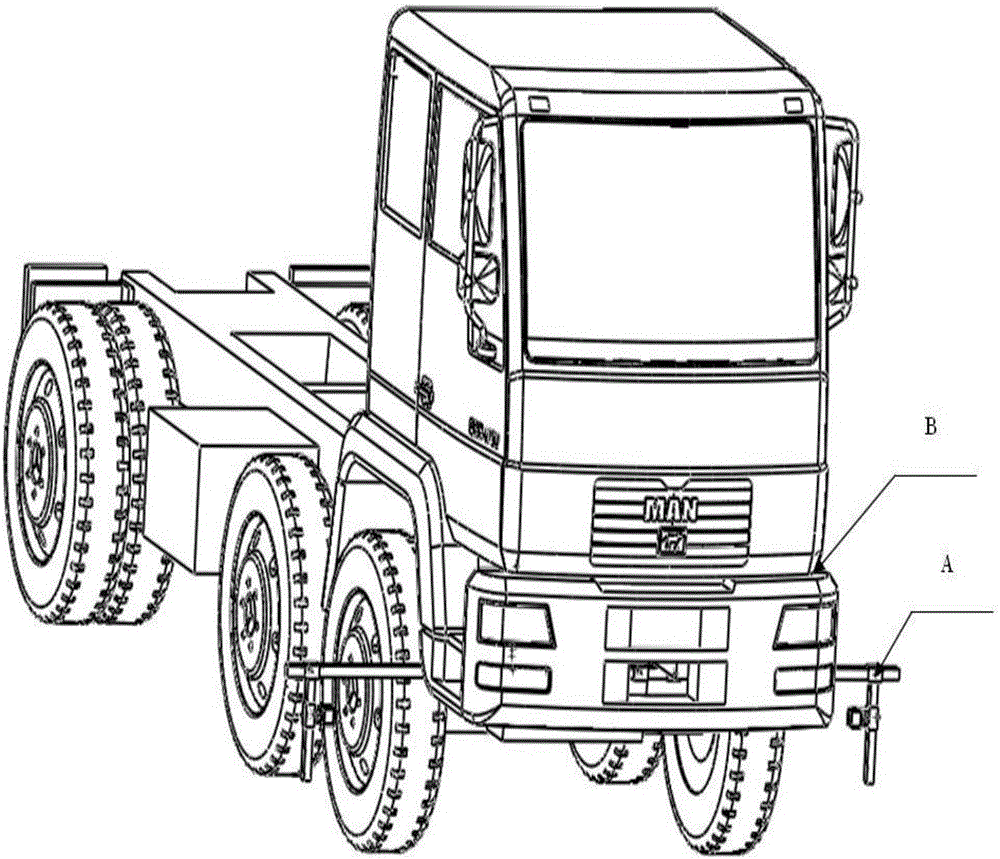

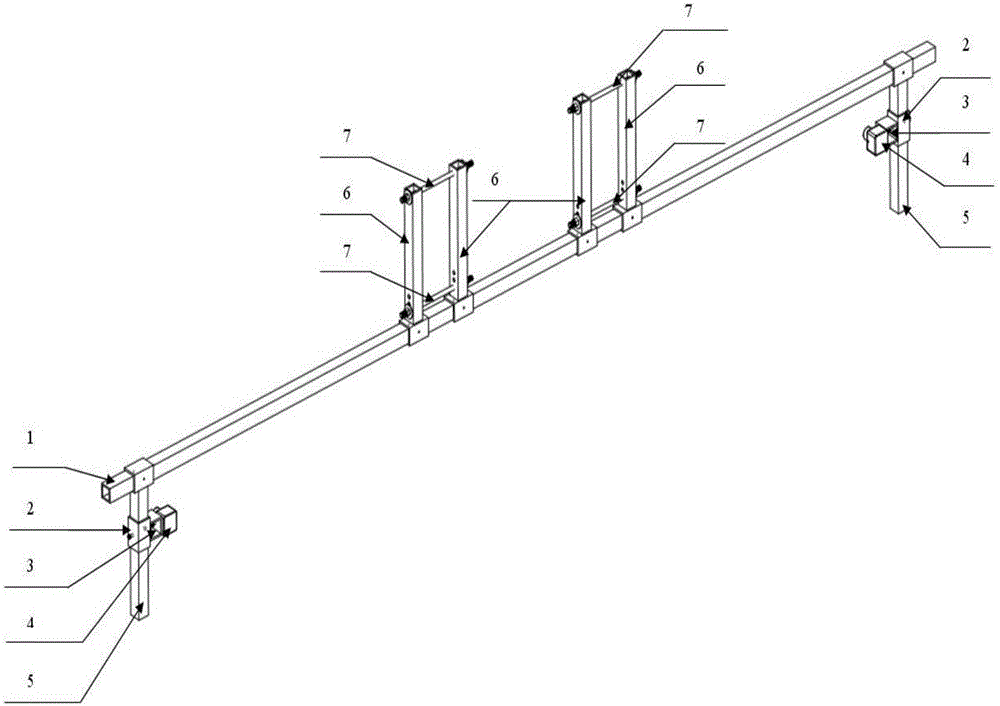

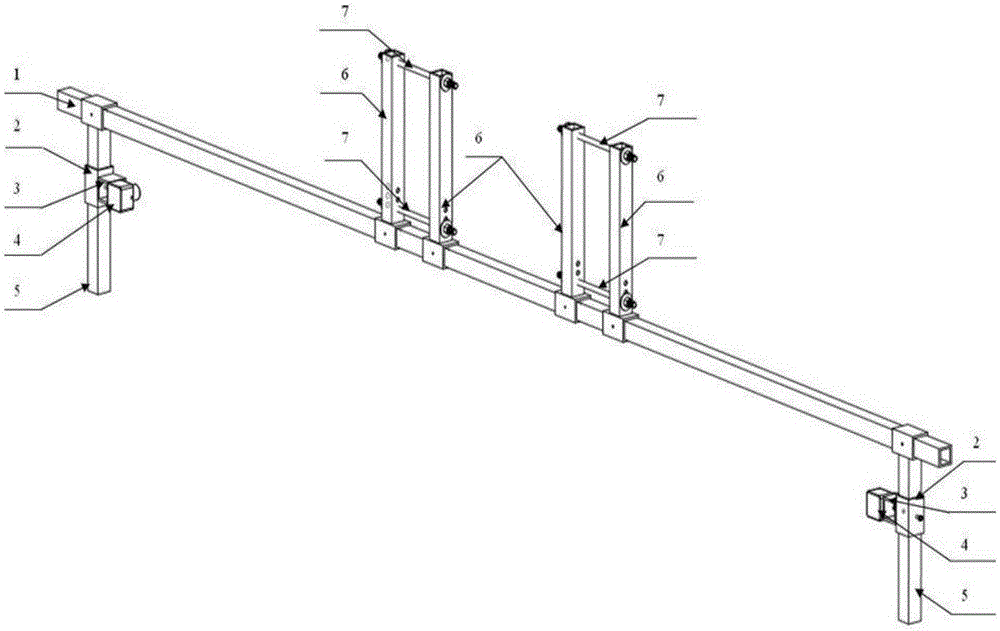

Vision measurement system for wheel alignment parameters of multi-axle commercial vehicles based on two-dimensional targets

InactiveCN103592139BAvoid self-locking phenomenonImprove detection efficiencyUsing optical meansVehicle wheel testingMachine visionEngineering

The invention discloses a system for vision measurement of multi-shaft commercial vehicle wheel location parameters on the basis of a two-dimensional target. The system aims at solving the problem that the multi-shaft commercial vehicle wheel location parameters cannot be detected by means of a machine vision measurement technology. The system for vision measurement of the multi-shaft commercial vehicle wheel location parameters on the basis of the two-dimensional target is composed of a beam, a connecting block, a camera base, a camera, a camera stand, a clamping plate and a stud. A three-dimensional linear guide rail and a two-dimensional arc-shaped guide rail are utilized to enable a standard target to reach the random spatial position and angle, the system has the advantages that the automobile chassis longitudinal axis determined by a commercial vehicle chassis longitudinal beam serves as the standard and the system is simple in structure, high in detection precision, small in accumulated errors and simple and convenient to operate, and vision measurement of the multi-shaft commercial vehicle wheel location parameters on the basis of machine vision is achieved.

Owner:JILIN UNIV

Universal joint and equipment realized by using the universal joint

ActiveCN101561015BAvoid self-locking phenomenonYielding couplingOptical fibre/cable installationUniversal jointAngular degrees

The embodiment of the invention discloses a universal joint and equipment realized by using the universal joint. The universal joint comprises at least two rotating rings, at least one joint and at least four rotating pins, wherein one end of the joint is connected with the first rotating ring through two embedded rotating pins with certain angle in between; the other end of the joint is connectedwith the second rotating ring through the other two embedded rotating pins with certain angle in between, wherein the value selection range of certain angle includes 180 degrees, two rotating pins atone end of the joint are parallel to the other two rotating pins at the other end of the joint. While avoiding a self-locking phenomenon, the universal joint provided by the embodiment effectively protects the rotating pins.

Owner:HUAWEI MARINE NETWORKS CO LTD

Air duct seed selection reel type seed cell precision seeding device

ActiveCN110447348AAvoid shortagePrevent fallingSeed depositing seeder partsEngineeringMechanical engineering

The invention relates to an air duct seed selection reel type seed cell precision seeding device. The device comprises a seed selection mechanism, a seed filling mechanism and a seed filling-unloadingmechanism; the seed selection mechanism comprises a seed cleaning part and a sorting part; the seed filling mechanism comprises a mechanical translational drive mechanism fixedly connected to the side wall of a seed filling box, the side, opposite to the mechanical translational drive mechanism, of the seed filling mechanism is provided with a translational sliding piece structure, and a supporting sliding piece of the translational sliding piece structure slides in a U-shaped sliding groove; the seed filling-unloading mechanism comprises a soft reel, the two sides of the reel are positionedthrough rotating shafts, the middle of the reel is divided into an upper layer structure and a lower layer structure, the upper layer structure and the lower layer structure are both provided with thesame seed cells, seeds firstly fall into the seed cells of the seed filling box through the upper layer structure to complete seed filling, the reel rotates until the seed cells of the lower layer structure correspond to the seed cells of the seed filling box, and seed falling is completed.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

A constant lock hydraulic disc brake device

ActiveCN109532998BAvoid instabilityRelieve stressCarriage/perambulator accessoriesHand cart accessoriesSet screwPilot hole

The invention discloses a normally-locked hydraulic disc brake device which comprises main clamp body, adjusting screw plug, limit screw, piston, limit location step, first sealing ring, second sealing ring, spring, third sealing ring, fourth sealing ring and positioning screw, step guiding hole and threaded hole are arranged in the main clamp body, adjusting screw plug is connected at bottom of the main clamp body through the threaded hole, adjusting gasket is arranged between the adjusting screw plug and the main clamp body, piston is pressed into the step guiding hole through matching, limit screw is connected at bottom of the adjusting screw plug through threads, spring is arranged in step guiding hole of the large shaft end, the piston is provided with first groove and second groove outside the large shaft end, first sealing ring and second sealing ring are respectively arranged in the first groove and the second groove, the piston is provided with third groove and fourth groove outside the small shaft end, and third sealing ring and fourth sealing ring are respectively arranged in the third groove and the fourth groove. The overall structure design of the invention is ingenious and convenient to use.

Owner:YANSHAN UNIV

Reel type accurate hole-seeding device

ActiveCN110402646ATake advantage ofAvoid shortageSeed depositing seeder partsMotor driveSoft materials

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Air duct seed selection translational precision seeding device

ActiveCN110337865BAvoid shortagePrevent fallingSeed depositing seeder partsReciprocating motionGear wheel

The present invention relates to an air duct seed selection translational precision seeding device, comprising a seed selection mechanism, a seed filling mechanism, a seed filling-unloading mechanism; the seed selection mechanism includes a seed cleaning component and a sorting component; the seed filling mechanism includes a The mechanical translation drive mechanism fixedly connected to the side wall of the seed filling box is provided with a translation slide structure on the opposite side of the mechanical translation drive mechanism. The translation slide mechanism includes a U-shaped slide groove and a support slide fixedly arranged. One end of the supporting sliding piece can slide in the U-shaped sliding groove; the power output shaft of the filling-unloading mechanism is provided with a lower connecting gear and an upper connecting gear, the upper connecting gear meshes with the upper rack frame, and the lower connecting gear and The lower rack frame meshes; the small motor drives the upper cover plate and the lower bottom plate to reciprocate through the two rack frames to realize seed filling and unloading.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Reel type hole precision seeding device

ActiveCN110402646BTake advantage ofAvoid shortageSeed depositing seeder partsAgricultural engineeringElectric machinery

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

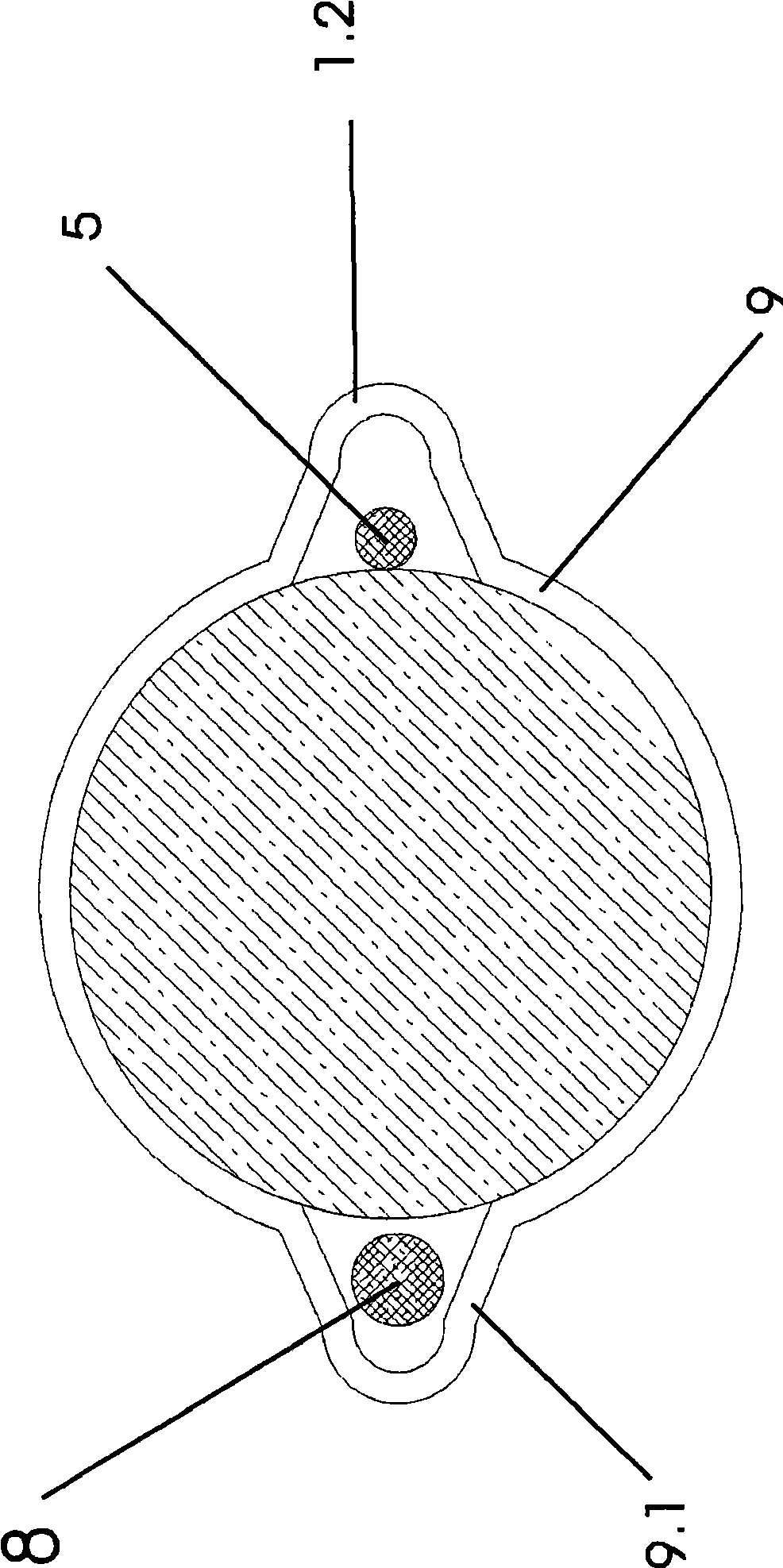

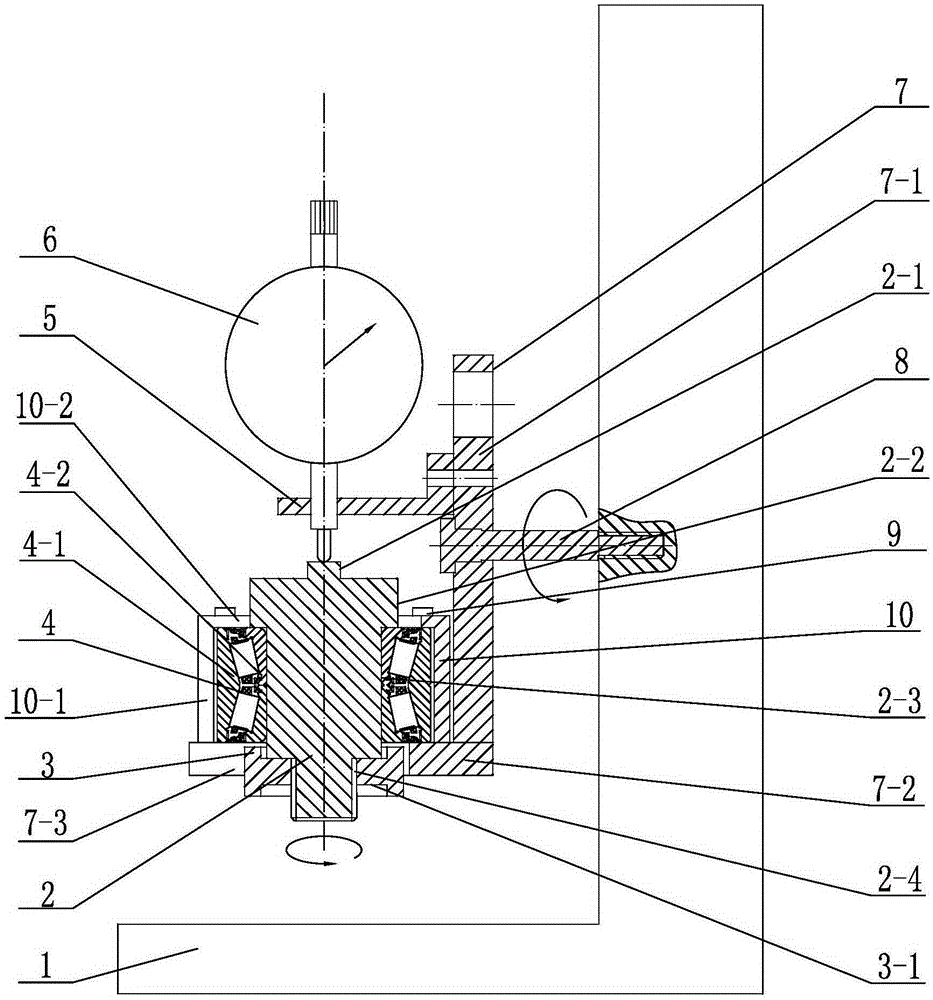

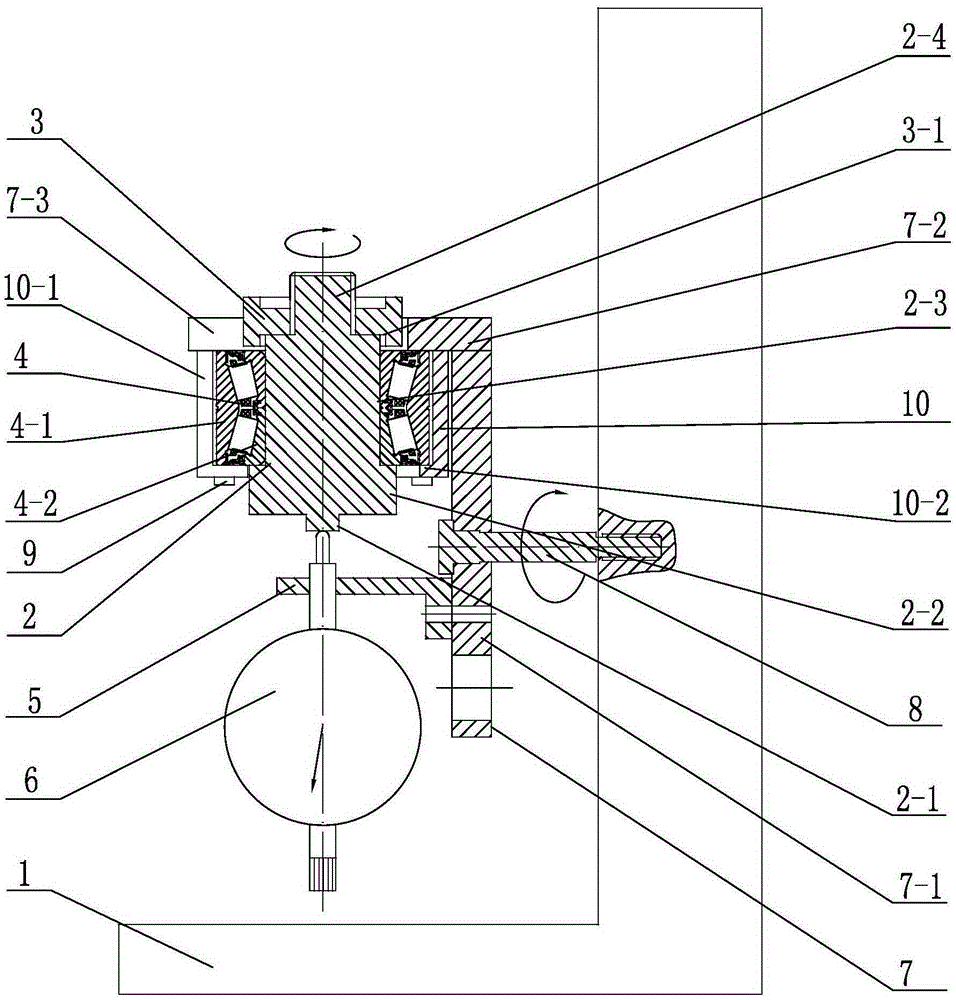

Testing Device for Axial Clearance of Double Row Tapered Roller Bearing

ActiveCN103759618BEasy to installPrecise positioningMechanical clearance measurementsCircular coneEngineering

The invention relates to a device for detecting an axial clearance of a double-row tapered roller bearing. A base plate of an L-shaped support is provided with a U-shaped groove for a mandrel to pass through, a fixed seat is installed on the base plate, and an opening for the detected bearing to pass through is formed in the fixed seat. A baffle ring extending inwards is arranged on the fixed seat, and the outer ring of the detected bearing is arranged in the fixed seat. One end of the outer ring of the detected bearing is connected with the base plate, and the other end of the outer ring of the detected bearing is connected with the baffle ring on the fixed seat and is axially limited. The step-shaped mandrel is installed on the base plate through the detected bearing, a locking ring is connected to a threaded shaft of the mandrel in a screwed mode, and a shaft shoulder on the mandrel is connected with one end of the inner ring of the detected bearing and is axially limited. A meter frame is installed on a vertical plate of the L-shaped support, and a measurement meter is installed on the meter frame. The detecting end of the measurement meter is connected with the end face of the mandrel, and the center axis of the detection end coincides with the rotation central axis of the mandrel. The device for detecting the axial clearance of the double-row tapered roller bearing is simple in structure and convenient to operate, detection efficiency can be improved, and detection accuracy can also be improved.

Owner:CHANGZHOU NRB CORP

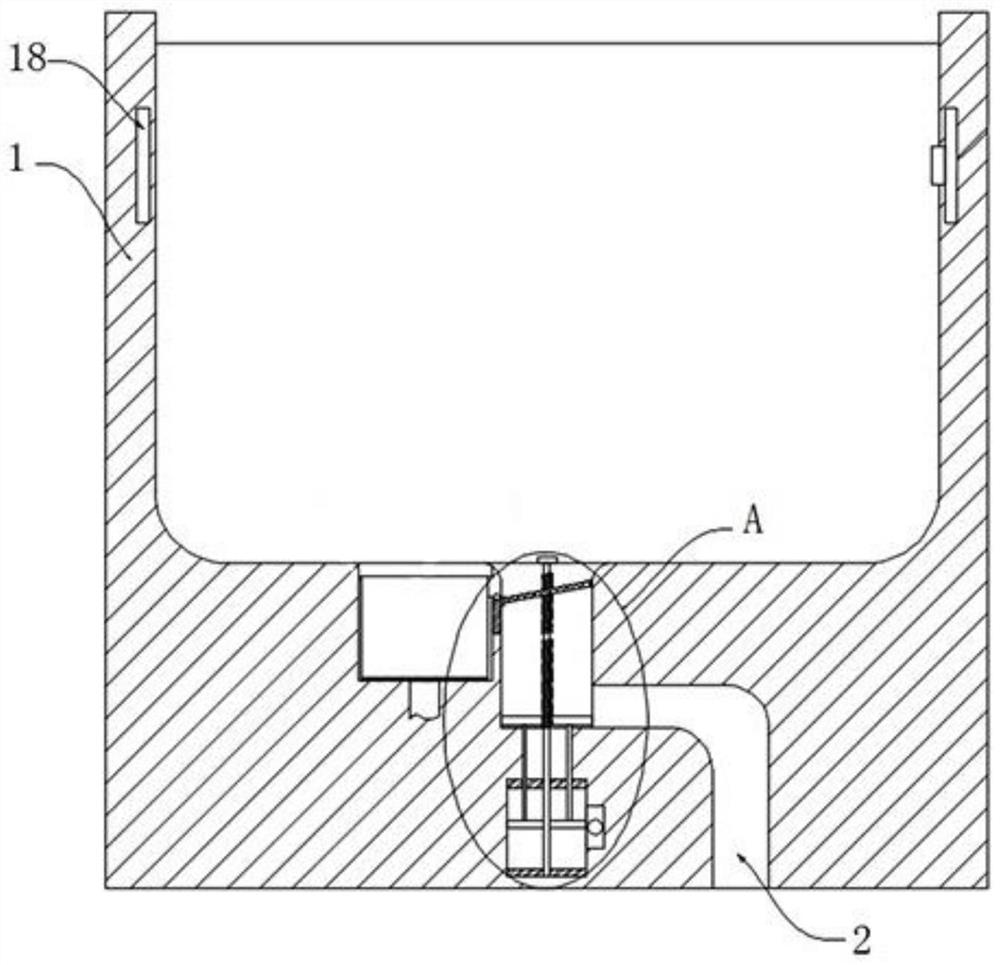

A pool water outlet device for automatically cleaning residues

The invention discloses a pool water outlet device for automatically cleaning residues, comprising a pool and a downpipe, the pool and the downpipe communicate with each other to form a square water cavity, the water cavity communicates with the bottom of the pool and is sealed and connected with a filter plug , the filter plug adopts a square ring slider structure and the ring is fixedly connected with a filter screen, the filter plug is obliquely sealed and slidably connected to the inner wall of the water chamber, and the water chamber is located on the side of the lower end of the filter plug to open a sundry chamber , the sundry box is provided with a sundry box, the bottom of the sundry box is fixedly connected with a filter screen and communicated with the downwater pipe, and the water chamber is located at the high end side of the filter plug and is sealed and connected with the downwater pipe. The advantage is that the present invention displaces the impurities on the filter plug by gravity, so that it does not hinder the passage of water flow, and reduces operational troubles through the concentrated treatment of impurities, and can be removed from the bottom of the filter plug under the reciprocating action of the push plate. Recoil it several times to improve the efficiency of impurity removal.

Owner:程小燕

Coiled tubing conveying resistance reducing device and using method

ActiveCN114135236AReduce resistanceAvoid self-locking phenomenonDrilling rodsDrilling casingsCoiled tubingStructural engineering

The invention discloses a coiled tubing conveying resistance reduction device and a using method. The coiled tubing conveying resistance reduction device comprises a limiting mechanism, a resistance reduction mechanism, a control mechanism, a power mechanism and a shell. The coiled tubing conveying drag reduction device is installed in an annular space between a coiled tubing and a casing pipe / open hole well wall, the coiled tubing conveying drag reduction device is tripped into a well along with the coiled tubing during installation, the coiled tubing conveying drag reduction device is anchored near a coiled tubing self-locking point position in a drag reduction working state, and the position is obtained through calculation according to a well body structure and related parameters of the used coiled tubing. The device has the advantages of being economical, practical, simple in structure and convenient to operate and maintain.

Owner:XI'AN PETROLEUM UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com