Air duct seed selection reel type seed cell precision seeding device

A technology of seeding device and reel, applied in the directions of seeding, seeder parts, application, etc., can solve the problems of increasing the installation accuracy, increase the workload, early breakage, etc., and meet the high requirements of reducing the installation accuracy and ensure reliability. and stability, the effect of reducing the requirements of installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Seed selection agency part:

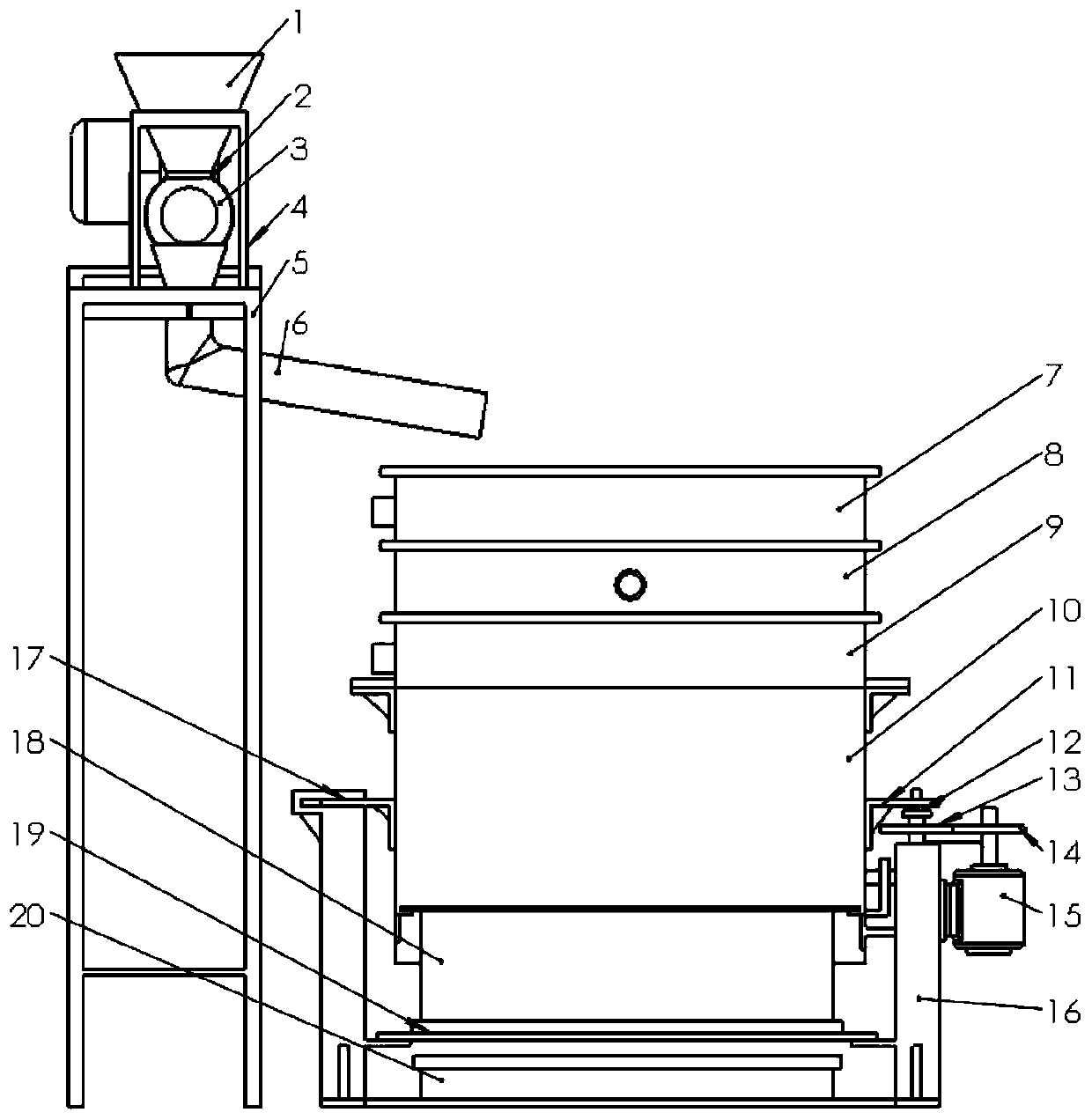

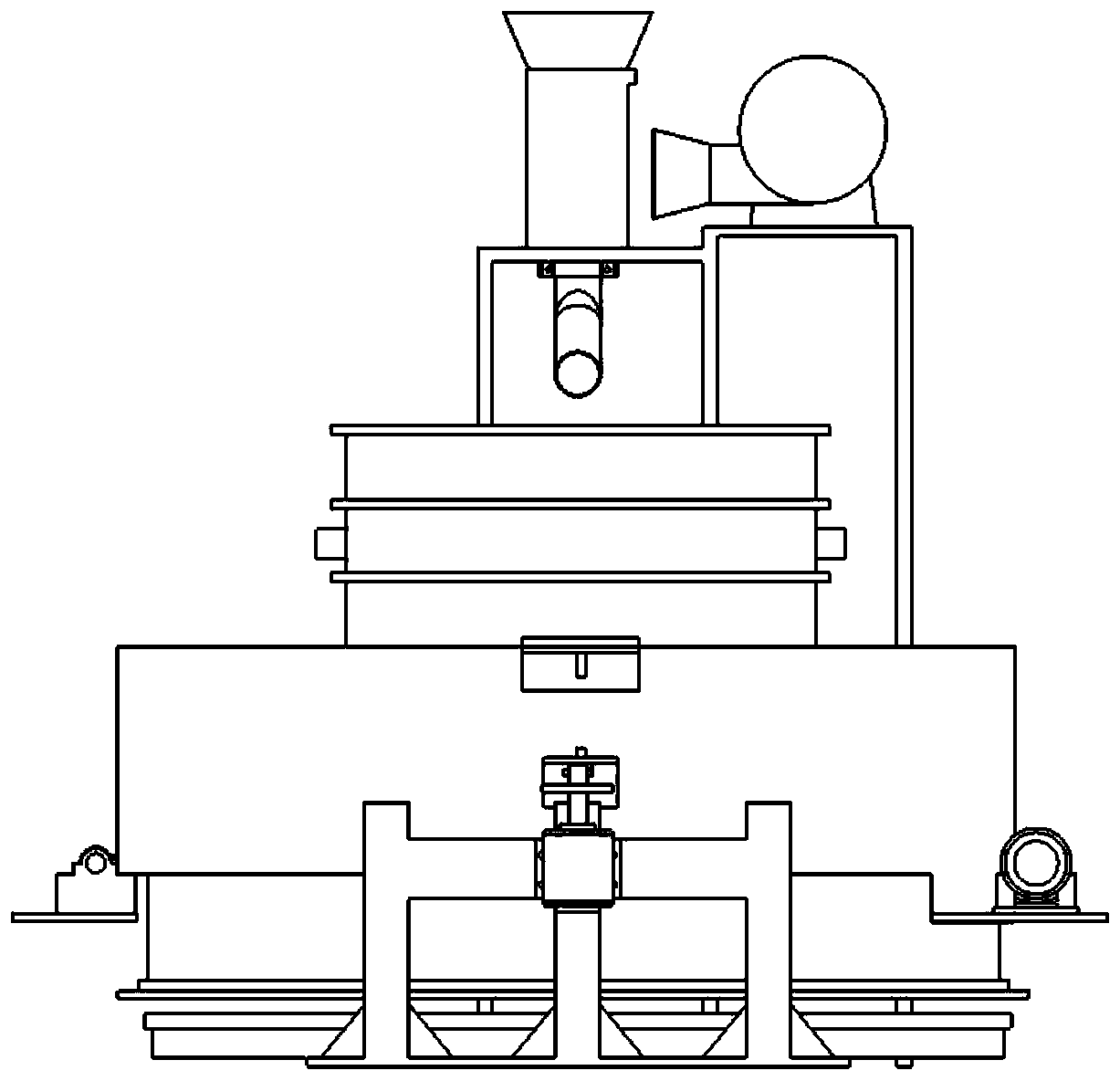

[0035] see Figure 1-4 , the funnel 1 is installed on the seed clearing frame 5; the bottom end of the funnel 1 is provided with a guide groove, and the seeding rate adjustment plate 2 is installed in the guide groove at the bottom end of the funnel 1; the fan 3 is installed on the seed clearing frame 5; On the seed rack 5; the conveying pipe 6 is installed on the seed clearing rack 5; the three-stage sorting box 9 is installed on the seed filling box 10; the second-stage sorting box 8 is installed on the third-stage sorting box 9; Box 7 is installed on the secondary sorting box 8.

[0036] Part of the filling mechanism:

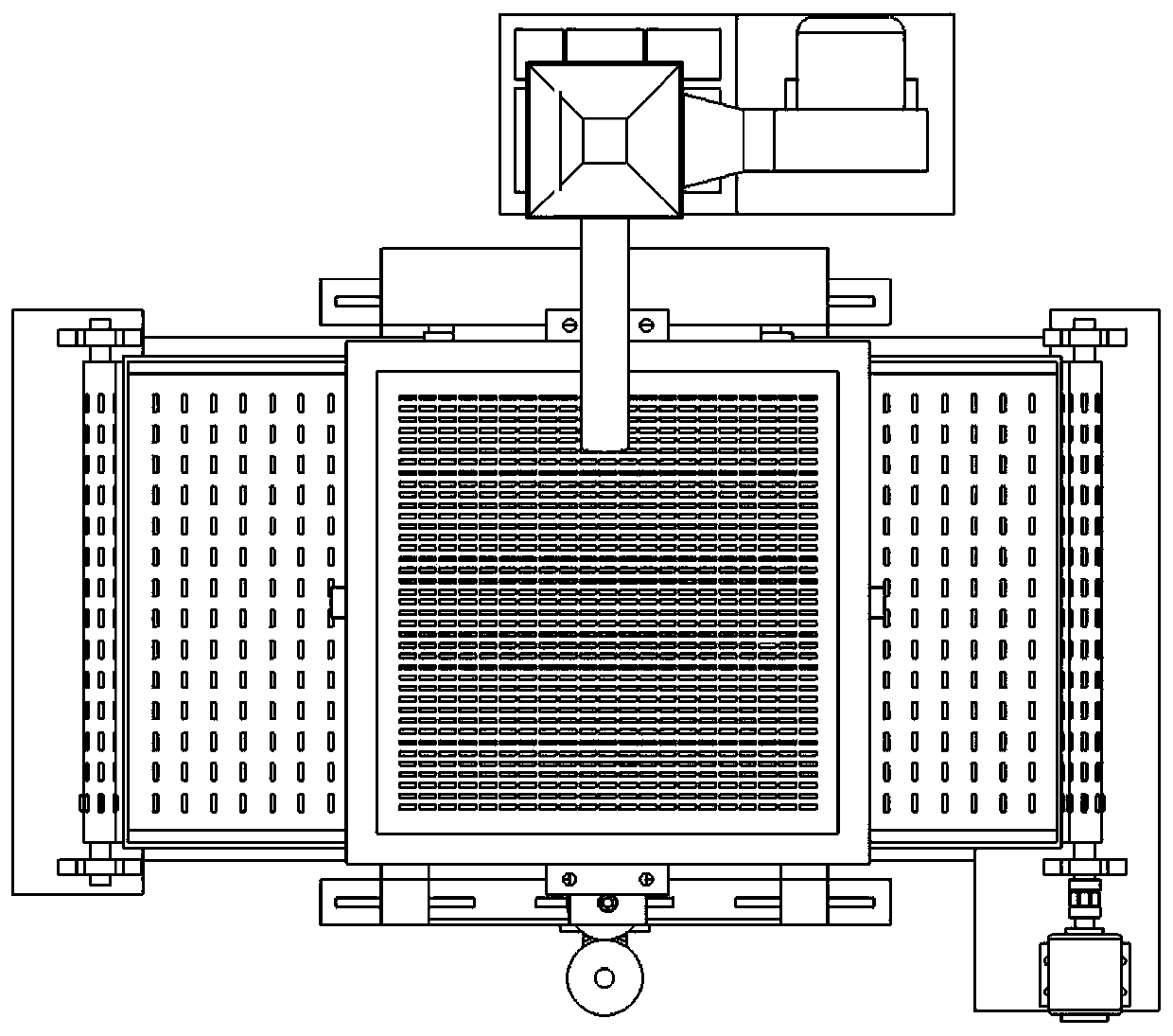

[0037] see Figure 1-5, the drive motor 15 is installed on the frame 16; the gear one 14 is installed on the drive motor 15, the gear two 13 is installed on the eccentric support 12, and is concentric with the main shaft of the eccentric support 12, the gear one 14 and the gear two 13 form a gear pair, for Drive motor...

Embodiment 2

[0046] This embodiment is aimed at seeds with larger hole sizes or low-density sowing, such as vegetable seeds. see Figure 7 , the bottom of the seed filling box 10 is directly provided with a hole tray. Mainly for low-density sowing seeds, such as cucumber, tomato, pepper and other vegetable seeds, etc., the eccentric support with small eccentricity is selected to complete the low-amplitude and high-frequency seed filling process. Composite movement is performed within the projection range of the hole size. When the upper cover is closed, the lower bottom plate opens, and the seeds fall freely into the hole to complete the sowing process. For the movement of the opening and closing mechanism of the upper and lower bottom plates of the seed filling box, please refer to the background The closest prior art cited in the art.

[0047] In this embodiment, the structure of the seed drop platform and the seed drop stand is abandoned, which saves materials and reduces the difficul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com